Integrated embedded pipe hot stamping die for automobile parts

A technology for hot stamping dies and auto parts, which is applied in the field of sheet metal stamping and forming. It can solve the problems of high precision assembly of inserts, complex mold cooling water system, and long processing cycle, so as to reduce the frequency of cooling water leakage defects and reduce production. Cost and use threshold, manufacturing process cycle and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

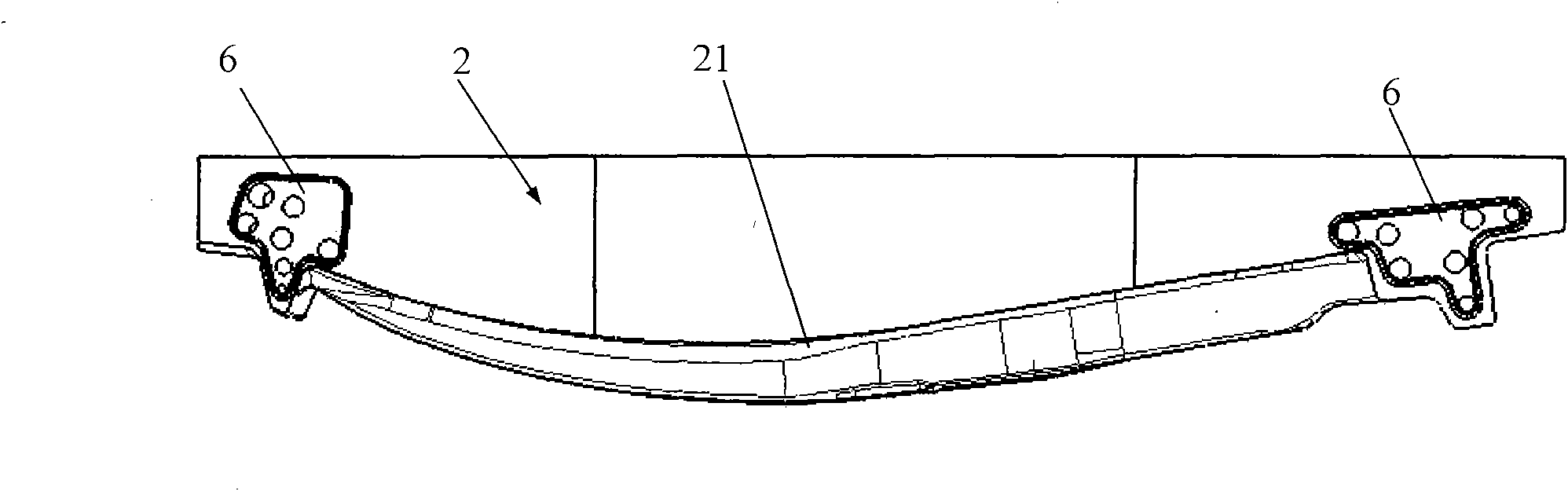

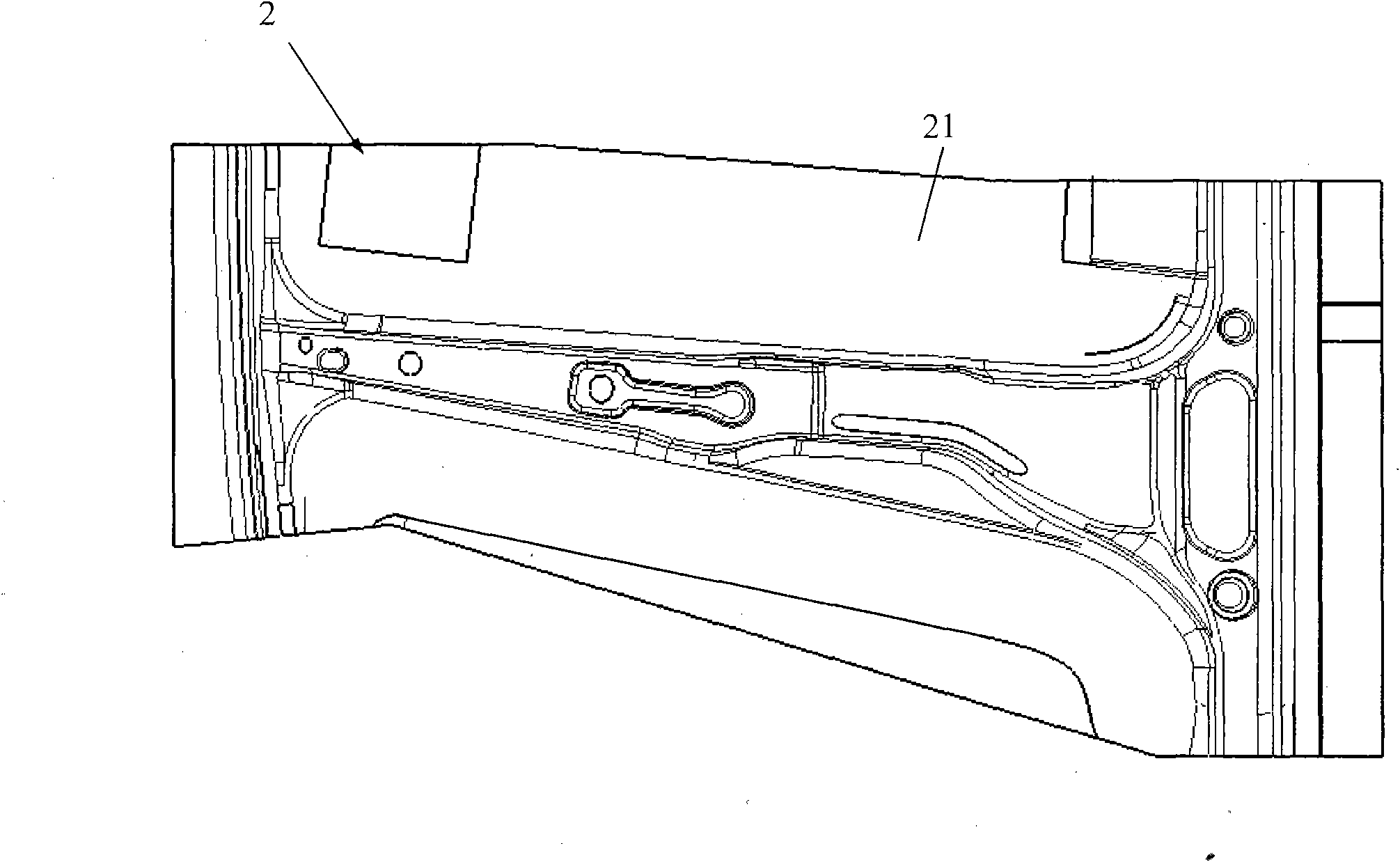

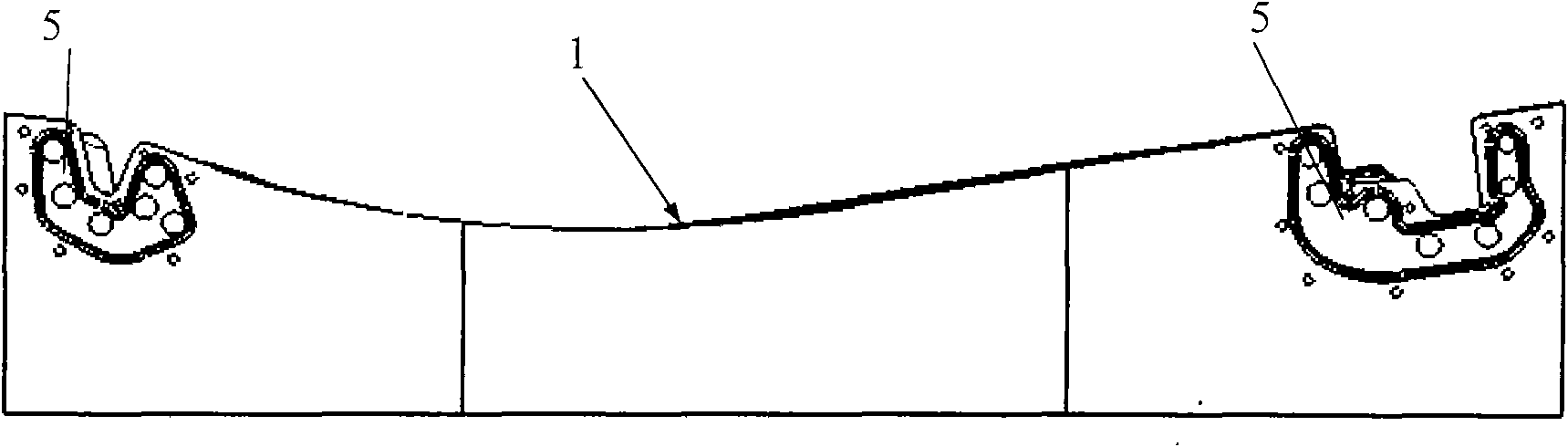

[0031] see Figure 1 to Figure 12 , the auto parts integral pre-embedded tube hot stamping die of the present invention, taking the automobile B-pillar parts as an example, the mold comprises a mold die 1 and a punch 2, which respectively have the same structural shape as the automobile B-pillar parts. The corresponding profiles 11 and 21 are T-shaped at both ends; the cooling water pipelines 3 and 4 are arranged in the profiles of the die die 1 and punch 2, and the cooling water pipelines 3 and 4 are connected by the diversion communication grooves 5 and 6. Seal plugs 7, 8 to form two sets of connected cooling water passages with different flow directions; both die die 1 and punch 2 are externally connected with a water inlet joint 12, 22 and a water outlet joint 13, 23, and are connected with the diversion communication groove 5 , 6 are connected; the cooling water pipelines 3 and 4 are bent and arranged with 6-8 branch pipelines 31 and 41 along the direction of the mold sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com