Patents

Literature

106results about How to "High hollow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

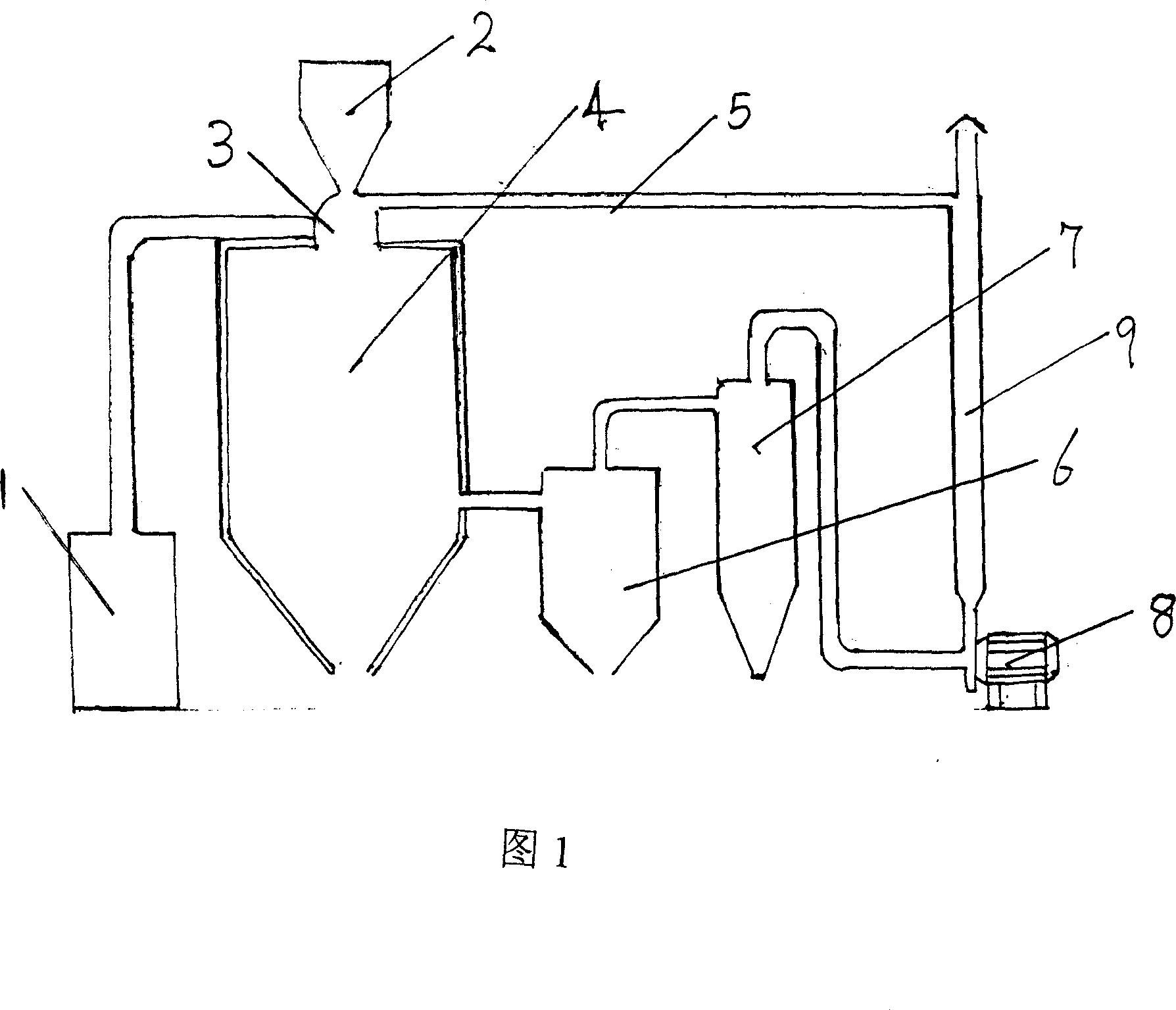

Production technology of full-dry desulfurizing gypsum building material product

The invention relates to a production technique of a total drying desulfurizing gypsum building material product, which comprises the following steps: desulfurizing gypsum, phosphor gypsum or natural gypsum are taken as the raw materials, through roasting, sieving, adding water and inorganic silicon water repellent compound, the raw materials are still dry powder; then the gypsum building material product with high consistency is obtained through installing by a paver and shaped by high pressure. The product has high strength, good rigidity, without shrinkage and no need of release agent. The gypsum product needs no drying to produce and greatly saves energy, and the energy-saving effect is good. The gypsum product having simple production technique saves energy consumption without discharge of contamination, and has no poison and damage with very low production cost. The invention can completely satisfy various requirements of users.

Owner:重庆金仓龙新型建材有限公司

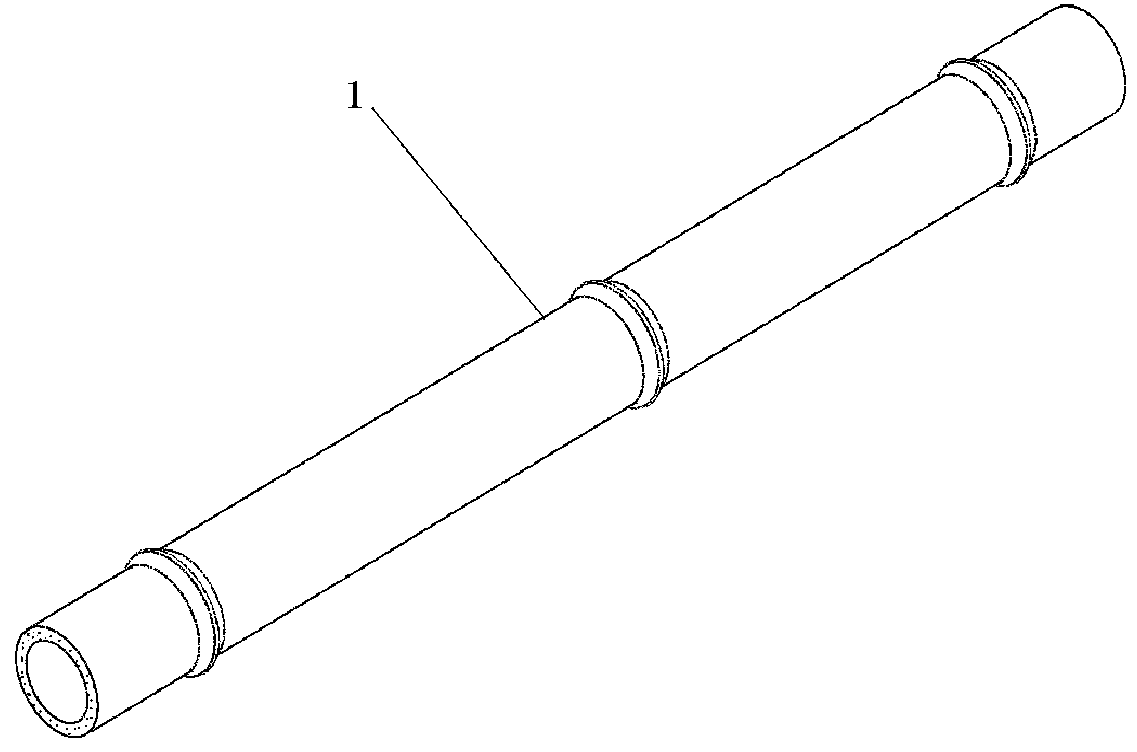

Hollow recombined bamboo and manufacturing method thereof

InactiveCN103182727AHigh hollow rateStrong impact resistanceWood working apparatusDomestic articlesEngineeringHigh pressure

