Elastic split type fastener of medium and low speed magnetic suspension rail

A maglev track and separate technology, applied in the direction of tracks, roads, buildings, etc., can solve the problems of lack of feasibility of gauge adjustment, poor vertical and horizontal adjustment ability of rail rows, failure to solve two-way vibration reduction, etc., to achieve good Maintenance and repairability, reduction of double impact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

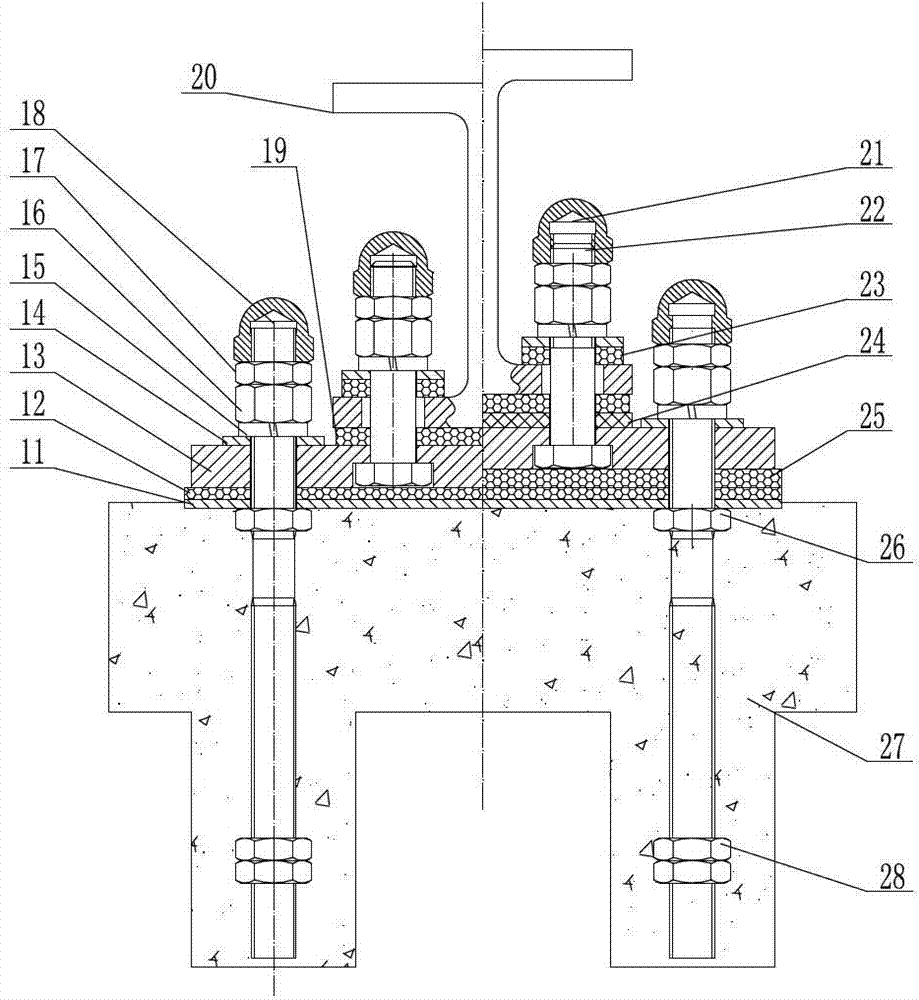

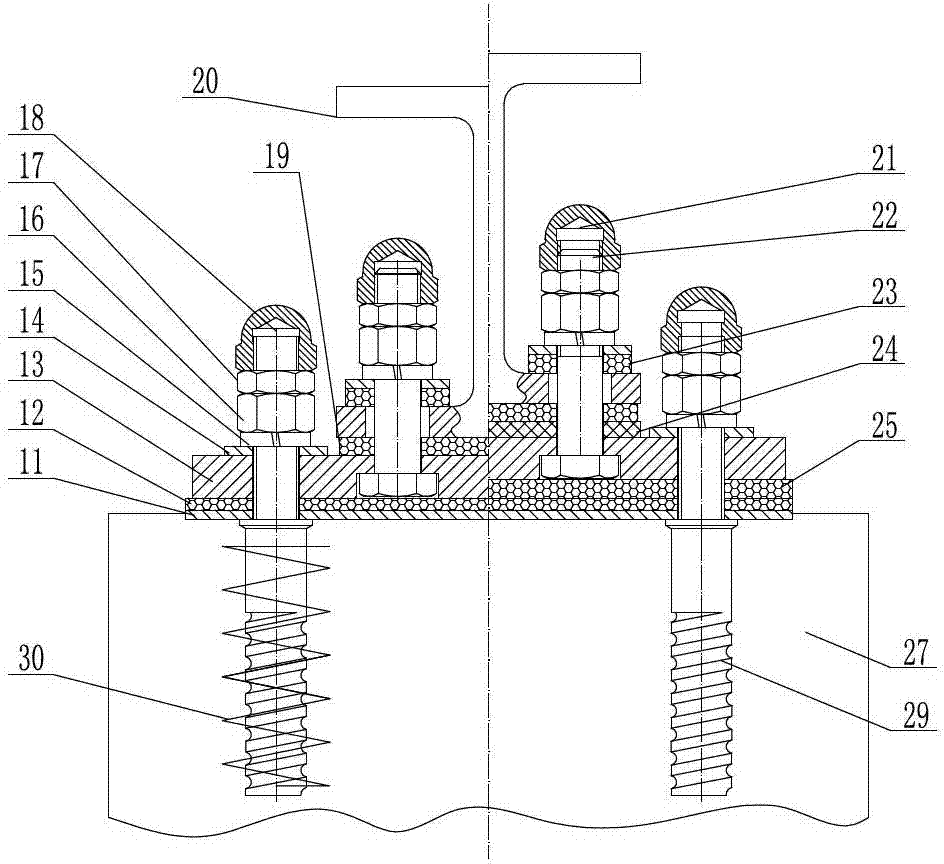

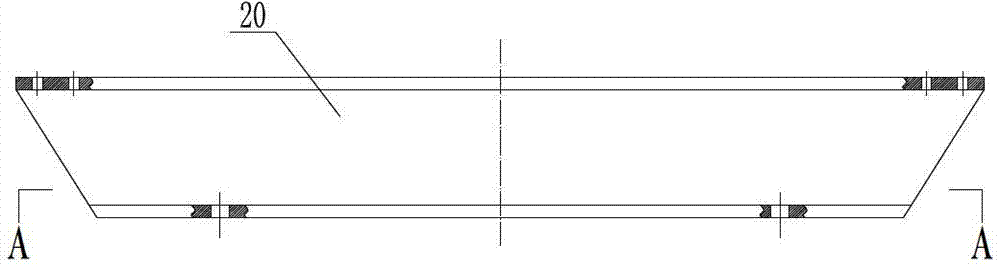

[0024] refer to Figure 1 to Figure 6 , the middle and low-speed maglev track elastic split fasteners of the present invention firmly connect the rail row composed of H-shaped steel sleepers 20 with the rail support platform 27 . It includes two sets of connecting bolt assemblies arranged at intervals in the transverse direction, and connects the H-shaped steel sleeper 20 with the connecting plate 13 as a whole. Between the bottom plate of the pillow 20 and the connecting plate 13, an elastic backing plate 19 under the pillow is arranged, and the bottom plates on both sides of the H-shaped steel sleeper 20 are provided with connecting bolt oblong holes 20a extending along the line direction for the upper part of the connecting bolt assembly to pass through. It also includes two sets of anchor bolt assemblies arranged at intervals in the transverse dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com