Waterproof roll film packaging equipment with film roll positioning mechanism

A positioning mechanism and waterproof membrane technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of high implementation cost, achieve the effect of improving structural strength, reducing specifications and tension, and prolonging the actual life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

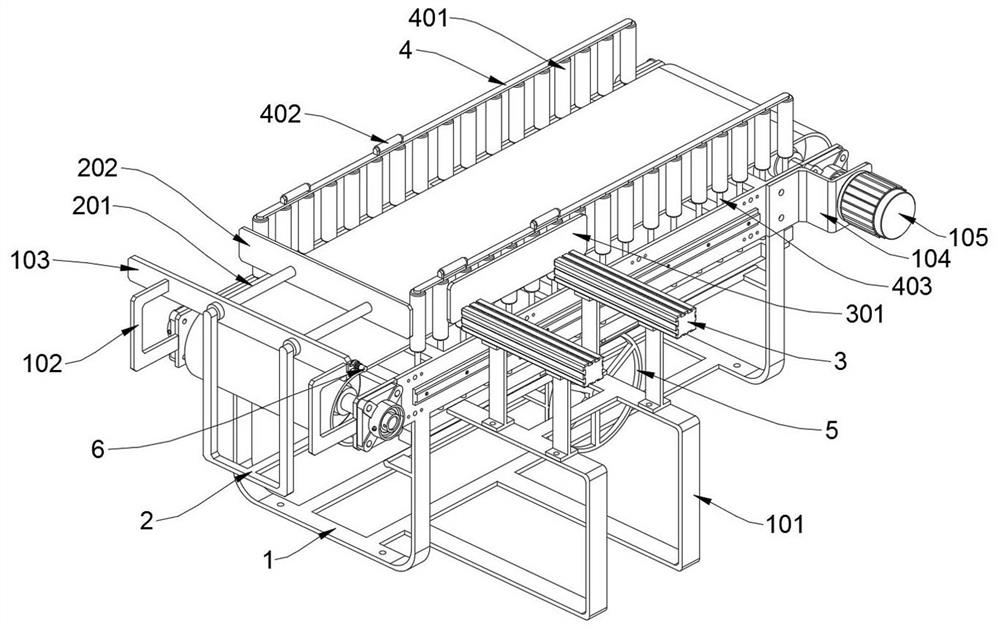

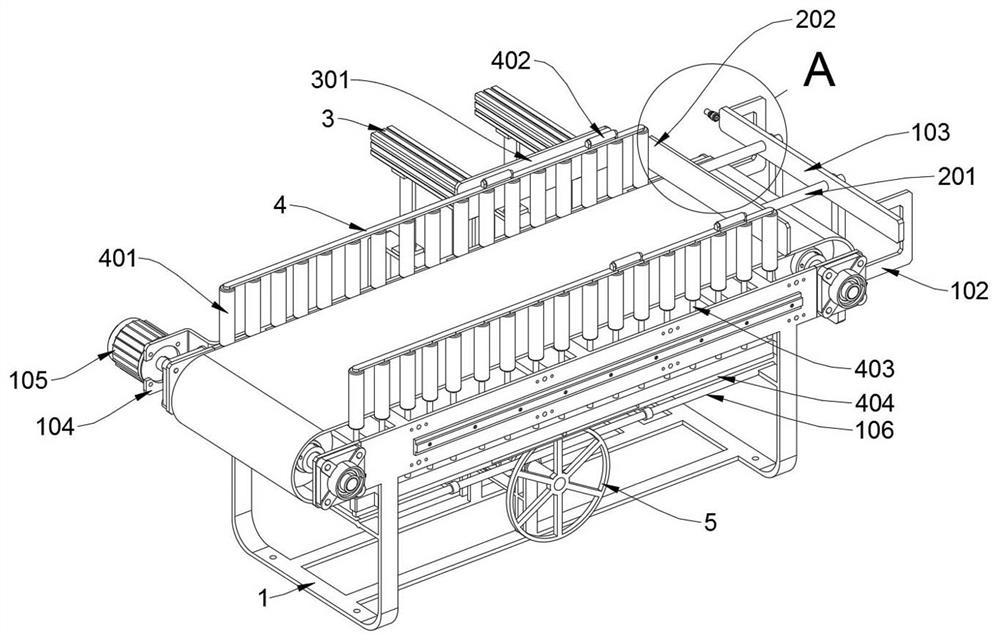

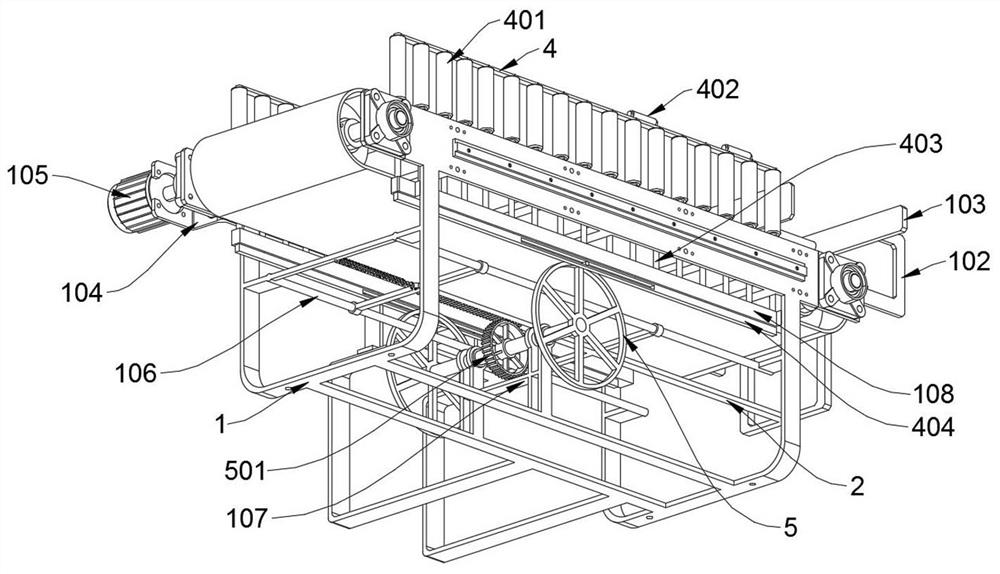

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] see Figure 1 to Figure 8, an embodiment provided by the present invention: waterproof roll film packaging equipment with a film roll positioning mechanism, including a bracket 1; the whole bracket 1 is composed of two vertical frames at the front and rear and symmetrically welded between the bottom plates of the two vertical frames. Two longitudinal braces are combined to form, and the tops of the two vertical braces are symmetrically welded with two side panels, and two belt rollers are installed symmetrically between the front and rear end sections of the two side panels. There is a conveyor belt between the rollers; the limit device 4 includes a vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com