Patents

Literature

220results about How to "Improve structural bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

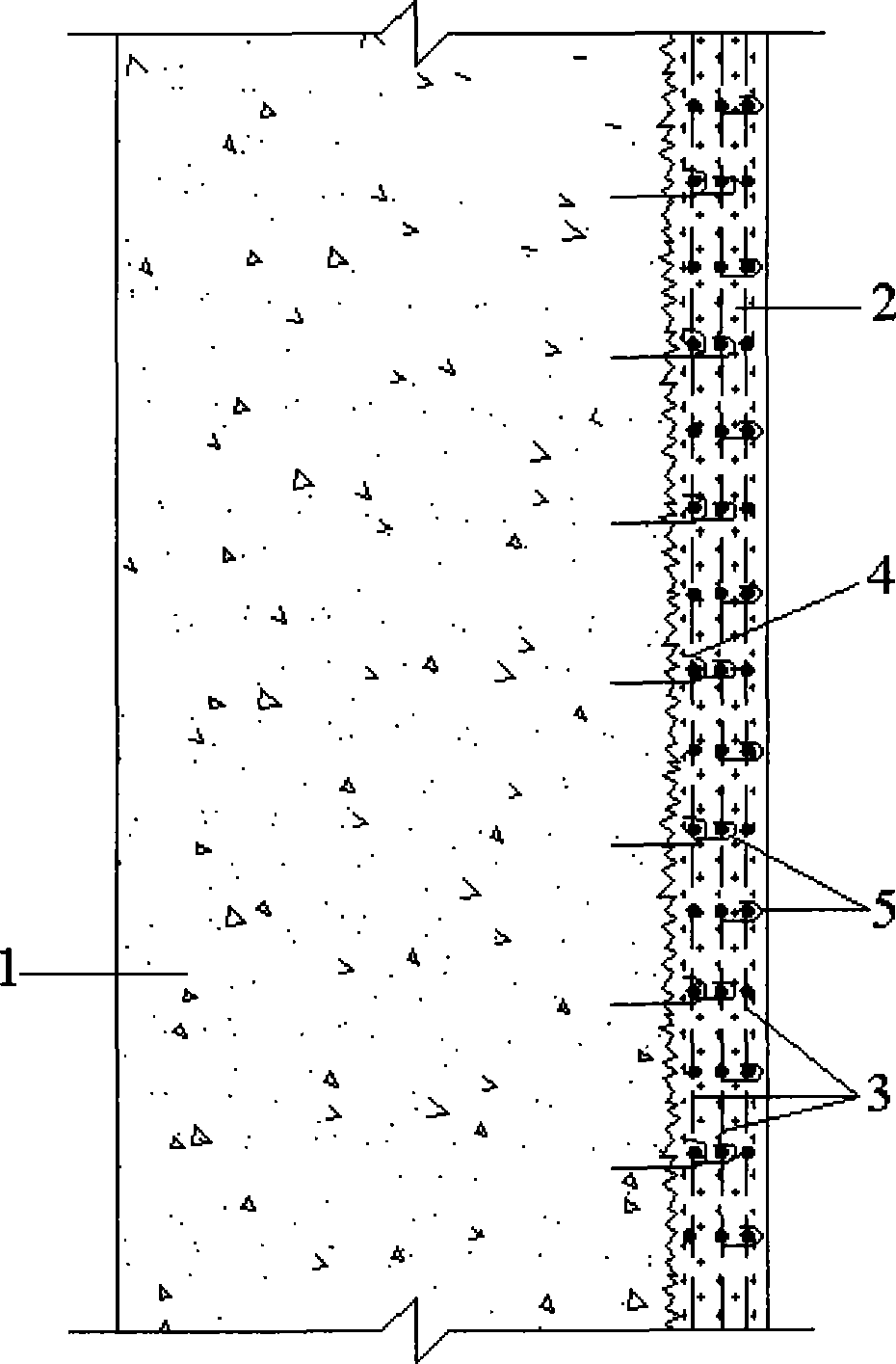

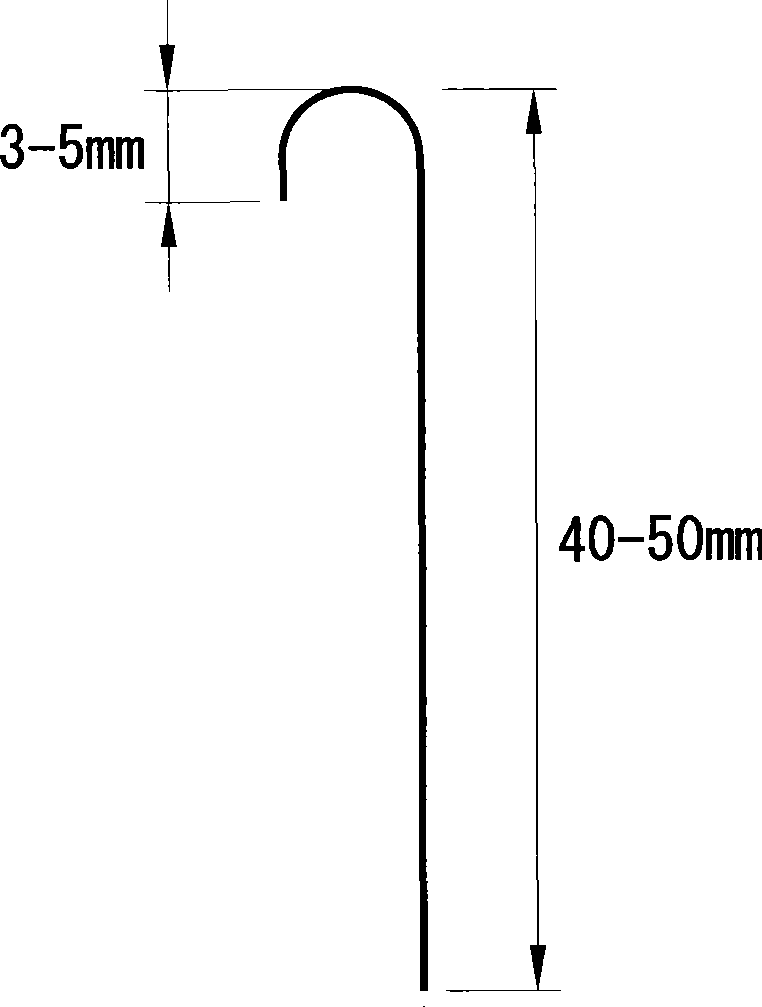

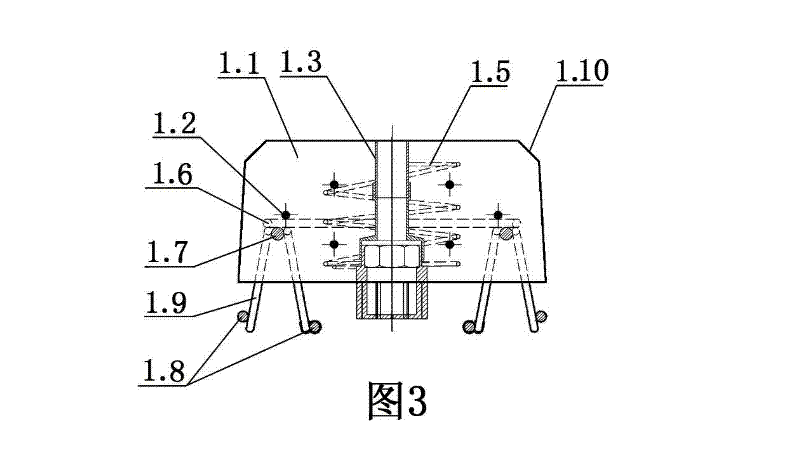

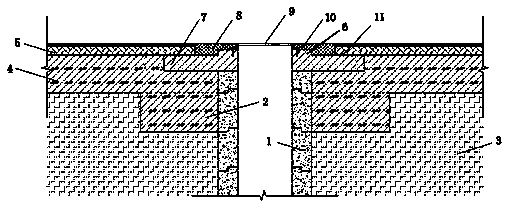

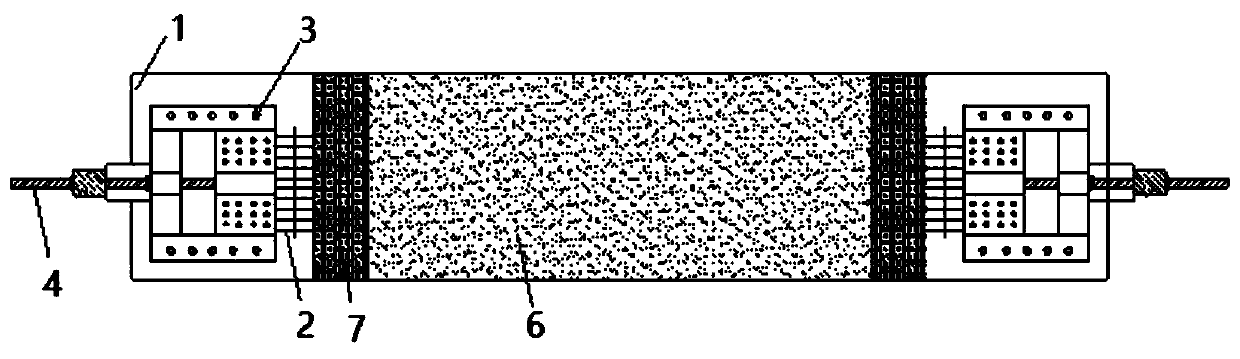

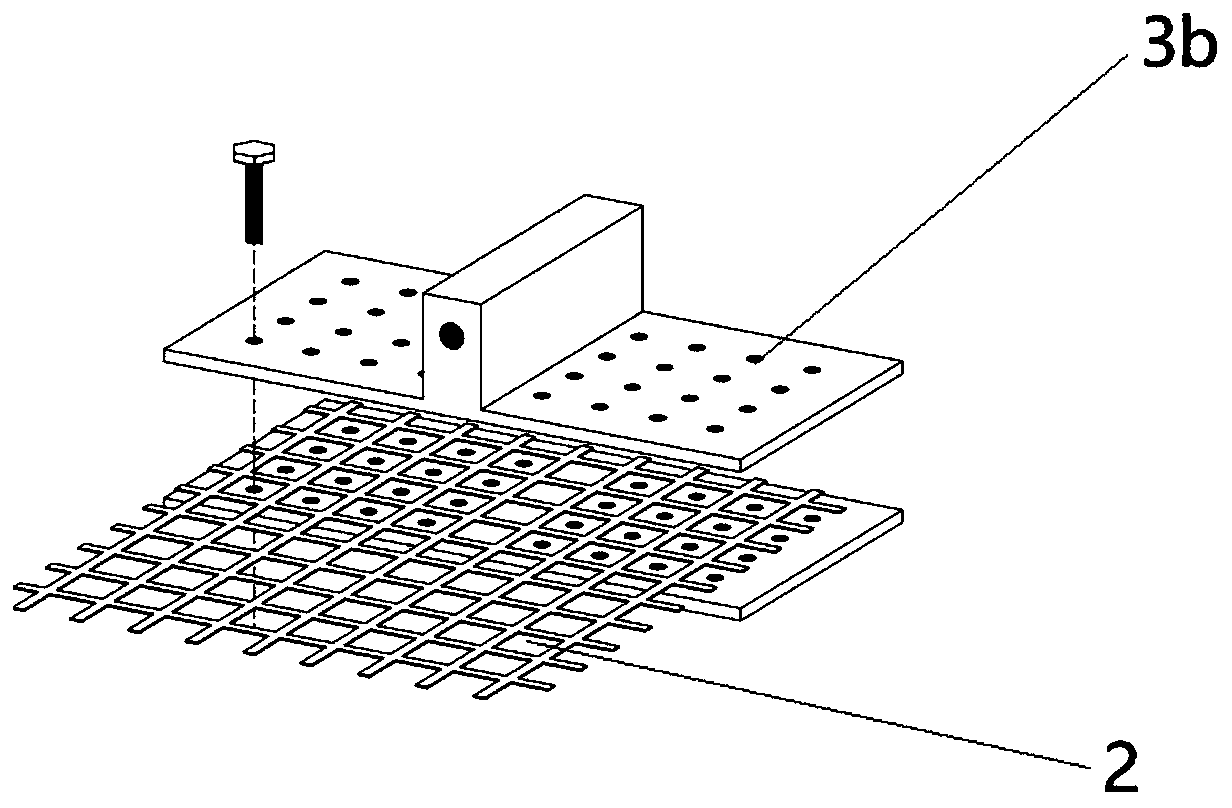

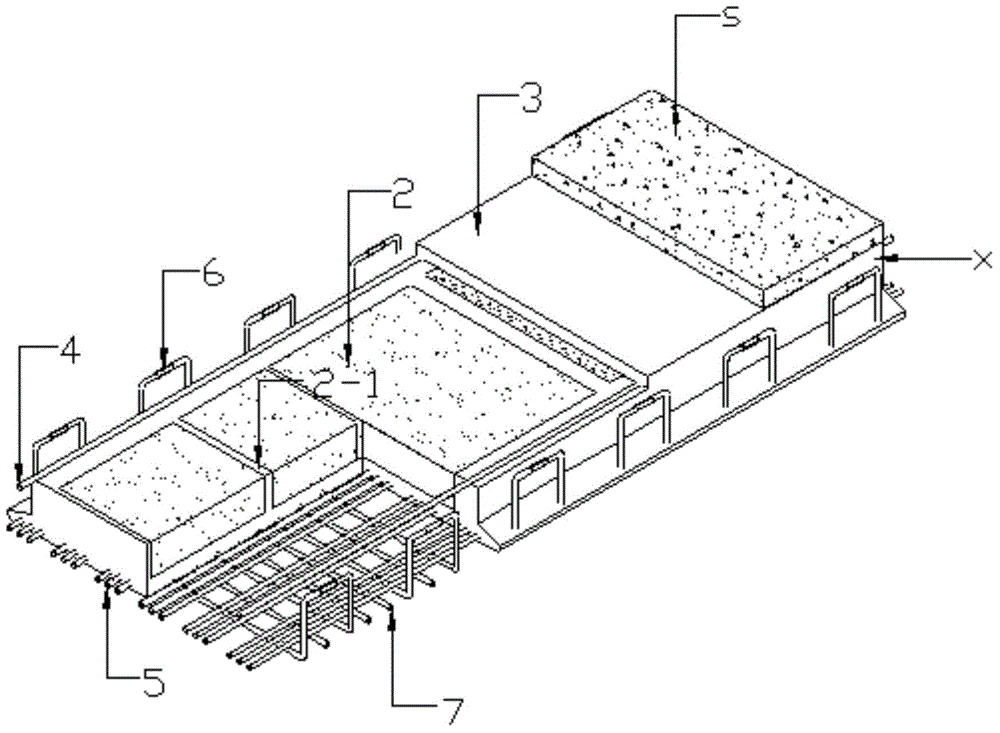

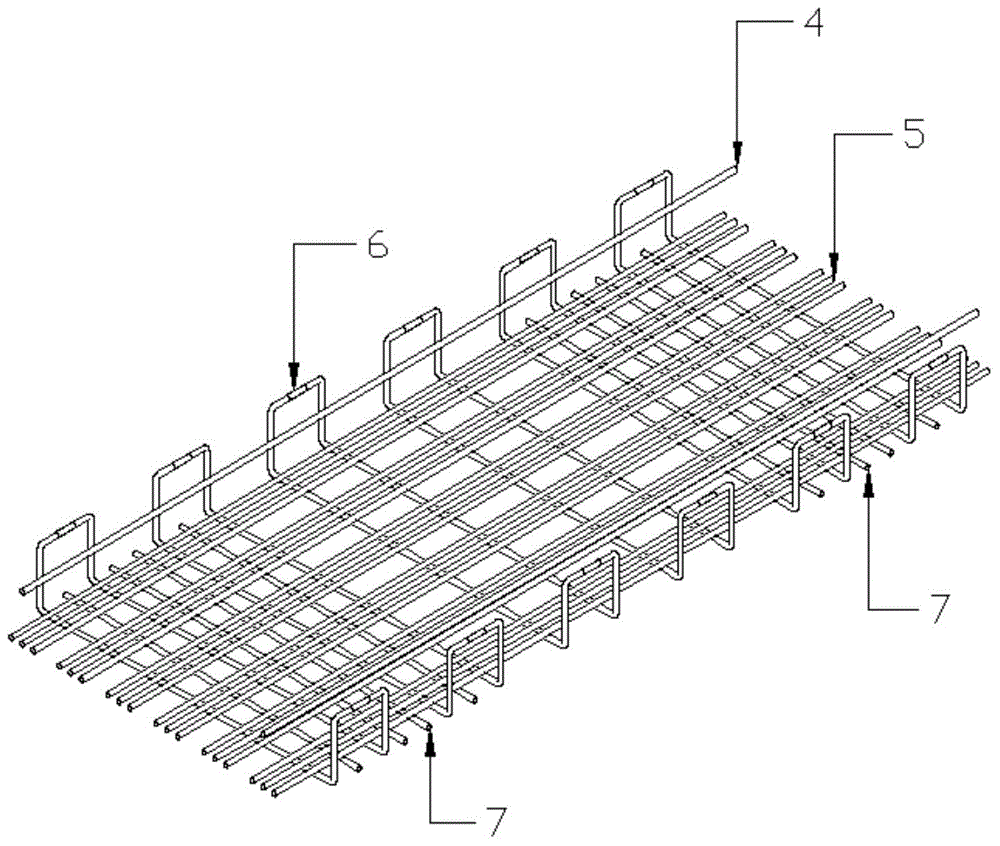

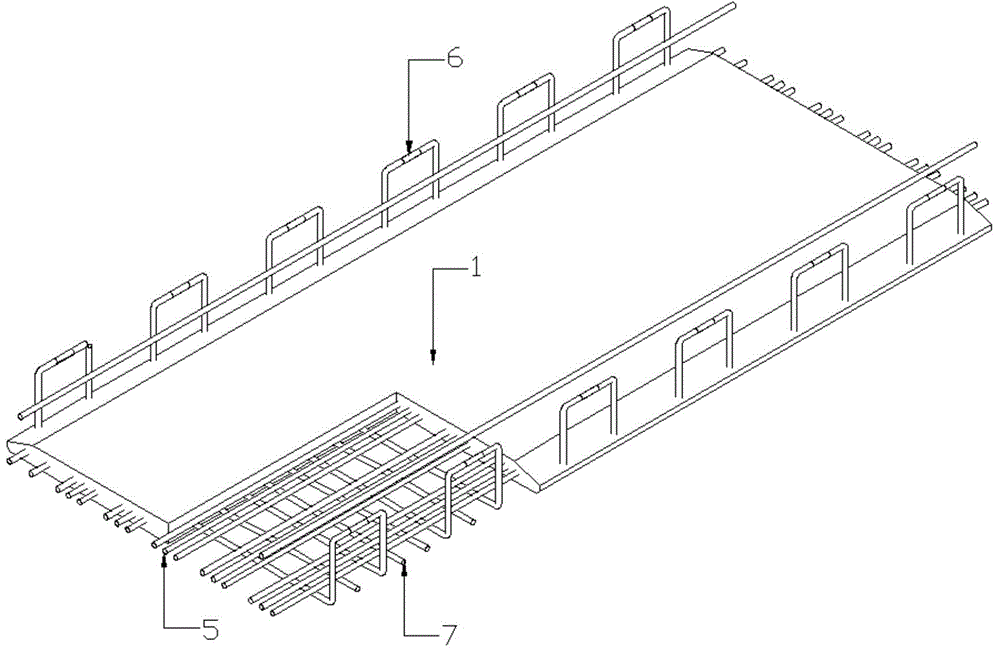

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

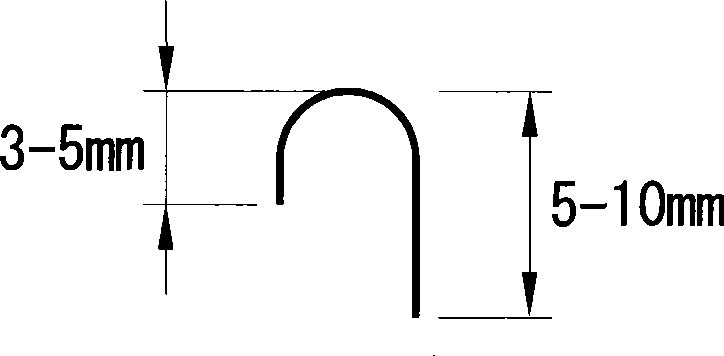

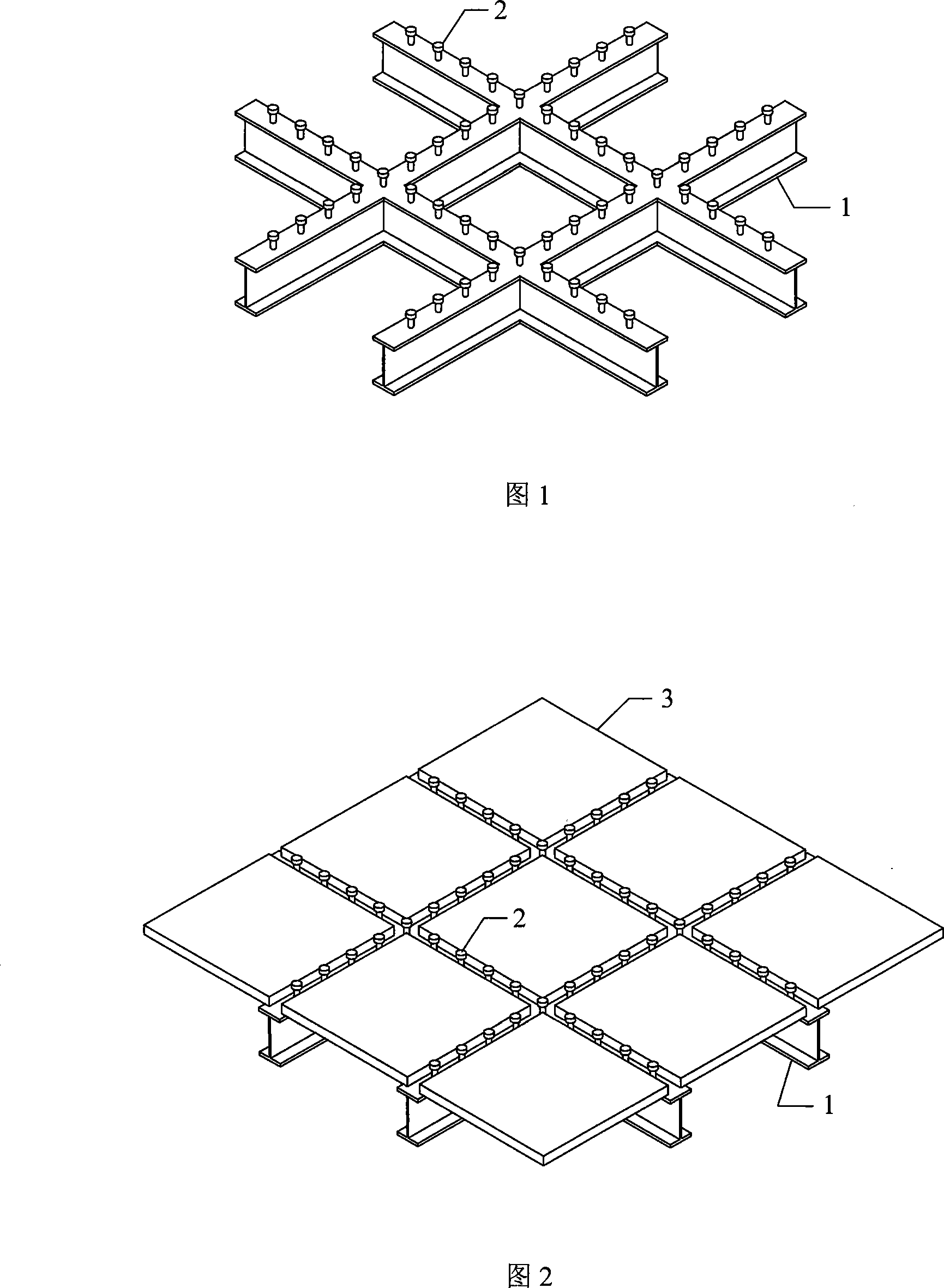

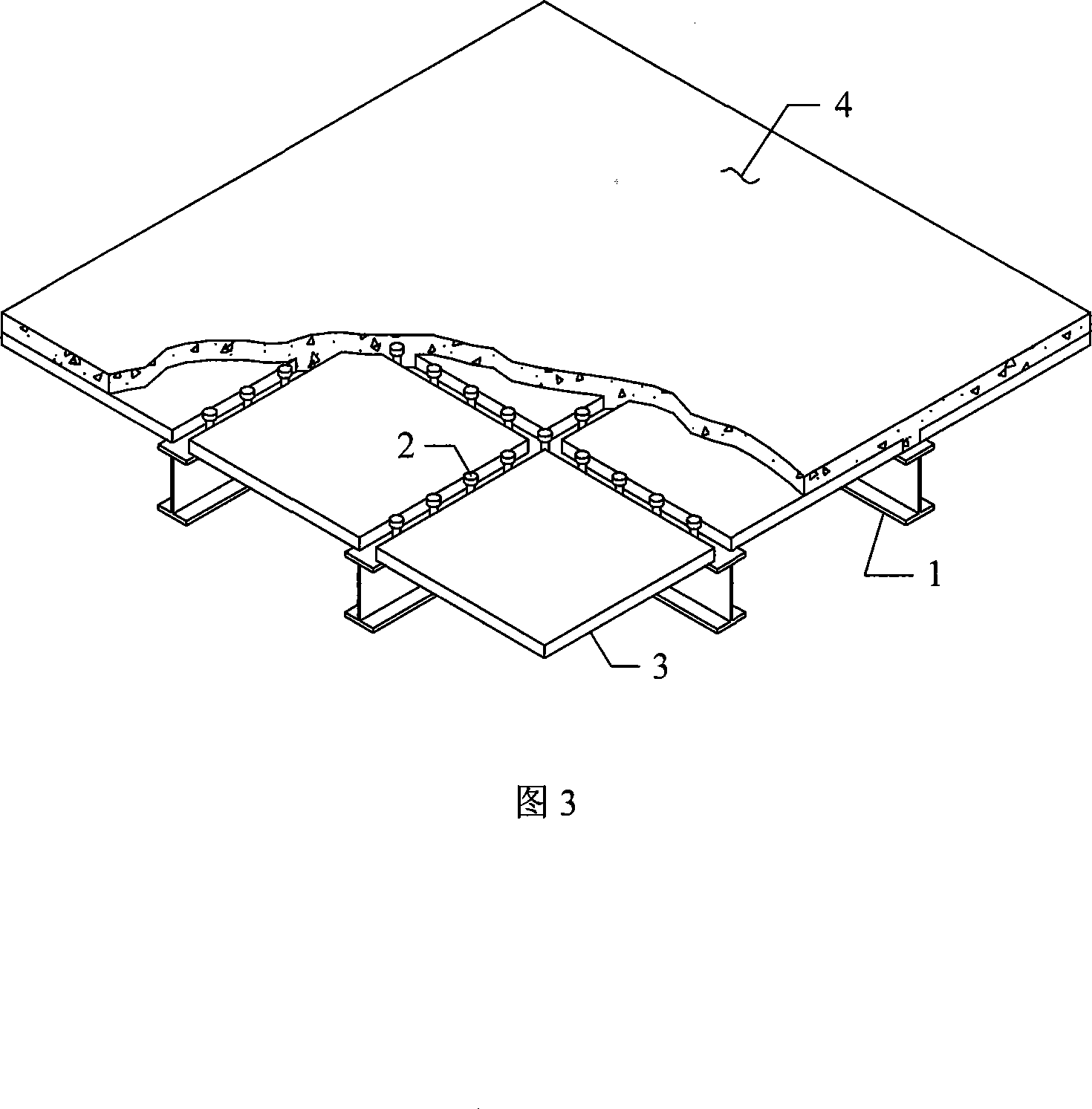

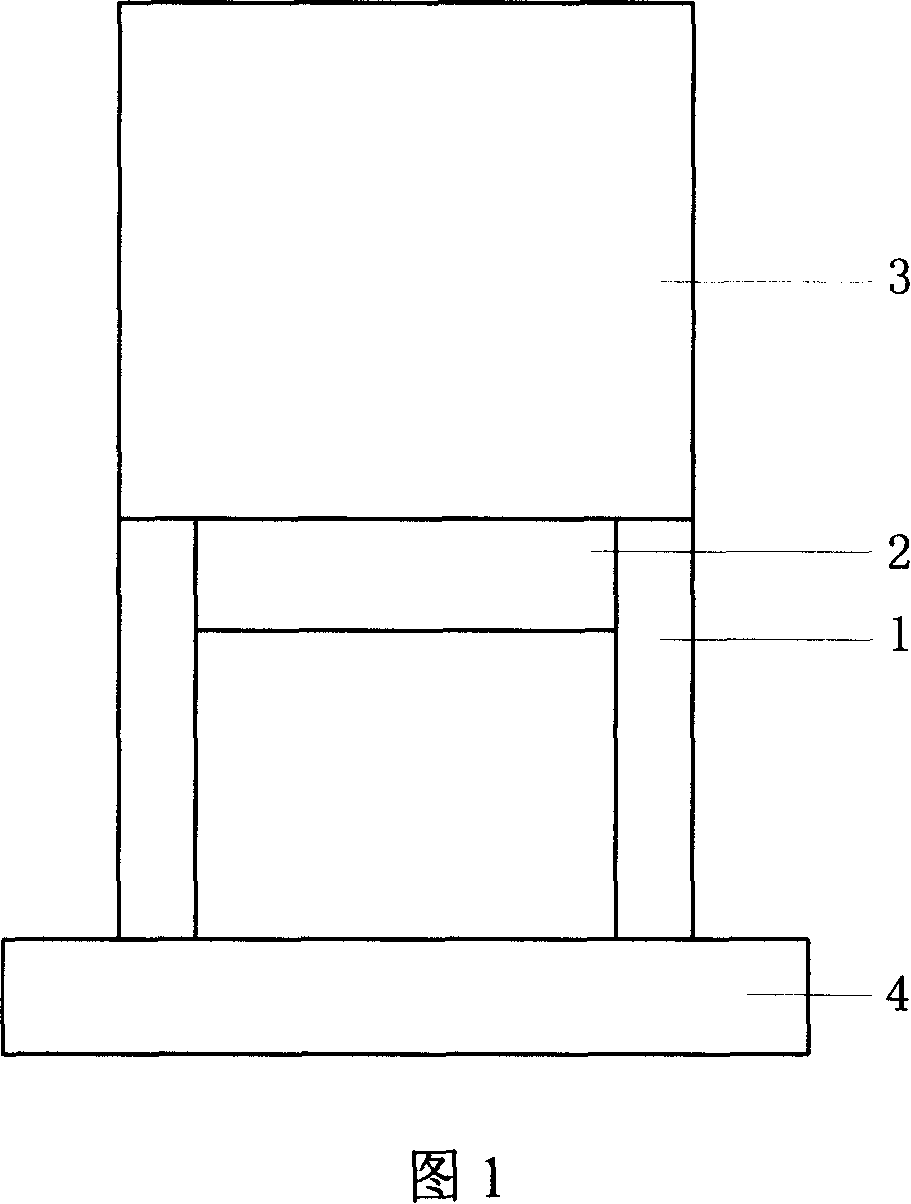

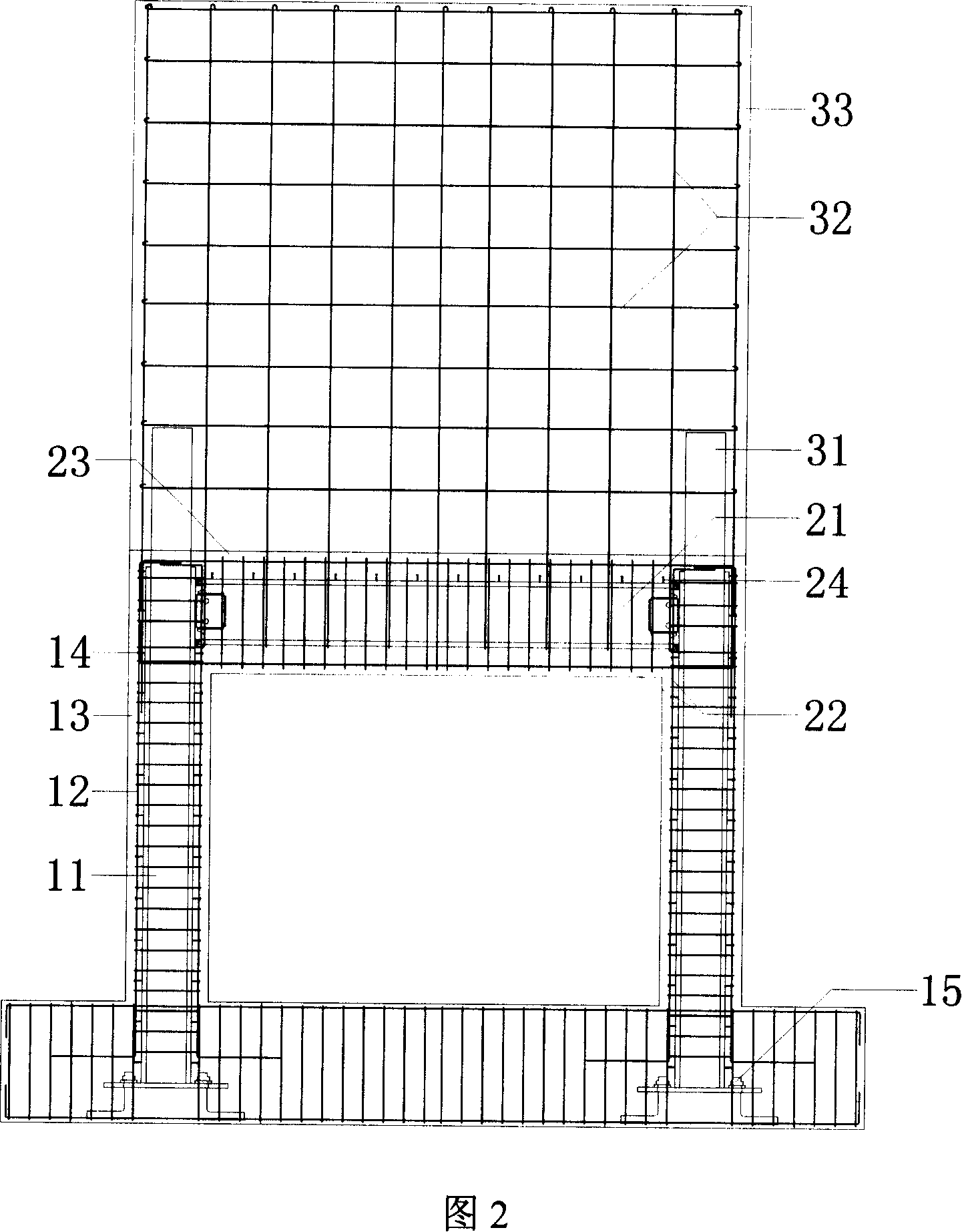

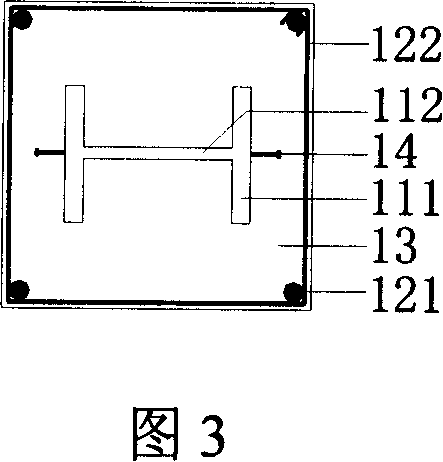

Bidirectional steel-stacked plate concrete composite building roof

The invention relates to a dual-way steel-laminated slab concrete composite floor, belonging to a new large span floor structure, comprising a cross steel beam, a prefabricated slab and a later pouring concrete layer, wherein the cross steel beam is an I shaped cross section or box section steel beam; the prefabricated slab, a common reinforced concrete slab or a prestressed concrete slab, is held on the cross steel beam and covered on the grids between the steel beams; the later pouring concrete layer is concrete poured on the prefabricated slab and the steel beam. The invention has the advantages of low structure height, high bearing capacity, stiffness, bilateral support effect, saved forming procedure and formwork, reduced the wet work amounts of site concrete, favorableness to the three-dimensional construction, and shortened construction period.

Owner:TSINGHUA UNIV

New type of frame supported shear wall structure and its making process

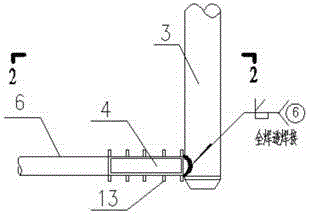

The present invention is new type of frame supported shear wall structure and its making process. The frame supported shear wall structure has frame struts stretching into shear wall and converting beams of shaped steel-concrete structure. The flange of the beam steel and the flange of the strut are jointed through welding, the web of the beam steel and the flange of the strut are welded through a knee-bracket plate, there are pegs in the flanges of the beam steel and the strut steel, and reinforcing steel plate is welded to the beam hole in the beam steel. The frame supported shear wall of shaped steel-concrete structure has small member cross section area, great bearing capacity, high rigidity and other advantages and is suitable for use in the shear wall of seismic region.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

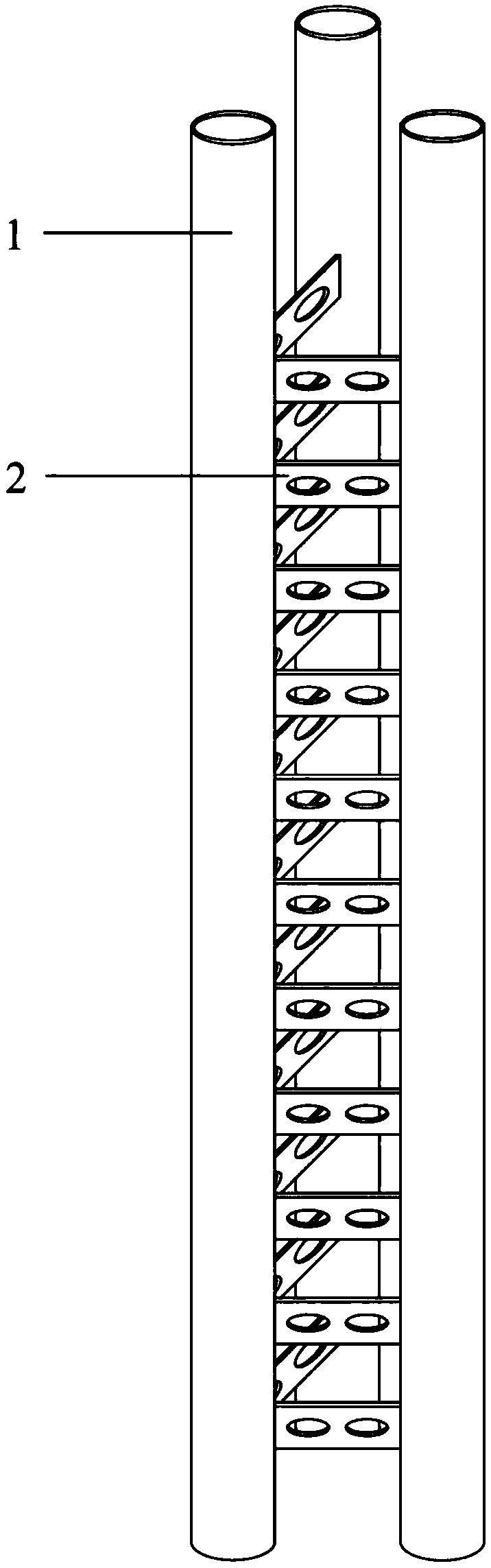

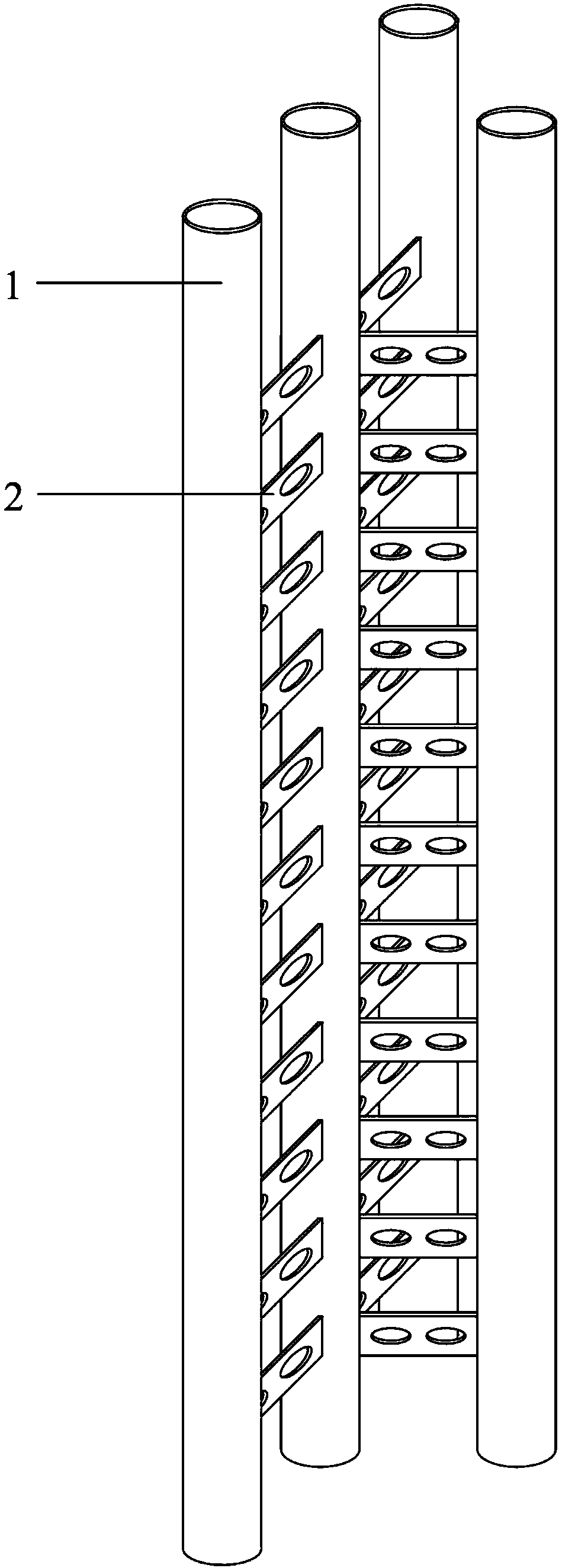

Steel frame reinforced column and reinforcing method thereof

InactiveCN101839074AReasonable structural stressImprove structural bearing capacityStrutsBuilding repairsSheet steelSteel frame