The invention provides a hollow recombined bamboo and manufacturing method thereof. The hollow recombined bamboo is formed through forming holes in the longitudinal direction inside a plate pasted and connected by bamboo bunches, bamboo filaments or tiny bamboo splits. The manufacturing method includes the steps: splitting the original bamboo into bamboo bunches, bamboo filaments or tiny bamboo splits in the longitudinal direction; softening after thermal treatment, and then drying and gum dipping; paving bamboo units in a mould pressing groove by different levels uniformly; paving a moulded rod in the direction parallel to the longitudinal direction of the bamboo bunches, bamboo filaments or tiny bamboo splits as per the requirements of hollow rate; gluing slabs in the mould pressing groove through high-frequency hot pressing or cold pressing pressure maintaining and baking, demoulding, removing the mould pressing groove or a high-pressure inflating device, or adopting permanently filling; and then forming the hollow recombined bamboo finished product through follow-up machining. The hollow recombined bamboo and the manufacturing method thereof can be applied in the field of building beam columns, structural members, furniture and decorating materials.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

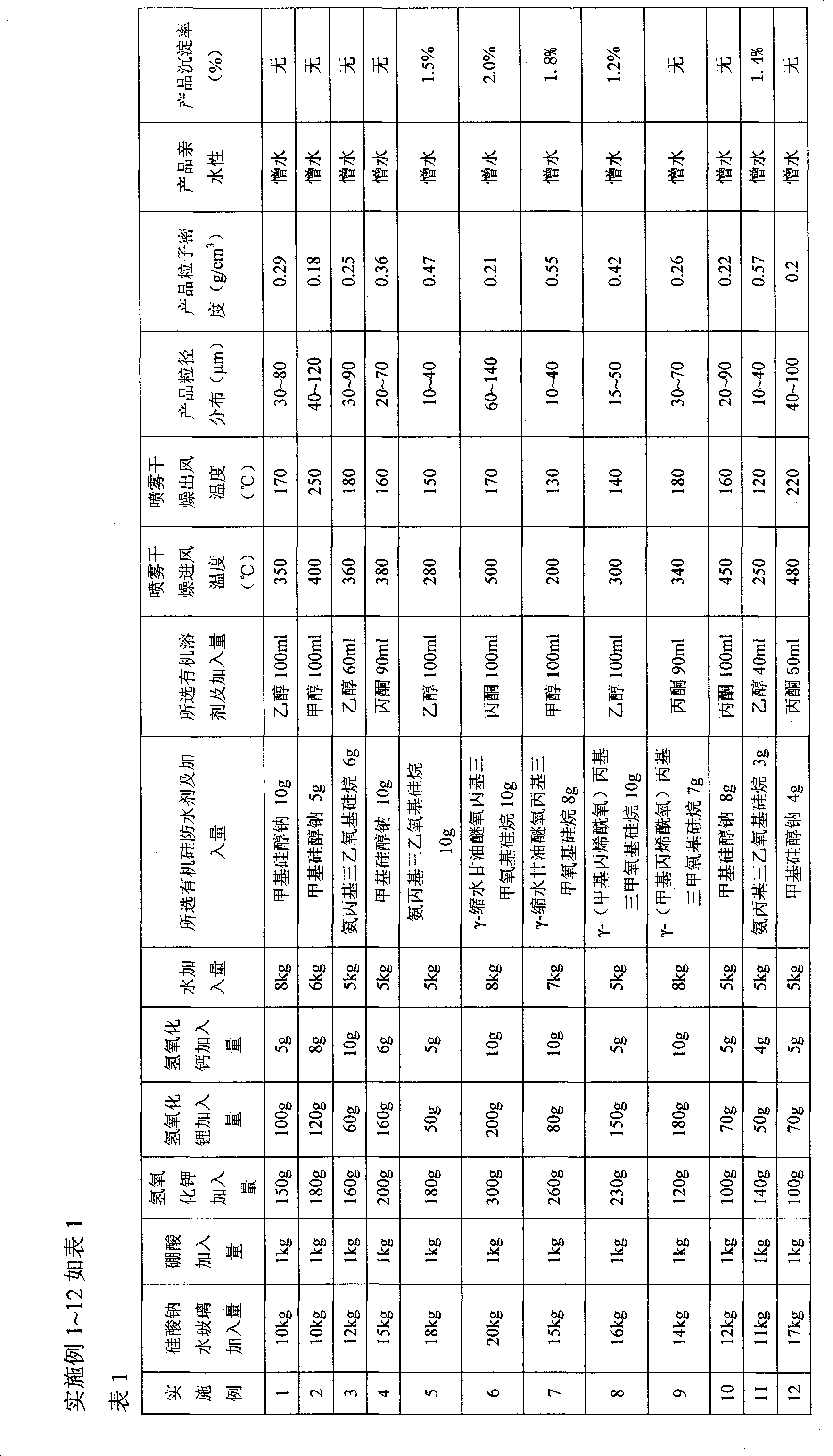

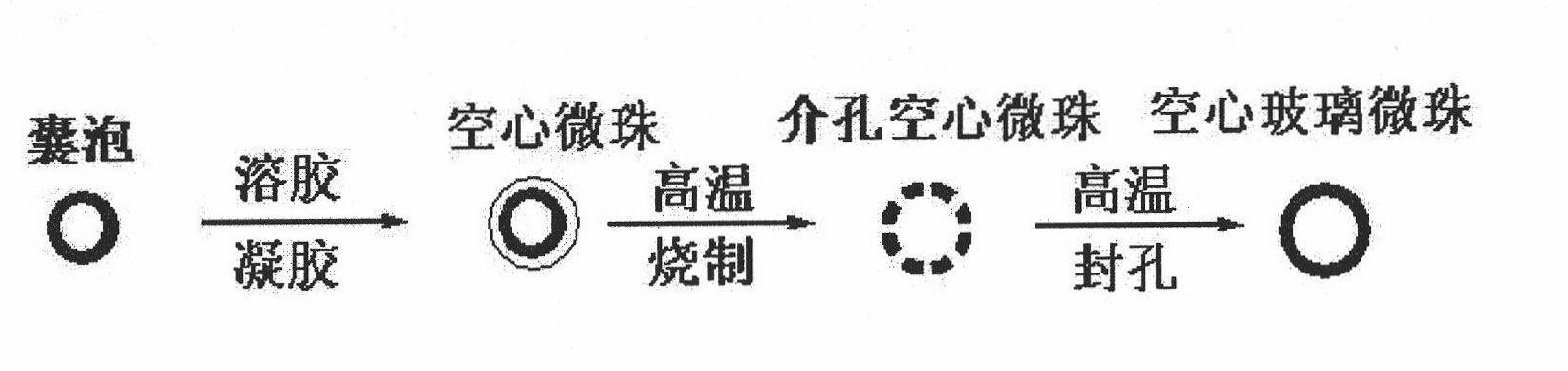

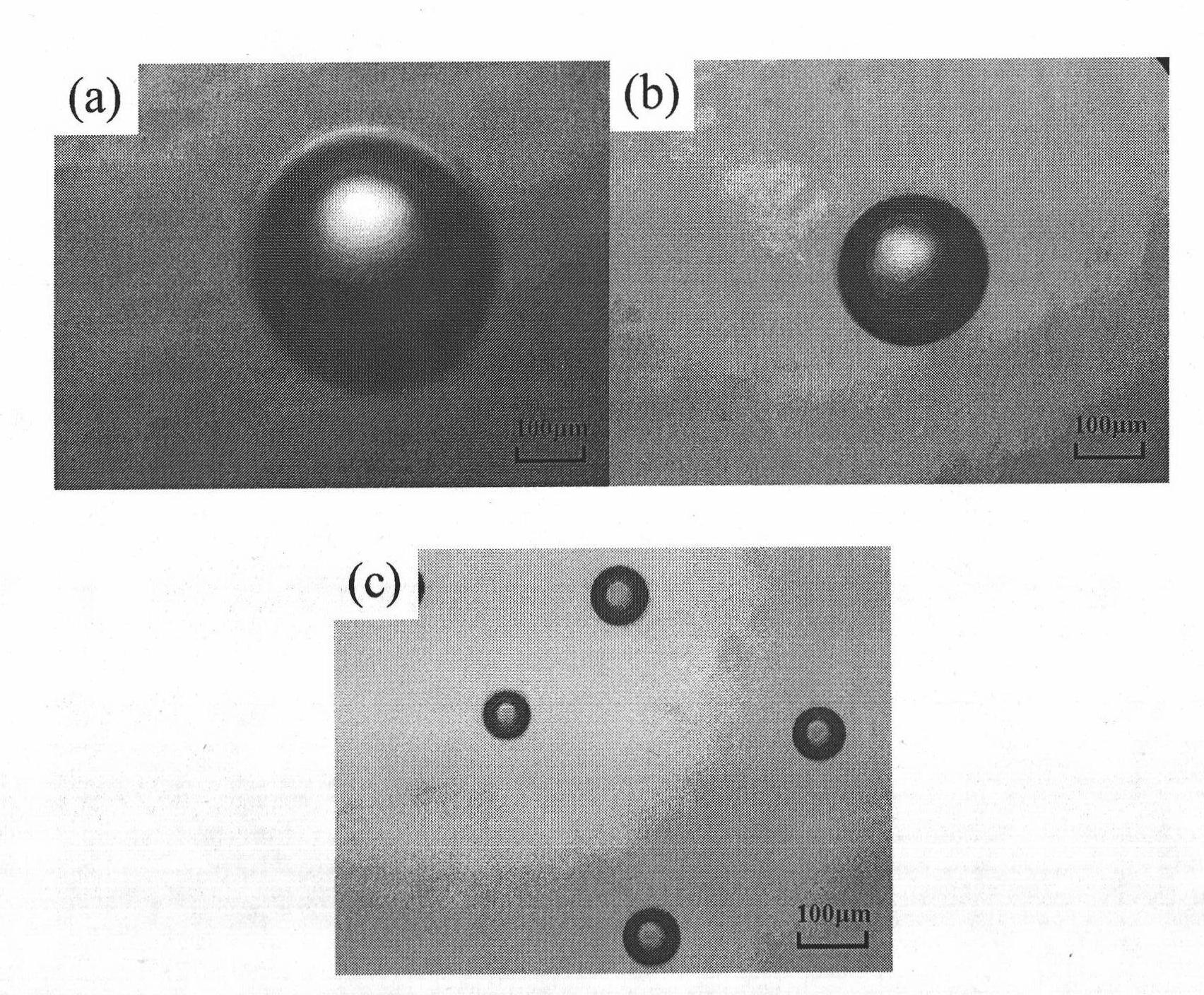

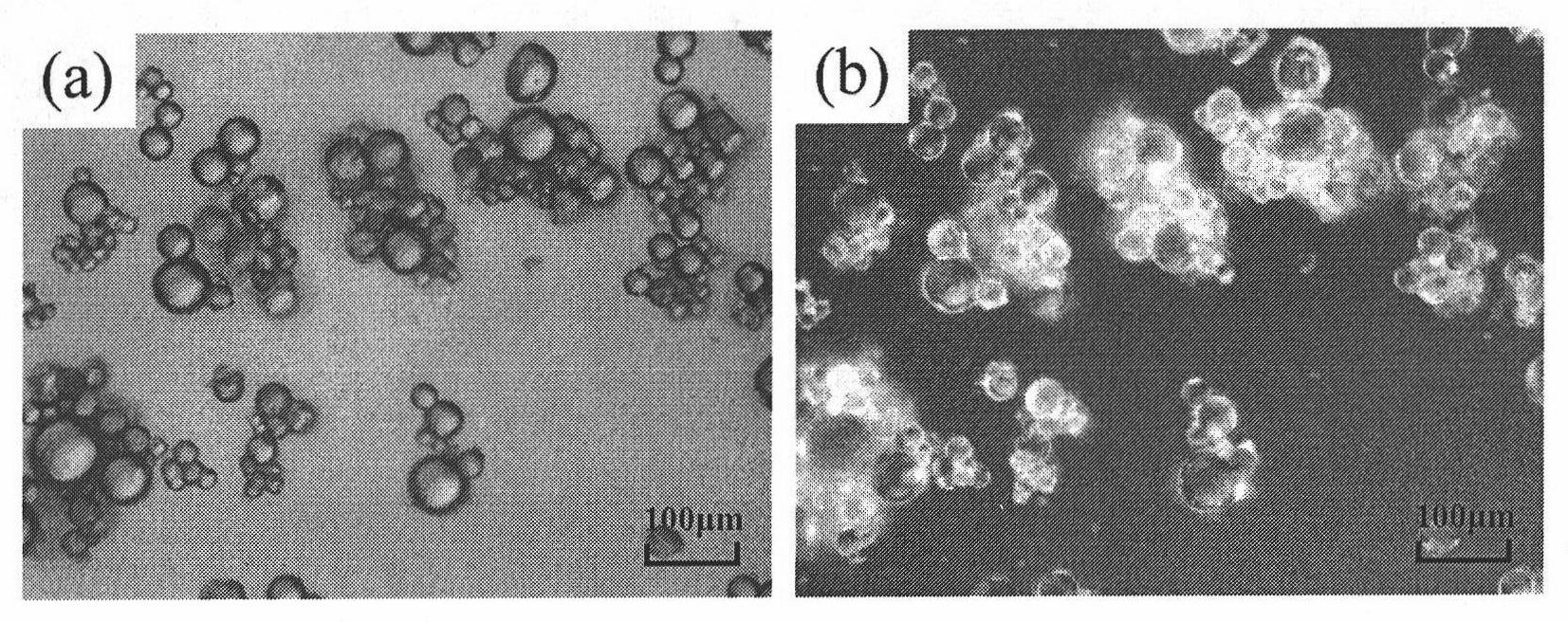

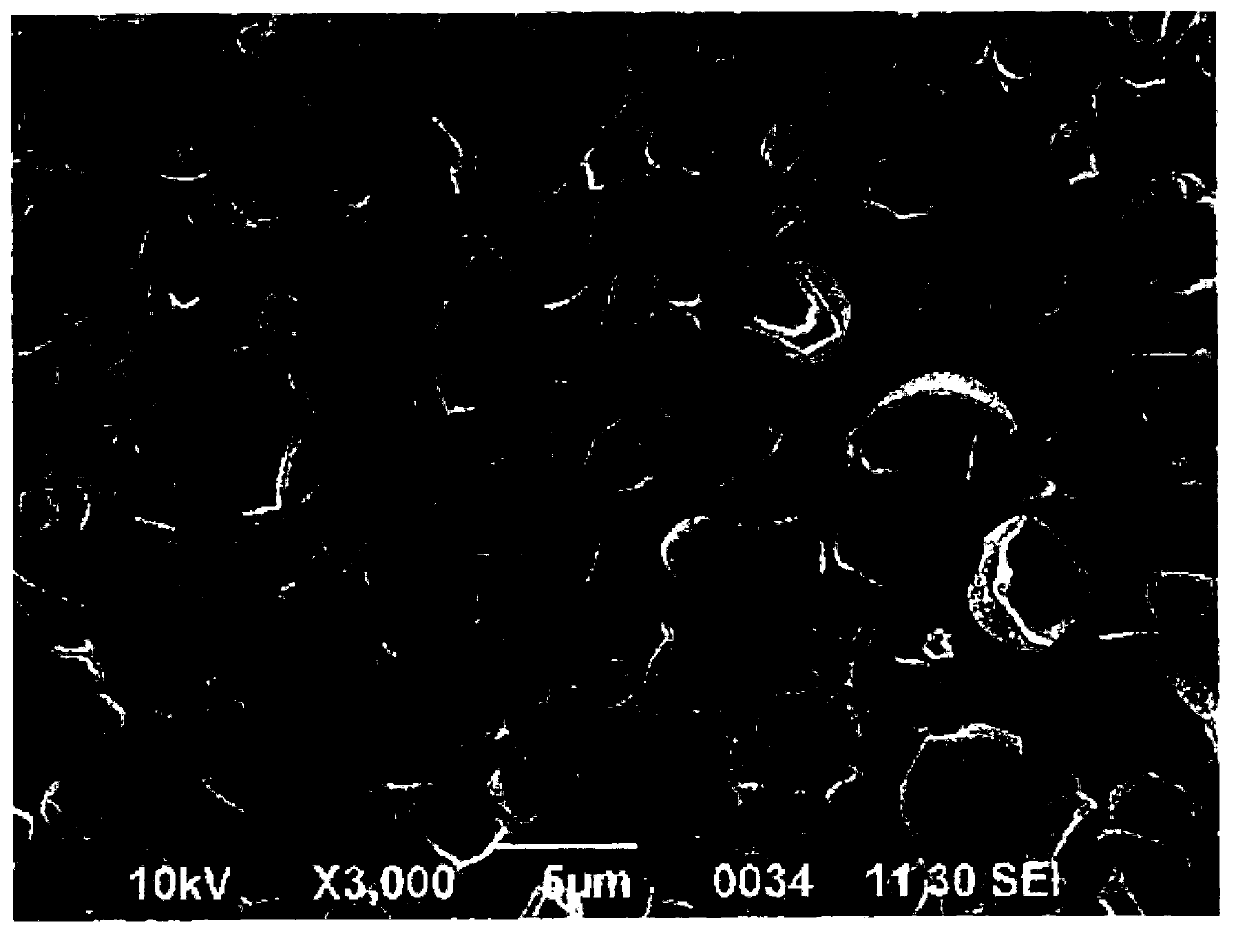

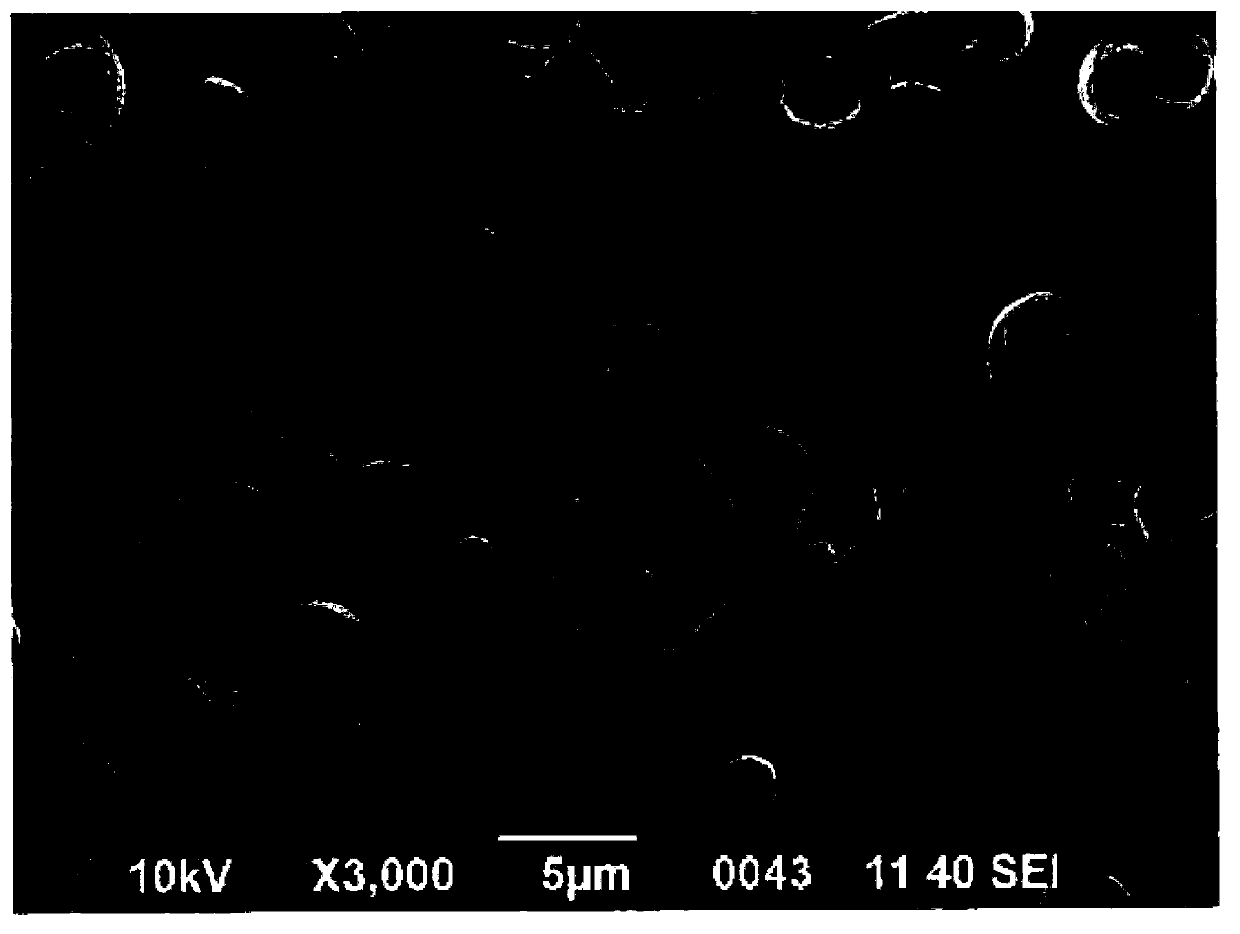

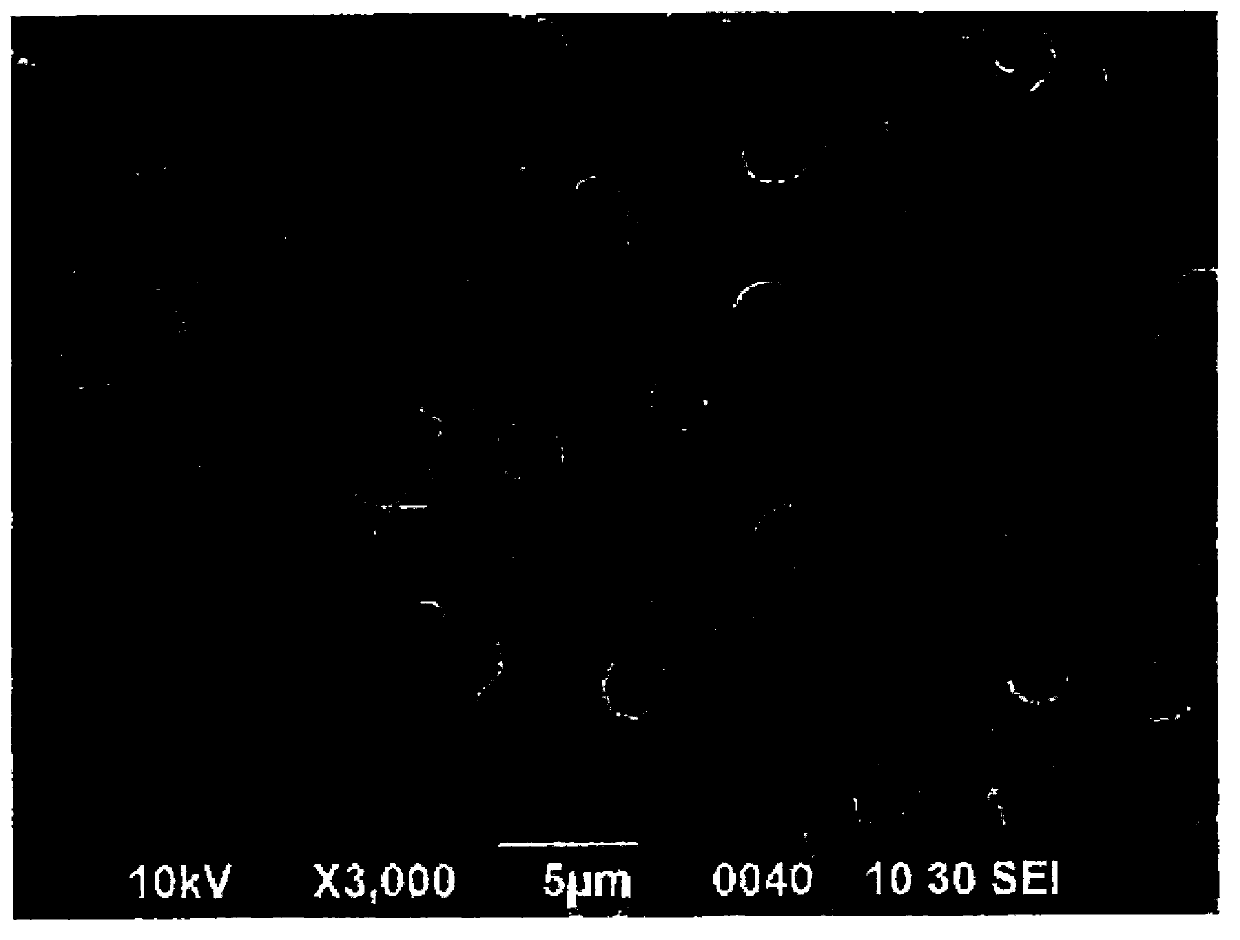

Hydrophobic hollow glass microsphere preparation method and prepared hydrophobic hollow glass microsphere thereof

