Train window installation structure and method of train body made of aluminum profiles

A technology for installing structures and aluminum profiles, applied in window devices, railway car body components, chemical instruments and methods, etc., can solve problems such as slippage, complicated installation and construction, and aluminum chips entering the cavity of car body profiles. The overall structure is simple, the workload is reduced, and the replacement is convenient and quick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

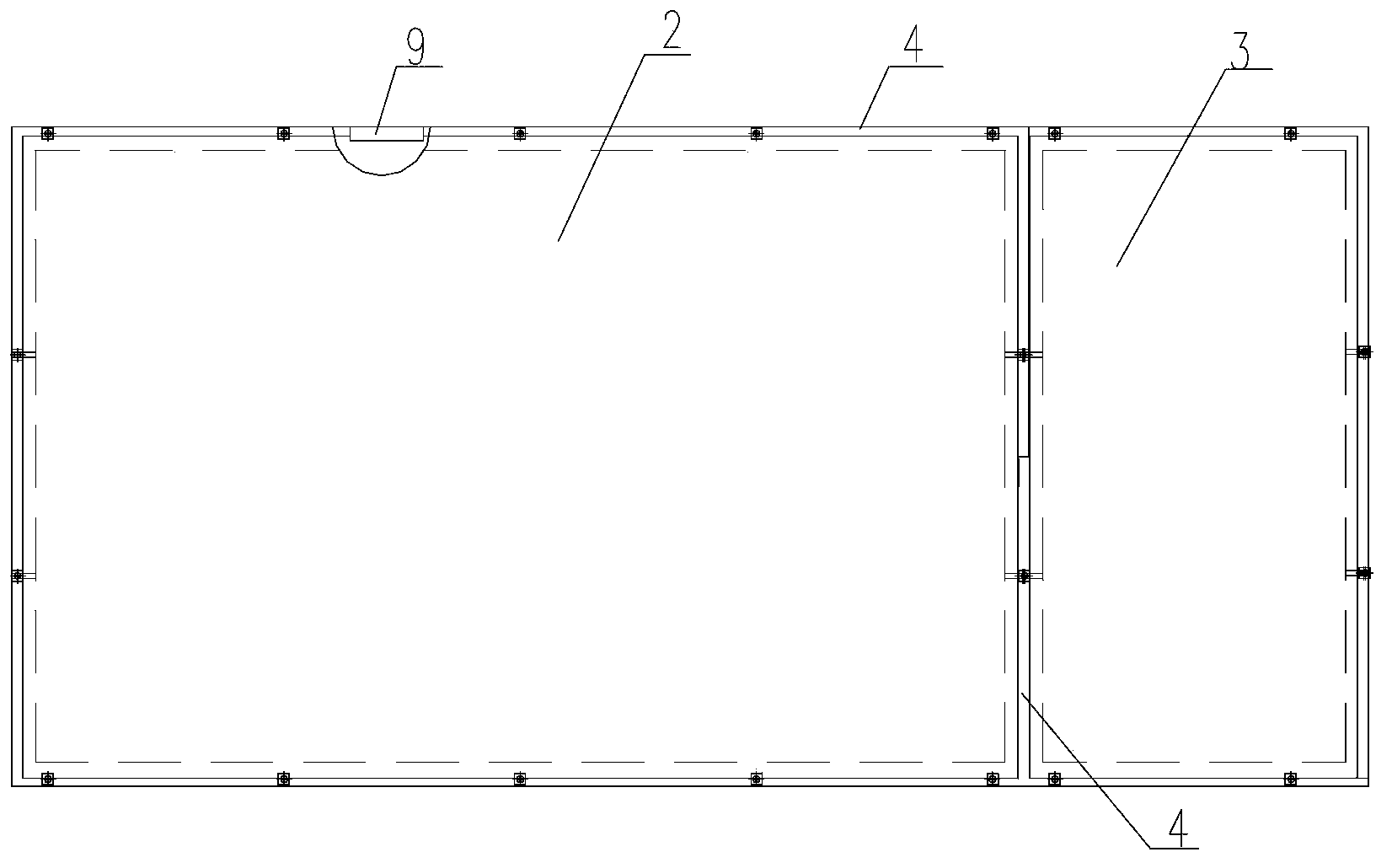

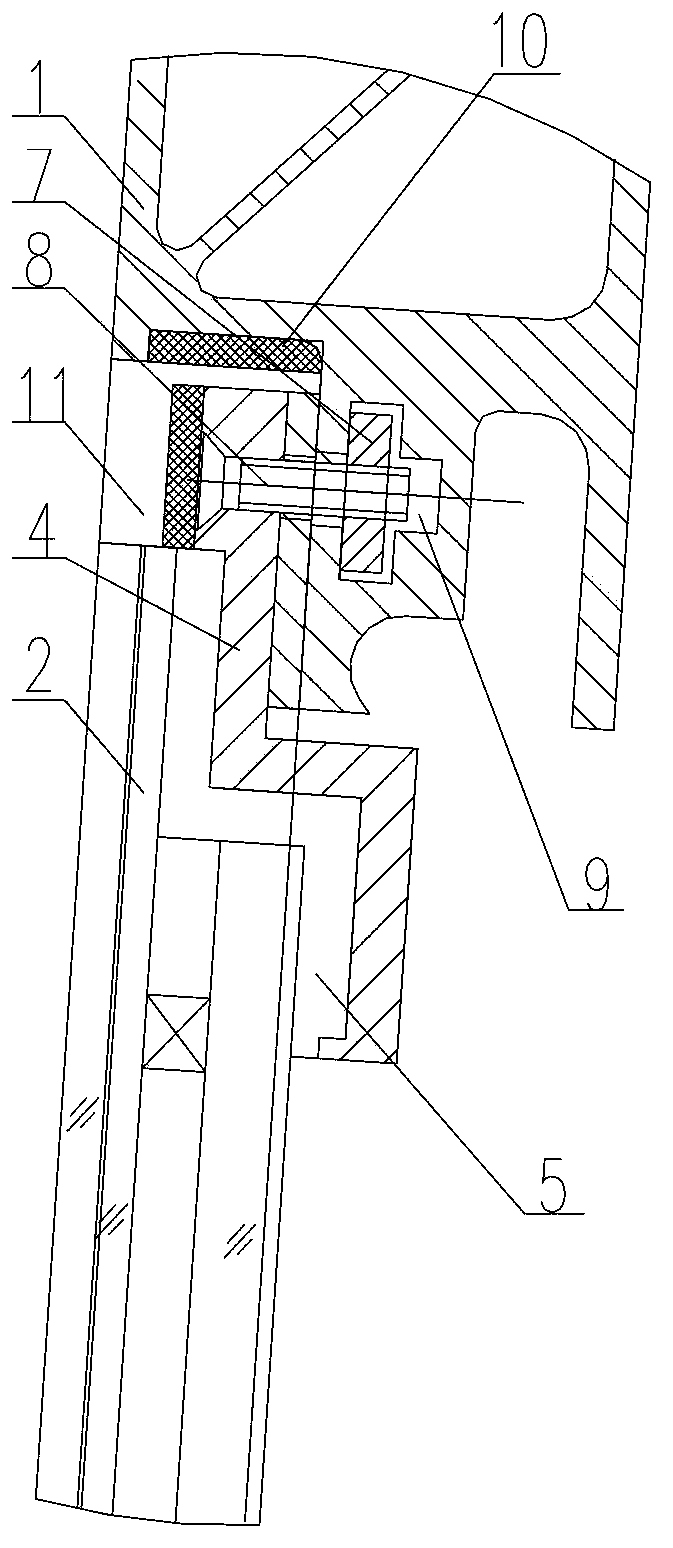

[0035] Such as figure 1 As shown, a car body window installation structure of aluminum profiles, the window glass includes a clear window glass 2 and a blind window glass 3 fixed on the side wall 1 of the car body, and the clear window glass 2 and the blind window glass 3 are all made of glue 5 Adhesively fixed on the window frame 4, a window matching the window frame 4 is provided on the side wall 1 of the car body, and the clear window glass 2, the blind window glass 3 and the window frame 4 are used as complete parts and the side wall of the car body 1 The profiles at the window are fixedly connected.

