Functional gradient and density gradient concrete material for 3D printing and preparation method thereof

A technology of density gradient and functional gradient, which is applied in the field of preparing a 3D printing concrete material with functional gradient and density gradient, can solve the problems of weak interactive coordination of nozzles, poor individual versatility, weak component interaction, etc., and achieve improvement Habitat comfort, self-weight reduction, and the effect of reducing the overall self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

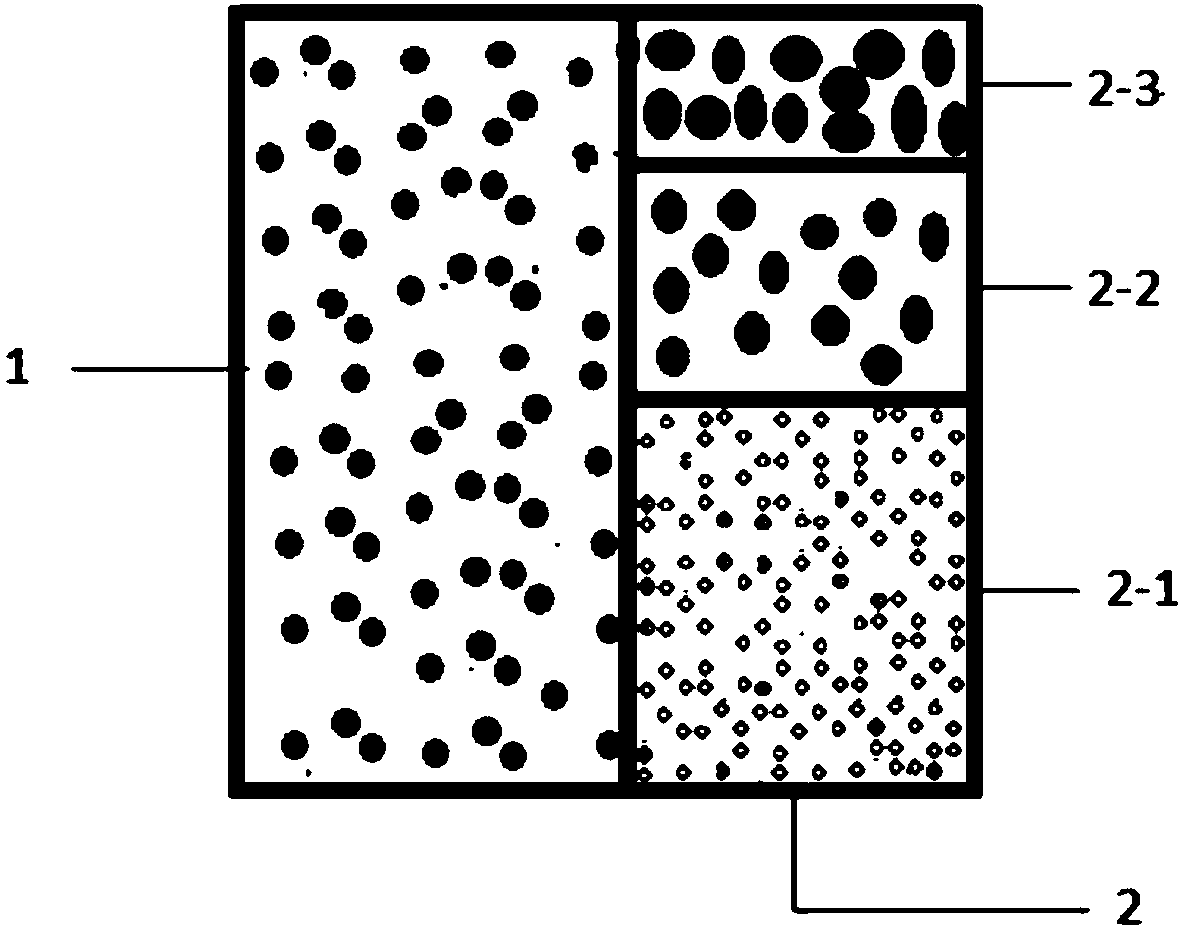

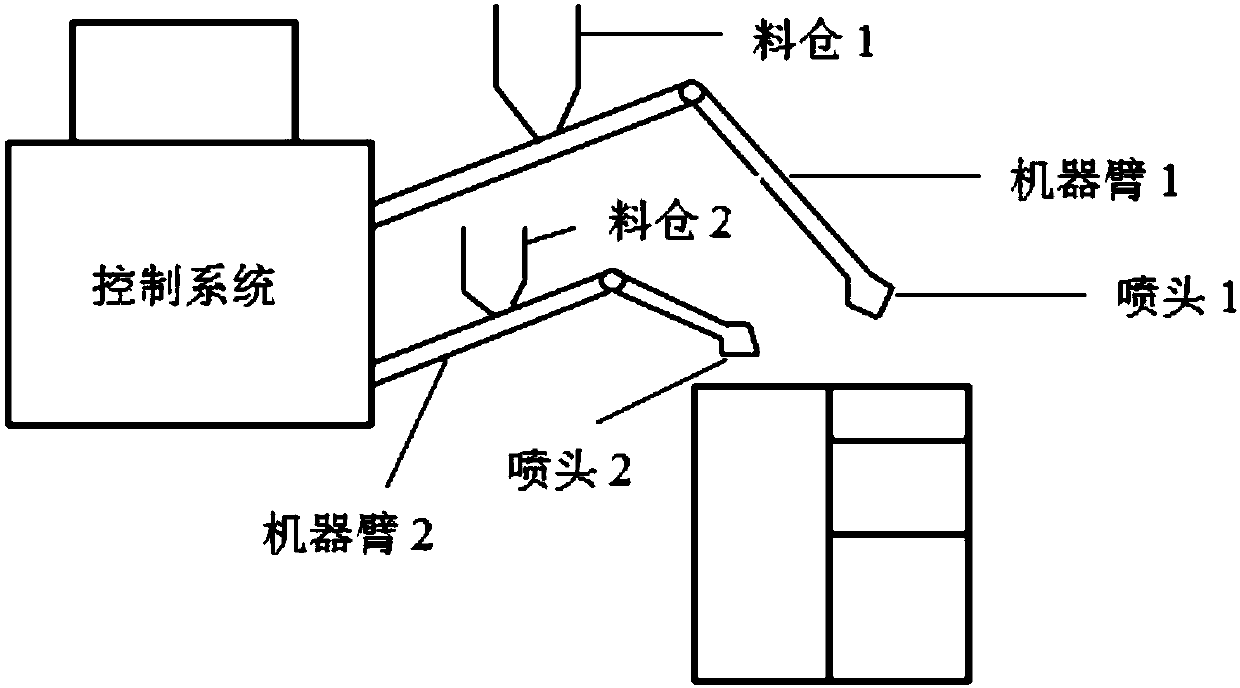

[0064] Weigh 48.7% of yellow sand, 16.8% of Portland cement, and 24.6% of first-grade fly ash into a mixer. After stirring for 3 to 5 minutes, mix 9.5% of water and 0.38% of polycarboxylic acid-based high-efficiency water-reducing agent and 0.02% antifoaming agent, slowly pour the mixed solution into the evenly stirred powder, and the formed slurry is the first gradient layer material of the density gradient layer; weigh 33.7% yellow sand, 16.8% silicon Salt cement, 24.6% of primary fly ash are put into the mixer, and after stirring for 3-5 minutes, 9.5% of water, 0.38% of polycarboxylate superplasticizer and 0.02% of defoamer are configured. Slowly pour the mixed solution into the evenly stirred powder. After the slurry is formed, pour 15% of the first-grade fly ash ceramsite into the mixer and stir for 3 minutes to obtain the second gradient layer material of the density gradient layer; then weigh 12.7 % of yellow sand, 16.8% of Portland cement, and 24.6% of primary fly ash ...

Embodiment 2