The invention relates to a steel frame reinforced column and a reinforcing method thereof. The steel frame reinforced column is characterized in that sealing reinforcing steel plates are welded between two flanges at two sides of an H-shaped steel frame column along the overall length of the column, are arranged in pair at two side openings of the H-shaped steel frame column and are welded with two flanges at the opening of the H-shaped steel frame column, and two sealing reinforcing steel plates adjacent up and down are mutually welded. In the invention, the reinforcing steel plates are prefabricated into parts in advance, are directly hoisted to the position during construction, pass through the steel column in over length along the direction of a weak shaft of the H-shaped steel frame column and are welded in pair, thereby enabling the structure stress of the steel reinforced column to be more reasonable and the structural bearing of an original building to be enlarged and satisfying the structural bearing stress requirement. By adopting the construction method of the invention, the original structure can be used for reinforcing the frame steel column of the original steel structure without being disassembled, thereby not influencing the normal work in the original building. All the reinforcing steel plates can be precast in factories, thereby not only shortening the time limit for a project and reducing the construction cost but also ensuring project quality and satisfying the requirement of building extension.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

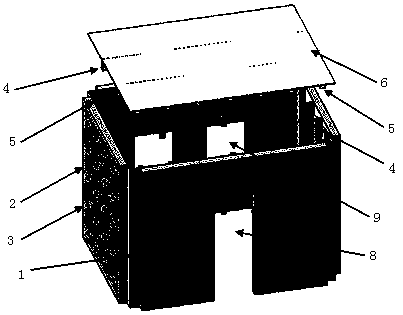

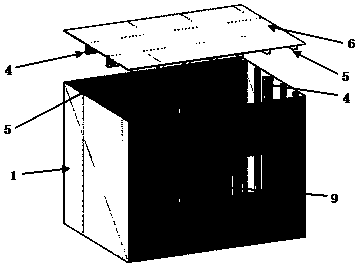

Prefabricated type box plate steel structure multi-storey and high-rise structural system and construction method

ActiveCN111287316AImprove bearing capacityGood shock resistance and ductilityProtective buildings/sheltersShock proofingSteel platesStructural system

The invention provides a prefabricated type box plate steel structure multi-storey and high-rise structural system and a construction method. The prefabricated type box plate steel structure multi-storey and high-rise structural system comprises a ground floor unit and standard floor units. The ground floor unit is composed of steel plate walls, a steel floor and precast concrete slabs. Each standard floor unit is composed of steel plate walls and a steel floor. Vertical reinforcing ribs are welded to the inner side of each steel plate wall. Reinforcing ribs are welded to the bottom side of each steel floor. The precast concrete slabs are attached to the outer sides of the steel plate walls of the ground floor unit. During an earthquake or large storey drift, the precast concrete slabs cangenerate certain sliding relative to the steel plate walls of the ground floor unit. The prefabricated type box plate steel structure multi-storey and high-rise structural system is high in bearing capacity, good in ductility and anti-seismic property, rapid in construction, low in work quantity, low in pollution on a construction site and low in comprehensive construction cost, and the prefabricated type box plate steel structure multi-storey and high-rise structural system can be widely applied to high-rise civil residential buildings.

