Prefabricated edge member, preparation method, formed shear wall structure and construction method

A technology of edge components and components, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of unable to place concrete vibrators, unable to penetrate, etc., to reduce construction workload, improve construction efficiency, and reduce steel bars. The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

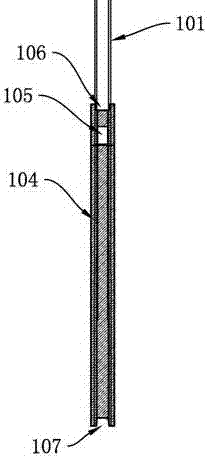

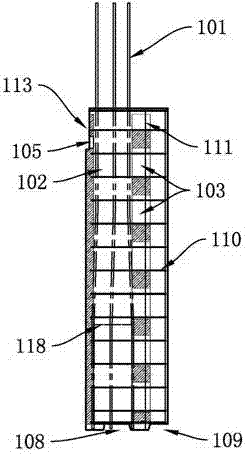

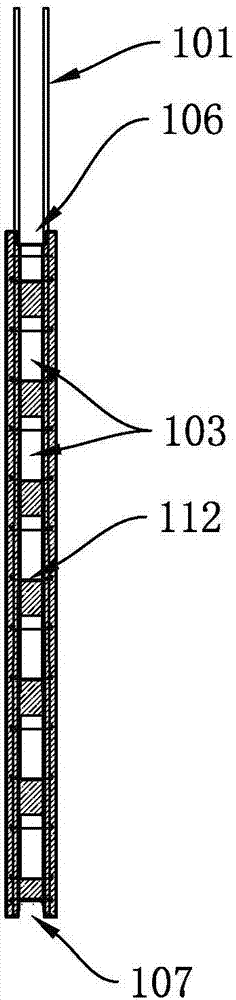

[0072] combine Figure 1-6 As shown, a concrete prefabricated edge member is provided with a reinforcement cage inside the panel, and the reinforcement cage is composed of panel horizontal ribs 110, panel vertical ribs, and panel tie bars 112, wherein some of the panel vertical ribs are non-linear shaped steel bars 101, and the vertical bars of the plate body also include straight steel bars 111.

[0073] The non-linear steel bar 101 protrudes from the upper end of the board body for a certain distance along the height direction of the board body, and its extension length is greater than or equal to the overlapping length of the steel bars required for building construction.

[0074] The plate body is provided with a first vertical hole 102 through up and down; the first vertical hole 102 is a variable section hole, and its cross section begins to gradually change at a certain height 118 in the plate body; the area of the cross section of the upper and lower ends of the firs...

Embodiment 2

[0091] As shown in Fig. 7-12, a concrete prefabricated edge member has a reinforcement cage inside the panel, and the reinforcement cage is composed of panel horizontal ribs 210, panel vertical ribs, and panel tie bars 212, wherein some panels are vertically The longitudinal reinforcement is a non-linear reinforcement 201, and the vertical reinforcement of the plate body also includes a linear reinforcement 211.

[0092] The non-linear steel bar 201 protrudes from the upper end of the plate body for a certain distance along the height direction of the plate body, and its extension length is greater than or equal to the overlapping length of the steel bars required for building construction.

[0093] The plate body is provided with a first vertical hole 202 through up and down; the first vertical hole 202 is a variable section hole, and its cross section begins to gradually change at a certain height 218 in the plate body; the area of the cross section of the upper and lower e...

Embodiment 3

[0110] As shown in Figures 13-18, a concrete prefabricated edge member is provided with a reinforcement cage inside the panel, and the reinforcement cage is composed of panel horizontal ribs 310, panel vertical ribs, and panel tie bars 312, wherein some panels are vertically The longitudinal reinforcement is a non-linear reinforcement 301, and the vertical reinforcement of the plate body also includes a linear reinforcement 311.

[0111] The non-linear steel bar 301 protrudes from the upper end of the plate body for a certain distance along the height direction of the plate body, and its extension length is greater than or equal to the overlapping length of the steel bars required for building construction.

[0112] The plate body is provided with a first vertical hole 302 through up and down; the first vertical hole 302 is a variable section hole, and its cross section begins to gradually change at a certain height 318 in the plate body; the area of the cross section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com