[0068] Weigh 48.7% of yellow sand, 16.8% of Portland cement, and 24.6% of finely ground blast furnace slag into a mixer, and after stirring for 3 to 5 minutes, mix 9.5% of water and 0.38% of polycarboxylate superplasticizer and 0.02% antifoaming agent, slowly pour the mixed solution into the evenly stirred powder, and the formed slurry is the first gradient layer material of the density gradient layer; weigh 30.7% yellow sand, 16.8% silicic acid Put salt cement and 24.6% finely ground blast furnace slag into a mixer, stir for 3 to 5 minutes, then mix 9.5% water, 0.38% polycarboxylate superplasticizer and 0.02% defoamer to prepare a mixed solution Slowly pour into the evenly stirred powder, and after the slurry is formed, pour 18% of the high-strength shale ceramsite into the mixer and stir for 3 minutes to obtain the second gradient layer material of the density gradient layer; then weigh 12.7% of yellow sand, Put 16.8% Portland cement and 24.6% finely ground blast furnace sla...

Embodiment 3

[0072] Weigh 48.7% of yellow sand, 16.8% of Portland cement, and 24.6% of silica fume into a mixer, stir for 3 to 5 minutes, mix 9.5% of water, 0.38% of polycarboxylate superplasticizer and Slowly pour the mixed solution of 0.02% defoamer into the evenly stirred powder, and the formed slurry is the first gradient layer material of the density gradient layer; weigh 26.7% yellow sand, 16.8% silicate Put cement and 24.6% microsilica fume into the mixer, and after stirring for 3 to 5 minutes, slowly pour the mixed solution of 9.5% water, 0.38% polycarboxylate superplasticizer and 0.02% defoamer Pour 22% of the high-strength clay ceramsite into the mixer after the slurry is formed and stir for 3 minutes to obtain the second gradient layer material of the density gradient layer; then weigh 12.7% of the yellow sand, 16.8% of the Put Portland cement and 24.6% microsilica fume into a mixer, stir for 3 to 5 minutes, then mix with 9.5% water, 0.38% polycarboxylate superplasticizer and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com