Box type prestress concrete light composite slab

A concrete and prestressed technology, applied in floors, building components, buildings, etc., can solve the problems of long construction period of densely ribbed floors and unbonded prestressed slabs, small span of ordinary prefabricated concrete slabs, poor thermal insulation and sound insulation effects, etc. Achieve the effects of shortening the construction period, improving the overall earthquake resistance, and good heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

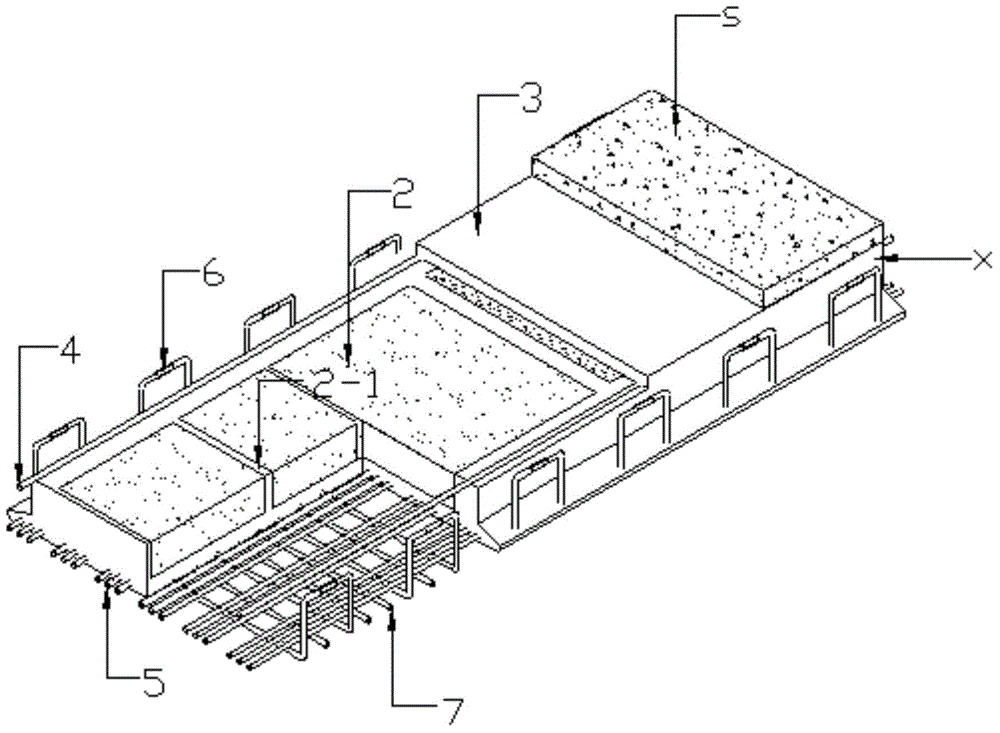

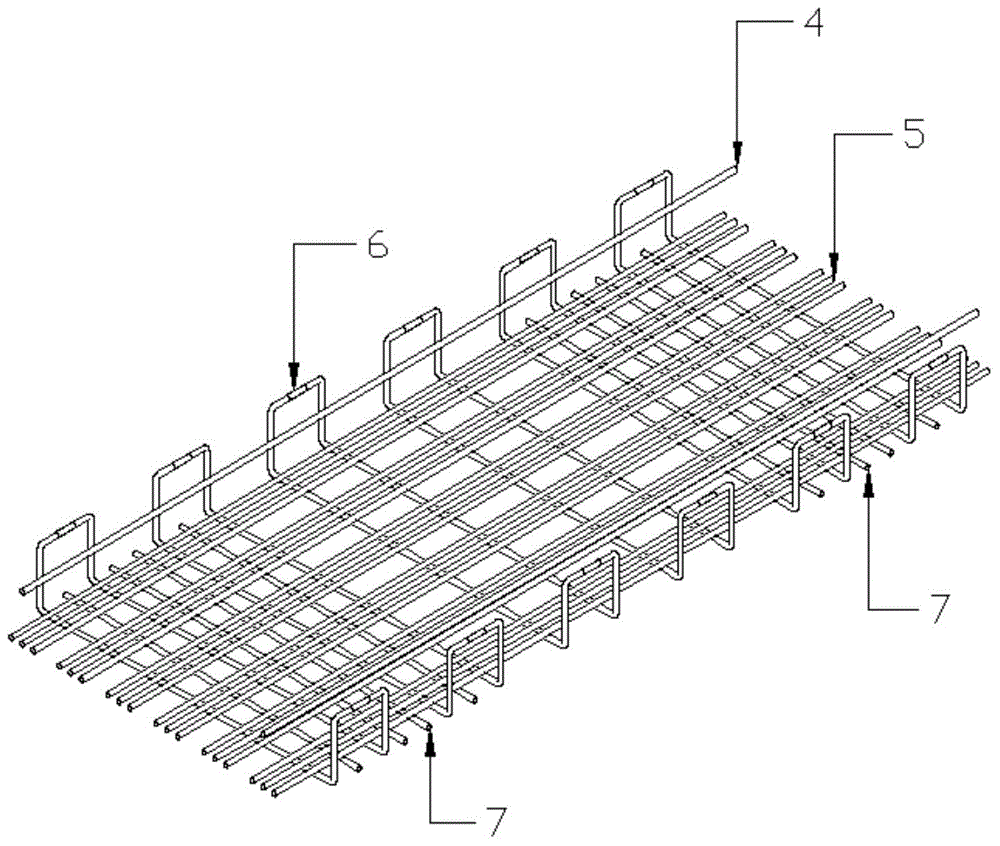

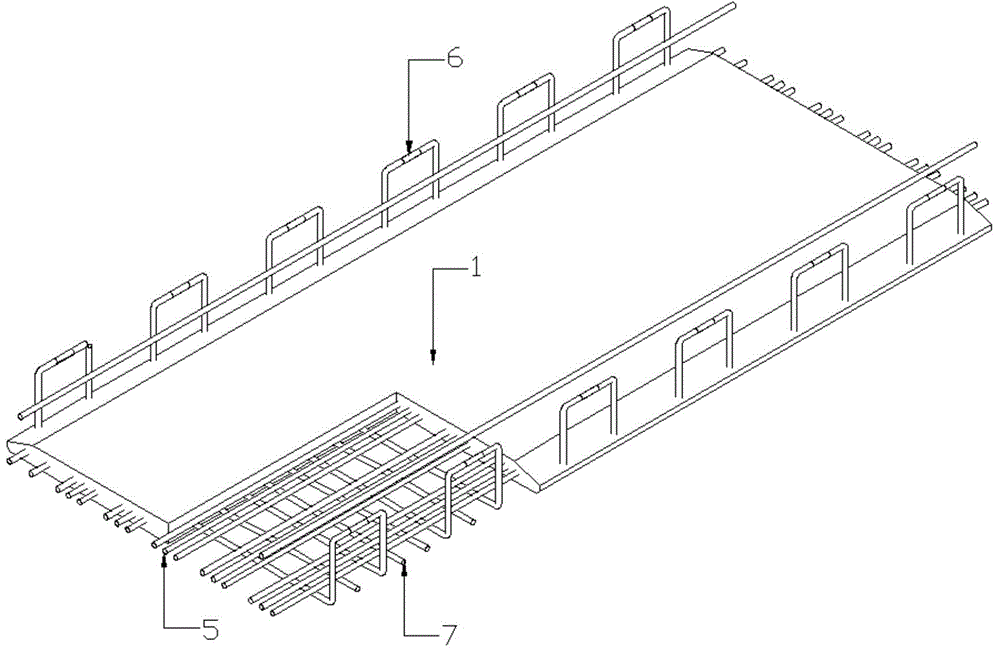

[0015] The invention is a box-type prestressed concrete light composite slab, which is composed of an upper cast-in-place concrete slab S and a lower reinforced concrete prefabricated slab X. The lower reinforced concrete prefabricated slab X is a closed prefabricated slab composed of a reinforced concrete bottom layer, a lightweight filled core layer and a concrete outer layer, such as Figure 5 . The reinforced frame of the reinforced concrete bottom layer 1 is composed of common steel bars and prestressed steel bars. The common steel bars are: there are П-shaped vertical end horizontal steel bars 6 arranged at longitudinal intervals, and the encrypted horizontal steel bars 7 are distributed at both ends of the longitudinal direction. The common longitudinal steel bars 4 are used The tensioning device is arranged between the lightweight filling core block 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com