Transverse stretching method for prestressed fiber cloth reinforced concrete column

A concrete column and lateral tensioning technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of complex construction process and large tension, and achieve a shortened construction period, uniform stress and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the fiber cloth is carbon fiber cloth, and the cross section of the concrete column is circular.

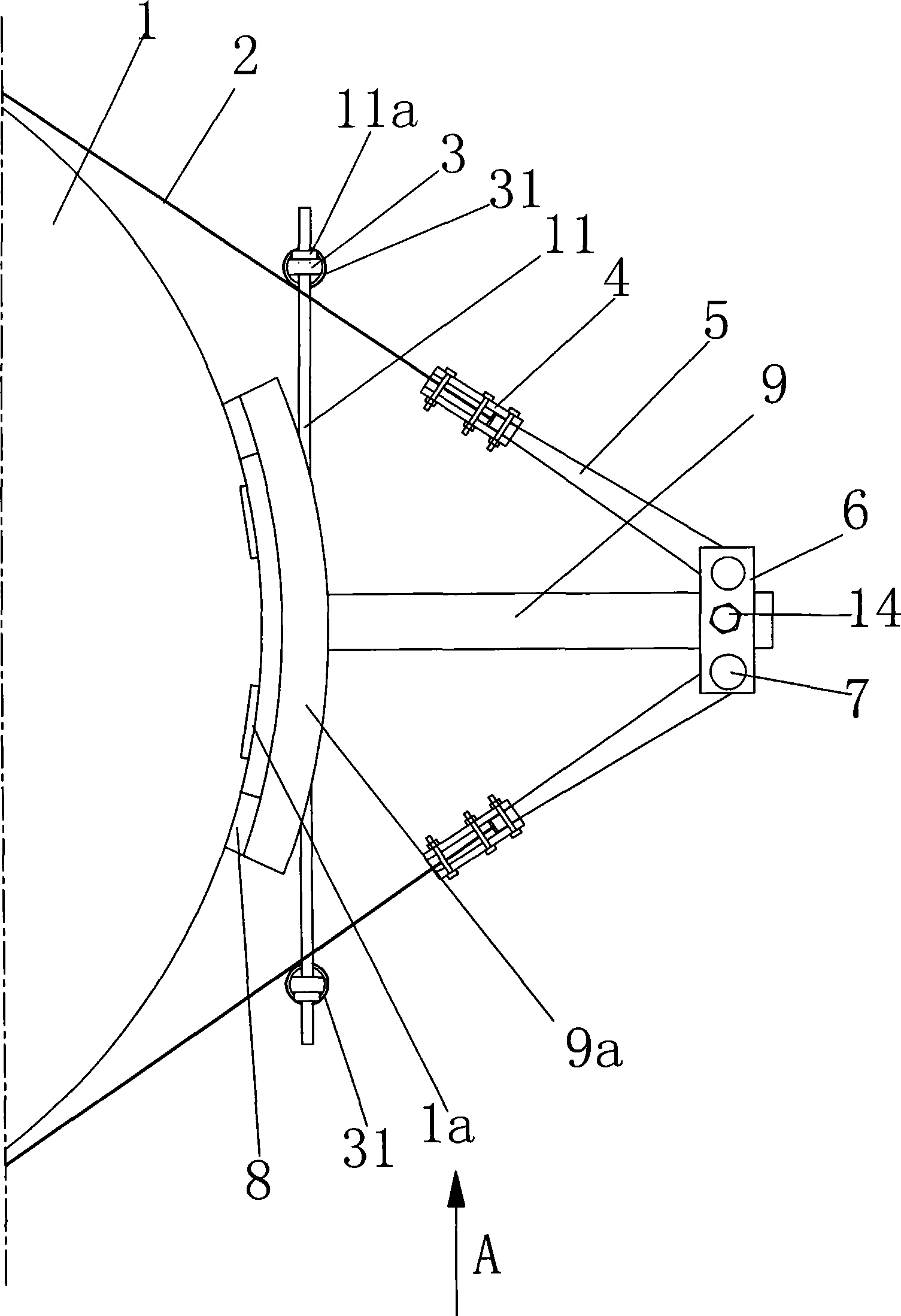

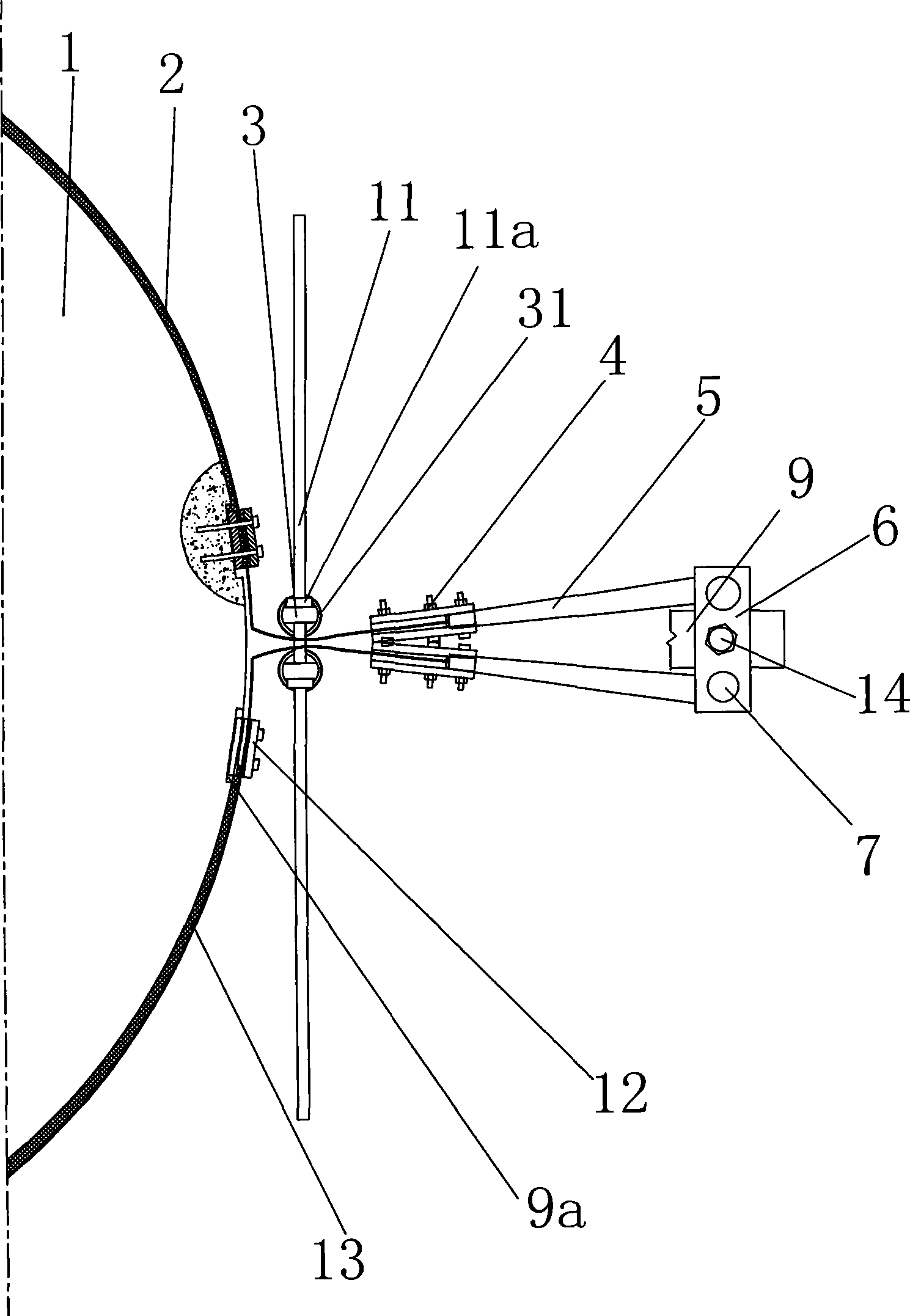

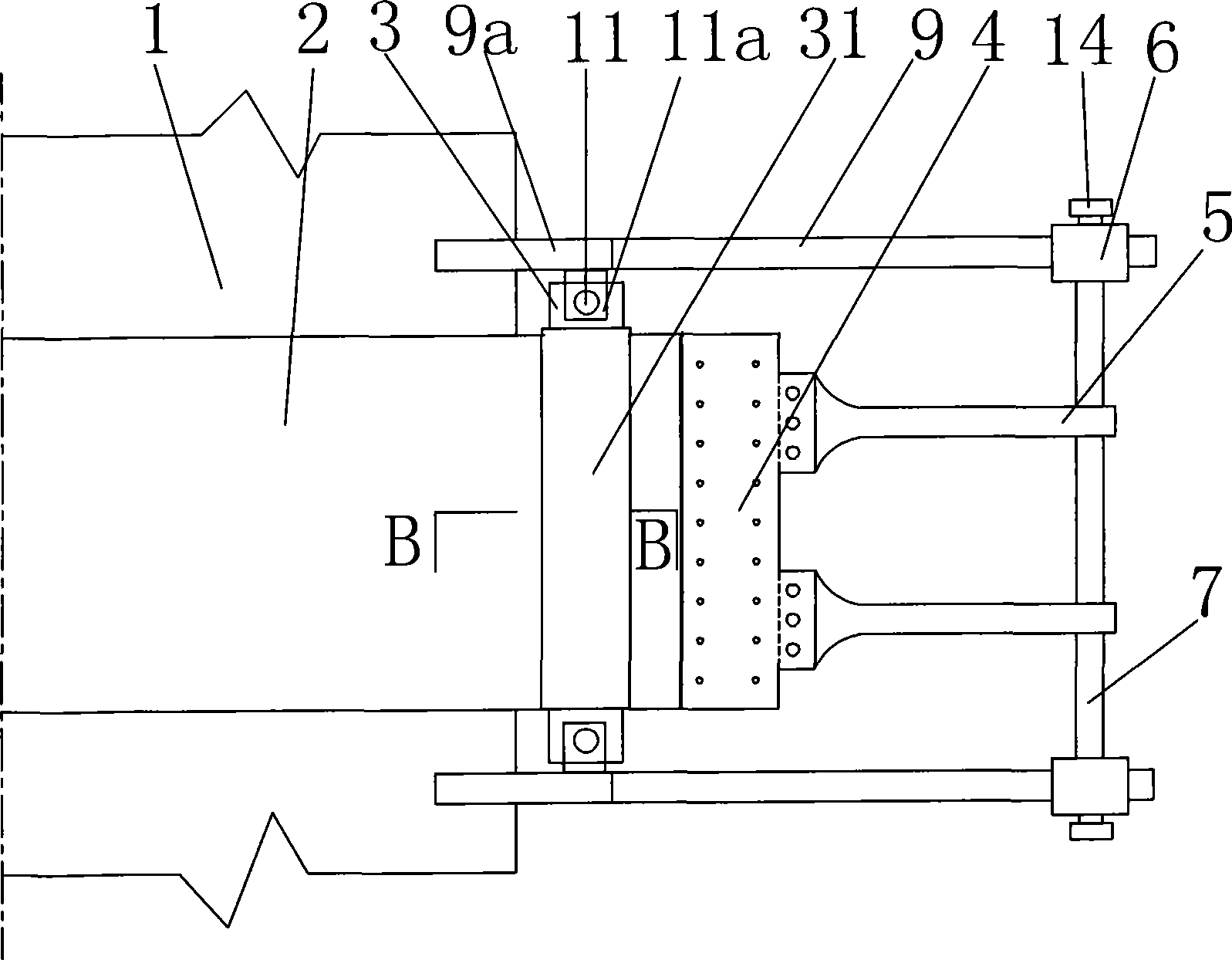

[0039] figure 1 It is a schematic diagram of the structure of the circular concrete column of the present invention before tensioning, figure 2 It is a schematic diagram of the structure of the circular concrete column of the present invention after