Rapid prestress FRP grid reinforcing method

A prestressing and grid technology, applied in building maintenance, construction, building construction, etc., can solve the problems of low utilization rate of FRP grid strength, limit the popularization and application of FRP grid, and lagging reinforcement effect, so as to suppress structural cracks The effect of development, reducing the impact of production and life, and improving the structural bearing capacity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

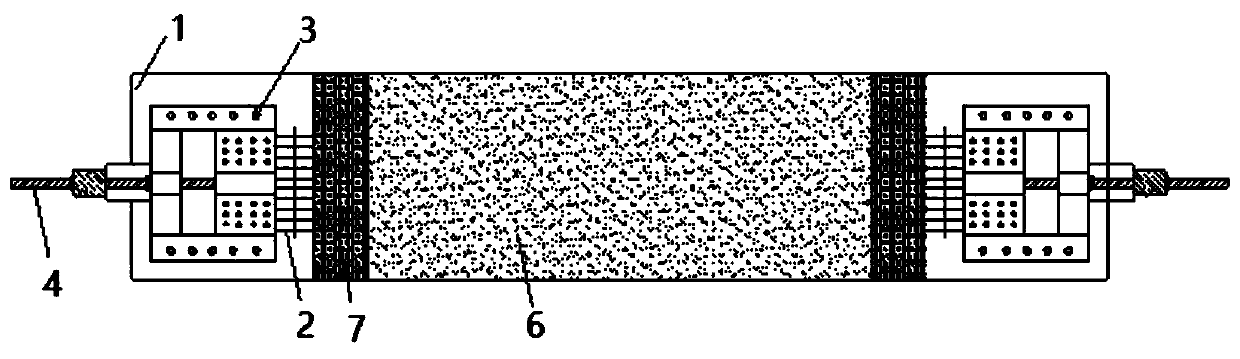

[0032] Embodiment: a kind of rapid prestressed FRP grid reinforcement method comprises the following steps:

[0033] (1) The concrete structure 1 to be reinforced is a reinforced concrete stress structure in the building, and the reinforcement surface should be flat; the surface of the concrete structure 1 to be reinforced should be cleaned, and the deteriorated layer (such as laitance, laitance, etc.) Weathered layer, etc.) are removed and polished with a grinder, and the misalignment and protruding parts are smoothed, and then the dust is removed with compressed air, and the reinforced surface is washed with a high-pressure water gun.

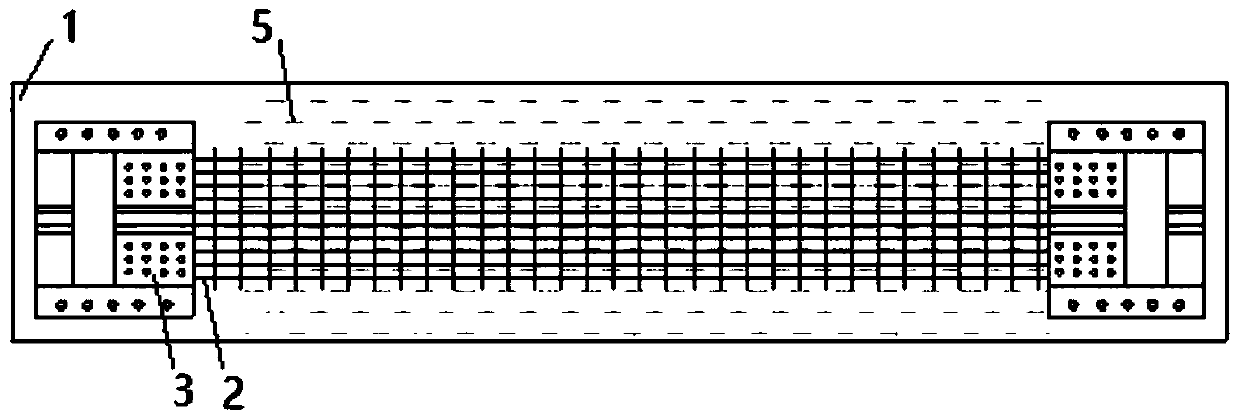

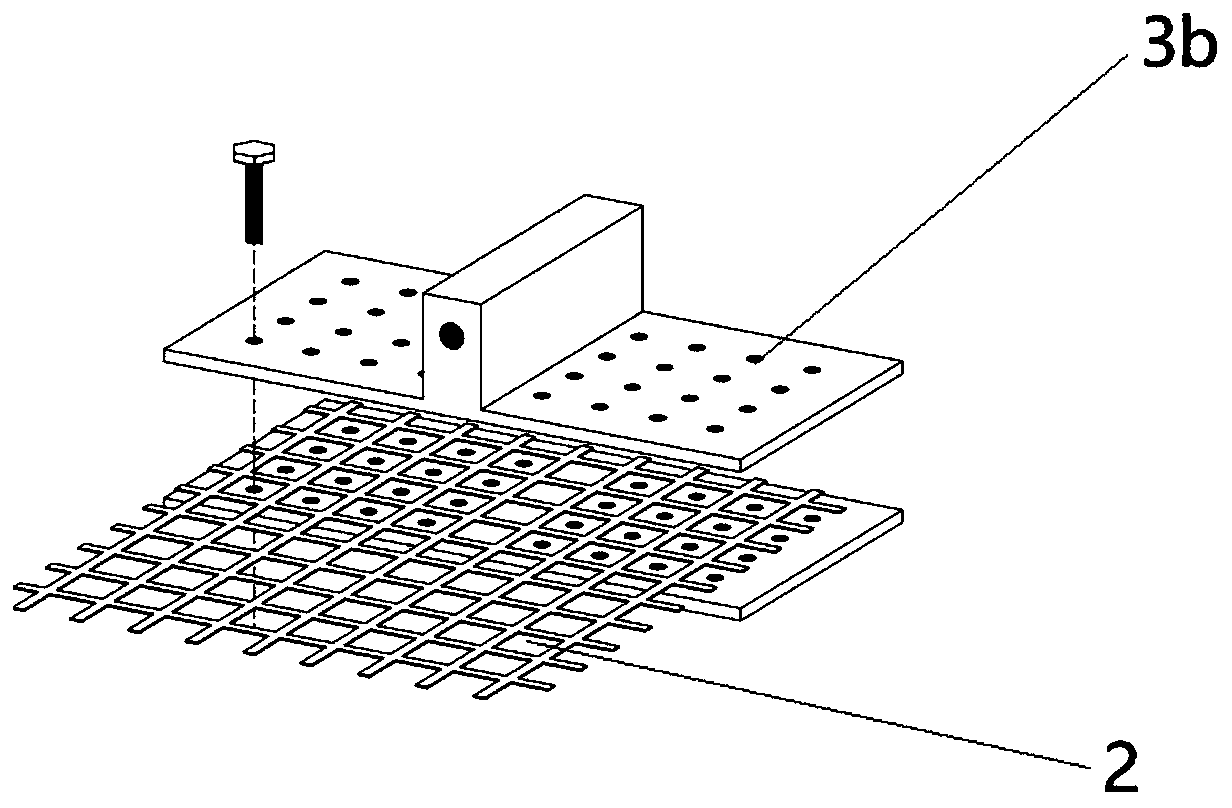

[0034] (2) On the surface of the concrete structure 1 to be reinforced, install the prestressed anchorage 3 for the tensioning of the FRP grid 2; The upper cover plate 3a of the stress anchor 3 is anchored on the concrete structure 1 to be reinforced.

[0035] (3) Apply a layer of interface agent 5 to the surface of the concrete structure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com