Owner:CSIC INT ENG CO LTD +7

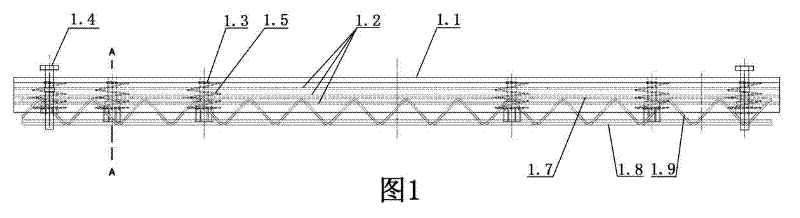

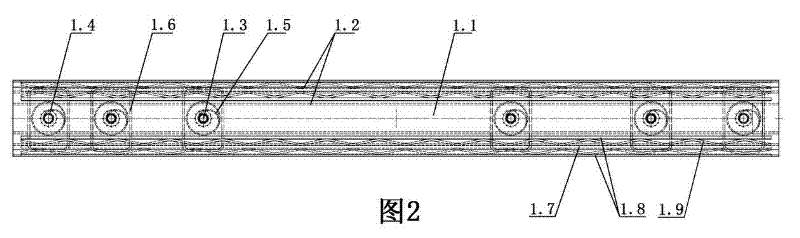

High-speed turnout switch tie for speed of 350km per hour and manufacturing method thereof

ActiveCN102162209AImprove bearing capacityHigh strengthRail switchesCeramic shaping apparatusAutomatic controlUltimate tensile strength

The invention discloses a high-speed turnout switch tie for speed of 350km per hour and a manufacturing method thereof. The method comprises the following steps of: 1, installing a template; 2, laying steel wires; 3, laying end plates; 4, installing sleeves and laying separators; 5, laying fittings; 6, starting a computer to automatically control the tensioned steel wires; 7, performing final tension; 8, fastening the separators, and binding the fittings; 9, putting an ash bucket and concrete into a die; 10, vibrating; 11, detaching the separators and partition plates; 12, clearing the production line; 13, curing; 14, performing concrete stripping; 15, tensioning; 16, breaking the wires, and stripping; 17, spraying, treating the sleeves, and cutting the exposed ribs; 18, clearing the die and the parting agent; and 19, warehousing. Accurate control of distribution quantity, uniform distribution and high speed are realized, stirring uniformity and concrete compactness are realized in automatic distribution, and the strength of the switch die is ensured.

Owner:中铁十四局集团房桥有限公司

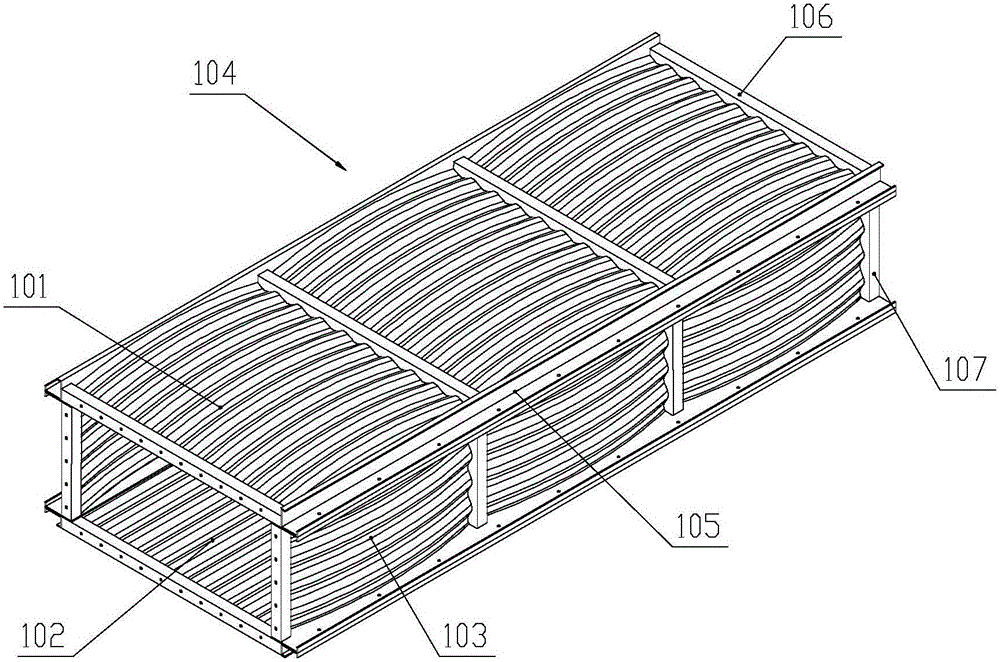

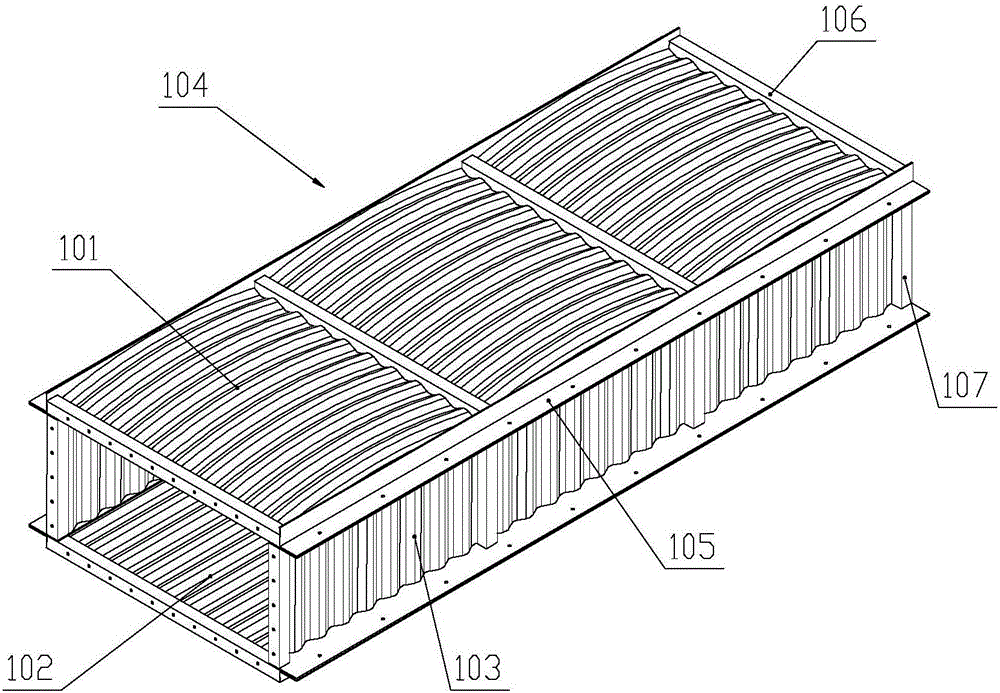

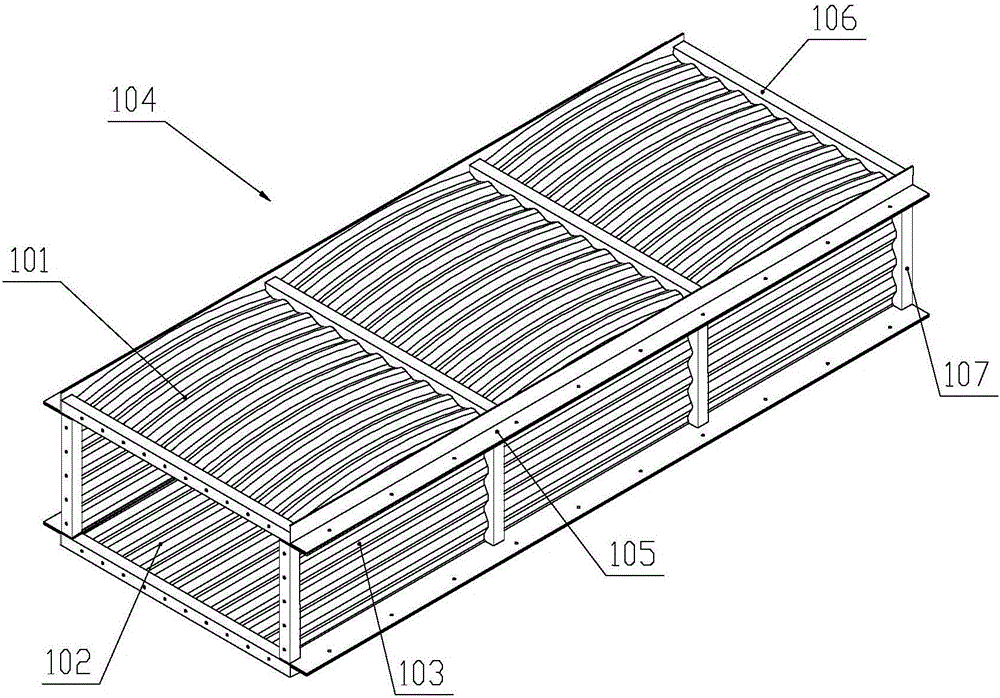

High-strength urban underground comprehensive pipe gallery

ActiveCN105926674AIncrease stiffnessImprove carrying capacityArtificial islandsUnderwater structuresEngineeringHigh intensity

The invention discloses a high-strength urban underground comprehensive pipe gallery. The high-strength urban underground comprehensive pipe gallery is characterized in that a top plate, a base plate and two side plates consisting of corrugated plates of which the outer sides and / or the inner sides are provided with protrusions are spliced to form a box-type pipe joint; the box-type pipe joints are spliced in the axial direction to form the comprehensive pipe gallery, wherein longitudinal beams are arranged at edges of the box-type pipe joints; cross beams are arranged at two ends of the top plates and / or the base plates in the axial direction of the box-type pipe joints; upright posts are arranged at two ends of the side plates; the cross beams and the upright posts are connected end to end to form a frame type framework; the top plates are arched; the direction of arched grains on the top plates are consistent with the extending direction of the pipe gallery; the top plates and the cross beams at two ends are combined to form a structure; the top plates apply the principles of joint stress of pipe and soil and a continuous arch bridge, and sheets of the top plates and backfill soil are collaboratively stressed; in addition, the direction of the arched grains on the sheets is consistent with the extending direction of the pipe gallery; in addition, the cross beams are arranged between adjacent top plates side by side in the extending direction of the pipe gallery; and except the cross beams at two ends of the pipe gallery, horizontal components of the top plates on the cross beams are offset leftwards and rightwards, so the bearing capacity of an overall structure is higher.

Owner:NANJING LIANZHONG CONSTR ENG TECH

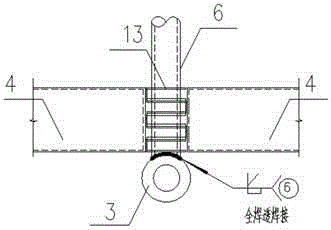

Foldable arch type bridge

InactiveCN105862563AStable structureEasy to buildPortable bridgeArch-type bridgeEarthquake disasterBending force

Provided is a foldable arch type bridge. According to the bridge form, the foldable arch type bridge is a bowstring arch bridge, and comprises two basic structural forms with an arch and a beam combined, and the arch and beam bear loads jointly; a self-balance system is formed through the combined action that the beam bears bending force while the arch bears pressure, a support at the arch end is prevented from generating horizontal thrust, and the horizontal thrust is converted to tension borne by a rod string; and the arch and the string are fixedly connected by being connected with the two ends of a closed framework in a hinged mode. The developable arch type bridge is more reasonable in outline stress and high in material utilization rate. The structural unfolding speed of the developable arch type bridge is far higher than the bridge assembling speed. Construction is convenient and rapid without assistance by large-sized machines. The developable arch type bridge is particularly suitable for solving the problems caused to rescue work by road and bridge destruction and traffic interruption in earthquake disaster regions, and enables vehicles and supplies to move across obstacles fast in emergency circumstances.

Owner:TONGJI UNIV

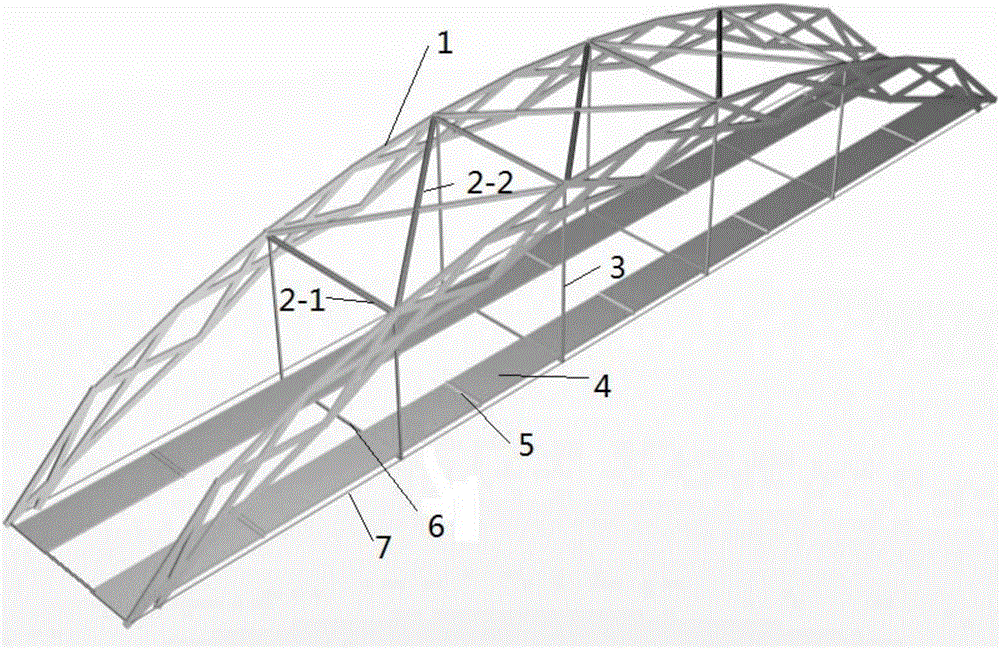

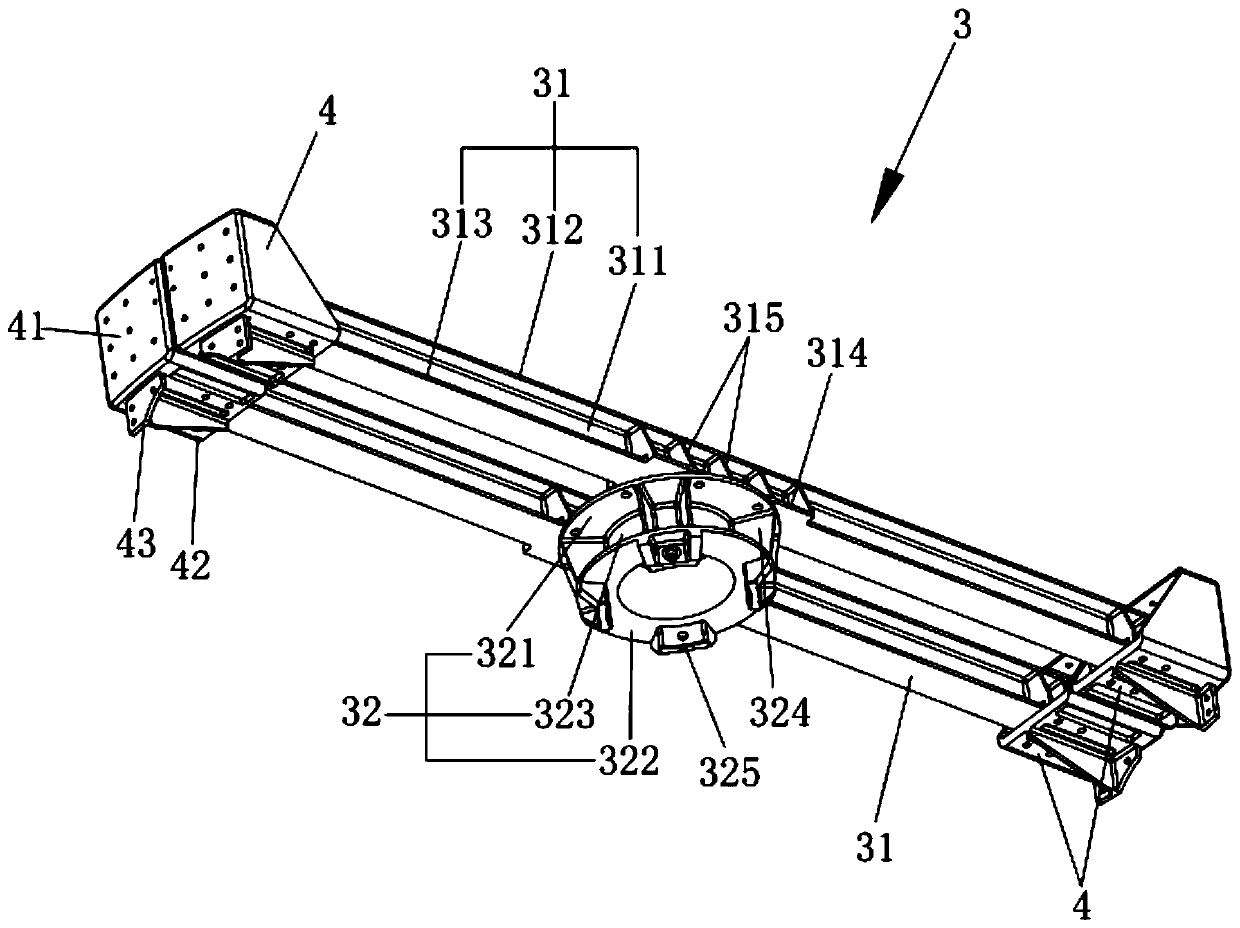

Sectional type modularization rapid assembled and spliced bridge

InactiveCN103422423AImproves buckling stabilityImprove carrying capacityConstructionsOn boardModularity