tensioning, image 3 for figure 1 Schematic diagram along the A direction, Figure 4 for image 3 A cross-sectional view along the B-B direction, Figure 5 The structure diagram of the tool clamp of the present invention, Figure 6 It is a schematic diagram of the structure of the working clamp of the present invention, as shown in the figure: the transverse tension method of the prestressed fiber cloth reinforced concrete column of this embodiment includes the following steps:

[0040] a. A longitudinally tightened fiber cloth 2 is arranged on the surface of the concrete column 1 and the area to be reinforc...

Embodiment 2

[0050] In this embodiment, the cross section of the concrete column is rectangular.

[0051] Figure 7 It is a schematic diagram of the structure of the rectangular concrete column of the present invention before tensioning, Figure 8 It is a schematic diagram of the structure of the rectangular concrete column of the present invention after tensioning, Picture 9 for Figure 7 A schematic diagram along the C direction, as shown in the figure: the difference between this embodiment and the first embodiment is that the cross section of the concrete column of this embodiment is rectangular, and the support of the support frame 9 of this embodiment is right-angled to the concrete column 1 The right-angle support 9a is supported by the right-angle support 9a, and the support frame 9 is supported on the right-angle surface of the concrete column 1 through the right-angle support 9a; the support frames 9 are two groups arranged diagonally, and each group has two support frames 9 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com