Telescopic steel formwork

A technology of steel formwork and steel slats, which is applied to the preparation of formwork/formwork components, formwork/formwork/work frames, and building components on site. Easy to run out of pulp and other problems, to achieve the effect of uniform and beautiful natural joints of the formwork, speed up construction, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

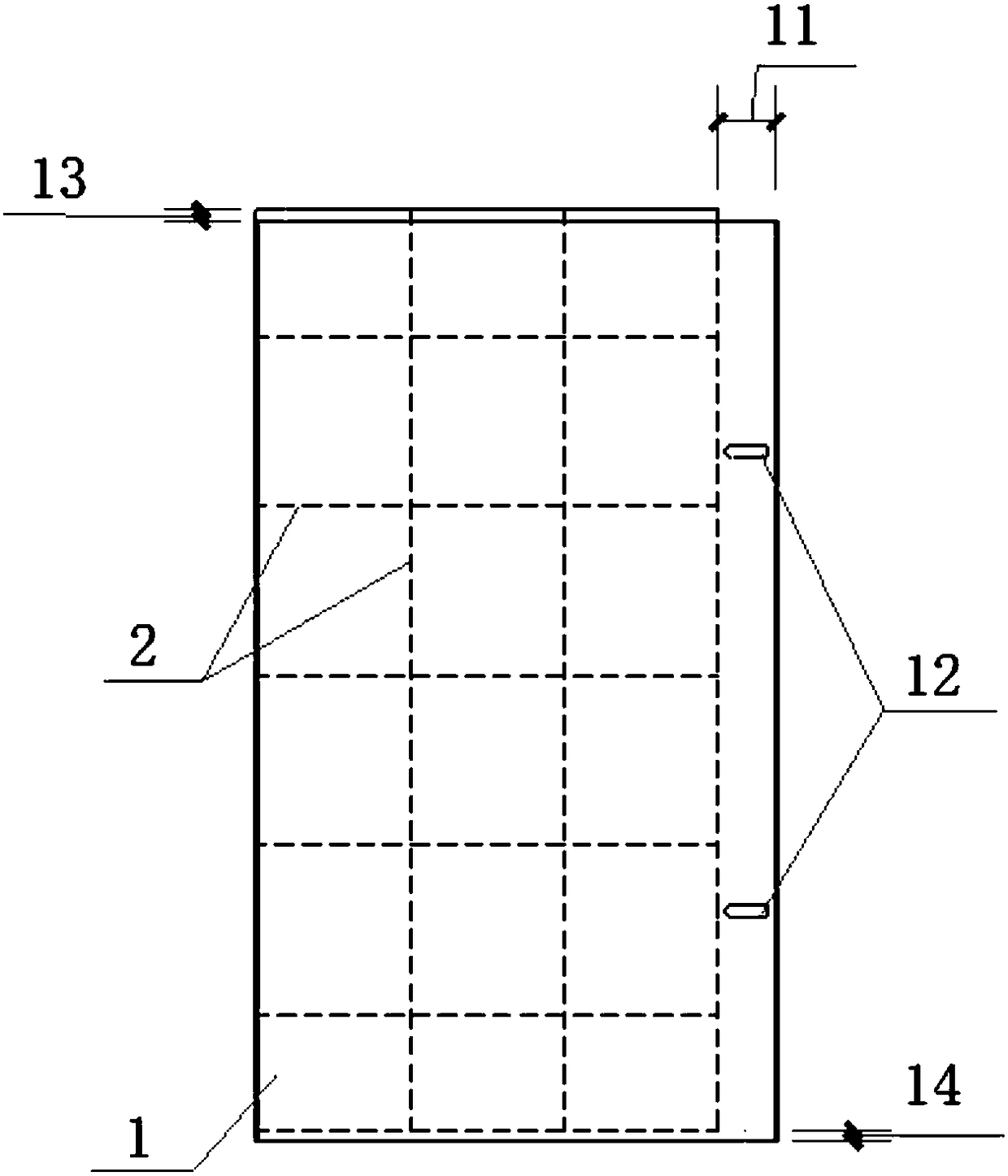

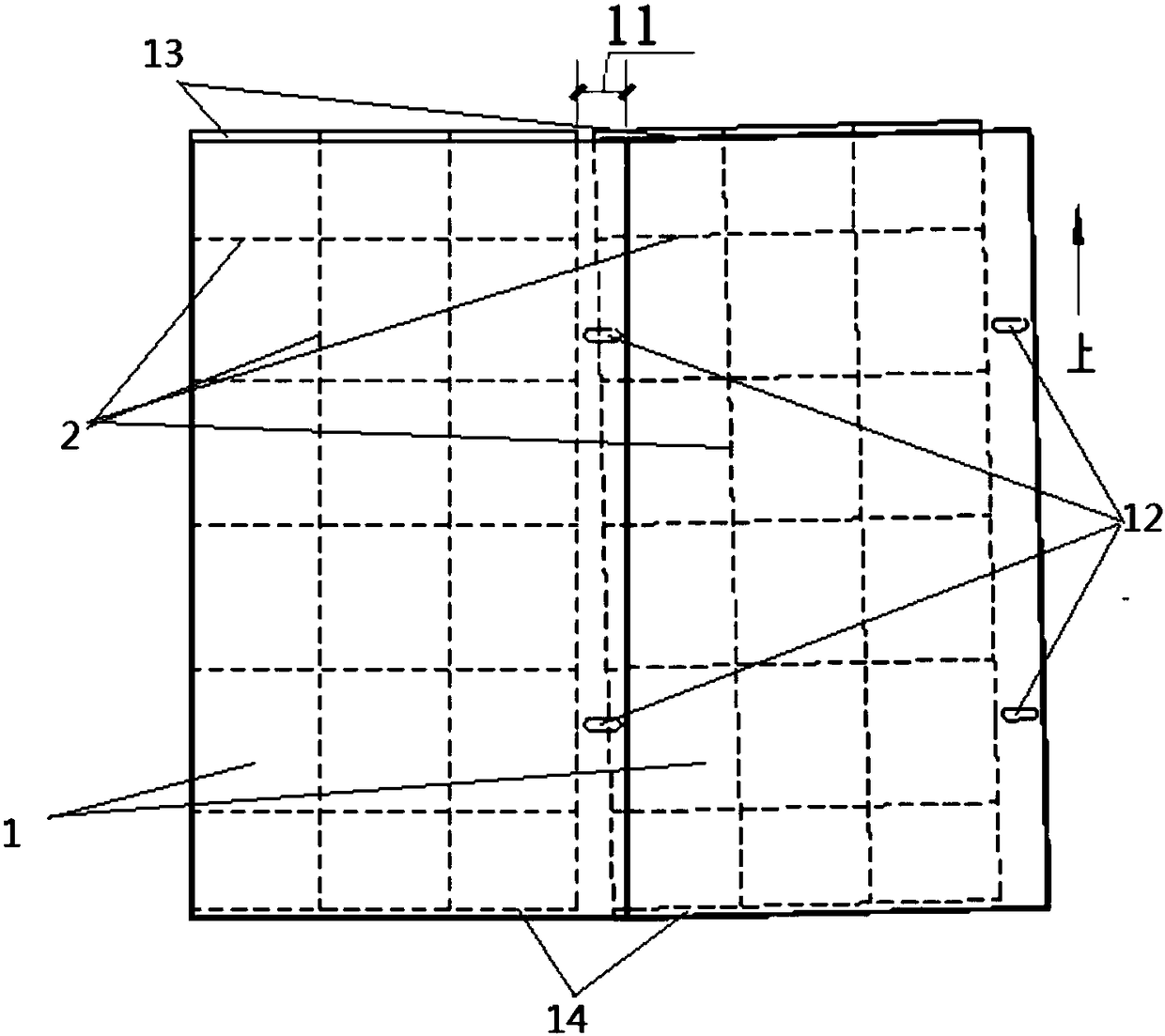