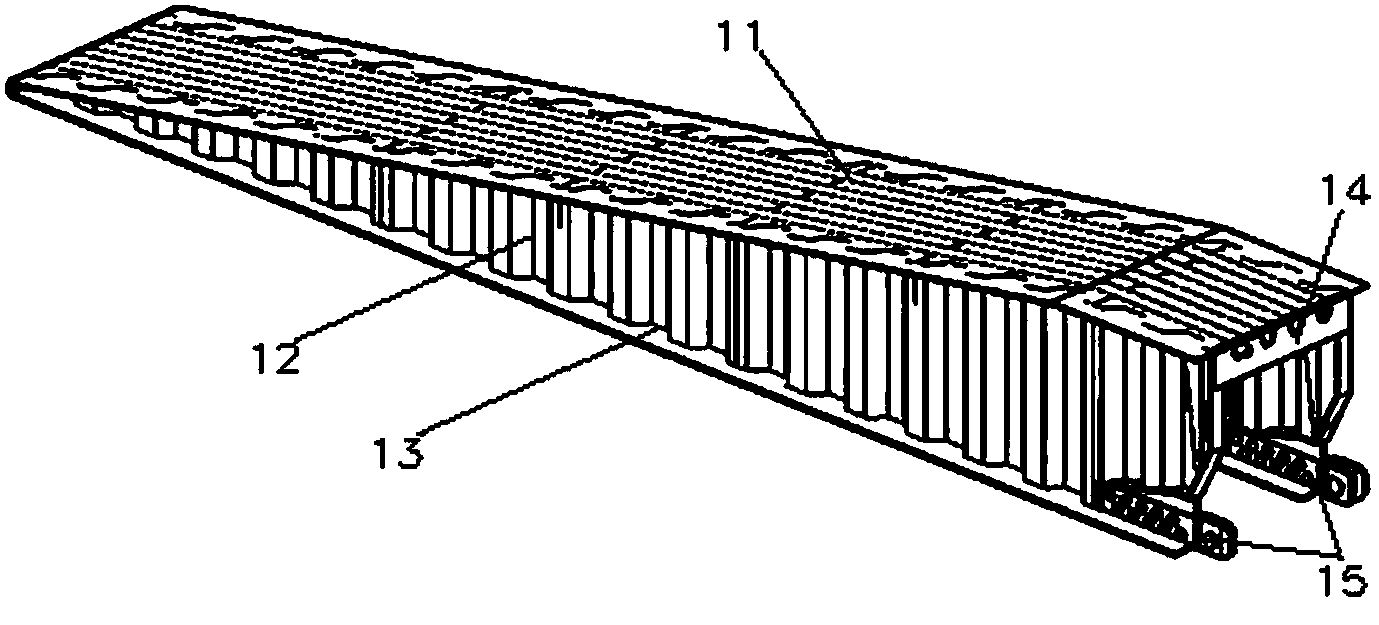

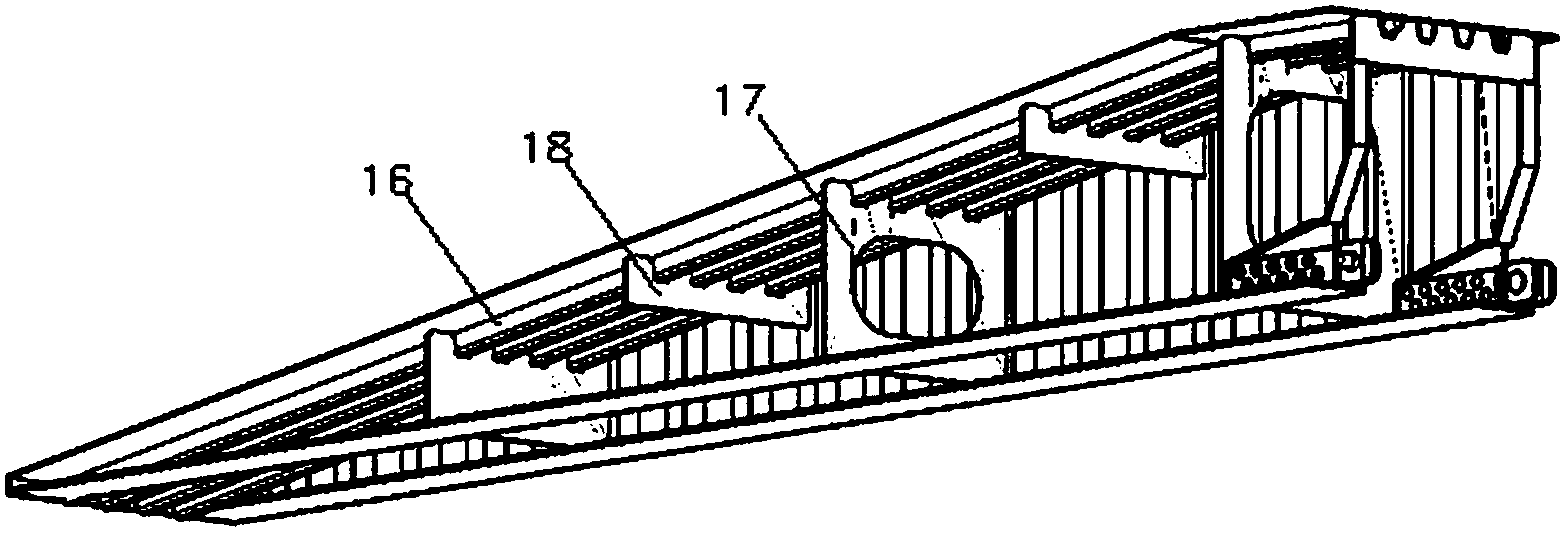

The invention relates to a sectional type modularization rapid assembled and spliced bridge which comprises springboard bridge sections (1) and standard bridge sections (2). Each springboard bridge section (1) comprises a top board (11), a web (12), a bottom board (13), a pressure bearing interlocking end board (14) and a negative head and positive head connecting lug board (15). Each standard bridge section (2) comprises a top board (21), a web (22), a bottom board (23), a pressure bearing interlocking end board (24) and a negative head and positive head connecting lug board (25). The springboard bridge sections (1) and the standard bridge sections (2) are fixedly connected through the pressure bearing interlocking end boards (14), the negative head and positive head connecting lug boards (15), the pressure bearing interlocking end boards (24) and the negative head and positive head connecting lug boards (25). Every two standard bridge sections (2) are fixedly connected through the pressure bearing interlocking end boards (24) and the negative head and positive head connecting lug boards (25). Every two assembled and spliced bridges are fixedly connected through a transverse connecting arm (3). The sectional type modularization rapid assembled and spliced bridge has the advantages of being convenient to transport, flexible to assemble and splice, capable of being erected rapidly, and particularly suitable for releasing emergencies and disasters. The webs are made of corrugated steel, and the bottom boards are made of laminated composite materials.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

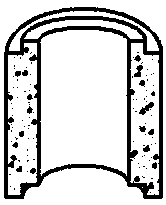

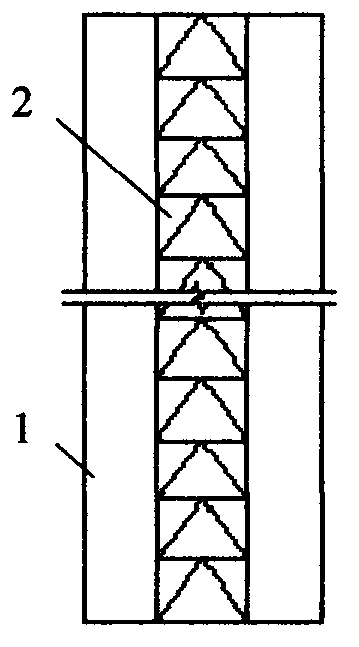

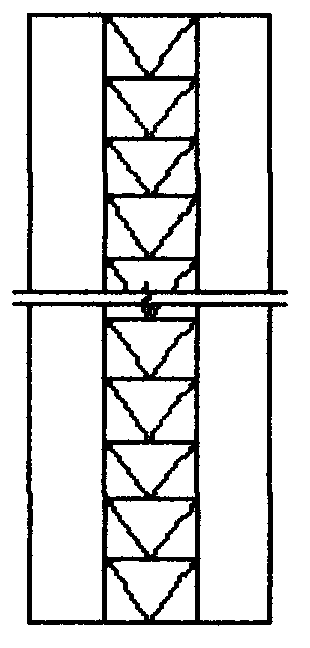

Ultra-high performance concrete column permanent formwork and preparation method thereof

The invention discloses an ultra-high performance concrete column permanent formwork which comprises a hollow columnar ultra-high performance concrete layer and a steel reinforcement cage arranged in the ultra-high performance concrete layer. Dents with the depth not lower than 5 mm are formed in the inner surface of the ultra-high performance concrete layer. The cross section of the ultra-high performance concrete layer is in the shape of a hollow column and a hollow square column. The dents are in strip, grid, dot and spiral shapes. The invention further discloses a preparation method of the ultra-high performance concrete column permanent formwork. By preparing the ultra-high performance concrete column permanent formwork with the dents with the depth not lower than 5 mm in the inner surface, the binding powder between ultra-high performance concrete and post-cast core concrete is enhanced, so that the column component bearing capacity is improved; the ultra-high performance concrete column permanent formwork is good in integrality, convenient to prepare, low in cost, remarkable in economic benefit and excellent in endurance quality.

Owner:广东利盈投资集团有限公司

Profiled steel sheet-UHP (ultra high performance) fiber reinforced concrete composite bridge deck

InactiveCN104674657ATake advantage of the tensile strengthReduce in quantityBridge structural detailsBridge materialsBridge deckRebar

A profiled steel sheet-UHP (ultra high performance) fiber reinforced concrete composite bridge deck comprises U-shaped profiled steel sheets, perforated steel sheets, vertical studs, horizontal reinforcements, longitudinal reinforcements and UHP fiber reinforced concrete. The vertical perforated steel sheets are longitudinally fixed in the centers of the grooves of the U-shaped profiled steel sheets. A plurality of fixed vertical stud rows are arranged on raised portions of the U-shaped profiled steel sheets. The horizontal reinforcements penetrate connecting holes in the perforated steel sheets and are welded with the upper ends of the vertical studs. The longitudinal reinforcements are perpendicular to the horizontal reinforcements and fixedly connected with joints of the horizontal reinforcements and the vertical studs. The UHP fiber reinforced concrete is poured in the U-shaped profiled steel sheets to cover the perforated steel sheets, the vertical studs and the horizontal and the longitudinal reinforcements. According to the arrangement, the adhesion performance of the interfaces of the profiled steel sheets and the UHP fiber reinforced concrete is improved, and mechanical advantages of the profiled steel sheets and the UHP fiber reinforced concrete are fully played. The profiled steel sheet-UHP fiber reinforced concrete composite bridge deck dead is low in weight, high in bearing capacity, excellent in anti-fatigue performance, available in industrialized production and on-field assemble, higher in bridge deck building and changing speed and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY

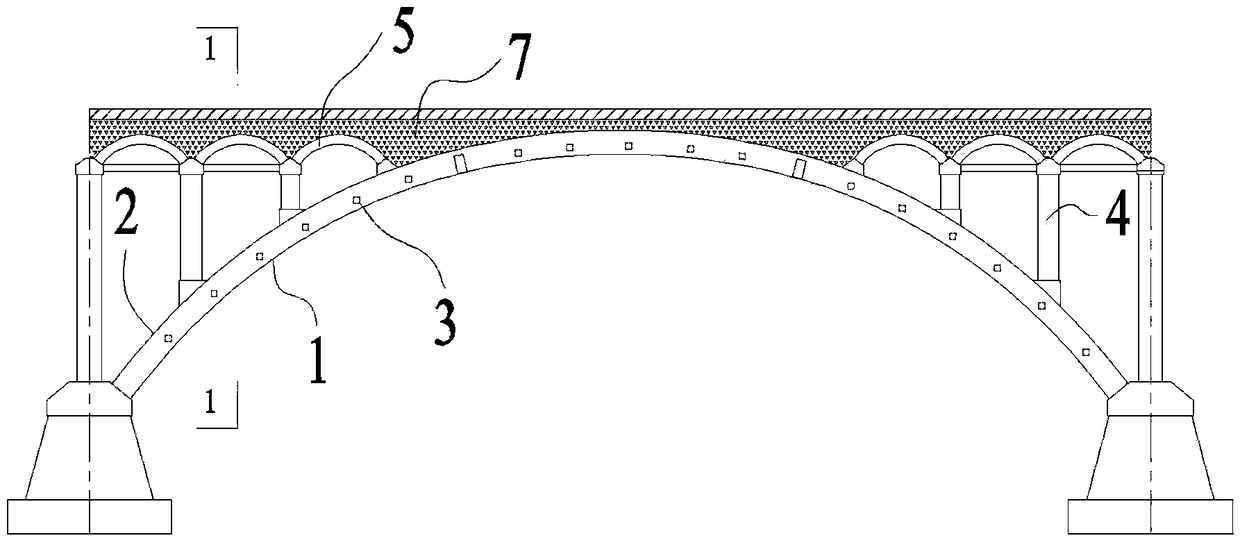

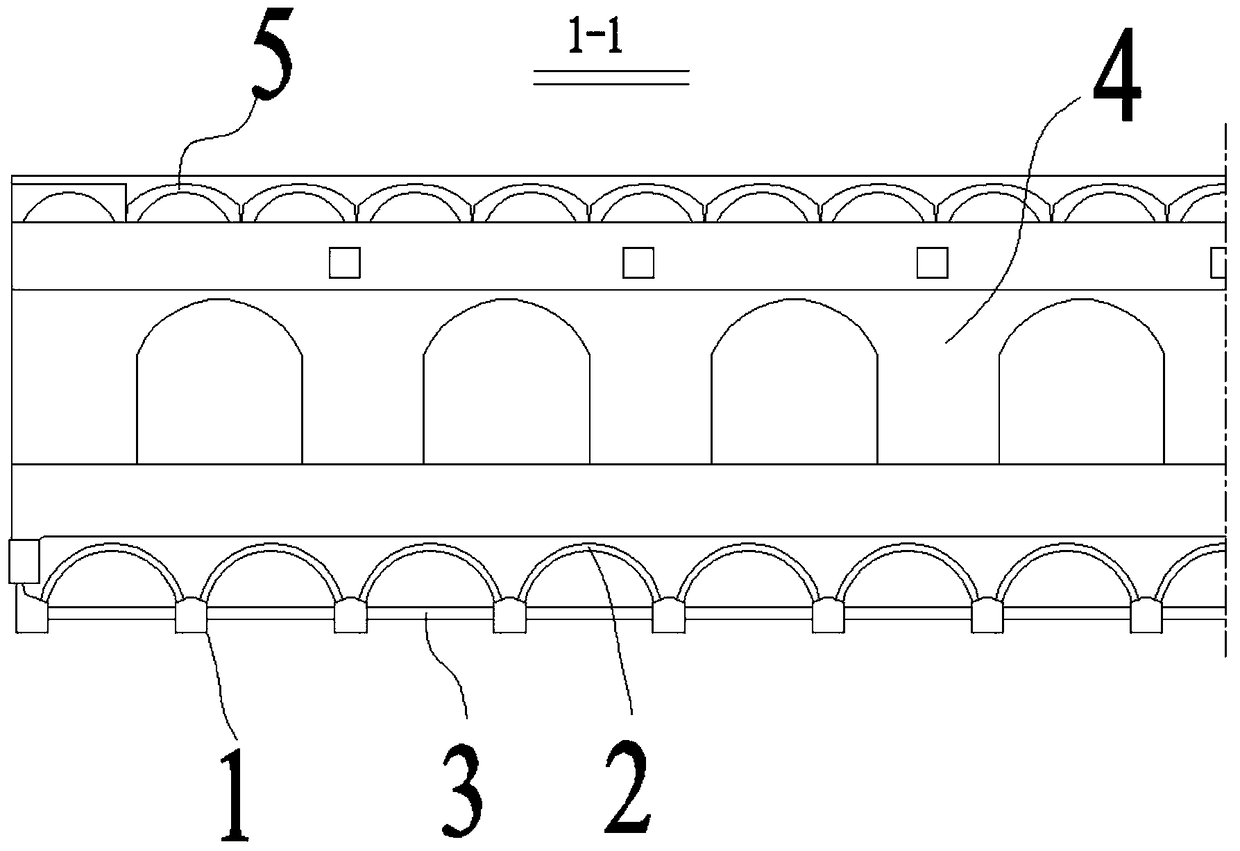

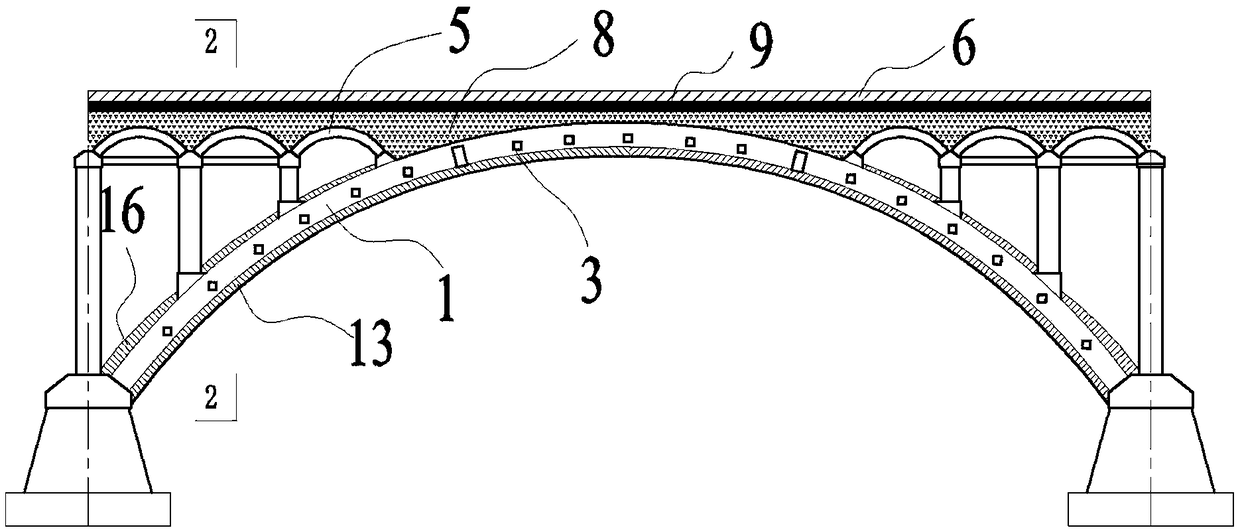

A method for reinforcing a double-curved arch bridge with a corrugated arch plate

ActiveCN109137762AImprove the bearing capacity of the structureGuaranteed safety and durabilityBridge erection/assemblyBridge strengtheningMaterial consumptionBending moment

A method for reinforcing a double-curved arch bridge with a corrugated arch plate comprises pouring a main arch ring arch rib reinforcement layer on the outside of the main arch ring supply rib, pouring a main arch plate reinforcement layer on that main arch ring arch plate, the main arch plate reinforcement layer and an arch plate groove area forming a cavity. Compared with the reinforcement method of directly filling the groove area on the arch plate in the prior art, the invention increases the bending moment of inertia of the section, at the same time, the material consumption is small, which is favorable for the stress of the structure before the newly poured concrete reaches the strength standard value. The invention does not change the characteristics of the double-curved arch bridge, and retains the historical style and features of the bridge. The invention also replaces the original filler with the lightweight filler, lightens the dead weight of the structure, reduces the stress level under the action of the original structure under the dead load, makes the load shared by the reinforcement layer larger, and gives full play to the bearing capacity of the reinforcement layer.

Owner:CHONGQING JIAOTONG UNIVERSITY

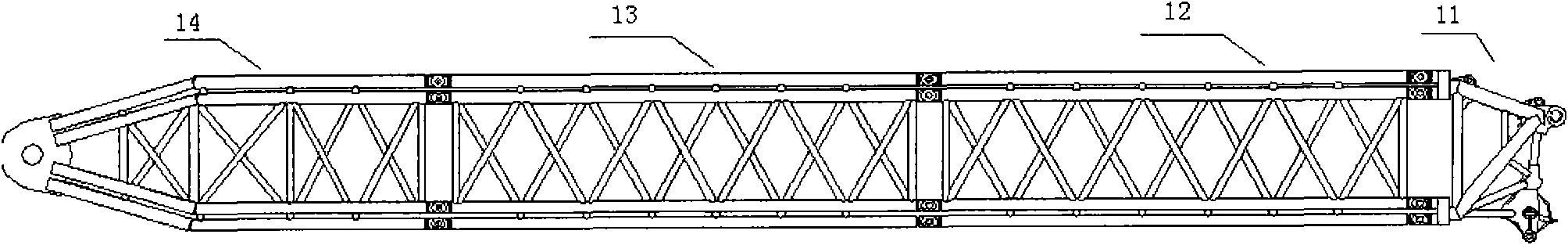

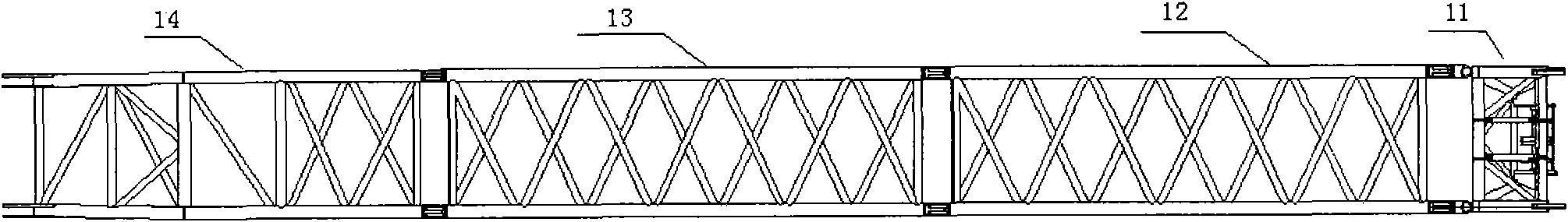

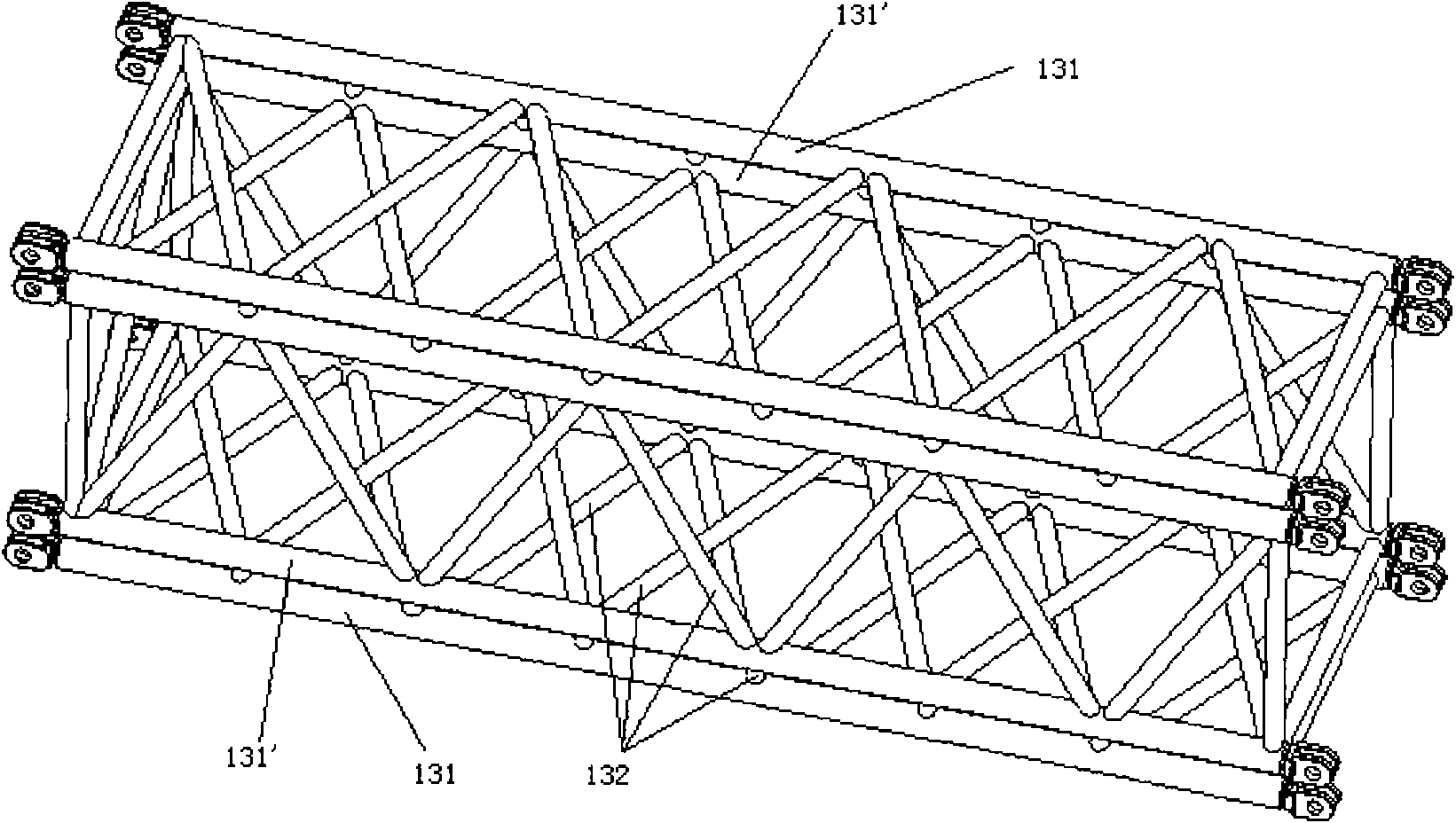

Multi-main-chord arm support for crane

InactiveCN102249161AIncrease the number ofIncrease the cross-sectional areaCranesCarrying capacityEngineering

The invention provides a multi-main-chord arm support for a crane. The multi-main-chord arm support comprises a lower arm section, a middle arm section and an arm head which are connected in sequence, wherein the lower arm section and the middle arm section are multi-main-chord arm sections; each corner part of the cross section of each multi-main-chord arm section is provided with a main chord; the main chords are connected with one another through a plurality of web members; and at least one main chord is additionally arranged on each corner part of the cross section of each multi-main-chord arm section along the width direction or height direction of the multi-main-chord section, and is parallel to the original main chord. In the multi-main-chord arm support for the crane, provided by the invention, the quantity of arm section main chords is increased under the condition that the arm section transportation size is not changed, so that the cross-sectional area of each main chord and the overall rigidity of the arm support are increased, and the structural carrying capacity of the arm support is further increased multiply; and the multi-main-chord arm support is suitable for a large-sized crane.

