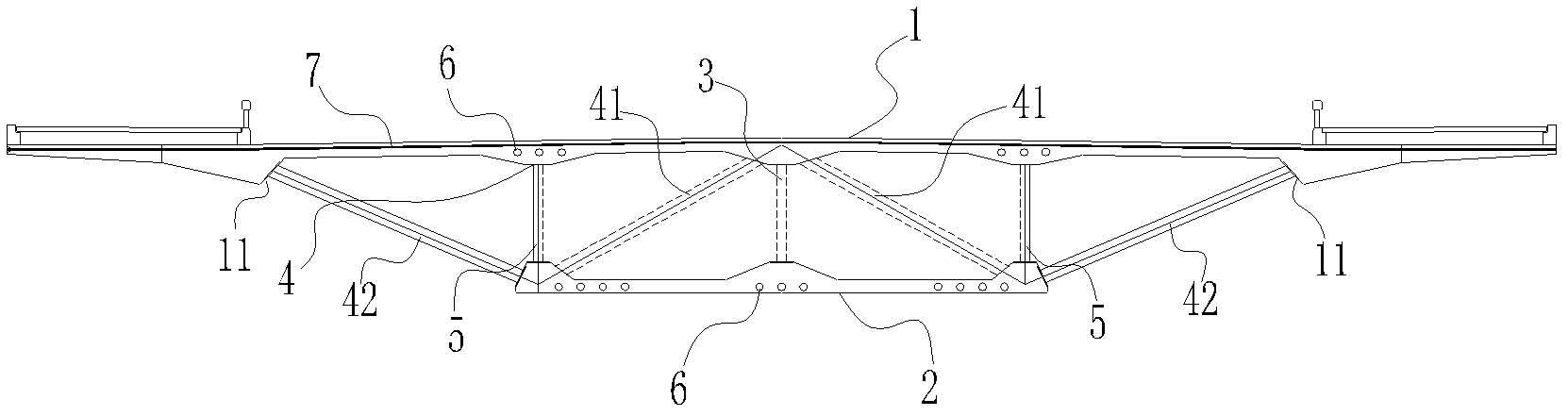

Large cantilever wave-purlin combined PC bridge and manufacture method thereof

A cantilever and bridge technology, used in bridges, bridge construction, bridge parts, etc., can solve problems such as the deformation of the main girder of the bridge, poor torsional performance of the corrugated steel web, and achieve reasonable structural stress, saving formwork support, structural Lightweight and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

