HD700 pattern radial tire of car

A technology for radial tires and patterns, applied to tire parts, tire treads/tread patterns, vehicle components, etc., can solve problems such as high handling performance requirements, reduce noise, compensate for tire cornering stiffness and return to alignment Loss of stiffness, effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

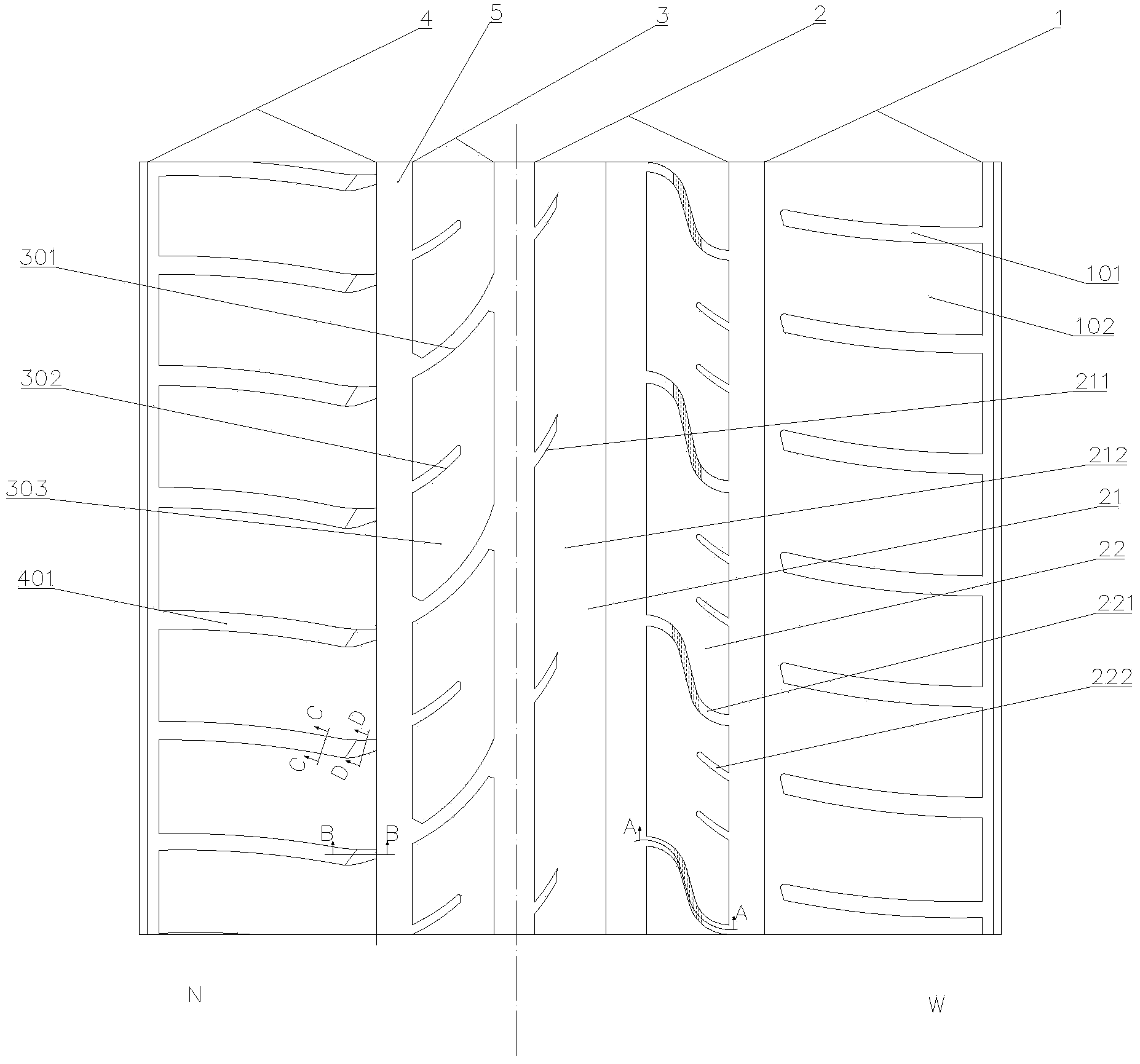

[0029] The present invention includes a carcass and a tread. The tread is arranged on the carcass and is in contact with the ground. The tread is provided with longitudinal grooves 5 and transverse grooves on its circumference to form a tread pattern. The tread pattern is asymmetrical. a pattern comprising an outer pattern region and an inner pattern region,

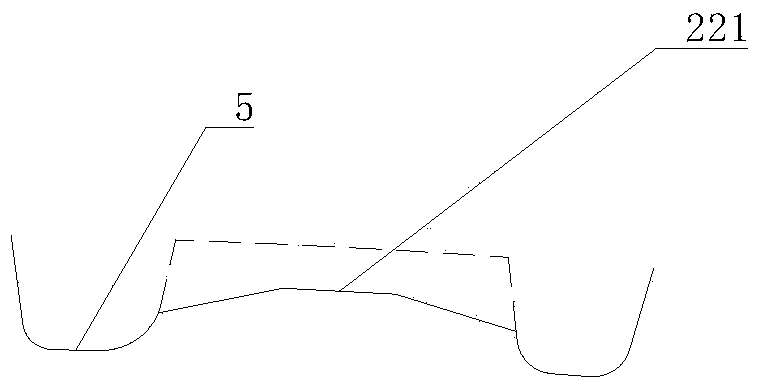

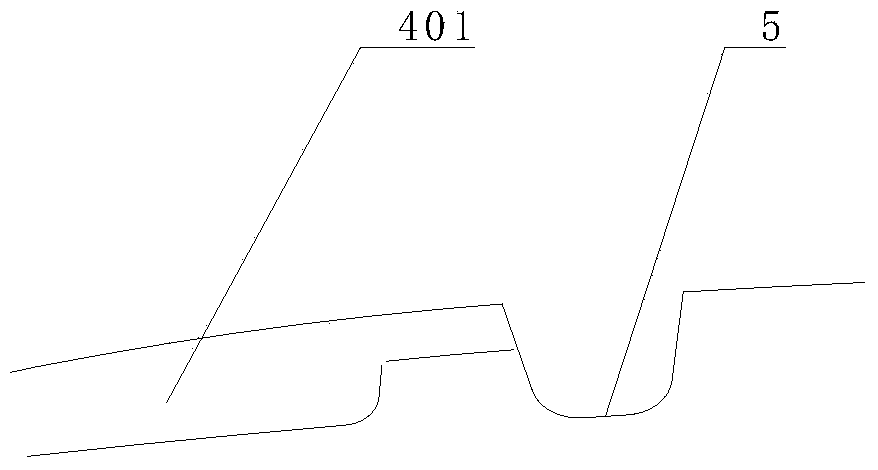

[0030] The outer pattern area includes an outer transverse rigid zone 1 and an outer longitudinal rigid zone 2, the outer transverse rigid zone 1 is composed of barrier type transverse grooves 101 to form transverse tread blocks 102, and the outer longitudinal rigid zone 2 includes a longitudinal rigid zone I21 and the longitudinal rigid zone II22, the longitudinal rigid zone I21 is composed of oblique transverse grooves 211 to form continuous tread blocks 212, and the longitudinal rigid zone II22 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com