Owner:SHANGHAI SANY TECH

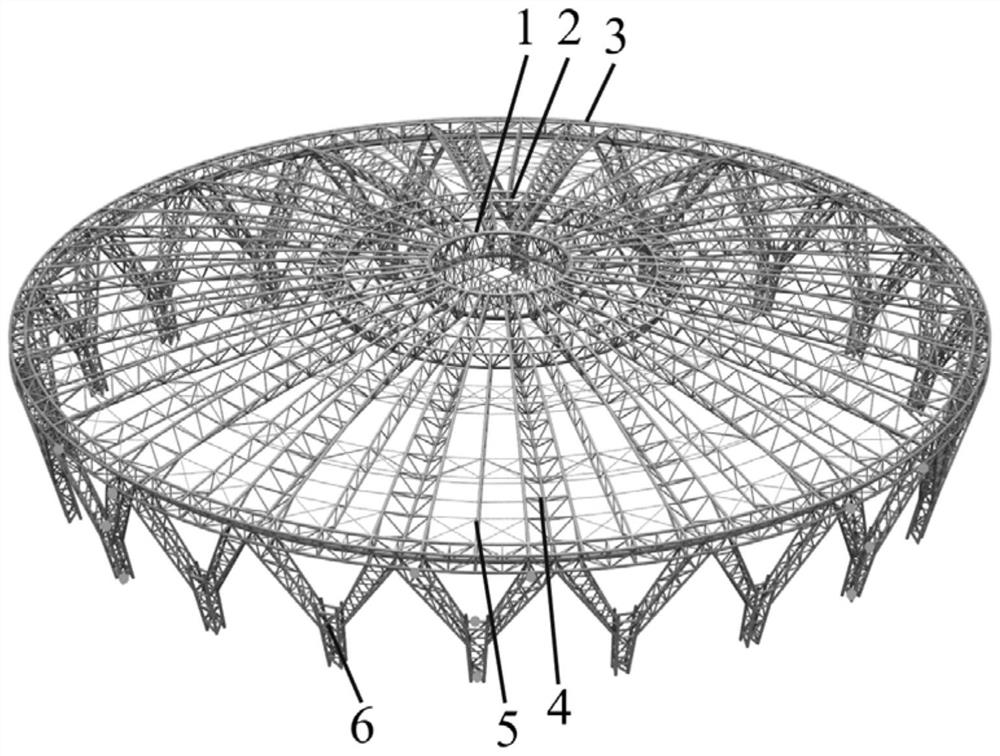

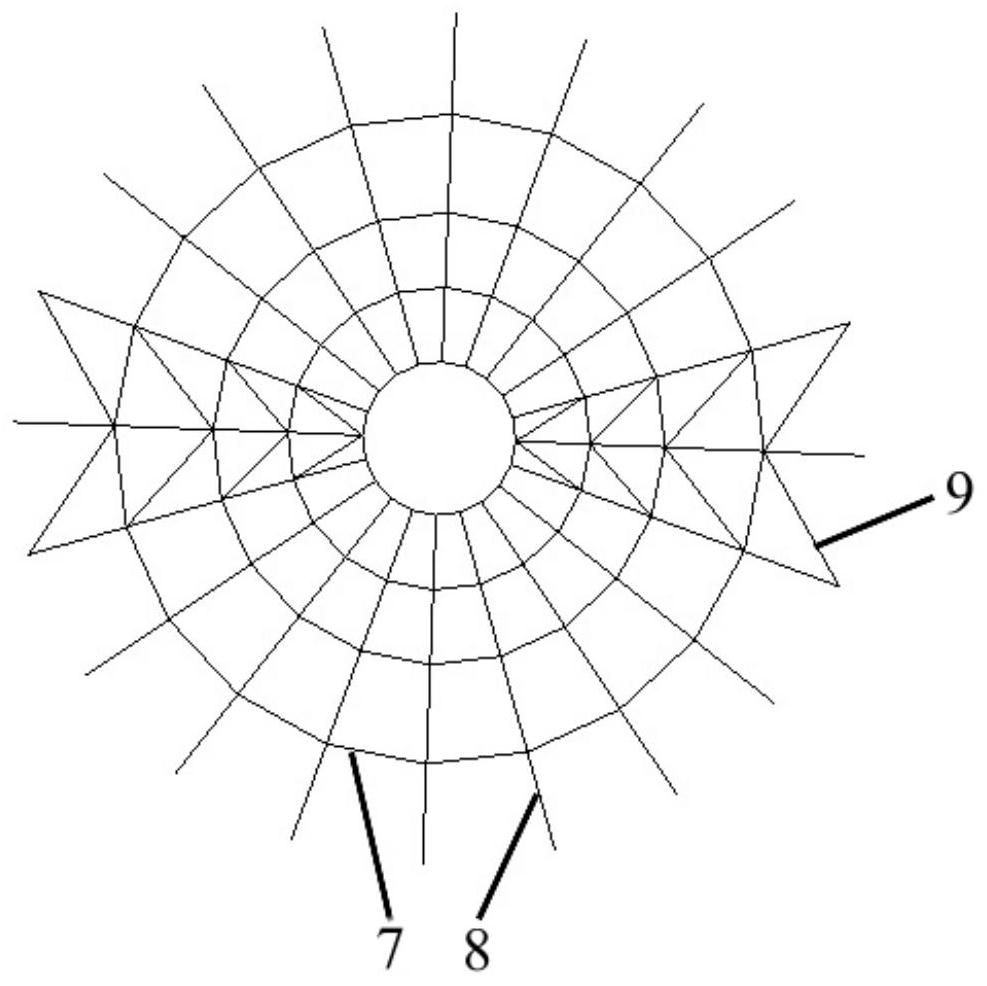

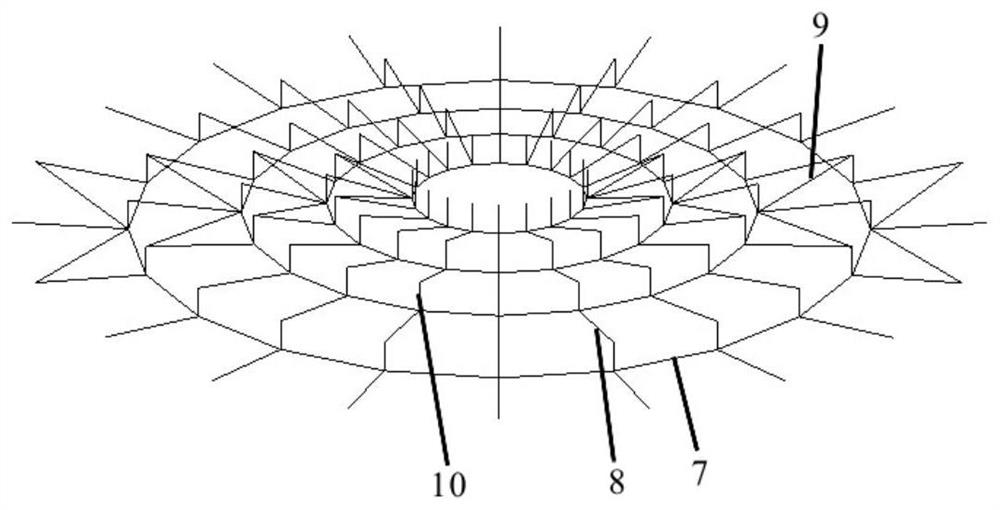

Large-span space suspended spoke type truss structure system and construction method

ActiveCN112482577AImprove stabilityImprove carrying capacityBuilding roofsExtraordinary structuresSynchronous controlPre stress

The invention discloses a large-span space suspended spoke type truss structure system and a construction method, and relates to the technical field of civil engineering. The large-span space suspended spoke type truss structure system comprises a dome part, wherein the dome part comprises an upper structure and a lower structure; the lower structure is arranged below the upper structure; the upper structure comprises a central ring truss, a middle ring truss, an outer ring truss, an inverted triangular truss and a secondary truss; and the lower structure comprises an annular cable, a radial cable, a stabilizing cable and a supporting rod. The stability and the bearing capacity of the structure are enhanced, so that the span of the structure is increased, and the advantages of convenient construction, high structural bearing capacity, good stability and the like can be realized. A hydraulic synchronous sliding technology is adopted in construction, a counter-force frame can be abandoned, the reinforcing problem of a counter-force point is solved, time and labor are saved, rigid connection and synchronous control with a moved component are easy to achieve, and the in-place precisionis high. A lower part is composed of the annular cable and the radial cable, a prestressed cable is tensioned by adopting a two-stage cyclic tensioning method, the annular cable is a passive tensioning cable, and the radial cable is an active tensioning cable.

Owner:陕西建工集团股份有限公司 +2

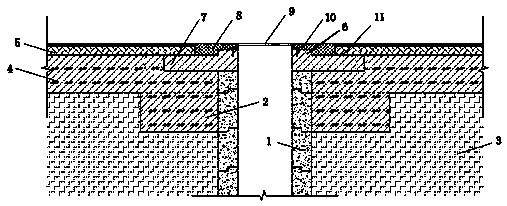

Novel municipal inspection well structure and construction method

PendingCN109972659AEnhance peripheral strengthImprove bearing capacityArtificial islandsTemporary pavingsFiberRoad surface

The invention belongs to the technical field of municipal engineering, and specifically relates to a novel municipal inspection well structure and a construction method. The novel municipal inspectionwell structure composed of a prefabricated pitshaft, a manhole cover, a base course reinforcement layer, a force holding well ring, color steel fiber concrete and the like, wherein the base course reinforcement layer is located on the periphery of the prefabricated pitshaft and at the bottom of a road base course at the same time; and the force holding well ring is inlaid in the road base course,the manhole cover is fixed to the force holding well ring, and the color steel fiber concrete is arranged on the periphery of the manhole cover with the same color as the road surface. According to the novel municipal inspection well structure and the construction method, intensity on the periphery of an inspection well is improved, the construction efficiency, quality and durability of the inspection well are improved, the accuracy of the mounting height of the well ring is realized, and unification of the color on the periphery of the manhole cover and the color of a road surface structureis realized.

Owner:JINAN URBAN CONSTR GRP

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

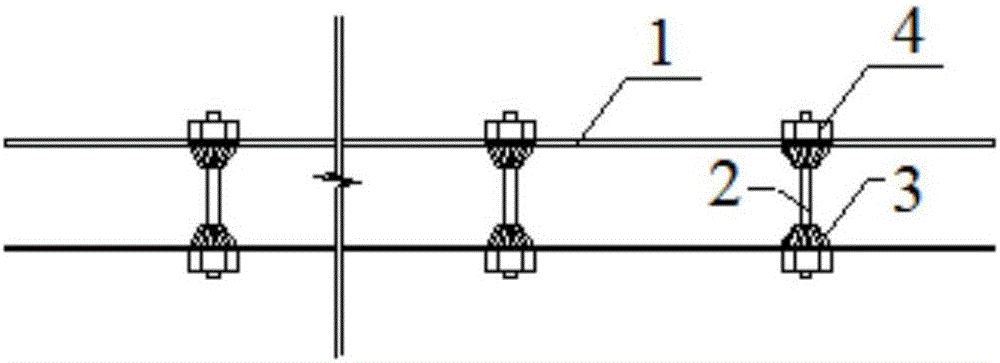

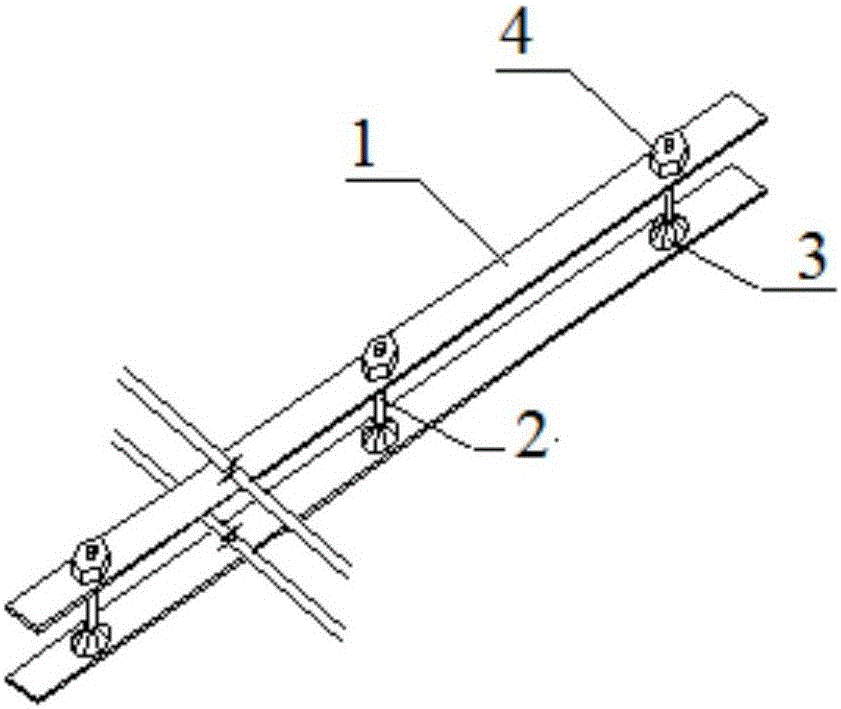

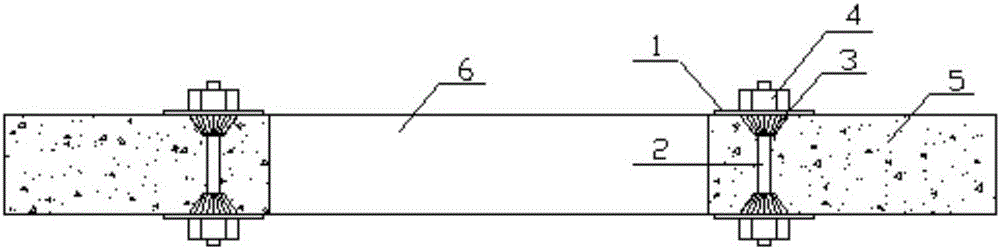

Steel structure spatial system for reinforcement and construction method thereof

InactiveCN105863289AGood anchoring effectIncreased bearing capacity and stiffnessBuilding repairsSpatial systemSteel plates

The invention discloses a steel structure spatial system for reinforcement and a construction method thereof. The steel structure spatial system for reinforcement and the construction method thereof are mainly applied to building structure reinforcement and reconstruction in the technical field of building science. The steel structure spatial system for reinforcement structurally comprises steel plates; the steel plates comprise the floorslab top steel plates and the floorslab bottom steel plates; the floorslab top steel plates are located on the top surface of a concrete floorslab; the floorslab bottom steel plates are located on the bottom surface of the concrete floorslab; the floorslab top steel plates and the floorslab bottom steels plates are aligned in the longitudinal direction; the floorslab top steel plates and the floorslab bottom steels plates are fixedly arranged at the edges of an open hole position in the concrete floorslab so as to achieve reinforcement of the concrete floorslab; and rigid connecting devices for connecting the floorslab top steel plates with the floorslab bottom steels plates are disposed between the floorslab top steel plates and the floorslab bottom steels plates. According to the steel structure spatial system for reinforcement and the construction method thereof, the steel structure spatial system is combined with the concrete floorslab, thus the anchoring effect is good, and the bearing capacity and rigidity can be improved to the great degree; construction and mounting are convenient, and anchoring of the steel plates is achieved; and using space is not occupied, the steel consumption is small, and the cost is low.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES +2

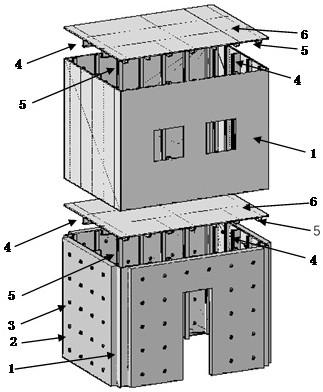

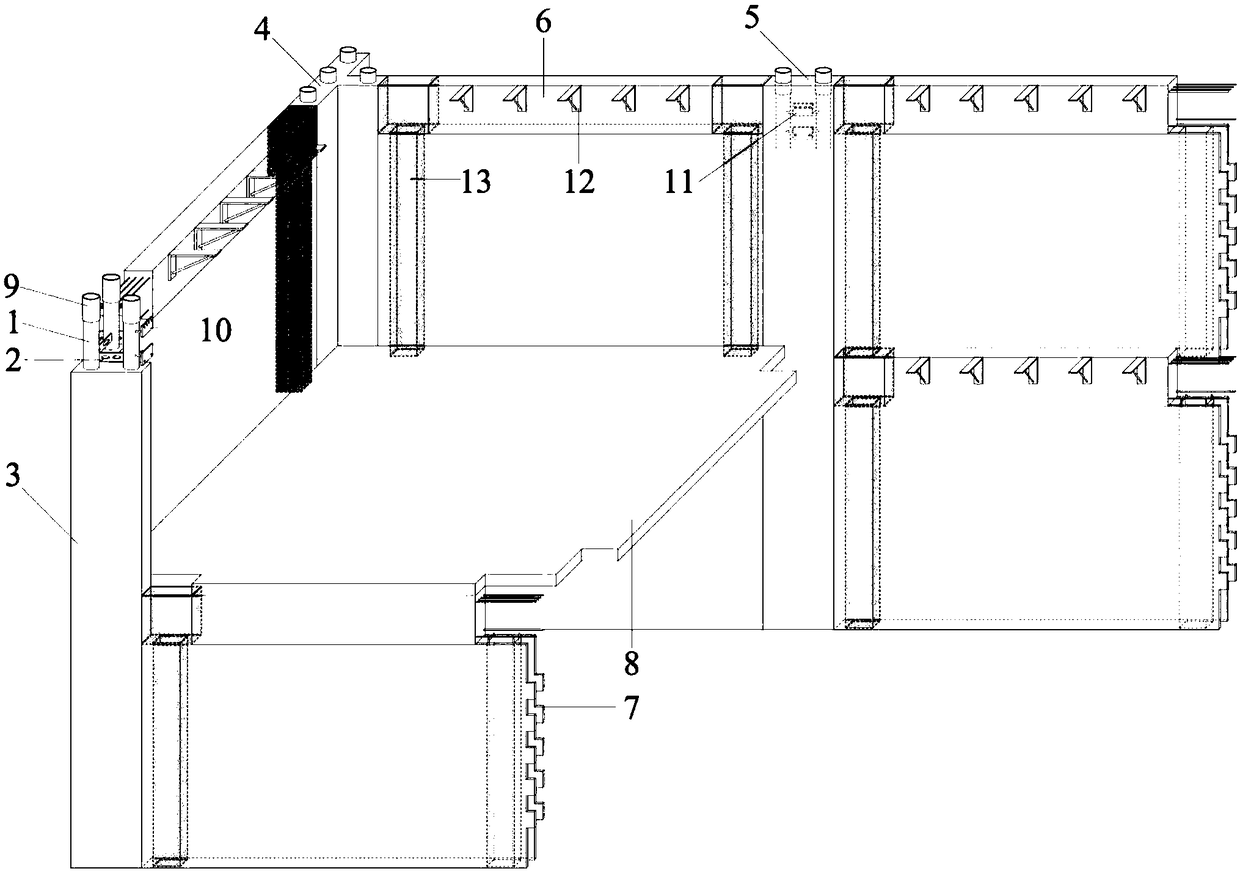

Assembled frame system with concrete filled steel tube branch limb combined special-shaped column and shock absorption wall

ActiveCN109372186AImprove seismic performanceFlexible layoutStrutsWallsEarthquake resistanceReinforced concrete

The invention discloses an assembled frame system with a concrete filled steel tube branch limb combined special-shaped column and a shock absorption wall and belongs to the field of building structure techniques and earthquake resistance and shock absorption of structures. The system primarily comprises a round concrete filled steel tube long column welded steel batten plate, and a prefabricatedcorner column, a prefabricated side column, a prefabricated middle column, a reinforced concrete beam, a steel plate wall, a prefabricated steel floorslab, a column-column connecting sleeve, a column-beam anchoring part, a middle column-beam anchoring part, a beam-plate connecting part, ECC post-cast strips and the like prepared by pouring concrete outside. Upper and lower concrete filled steel tubes are connected through the column-column connecting sleeve, and the column-beam anchoring part, the middle column-beam anchoring part and the round concrete filled steel tube long column are connected and prefabricated through dowels, so that the beam-column node connecting performance is enhanced. The ECC post-cast strips are arranged at two ends of the beam and the wall and are poured up anddown in a penetrating manner, so that the energy consumption ability and the anti-earthquake performance of the structural system are improved. The assembled frame system achieves the functions of hiding column edges and being attractive in building, a project is simple and rapid to construct, the construction efficiency is high, the nodes are connected stably and reliably, and the structural system is good in anti-earthquake performance.

