Steel frame reinforced column and reinforcing method thereof

A frame column and steel frame technology, applied in columns, pier columns, pillars, etc., can solve the problems of long period and complicated construction procedures, achieve the effect of convenient construction, meet the requirements of structural bearing force and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

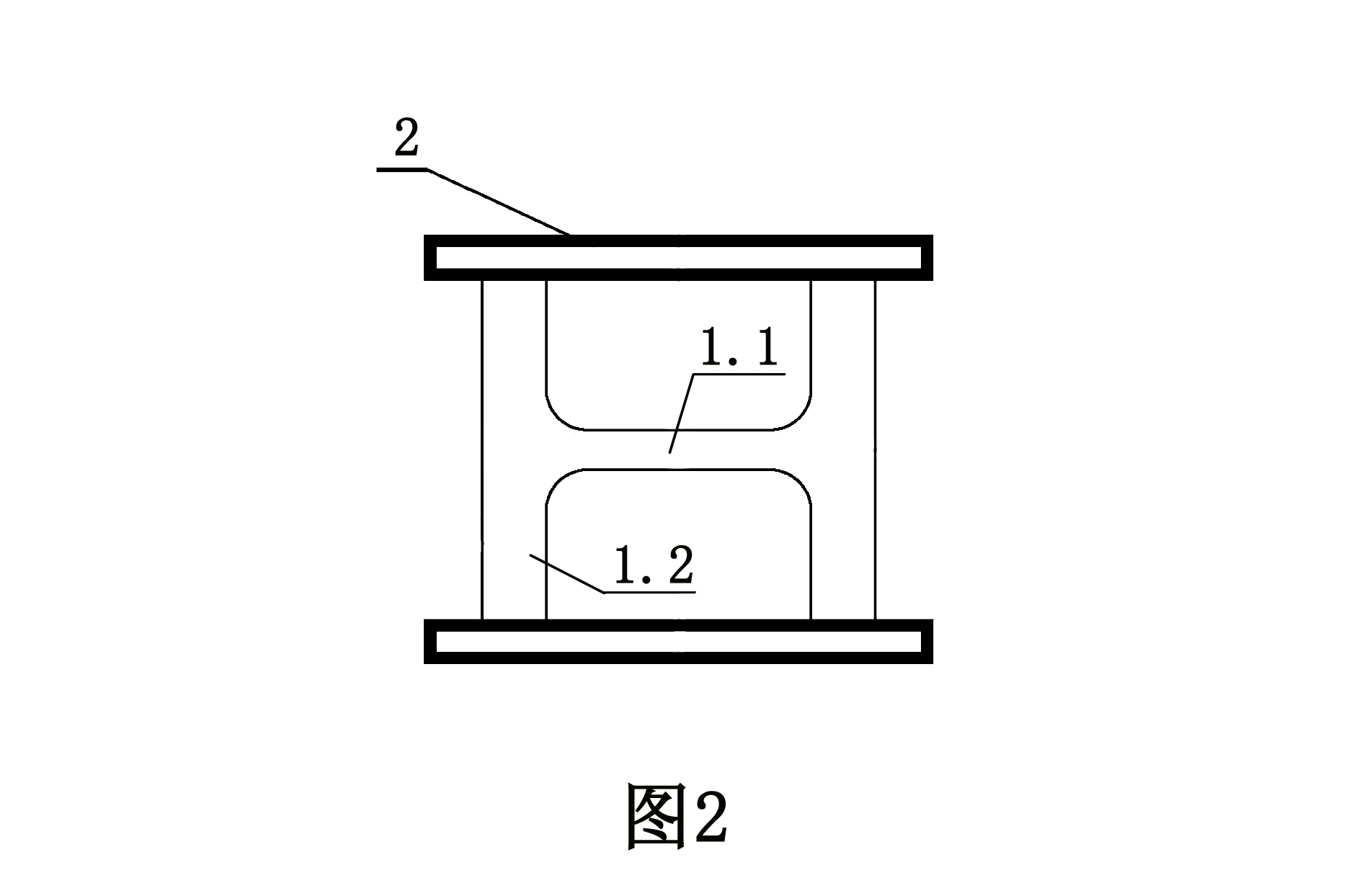

[0031] Examples see figure 2 As shown, this steel frame reinforced column includes an H-shaped steel frame column 1, and a sealing and reinforcing steel plate 2 is welded along the entire length of the column between the two wing plates 1.2 on both sides of the H-shaped steel frame column 1, and the sealing and reinforcing steel plate is on the H-shaped steel frame. The openings on both sides of the column are arranged in pairs, and are welded to the two wing plates 1.2 at the opening of the H-shaped steel frame column, and the upper and lower adjacent two sealing reinforcement plates 2 are welded to each other.

