Energy-saving and environment-friendly structural ultra-high performance fiber reinforced concrete

An ultra-high performance, energy-saving and environmentally friendly technology, applied in the field of building materials, can solve the problems of high internal stress, difficulty in ensuring dispersion and orientation, affecting structural durability, etc., achieve high tensile strength, reduce energy consumption and carbon dioxide Emissions, the effect of improving structural durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

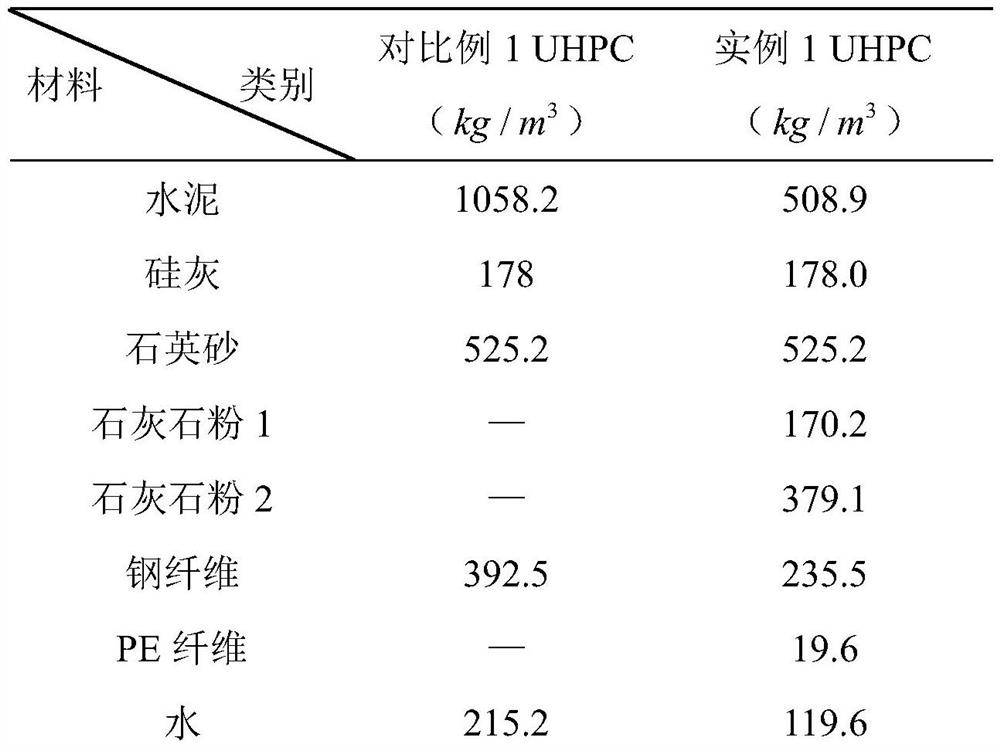

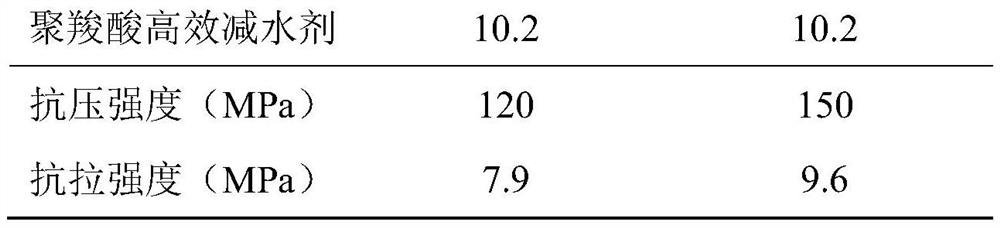

Embodiment 1

[0032]The UHPFRC material of the present embodiment is formed of cement, silica gray, two limestone blend, steel fibers, and PE fibers, water, quartz sand, and high efficiency water reduction. Among them, the cement uses CEMI type 52.5R stage common silicate cement with a dosage of 508.9 kg / m3; the average particle diameter of the silicone ash is 200 nm, the amount of two limestone powder used is an inert gelation material, wherein The limestone powder 1 has a average particle diameter of 10 μm, the amount of 1,70.2 kg / m3, the limestone powder 2 has average particle diameter of 2 μm, the amount of 379.1 kg / m3; the mixed fibers use a diameter of 0.2 mm, length 10 mm, length steel fiber and diameter It is 0.012mm, a PE fiber having a length of 6 mm, wherein the steel fiber volume is 3%, the amount of from 235.5 kg / m3, and the volume of PE fibers is 2%, the amount of water is from 19.6 kg / m3; the water used is 119.6 kg / M3; quartz sand has average particle size of 0.2 mm, ...