Owner:BEIJING UNIV OF TECH

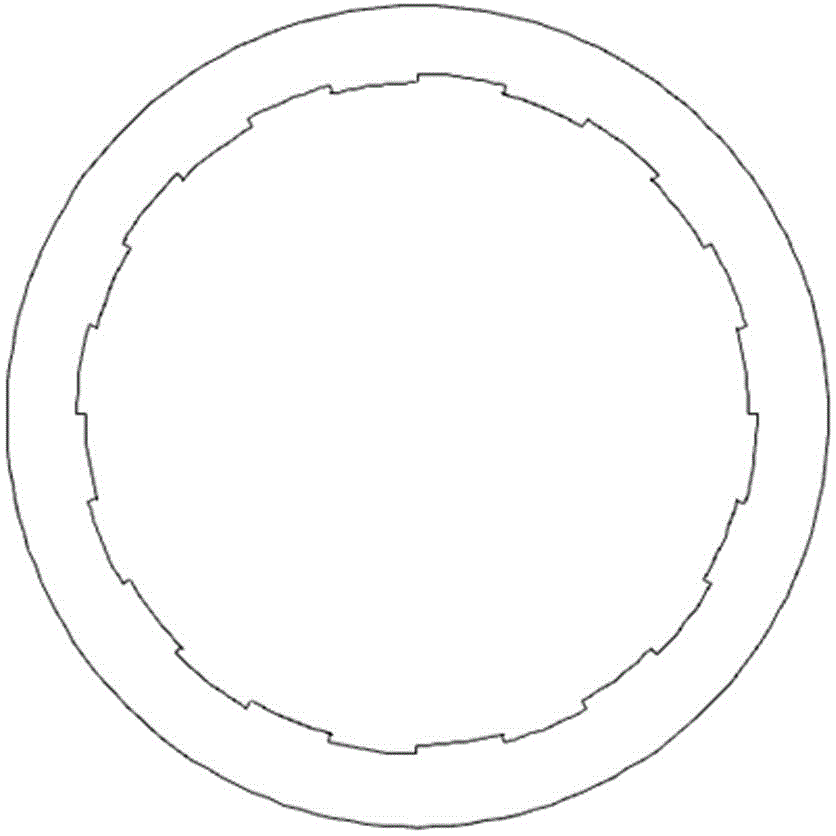

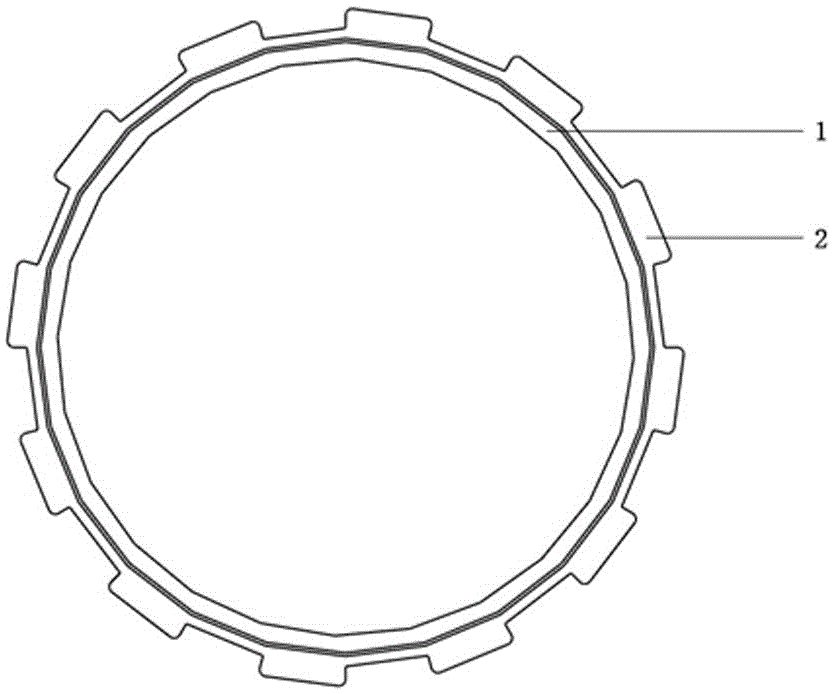

Tenon connection structure design method for turbine rotor of long-service-life small turbofan engine

The invention relates to a tenon connection structure design method for a turbine rotor of a long-service-life small turbofan engine, and relates to the technical field of turbofan engines. Accordingto the tenon connection structure design method for a turbine rotor of a long-service-life small turbofan engine, in order to reduce the average load of tenon teeth, a four-pair-tooth structure is adopted, the area of a tenon and mortise working face bearing face is increased, the bottom of a mortise is changed into large fillet transition, mortise stress concentration is reduced, the stress levelof a key position is effectively reduced, and the bearing capacity of the tenon and mortise is effectively improved. And through the optimal design of the characteristic size of the tenon connectionstructure, the stress concentration of the key positions of the tenon and mortise strength is reduced, the stress level of the key positions is further reduced, and the bearing capacity of the structure is improved.

Owner:BEIJING POWER MACHINERY INST

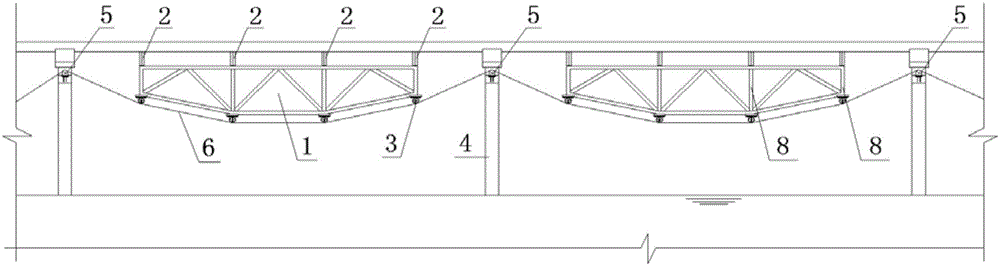

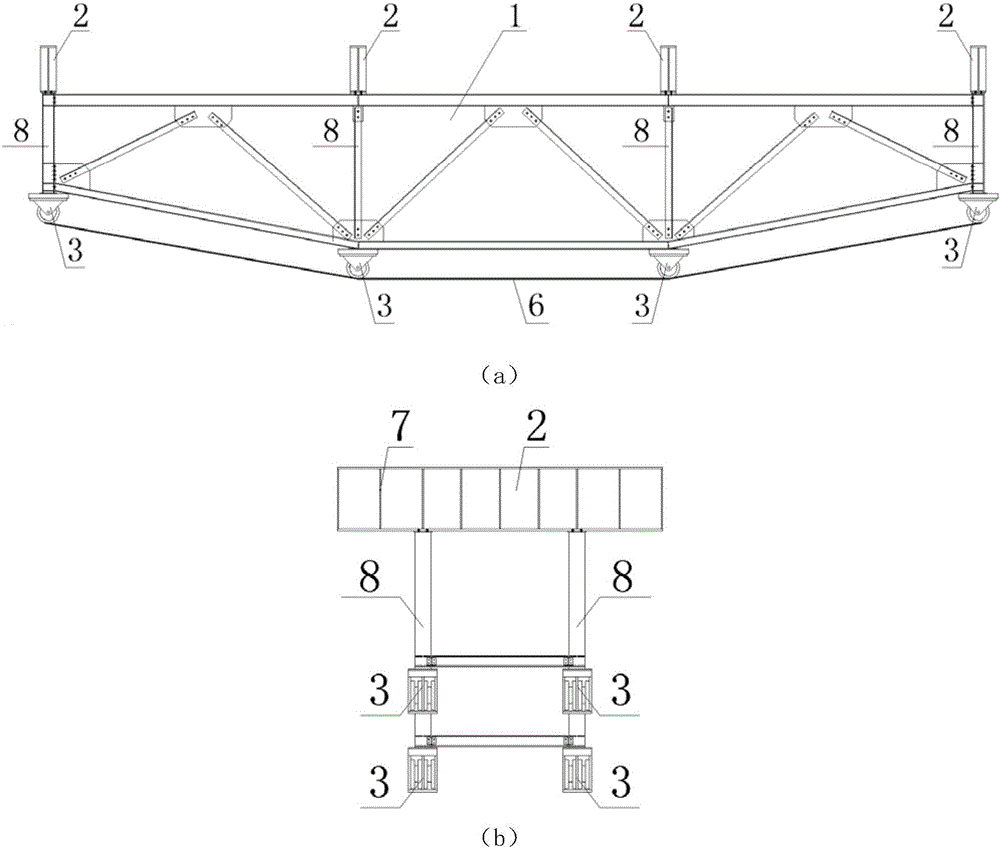

Variable-height cable-truss bridge reinforcing structure system

ActiveCN106567344ASignificant liftUniform jacking forceBridge erection/assemblyBridge strengtheningNet forcePre stress

The invention discloses a variable-height cable-truss bridge reinforcing structure system. The system comprises five parts including a prestress wire, a truss, a distributing beam, steering sliding wheels and a force transmission sliding wheel; the steering sliding wheels are fixed to the upper portion of a bridge pier, the inversed force transmission sliding wheel is fixed to the bottom of the truss, and the distributing beam is placed on the top; and the prestress wire sequentially penetrates the steering sliding wheels and the force transmission sliding wheel for connecting the fixed end and the stretching end on the two sides of an overall bridge, and therefore the distributing beam abuts against the lower surface of a top bridge plate. the prestress wire form upward resultant force at the bottom of the truss, and the resultant force is transmitted by the truss to the bridge face plate to form jacking force. The lengths of vertical web members of the truss are in bilateral symmetry, the vertical web members on the outmost sides are shortest, and the best reinforcing effect is achieved. By means of the above manner, the dead load of the bridge plate can be partially offset, the bearing capacity and the rigidity of the structure are effectively improved, and the aim of reinforcing the bridge is achieved.

Owner:ZHEJIANG UNIV

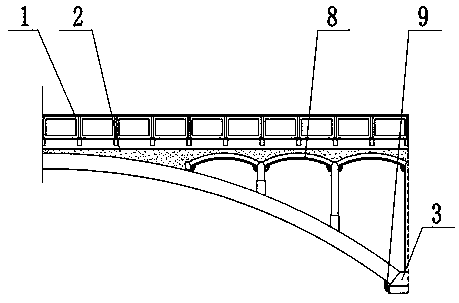

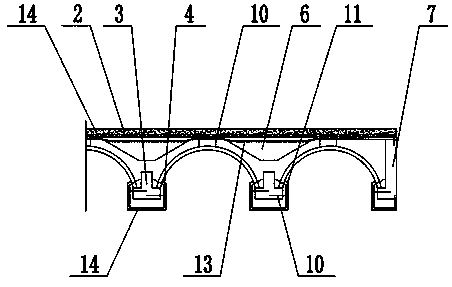

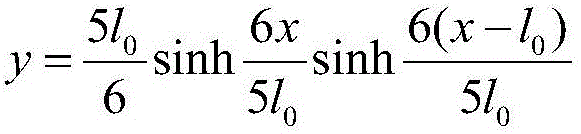

Weight-reducing load-increasing durability-prolonging two-way curved arch bridge reinforcing and maintaining method

InactiveCN108708300AExtended service lifeReduce rust rateBridge erection/assemblyBridge strengtheningReinforced concreteBridge deck

The invention relates to the field of bridge reinforcing and maintaining methods, in particular to a weight-reducing load-increasing durability-prolonging two-way curved arch bridge reinforcing and maintaining method. The method comprises the following steps that traffic on a bridge pavement is closed; arch padding materials are dismantled; concrete pouring is carried out on the upper end faces oftwo way curved arch tiles to increase cross sectional area of the two way curved arch tiles; reinforced concrete pouring is carried out on a main arch rib and a cross beam to increase cross sectionalareas of the main arch rib and the cross beam; and weight-reducing padding materials are arranged, in a filling mode, in the positions where arch padding materials are arranged of the two way curvedarch tiles and spandrel arch tiles, bridge deck structure pouring is carried out on the weight-reducing padding materials to complete arch bridge reinforcing and maintaining. The weight-reducing load-increasing durability-prolonging two-way curved arch bridge reinforcing and maintaining method has the advantaged of reducing self-weight of the structure, improving loading capacity of the structure,improving integral rigidity and stability, prolonging the service life of the structure, and having good application prospect.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

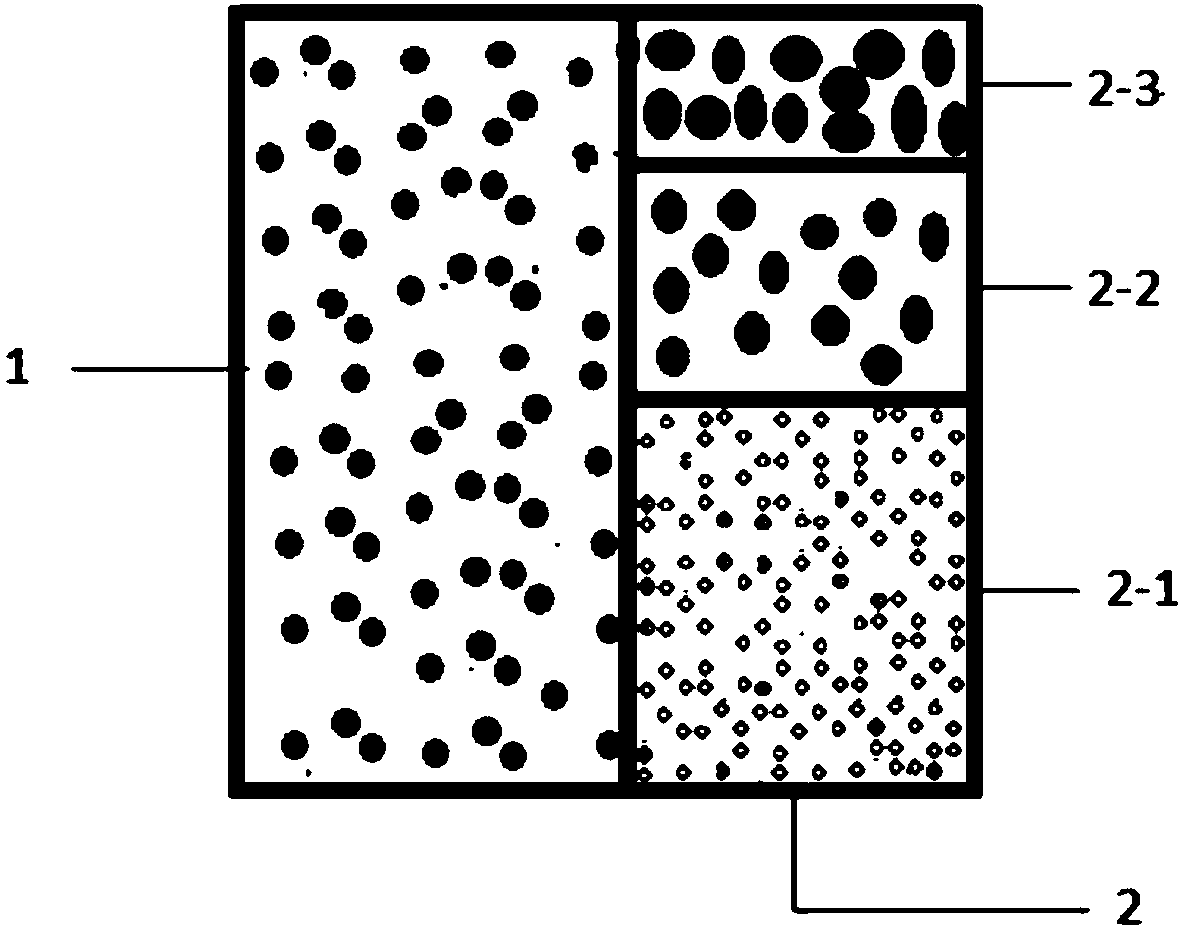

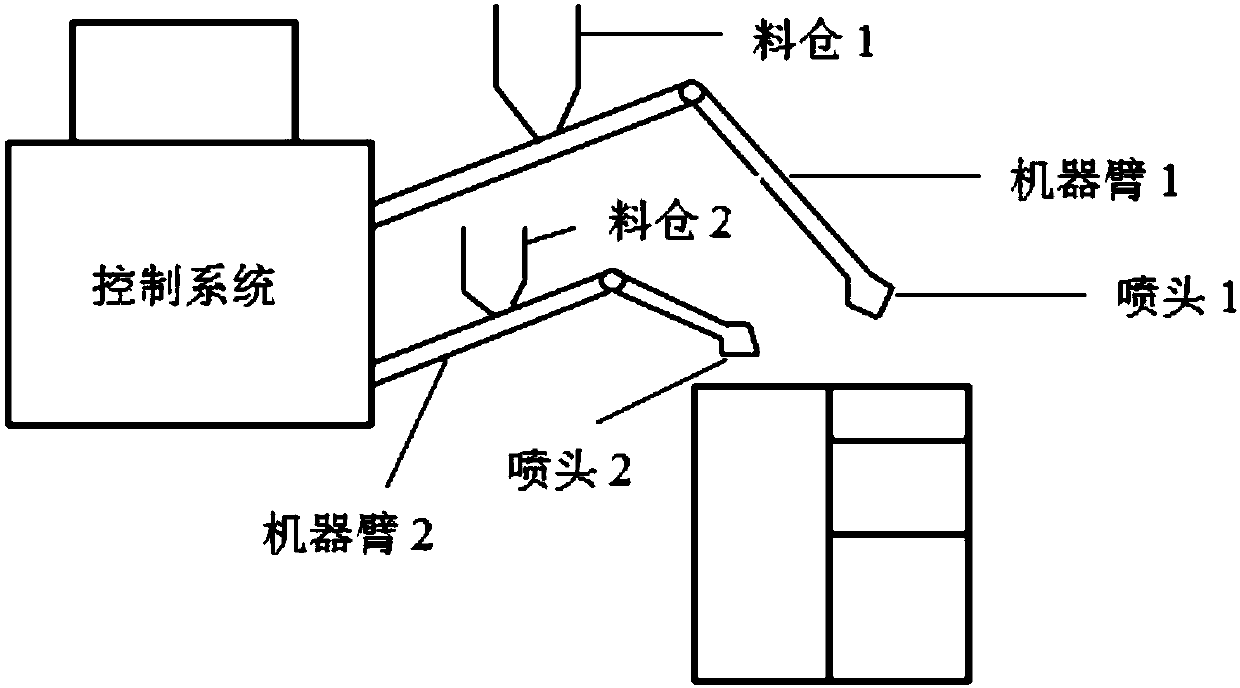

Functional gradient and density gradient concrete material for 3D printing and preparation method thereof

ActiveCN107555895ALight weightImprove seismic performanceAdditive manufacturing apparatusThermal insulationExpanded clay aggregate

The invention discloses a functional gradient and density gradient concrete material for 3D printing and a preparation method thereof. The material consists of a density gradient layer and a thermal insulation layer, and is prepared from lightweight ceramsite aggregate, a thermal insulation material, cement, industrial waste residue, fine aggregate, a defoamer, a superplasticizer and water. According to the concrete material prepared with the method, the comfort of 3D printed concrete is greatly improved, self-weight is reduced and the interaction of the concrete material with external environments is enhanced.

