Side-span-free closure section small side to main span ratio continuous rigid frame bridge and construction method thereof

A technology for rigid frame bridges and closing sections, which is applied to continuous rigid frame bridges with small side-to-main-span ratios and their construction fields in the closing section without borders, and can solve the problems of lack of safe and economical design and construction methods, unfavorable cost savings, and complicated construction procedures To improve the shear capacity and local pressure bearing capacity, increase the self-weight, and reduce the construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

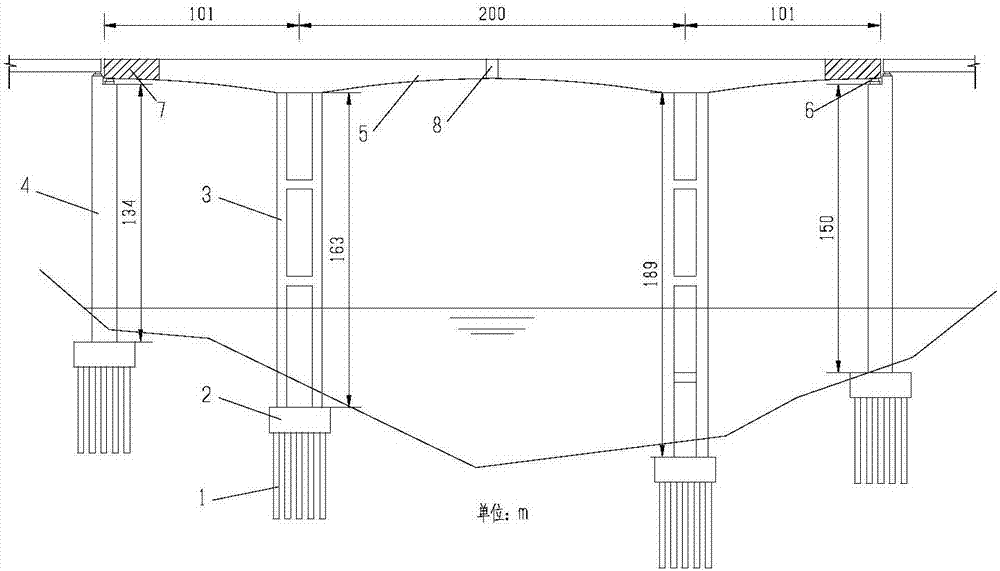

[0054] Now with a side pier up to 134m and 150m, main pier up to 163m and 189m, main span is 200m, side span 101m, the small side main span ratio three-span continuous rigid frame bridge that side main span ratio is 0.505 is example, the present invention is carried out Detailed explanation.

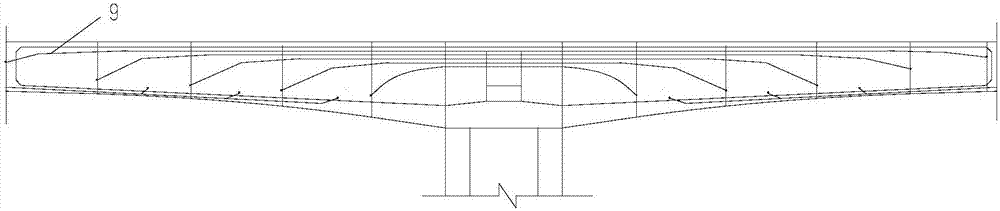

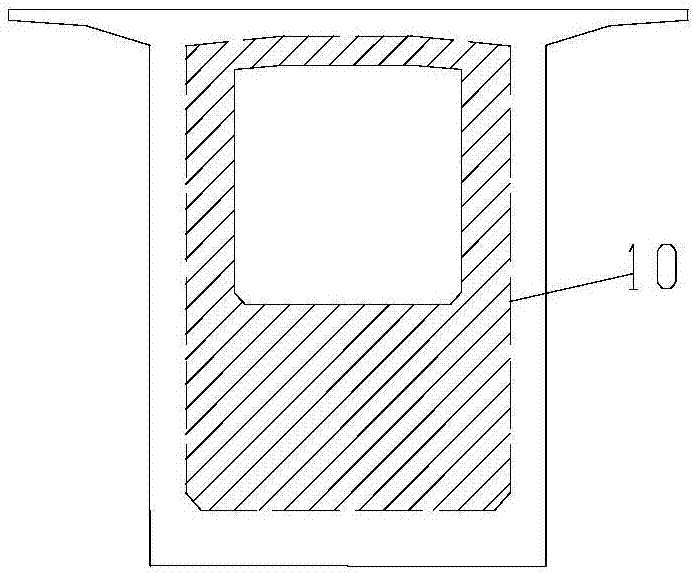

[0055] Such as Figure 1-3 As shown, the continuous rigid frame bridge of the present invention with a small side-to-main-span ratio in the closed section of the endless span includes a foundation 1, a cap 2, a main pier 3, a side pier 4, a main girder 5, a side pier tension and compression support 6, a side span Counterweight section 7 and main span closing section 8. The top of the side pier 4 is provided with a side pier tension and compression support 6, and a side span counterweight section 7 is provided near the side pier 4 on the side span. The side main span is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com