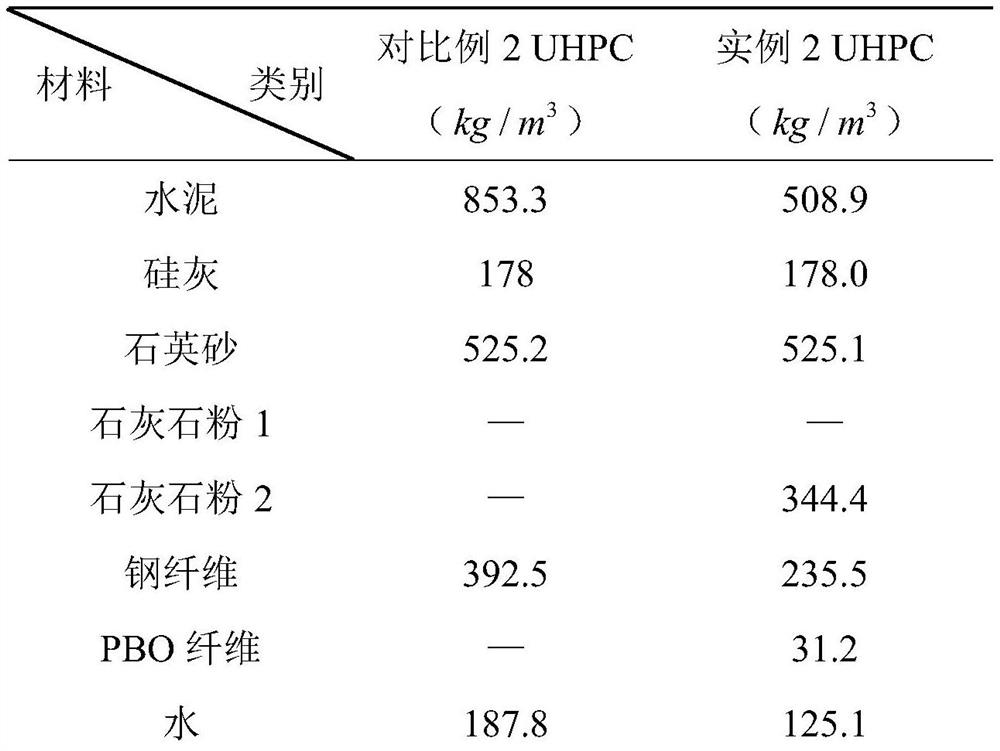

Embodiment 2

[0042] The novel UHPFRC material of this embodiment is formed of cement, silica gray, limestone powder, steel fiber, water, water, quartz sand, and high efficiency water reduction. Among them, the cement uses CEMI type 52.5R-stage ordinary silicate cement with a use of 508.9 kg / m3; the average particle diameter of the silicon ash is from 178.0 kg / m3; the amount of limestone is 344 kg / m3; hybrid fiber uses diameter A flat steel fiber and a diameter of 0.04 mm in length of 0.2 mm, a length of 4 mm, wherein the steel fiber volume is 3%, the amount of from 235.5 kg / m3, and the amount of PBO fiber is 2%. The amount of water used is 31.2 kg / m3; the amount of water used is 125.1 kg / m3; the average particle diameter of the quartz sand is 0.2mm, the amount of 525.1 kg / m3; the high-efficiency water reduction agent is highly efficient water reduction agent, 10.2 kg. / m3. The UHPC of the second embodiment employs an inert limestone substitution ratio of 40% cement dosage in rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com