Owner:NANJING UNIV OF SCI & TECH +2

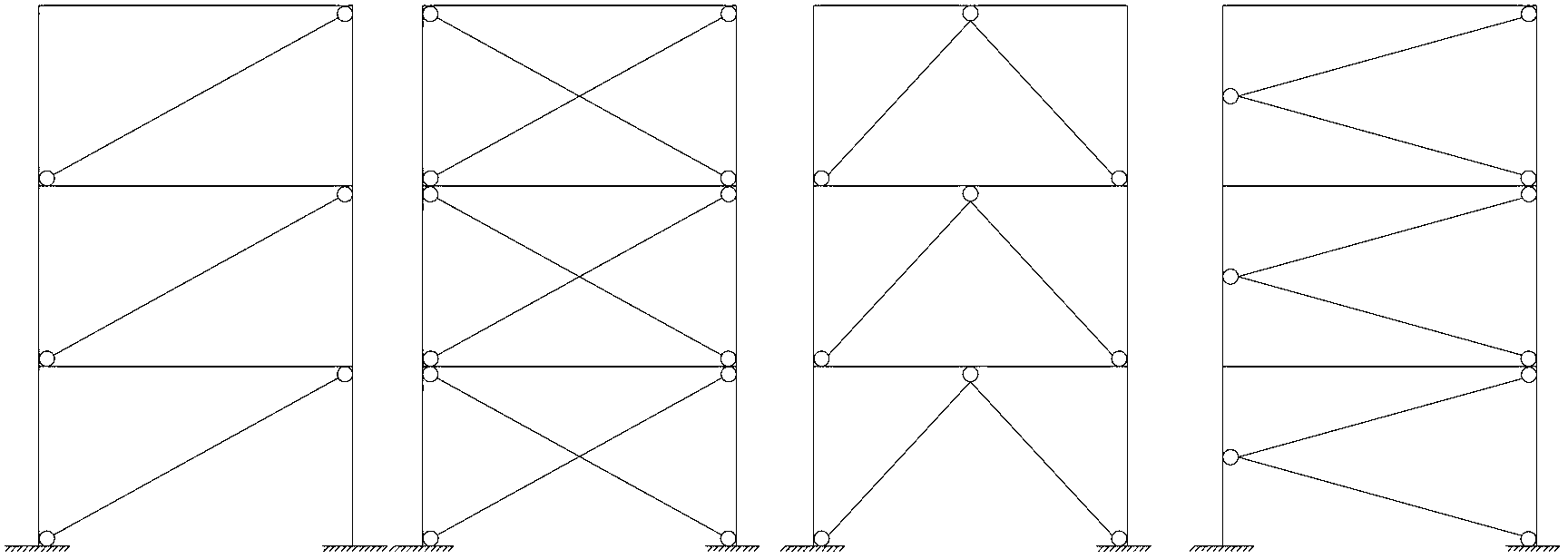

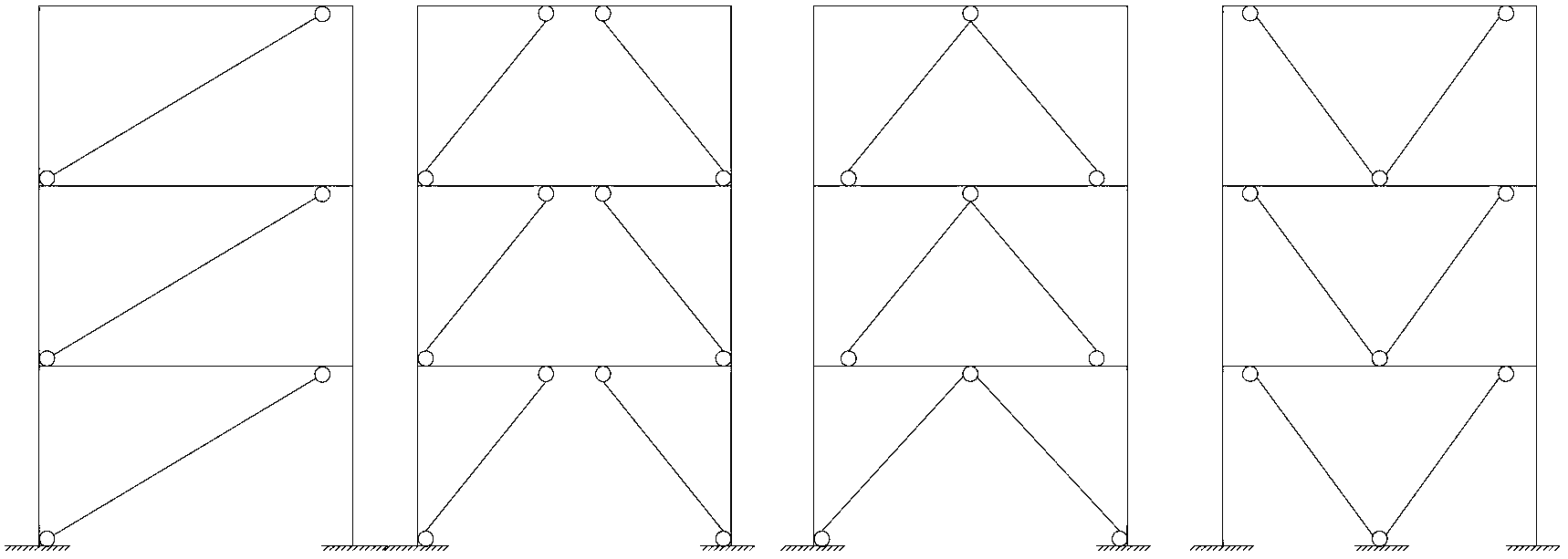

Shear wall-support structure system

InactiveCN102767251AImprove earthquake resistance and energy dissipation capacityImprove the level of earthquake resistanceWallsShock proofingFiberSupporting system

The invention relates to a shear wall-support structure system. Support systems are arranged among shear wall limbs to form the shear wall-support structure system. The support systems can utilize steel rod pieces, concrete-filled steel tube rod pieces and fiber reinforce plastic (FRP) confined concrete rod pieces, and damping members or damping devices can be arranged in the support systems. According to the structure system, anti-seismic and energy dissipation capabilities of concrete shear wall structures can be improved, material performances are played fully, the brittle failure of the structure can be prevented, and the shear wall-support structure system has the advantages of being convenient to construct and easy for restoration after shaking.

Owner:CHANGCHUN INST OF TECH

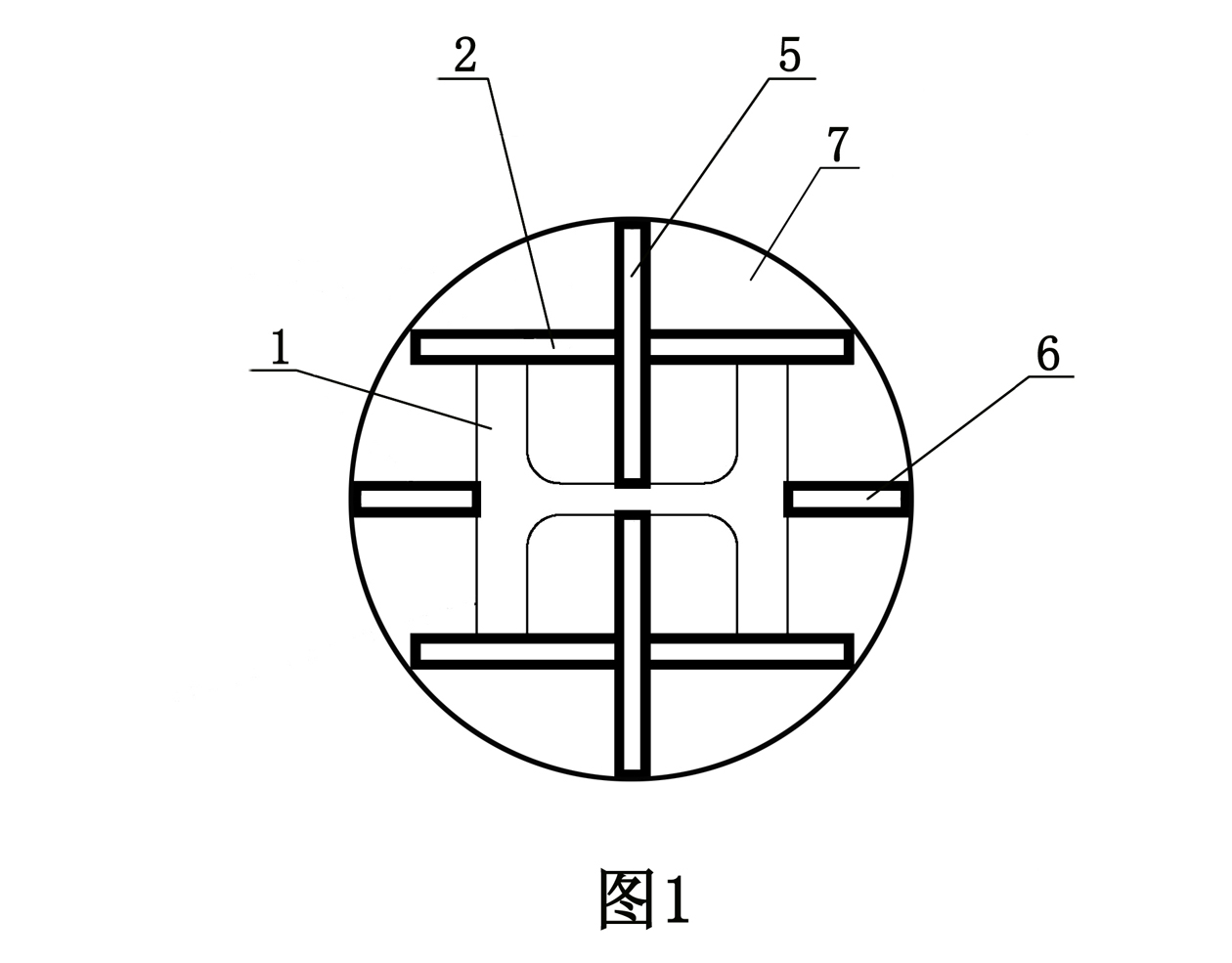

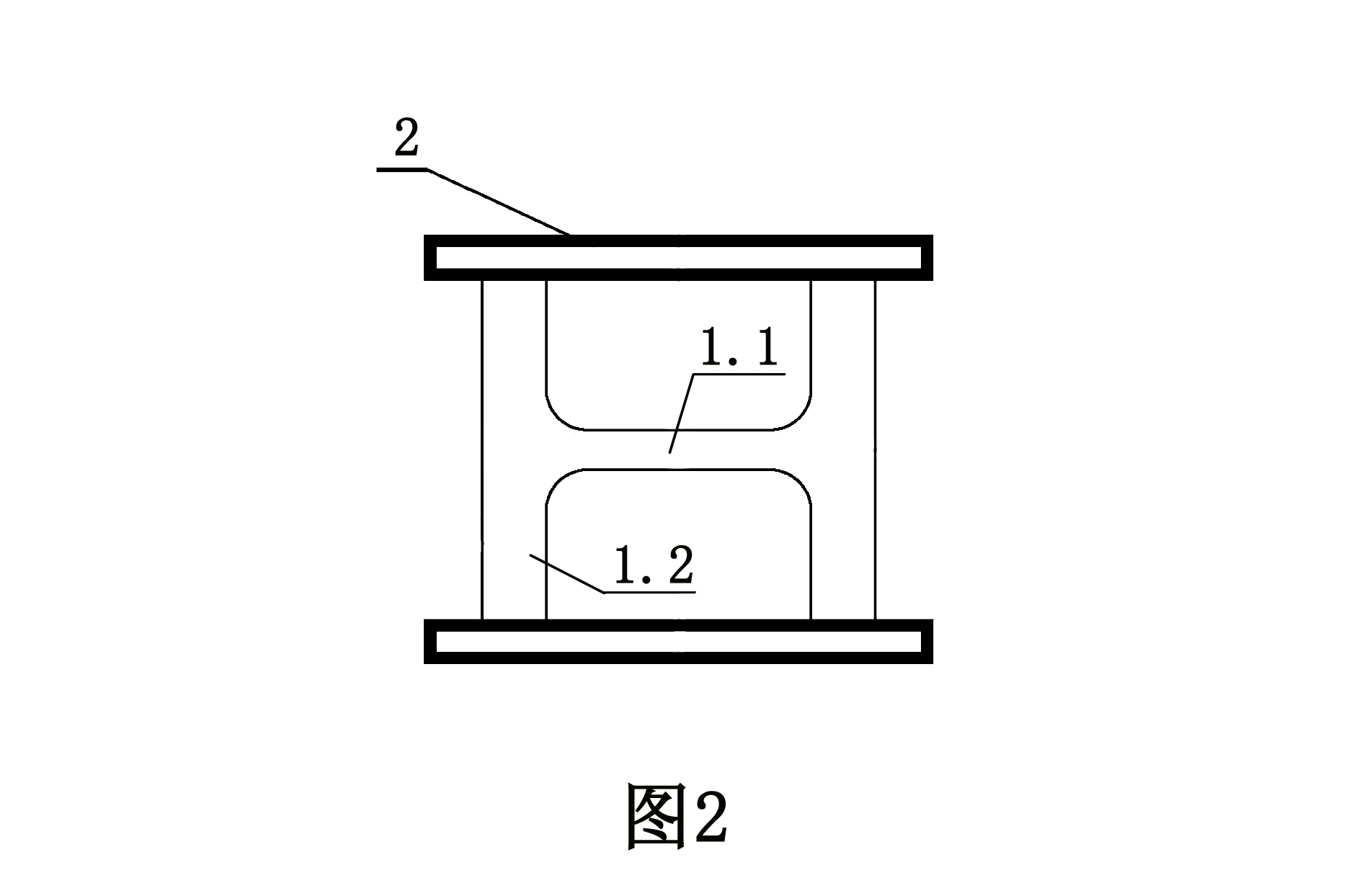

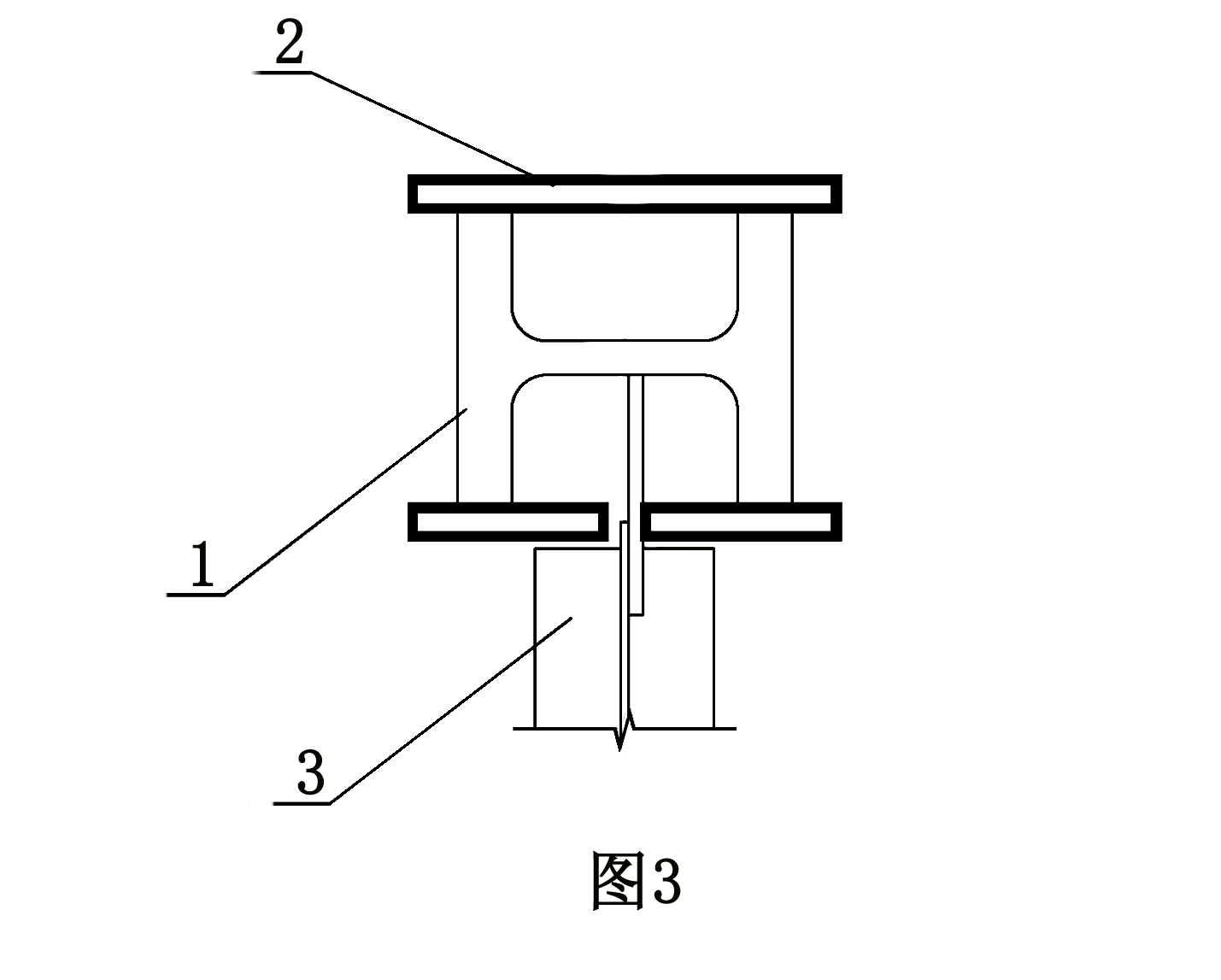

Steel truss support capable of windowing and steel truss barrel structure including same

ActiveCN103233510AImprove lateral force resistanceEliminates shear lag effectsBuilding constructionsEconomic benefitsEngineering

The invention belongs to a steel truss support capable of windowing and a steel truss barrel structure including the same. A node plate (7) is connected with a framed beam (5) and a frame column (6), two ends of a long inclined support (2) are respectively connected with a support rod (8), and the support rod (8) is connected with an end plate (9) and is respectively connected with the framed beam (5) and the frame column (6). A horizontal support (3) is connected with a vertical support (4), the connecting position between the horizontal support (3) and the vertical support (4) is connected with the long inclined support (2), and a short inclined support (1) is respectively connected with the node plate (7) and the long inclined support (2). Connectors of the short inclined support (1), the long inclined support (2), the horizontal support (3), the vertical support (4), the support rod (8) and the end plate (9) are prefabricated by a factory. The steel truss support improves the bearing capacity of the structure by increasing width and thickness of supporting flanges, a window can be arranged at a position where the support is arranged, and the economic benefit and the applicability are improved while steeling using amount is saved.