InactiveCN101781083AHigh strengthHigh hollow rateGlass shaping apparatusCoatingsCalcium hydroxideLithium hydroxide

Owner:钱紫阁

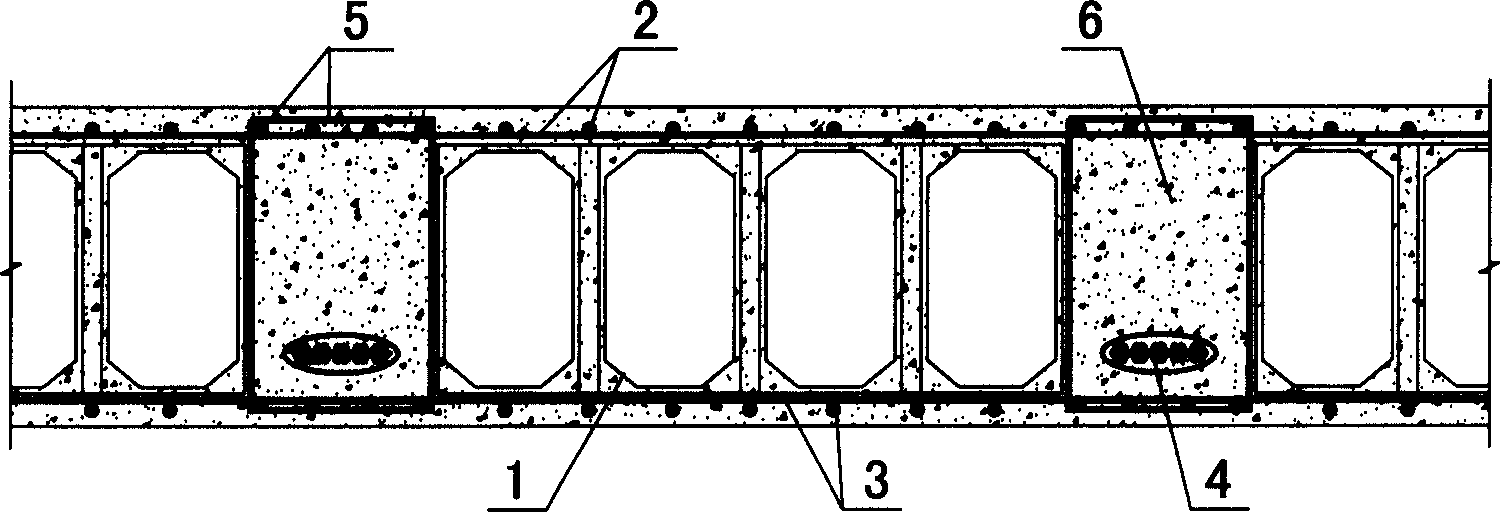

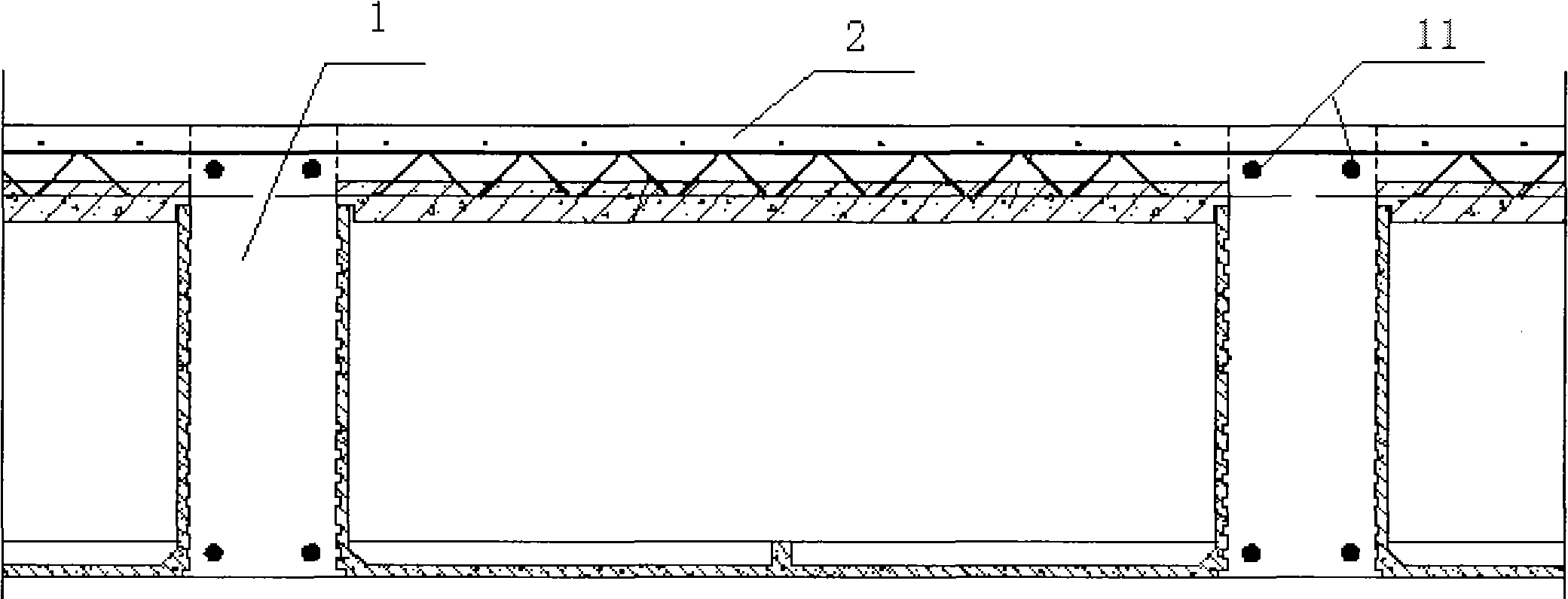

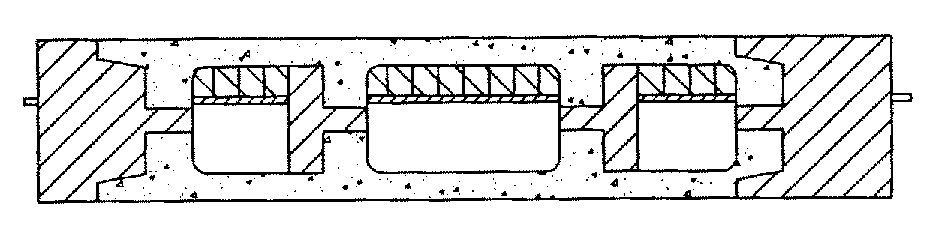

Lightweight material combination unit filled prestressed concrete cast-in-situ hollow slab

Disclosed is a prestressed concrete on-site pouring hollow slab filled with light material combined unit, which comprises light material combined unit, upper layer reinforcing steel bar, lower layer reinforcing steel bar, tendon, blind beam reinforcing steel bar and concrete. The light material combined unit consists of light tubes and connection bar, which is arranged between the upper layer reinforcing steel bar and the lower layer reinforcing steel bar, the combined unit tubes is in the same direction with the bigger bending moment within the slab, The blind beam is arranged at intervals of a certain distances, in which the tendon is centralized laid. Said on-site pouring slab has the advantages of both the prestressed structure and the hollow slab structure, has high hollow percentage, implements one time concrete pouring moulding, is suitable not only for one-way slab, but also for two-way slab. The slab has big span, light weight, good heat and sound insulation effects, good reliability, shock resistance and crack resistance.

