Supporting steel frame of high altitude large-span cantilever structure mold frame

A technology of large-span overhangs and support frames, which is applied in the fields of formwork/formwork/work frames, construction components on-site preparation, building construction, etc., and can solve problems such as small overhang spans and insufficient bearing capacity of cantilever ends , to achieve the effect of large frame rigidity, reasonable force, and light frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

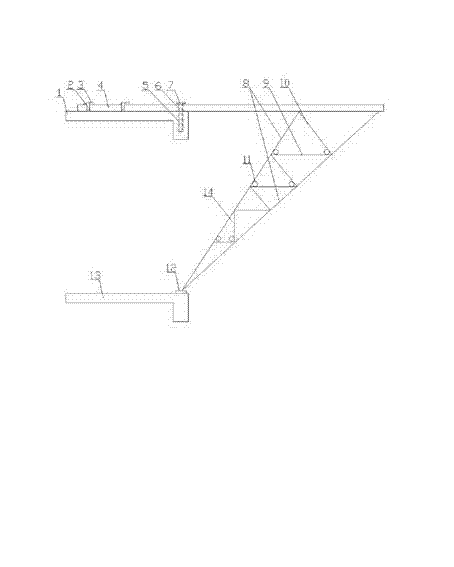

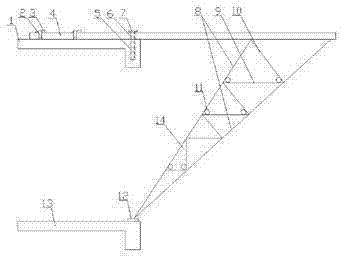

[0011] Embodiment: The supporting steel frame of the high-altitude and large-span cantilevered structure formwork as shown in the figure includes a floor slab, a support frame and a cantilever beam. The support frame 14 is triangular, and the triangular support frame 14 is composed of diagonal braces 8, horizontal The web bar 9 and the diagonal bracing web bar 10 are composed of two diagonal bracing bars 8. They form a certain angle and their lower ends are fixed on the embedded iron parts 12 on the lower floor 13. The horizontal web bar 9 is horizontal Installed between two diagonal braces 8, the diagonal brace webs 10 are installed between every two horizontal webs 9 and form a certain angle with the horizontal webs 9. A short pipe 11 is installed on the horizontal web bar 9 . The upper end of the triangular support frame is provided with a cantilever beam 4, and one end of the cantilever beam 4 passes through the anchor ring 2 installed on the upper floor 1, and is wedged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com