Owner:江苏瑞成建筑科技有限公司

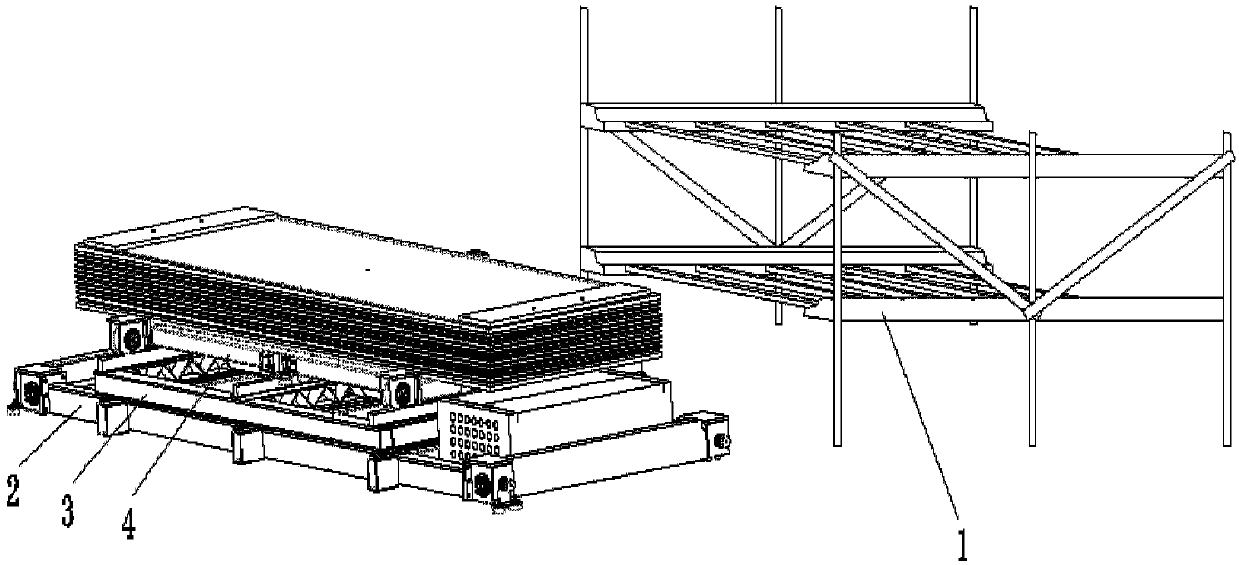

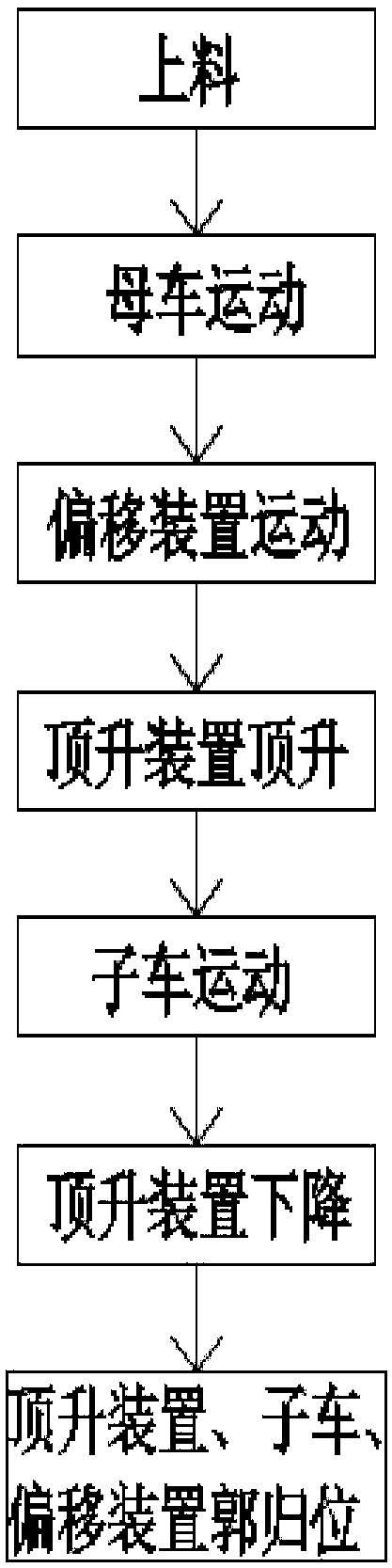

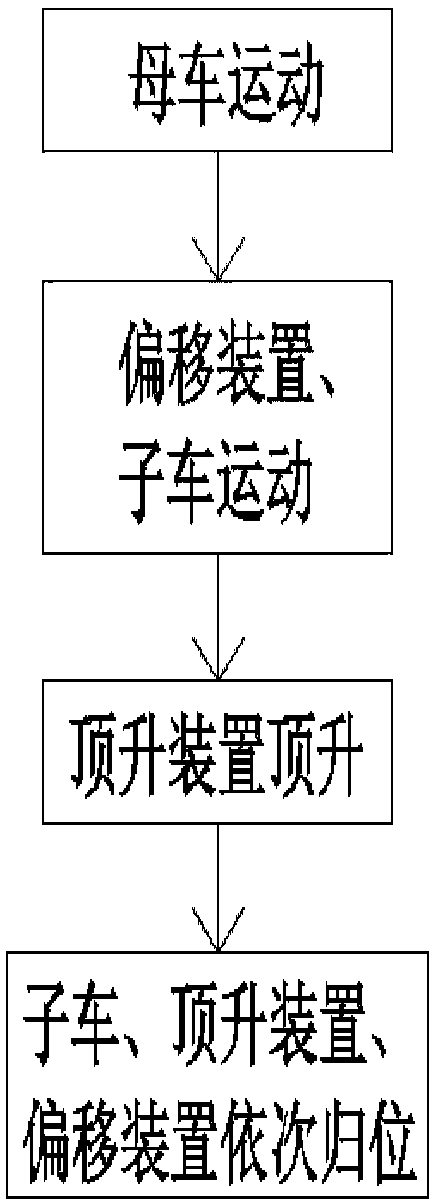

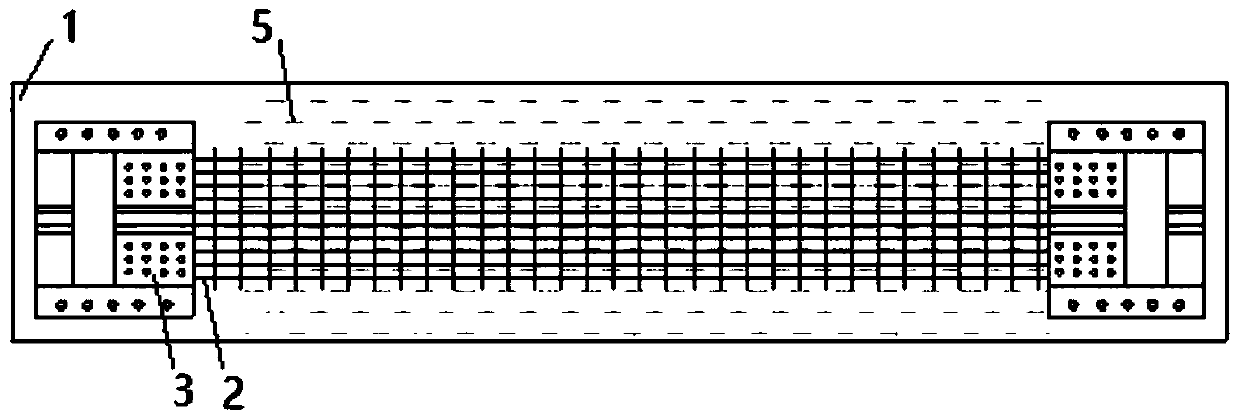

Goods storing and taking method

The invention provides a goods storing method. A child-mother car is adopted and comprises a mother car, a shifting device, a child car and a jacking device sequentially from bottom to top. The goodsstoring method includes the following steps that firstly, goods are placed on the jacking device, and the mother car runs to a designated position; the shifting device is butted to a rail; then, the jacking device is jacked up, and the child car moves along the butted rail; and finally, a hydraulic platform descends, one time of goods storing is completed, and each device returns to seat sequentially. The invention further provides a goods taking method. Firstly, the mother car runs to the designated position; the shifting device is butted to the rail, the child car moves along the butted rail, then, the jacking device jacks goods up, and finally, the child car, the shifting device and the jacking device return to seat sequentially. The shifting mechanism and the child car system can achieve high precision of goods taking and storing. Compared with a conventional goods taking and storing method such as forking, the system structure is small in displacement and operates more stably whena goods taking system takes the goods.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

Rapid prestress FRP grid reinforcing method

The invention discloses a rapid prestress FRP grid reinforcing method. The rapid prestress FRP grid reinforcing method comprises the following steps that (1) the surface of a to-be-reinforced concretestructure is cleaned; (2) prestress anchorage devices are mounted on the surface of the structure; (3) the surface of the structure is coated with a layer of interface agent; (4) the two ends of an FRP grid are fastened in the prestress anchorage devices correspondingly, and then the prestress anchorage devices are tensioned; (5) the middle of the FRP grid is sealed and coated with polymer mortar, and the two ends of the FRP grid are sealed and coated with geopolymer mortar; and (6) after the geopolymer mortar at the two ends reaches the design strength, the prestress anchorage devices are dismounted, and the middle polymer mortar continues to be cured till the middle polymer mortar reaches the design strength. The reinforcing method is simple in process and low in cost, reinforcing can be completed within a short time, the stress performance of the damaged part of the concrete structure is effectively improved, and the bearing capacity and durability of the structure are improved.

Owner:江苏绿材谷新材料科技发展有限公司

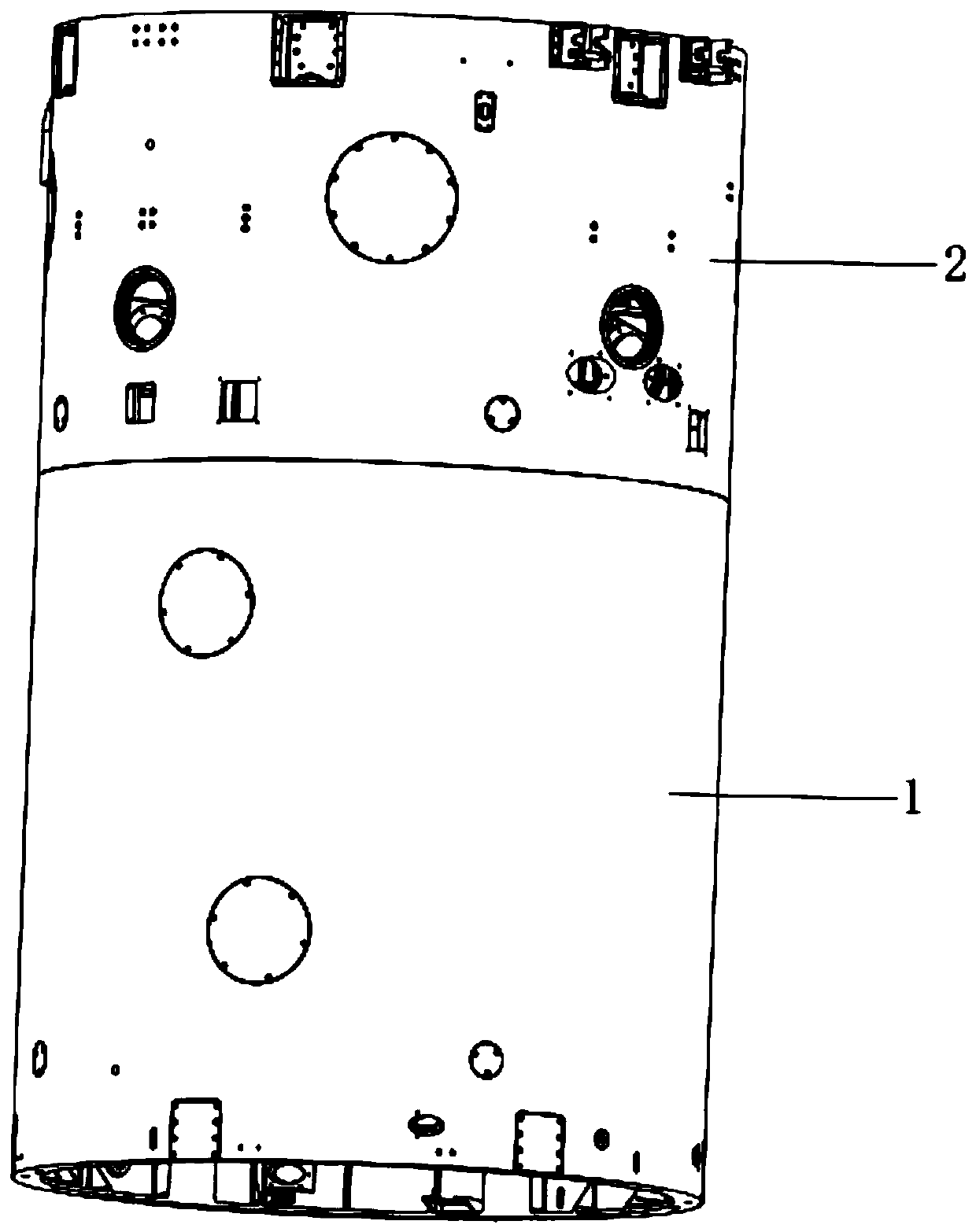

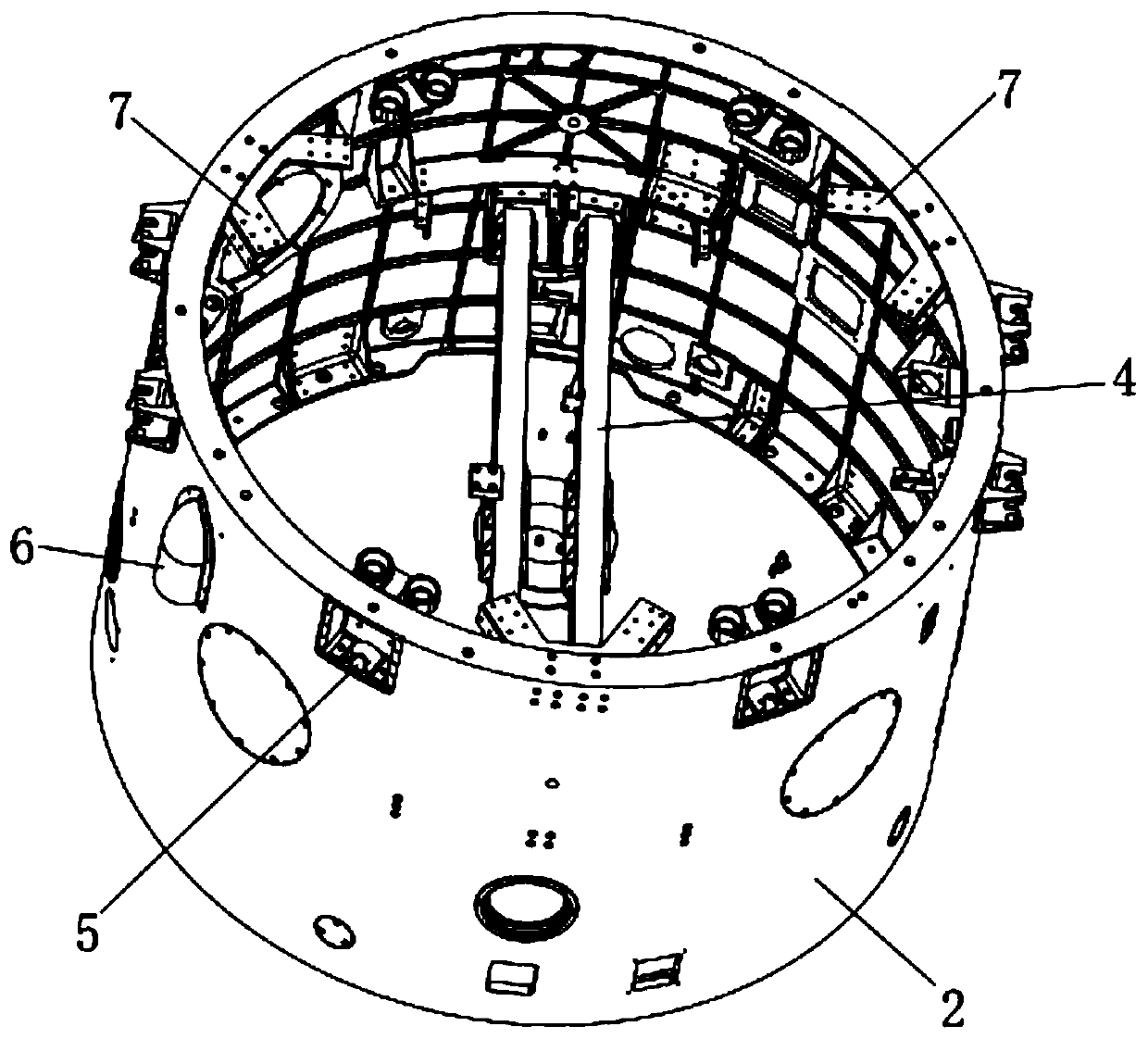

Carrier rocket tail sub-stage structure

PendingCN111023913AImprove delivery efficiencySimple structureSelf-propelled projectilesRocketMechanical engineering

The invention discloses a carrier rocket tail sub-stage structure, which comprises a power cabin, an instrument cabin and a stiffening beam structure, wherein the power cabin provides mounting space for a tail sub-stage power system; the instrument cabin is connected to the upper end of the power cabin, and a plurality of mounting interfaces for mounting instruments are formed in the inner wall ofthe instrument cabin; the stiffening beam structure comprises at least two stiffening beams which are arranged in parallel, and two ends of each stiffening beam are respectively connected with the inner wall of the instrument cabin; and the middle parts of the at least two stiffening beams are connected with a connecting disc for providing a connecting interface for the tail sub-stage power system. The stiffening beam structure of a double-beam parallel structure is adopted in the instrument cabin, the self weight of the stiffening beam structure can be reduced on the premise that the stability of a connecting disc installation structure is guaranteed, the power cabin and the instrument cabin are respectively made of an integrated structure, and the effect of reducing the self-weight of the whole carrier rocket tail sub-stage structure can also be achieved. Meanwhile, the inner wall of the instrument cabin can provide mounting interfaces for a large quantity of equipment, and the carrying efficiency of the rocket is improved while the starting resistance during rocket launching is reduced.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

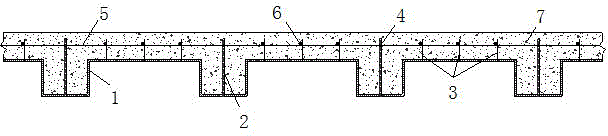

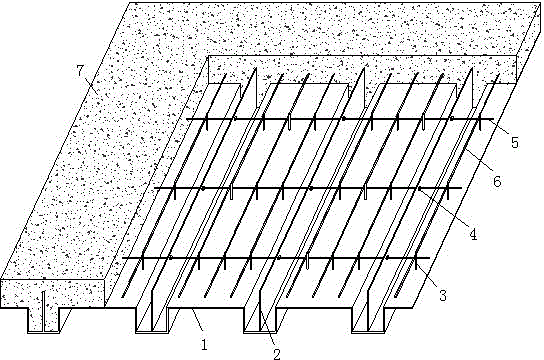

Box type prestress concrete light composite slab

InactiveCN103603455AHigh strengthImprove mechanical performanceFloorsEarthquake resistanceReinforced concrete

The invention discloses a box type prestress concrete light composite slab and belongs to the field of building components. The box type prestress concrete light composite slab is composed of an upper cast-in-place concrete slab and a lower reinforced concrete prefabricated slab. A reinforced concrete bottom layer of the lower reinforced concrete prefabricated slab is composed of a rebar framework and pouring concrete. The rebar framework is composed of prestress rebar and common rebar. Common transverse rebar is distributed on the lower layer. Longitudinal rebar is arranged on the two sides. Prestress steel is longitudinally arranged on the transverse common rebar. A soft filling core layer is composed of light filling core blocks which are transversally spaced and transverse concrete ribs and is arranged on the surface of the reinforced concrete bottom layer. A closed lower reinforced concrete prefabricated slab is formed by pouring concrete on the periphery and the top face of the light filling core. The box type prestress concrete light composite slab is formed after the upper cast-on-site concrete slab is poured on the surface of the lower reinforced concrete prefabricated slab. The box type prestress concrete light composite slab is reduced in self-weight, improves structural integrity and the overall earthquake resistance, and can meet the requirements of large-span buildings.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

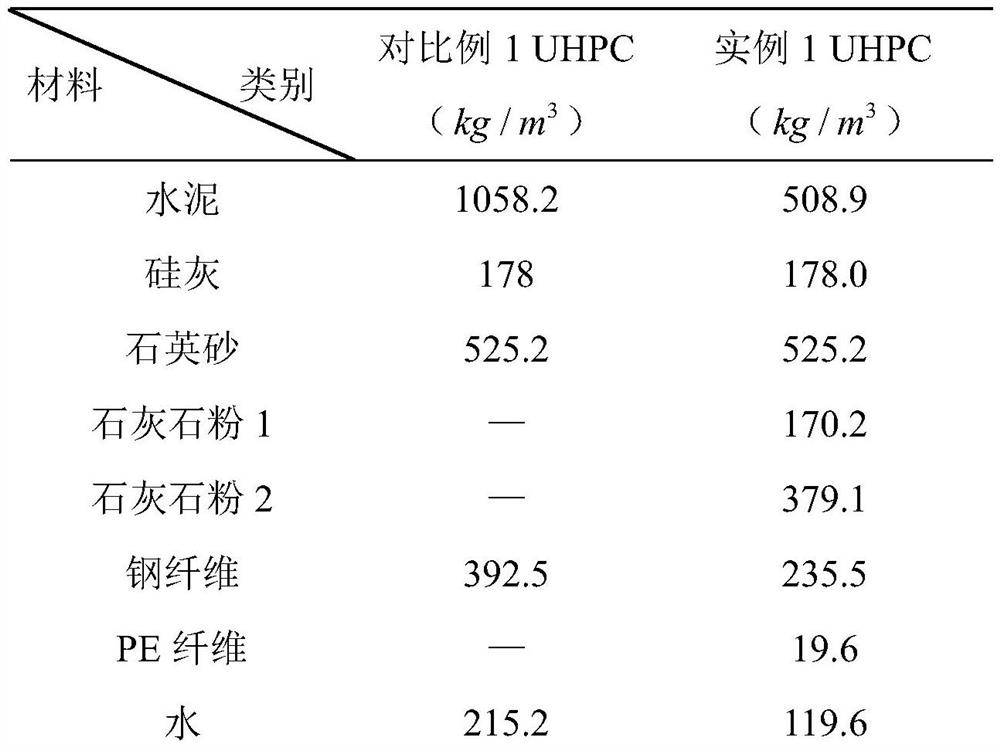

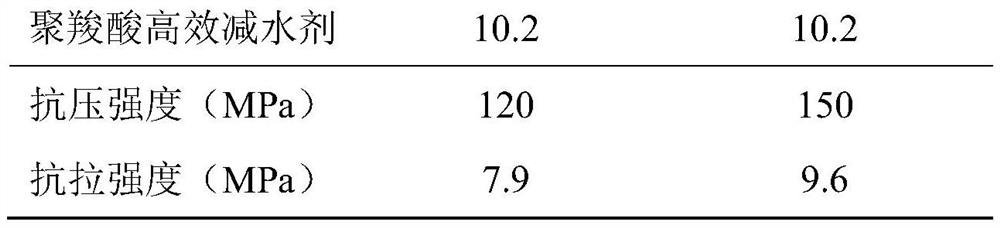

Energy-saving and environment-friendly structural ultra-high performance fiber reinforced concrete

The invention provides energy-saving and environment-friendly structural ultra-high performance fiber reinforced concrete, and belongs to the technical field of building materials. The concrete is prepared from cement, silica fume, a mineral admixture, quartz sand, hybrid fibers, water and a superplasticizer. The mass ratio of the components is as follows: 1 part of the cement, 0.2-0.4 part of the silica fume, 0.6-1.5 parts of the mineral admixture, 1-1.2 parts of the quartz sand and 0.17-0.25 part of the water; the mixing amount of the superplasticizer is 1.9-2.1%, the water-binder ratio is 0.14-0.20, and the total mixing amount of the volume of the hybrid fiber is 3-9%. According to the UHPFRC material, 40%-60% of cement in a traditional UHPFRC material is replaced with the mineral admixture, meanwhile, steel fibers are partially replaced with non-metal fibers, a multi-scale fiber hybrid system of the steel fibers and the non-metal fibers is formed, the bearing capacity of an engineering structure can be improved by effectively utilizing the characteristics of all the components, the use amount of the cement and the use amount of the steel fibers are reduced, the energy consumption and the emission of harmful gases in the environment are reduced, the purposes of energy conservation, emission reduction and environmental friendliness are achieved, and the application of the UHPFRC material in civil engineering structures is facilitated.

Owner:HUNAN UNIV OF TECH

Composite structural member capable of storing/releasing charge and preparing method and application thereof

ActiveCN105845445AReduce weightReduce volumeDouble layer capacitorsHybrid/EDL manufactureShaped beamNew energy

The invention provides a composite structural member capable of storing / releasing charge and a preparing method and application thereof. The composite structural member is stacked by structural member monomers of a laminated structure, and two sides of the structural member monomers are symmetrical outwards from the center, and successively comprise an electrolyte membrance, an aelectrolyte, a conductive electrode, a current collector, and an insulation and encapsulating layer from center to outside; by utilizing composite forming processes, composite structural members capable of circulating storage / releasing charge can be prepared, which are of different shapes and structures, such as a circular pipe, a C-shaped beam, an I-shaped beam, etc. The composite structural member has the functions of mechanics and energy storage, can effectively reduce the weight and size of a storage unit in a traditional electric system, and realize system comprehensive optimization, is safe and reliable, and has a bright application prospect in the fields such as new electrical vehicle, national defense, aerospace, new energy resources, etc.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com