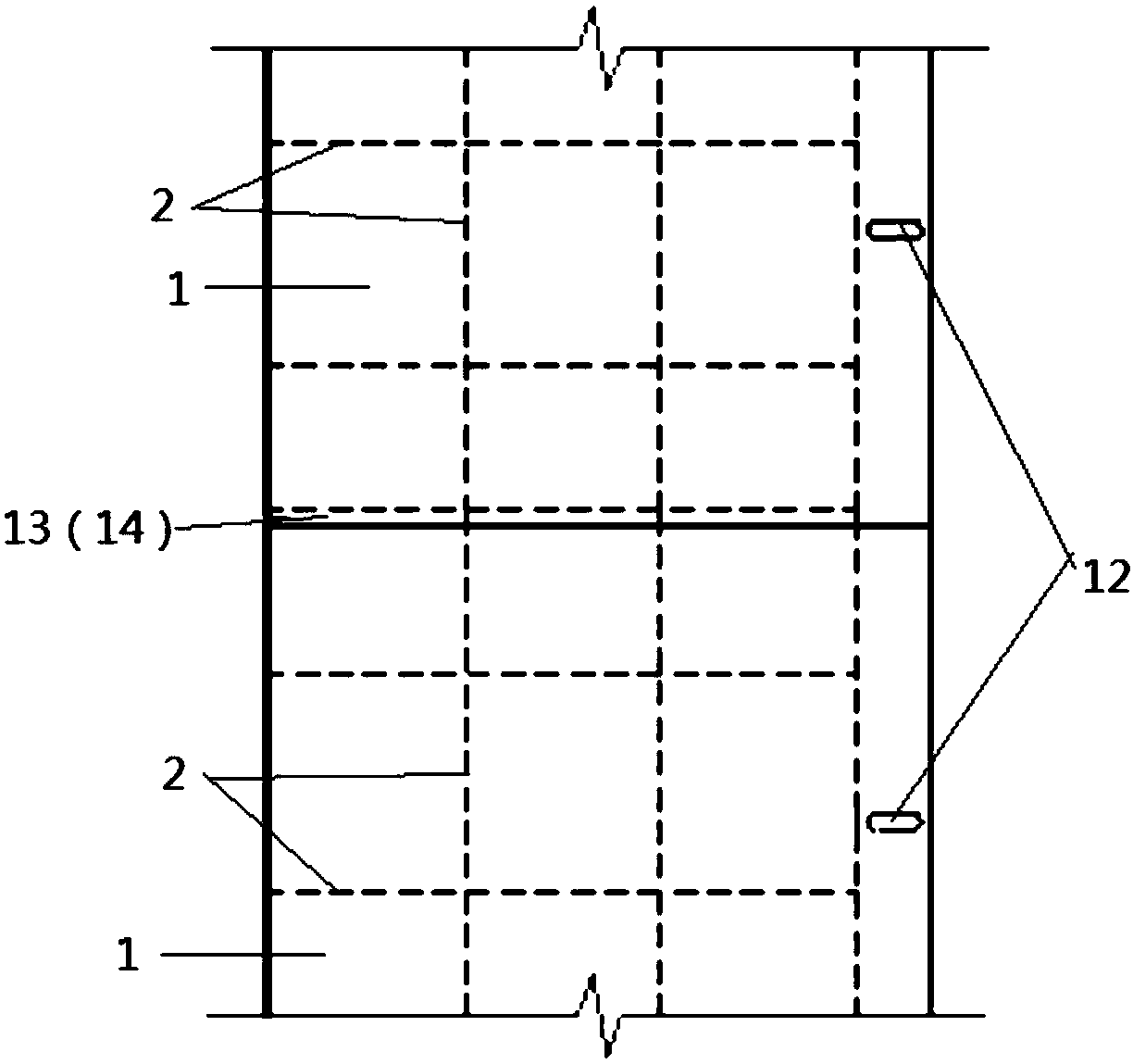

[0026] Such as figure 1 As shown, the telescopic steel formwork includes a rectangular panel 1 and stiffeners 2 fixedly arranged on the panel 1 , the stiffeners 2 are arranged to increase the rigidity of the panel 1 . The panel 1 in this embodiment is a steel plate. One of the two long sides of the panel 1 is provided with a telescopic adjustment side 11 of a certain width, and two long holes parallel to the short side of the panel are provided on the telescopic adjustment side 11 and are provided with pull bolts. 12. One of the two broad sides of the panel 1 is provided with a socket slot 13 , and the other of the two broad sides of the panel is provided with a socket key 14 .

[0027] In order to increase the rigidity of the panel, the stiffeners 2 are distributed on the outer side of the panel 1 in a criss-cross pattern, and the stiffeners 2 are n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com