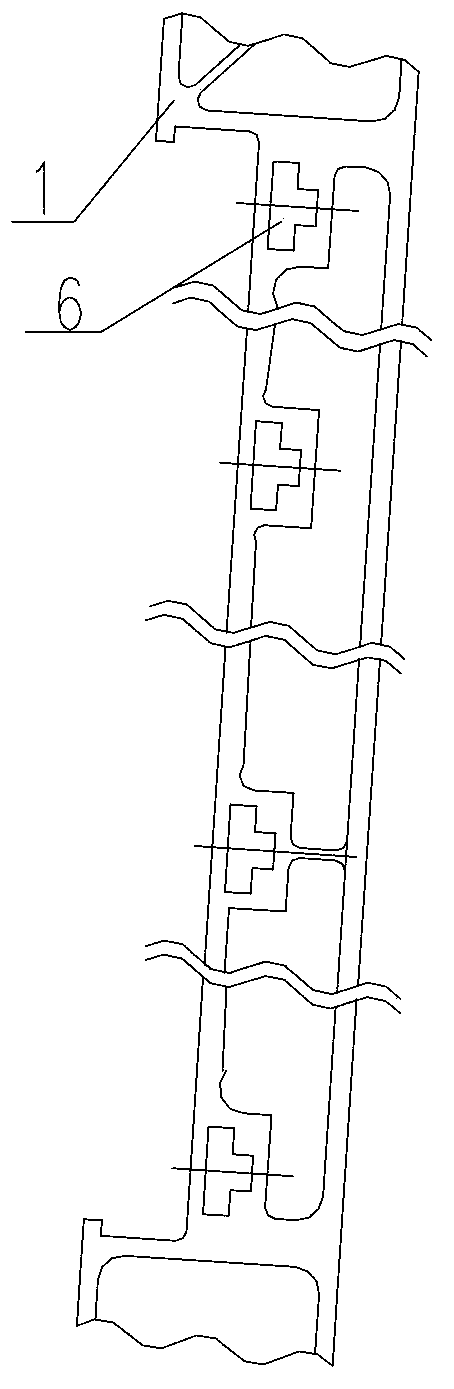

[0036] Such as figure 2 As shown, a plurality of T-shaped chutes 6 are reserved on the aluminum profile of the car body side wall 1 at the window, and the T-shaped chutes 6 are arranged along the upper, lower, and middle parts of the window frame 4 (clear window glass 2 and blind window The joints between the glass 3) and the corresponding heights of the two sides are res...

Embodiment 2

[0047] Such as Figure 5As shown, the difference from Embodiment 1 is that a nut 12 is arranged in each T-shaped chute 6. When installing, the nut 12 is loaded from the gap 9 on the T-shaped chute 6, and the nut 12 is installed in the T-shaped chute. The chute 6 slides up and down or left and right, and a plurality of screw holes arranged on the four sides of the window frame are respectively tightened and fixedly connected by bolts 13 and nuts 12, so that the clear window glass 2 and the blind window glass 3 have been installed. The window frame 4 is fixed on the side wall 4, and then the insulating tape 10 is pasted with glue around the window frame 4, and finally all of the gaps left are coated with the caulking glue 11, and the whole window installation process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com