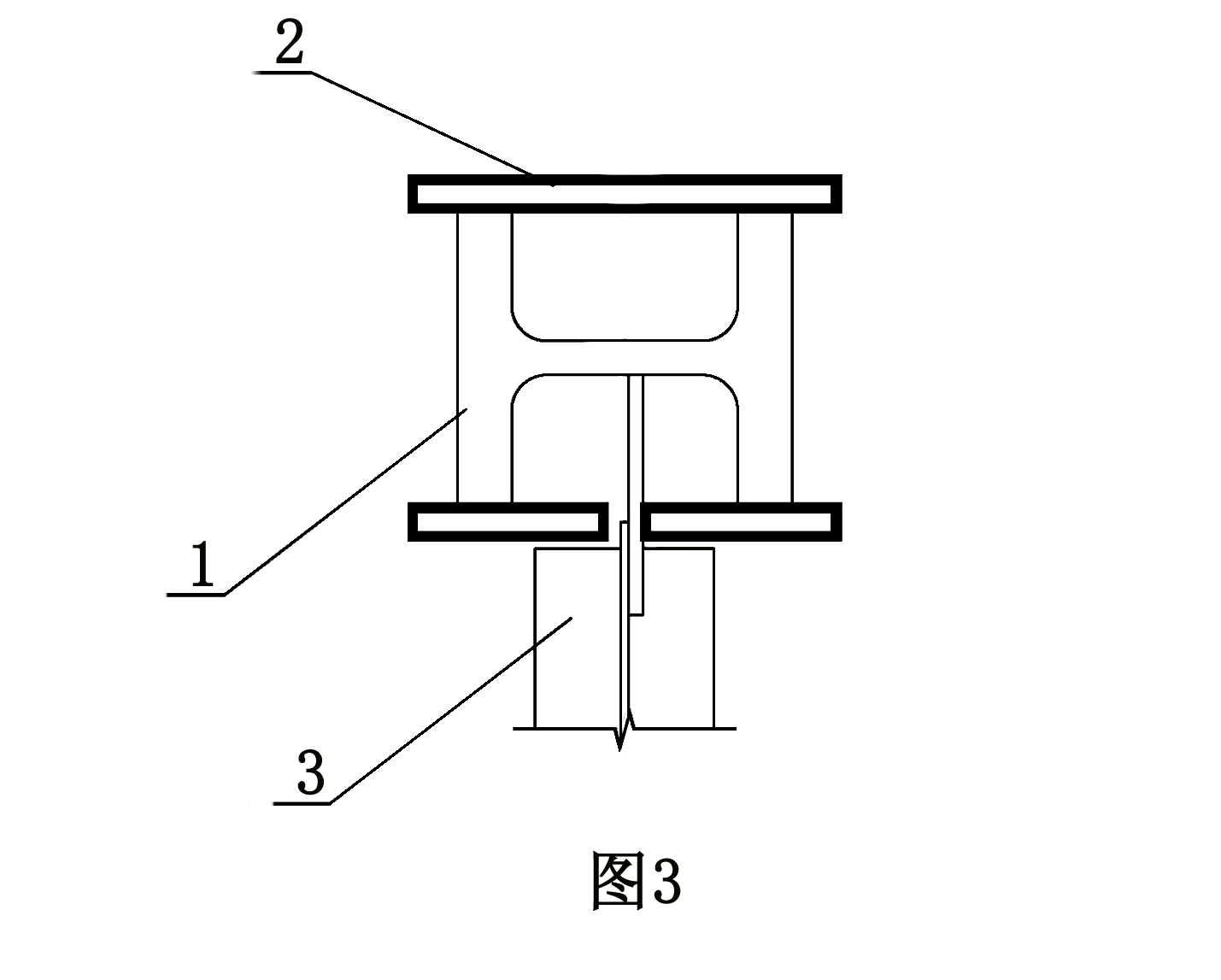

[0032] see image 3 As shown, the sealing reinforcement steel plate 2 is grooved at the intersection with the steel frame beam 3, and the steel frame beam is embedded in the groove.