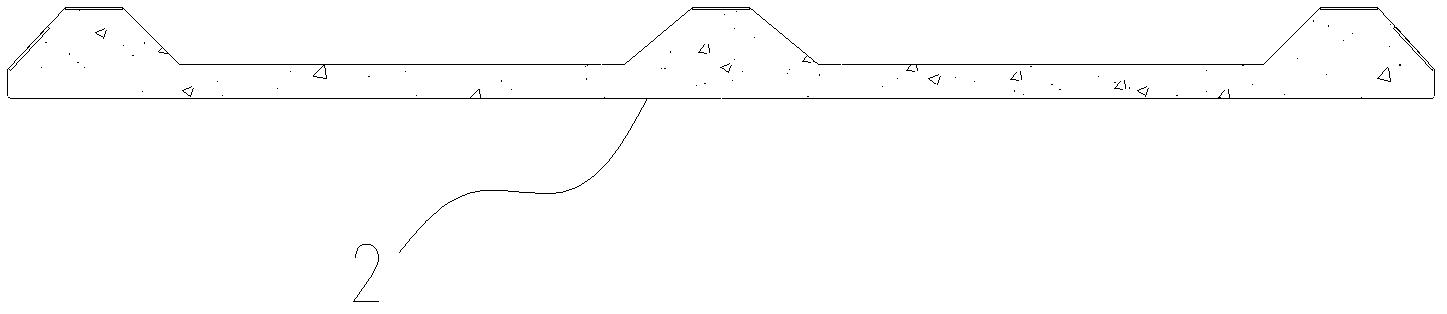

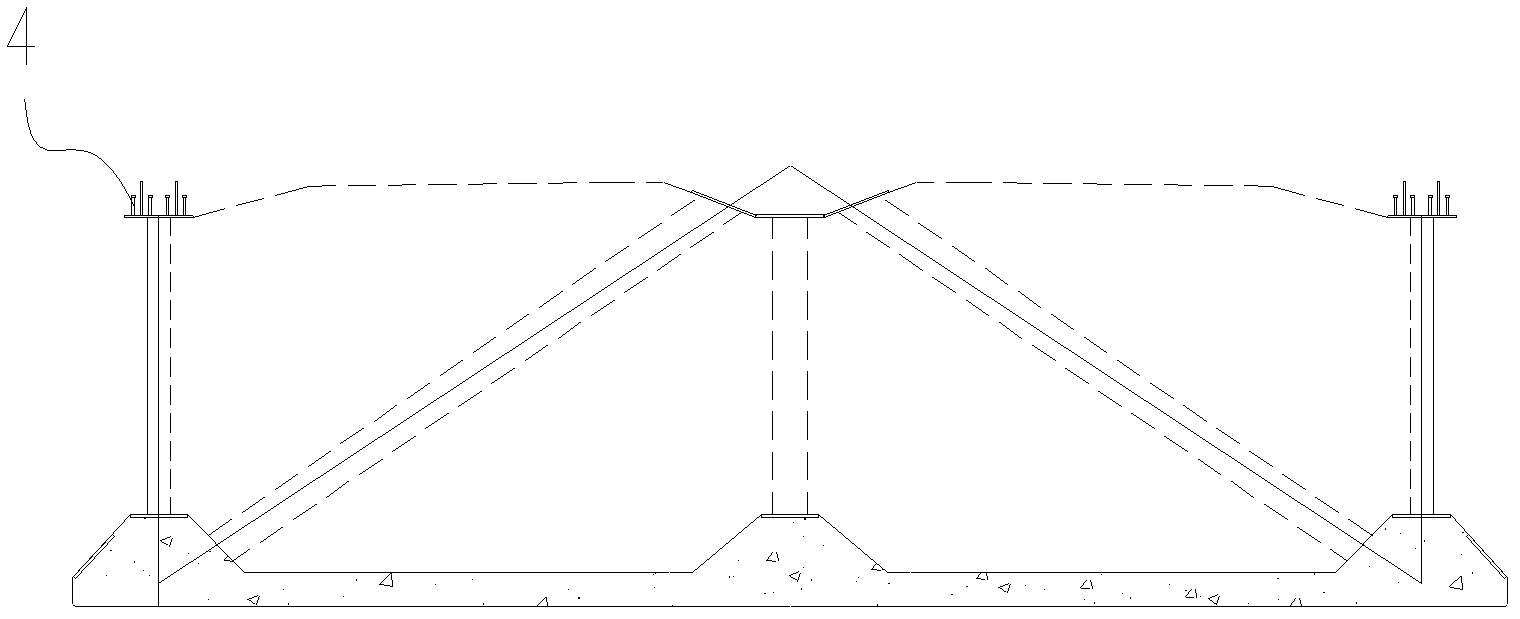

Method used

Image

Examples

Embodiment 2

[0059] Such as Figure 8 As shown, the difference between this embodiment and the first embodiment is only that the concrete floor 2 of the first embodiment is replaced by the beam bottom steel truss tube 2a, and the corrugated steel web 5 is replaced by the steel truss web 5a, which becomes a large cantilever plate- Composite truss beams.

Embodiment 3

[0061] Such as Figure 9 As shown, the difference between the present embodiment and the first embodiment is only that the concrete floor 2 of the first embodiment is replaced by the beam-bottom steel truss tube 2b to become a large cantilever wave-truss composite beam.

Embodiment 4

[0063] Such as Figure 10 As shown, the difference between the present embodiment and the first embodiment is that the corrugated steel web 5 of the first embodiment is replaced by the steel truss web 5b to become a large cantilever steel truss web composite PC girder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com