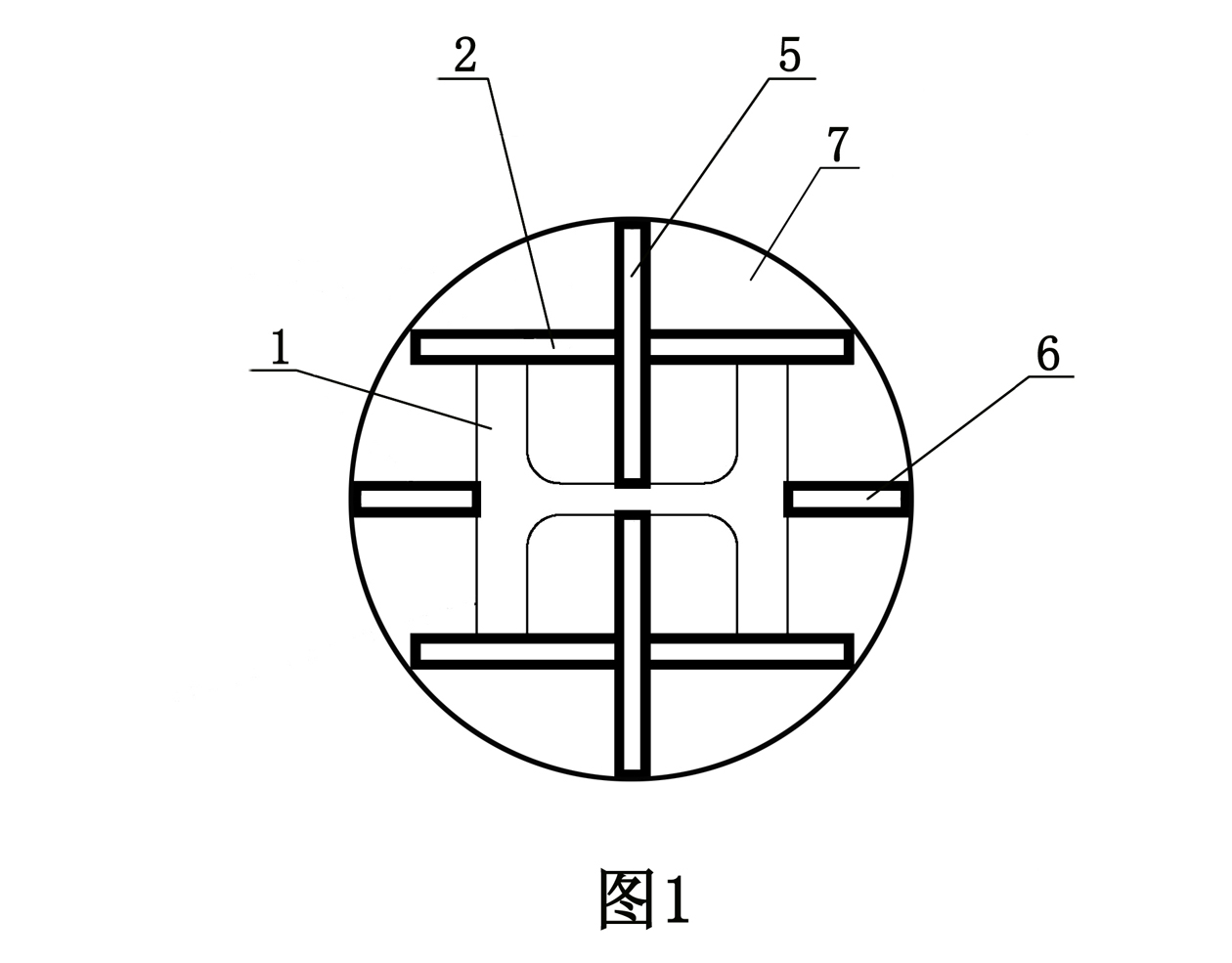

[0033] see figure 1 As shown, at the foot of the column of the H-shaped steel frame column 1, the bottom edge of the sealing reinforcement plate 2 is welded to the bottom plate 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com