Owner:徐焱

Preparation method for hollow glass mirco-bead

The invention relates to a method for preparing hollow glass bead, which comprises following steps: (1) preparing natrium silicate and boron, feeding them into spray drying machine, drying with temperature being inlet air of 180-300 Deg. C, and outlet being 120-145 Deg. C, collecting powder, which is solid spherical with diameter being 5-50 um; (2) feeding said powder from upper part of high temperature main tower of hollow glass bead energy-saving furnace, the temperature of inlet air in upper part is 400-650 Deg. C, the powder falls into the first and second under action of air force from air fan and normal air force from hole in lower part of pyramidale during falling from upper section to lower section. The temperature in lower pyramidale outlet is 115-150 Deg. C. The invention is characterized by simple construction of device and convenient preparation process.

Owner:曾佑成

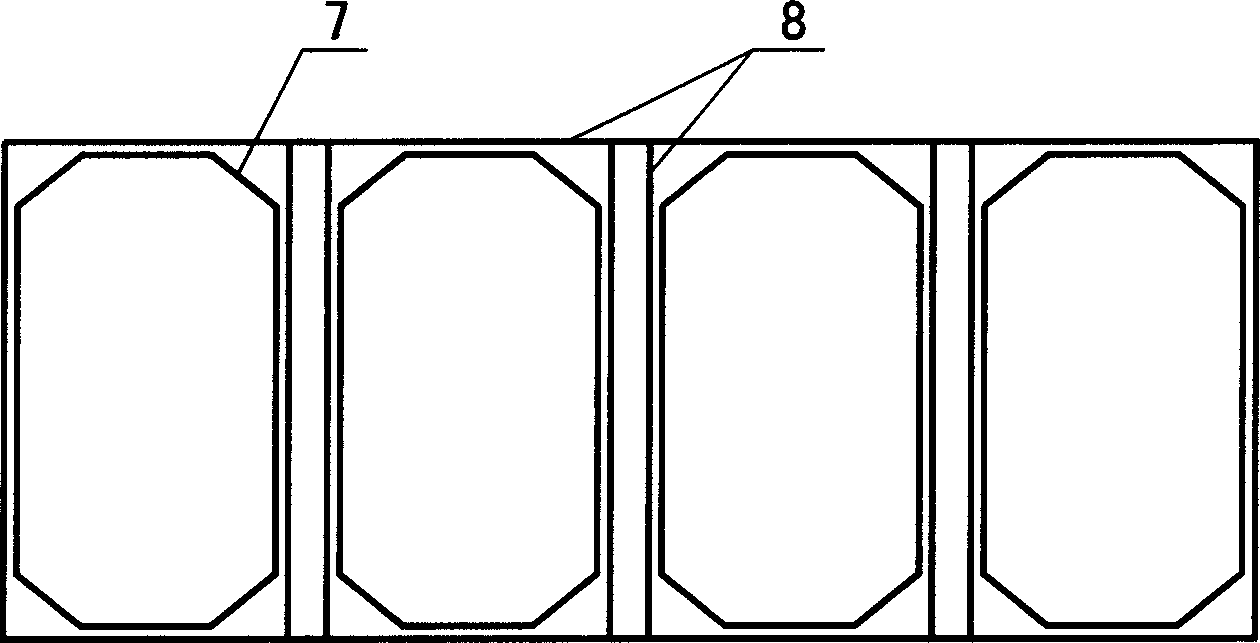

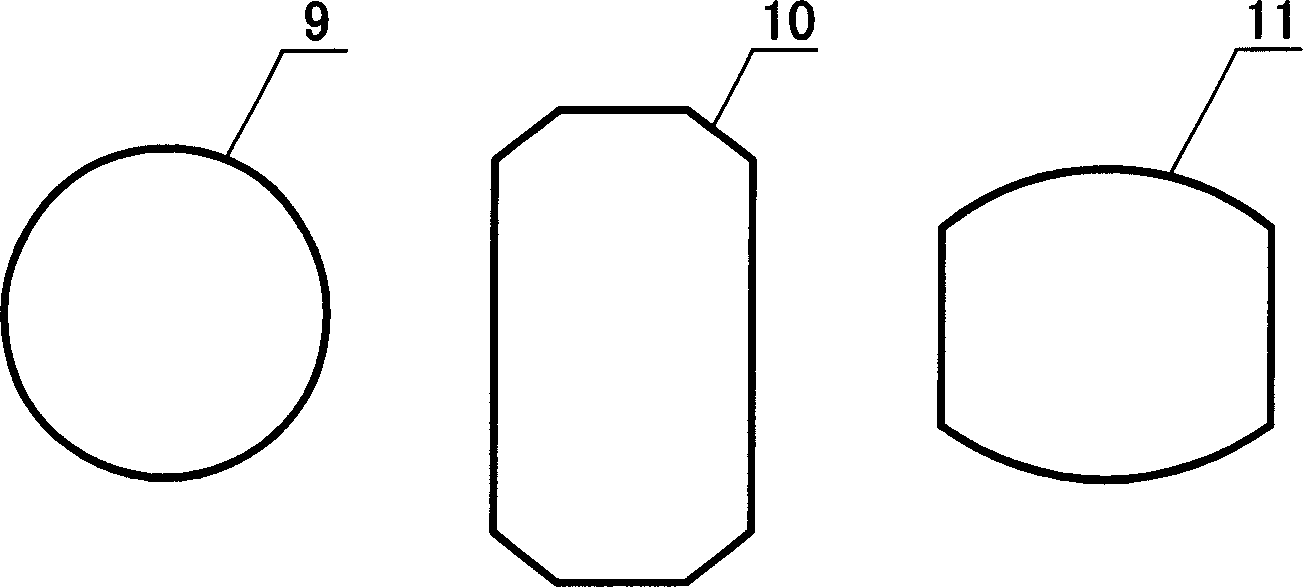

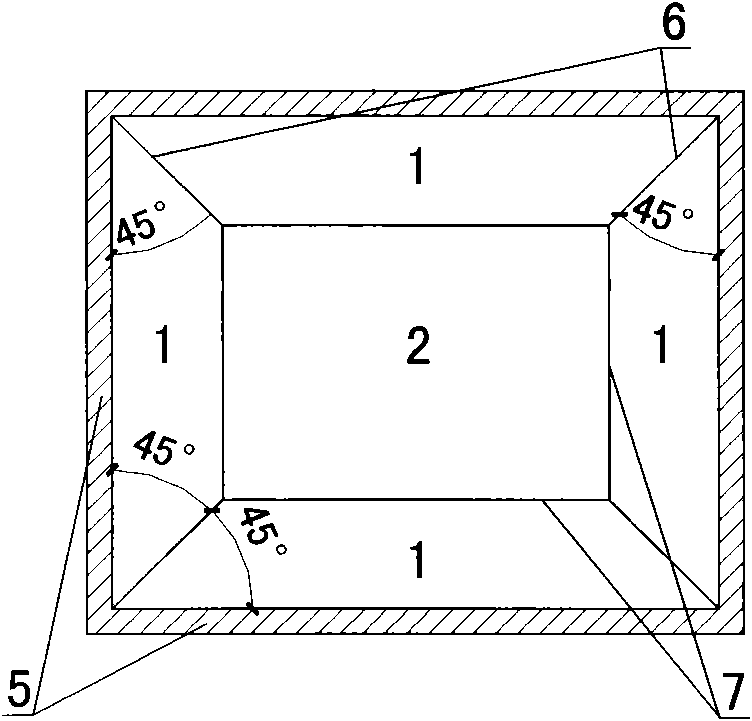

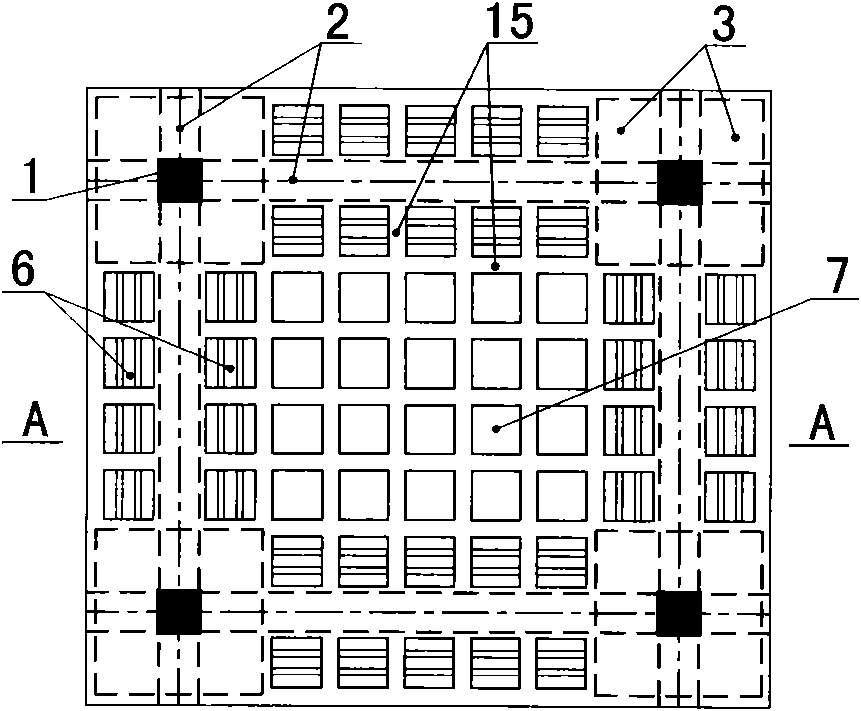

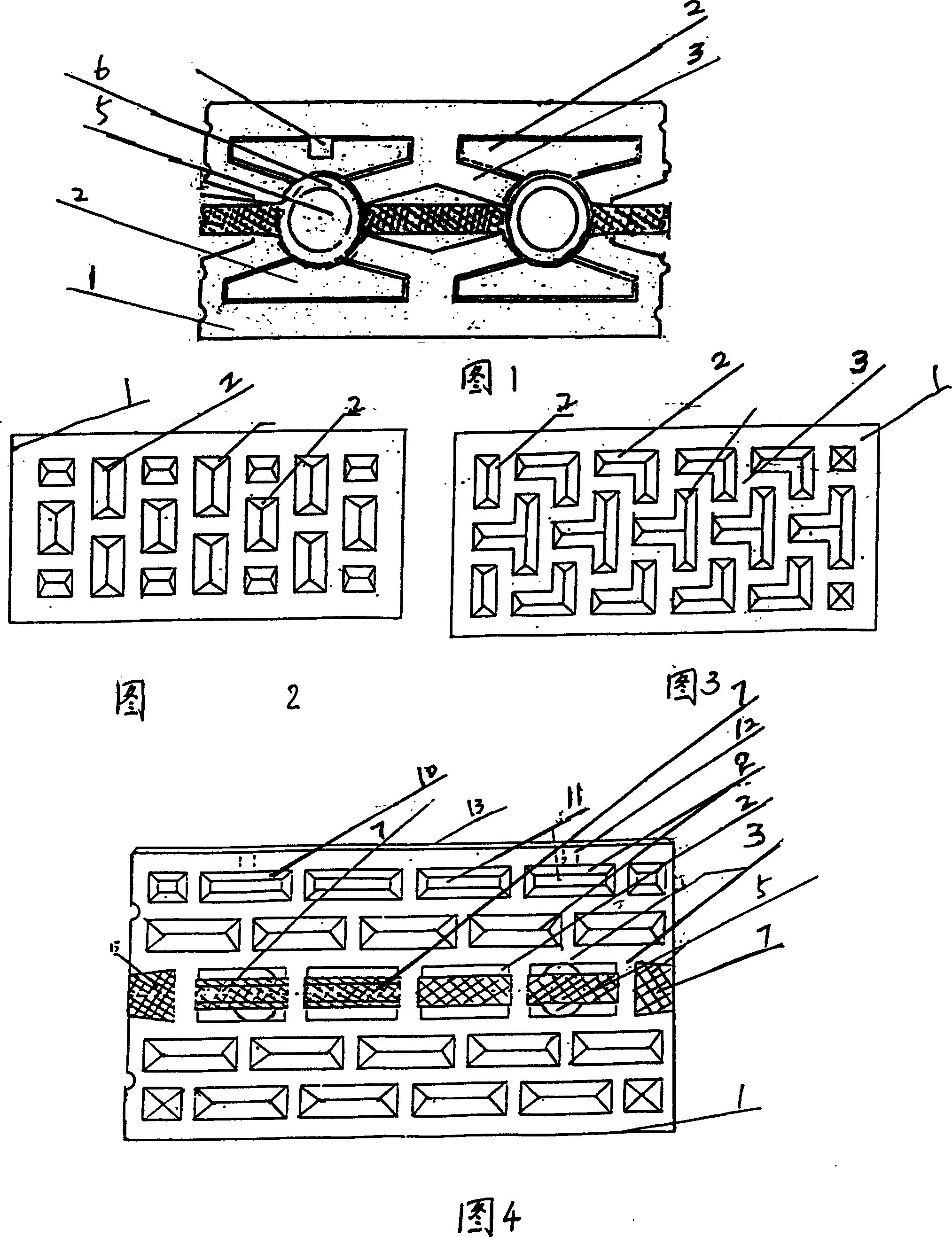

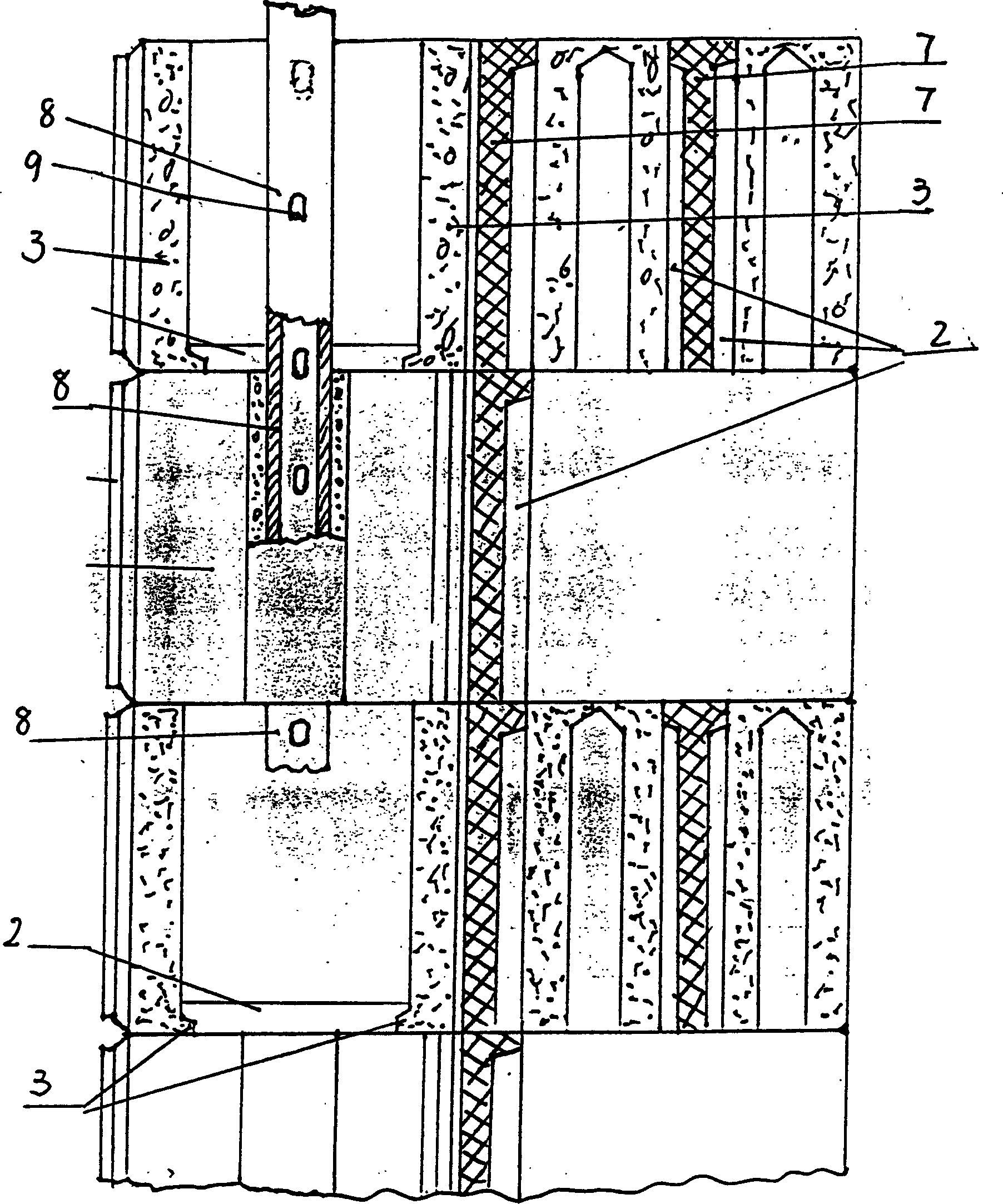

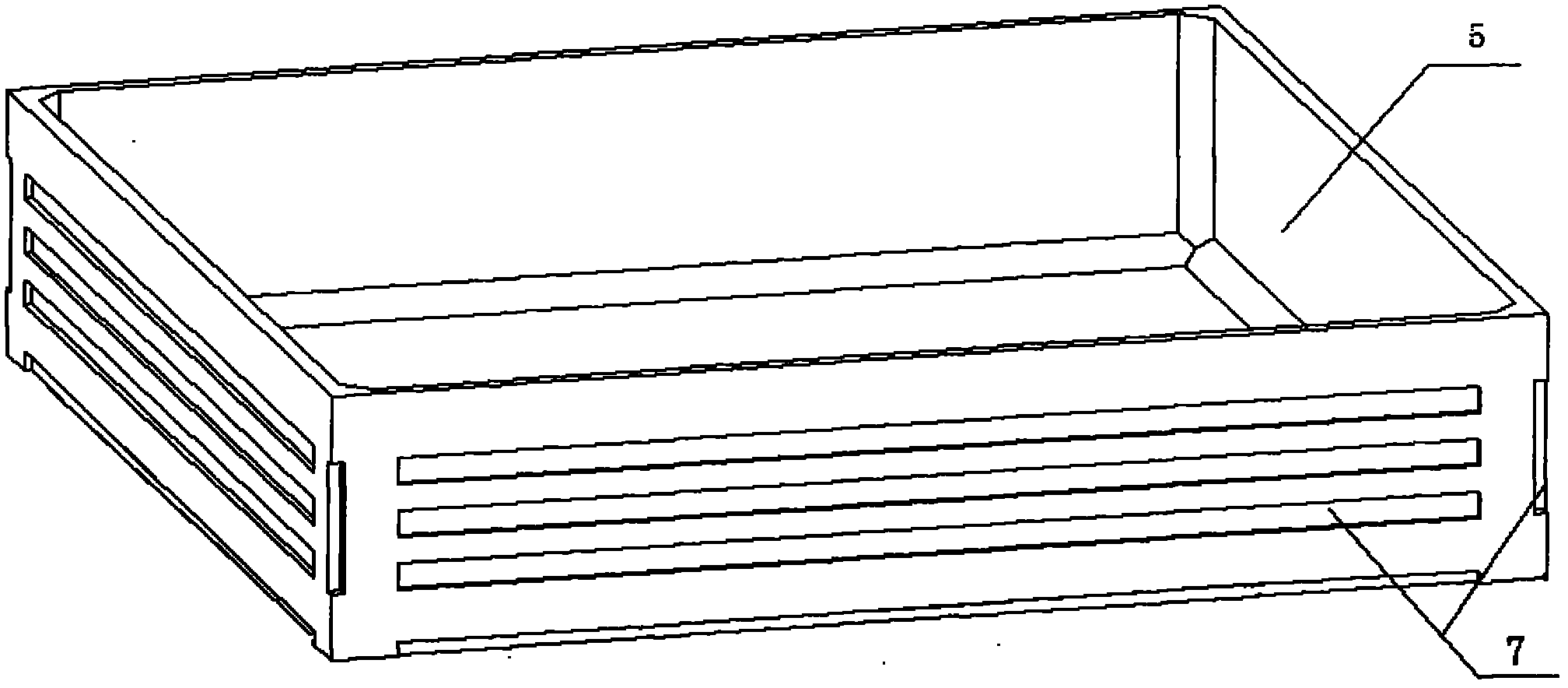

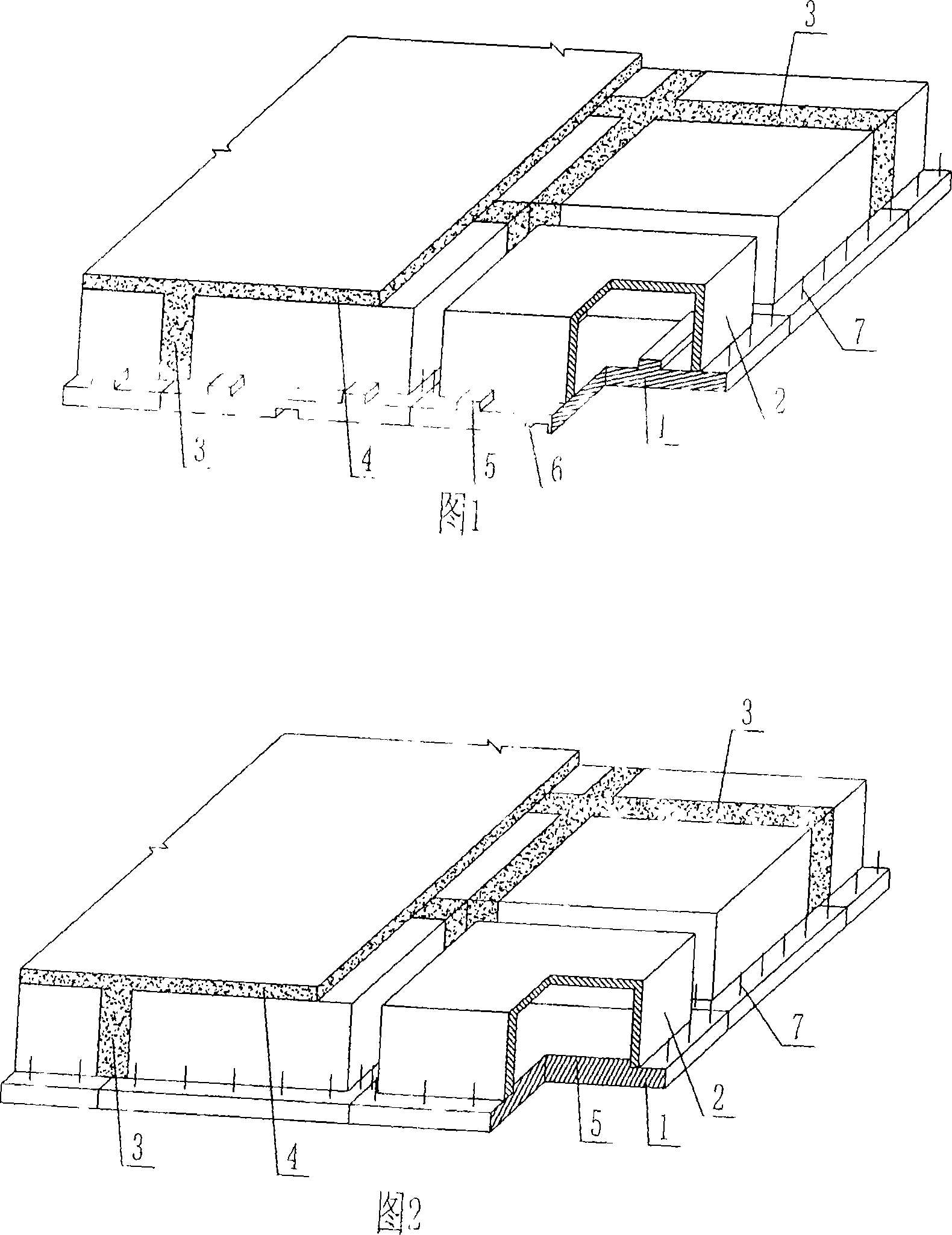

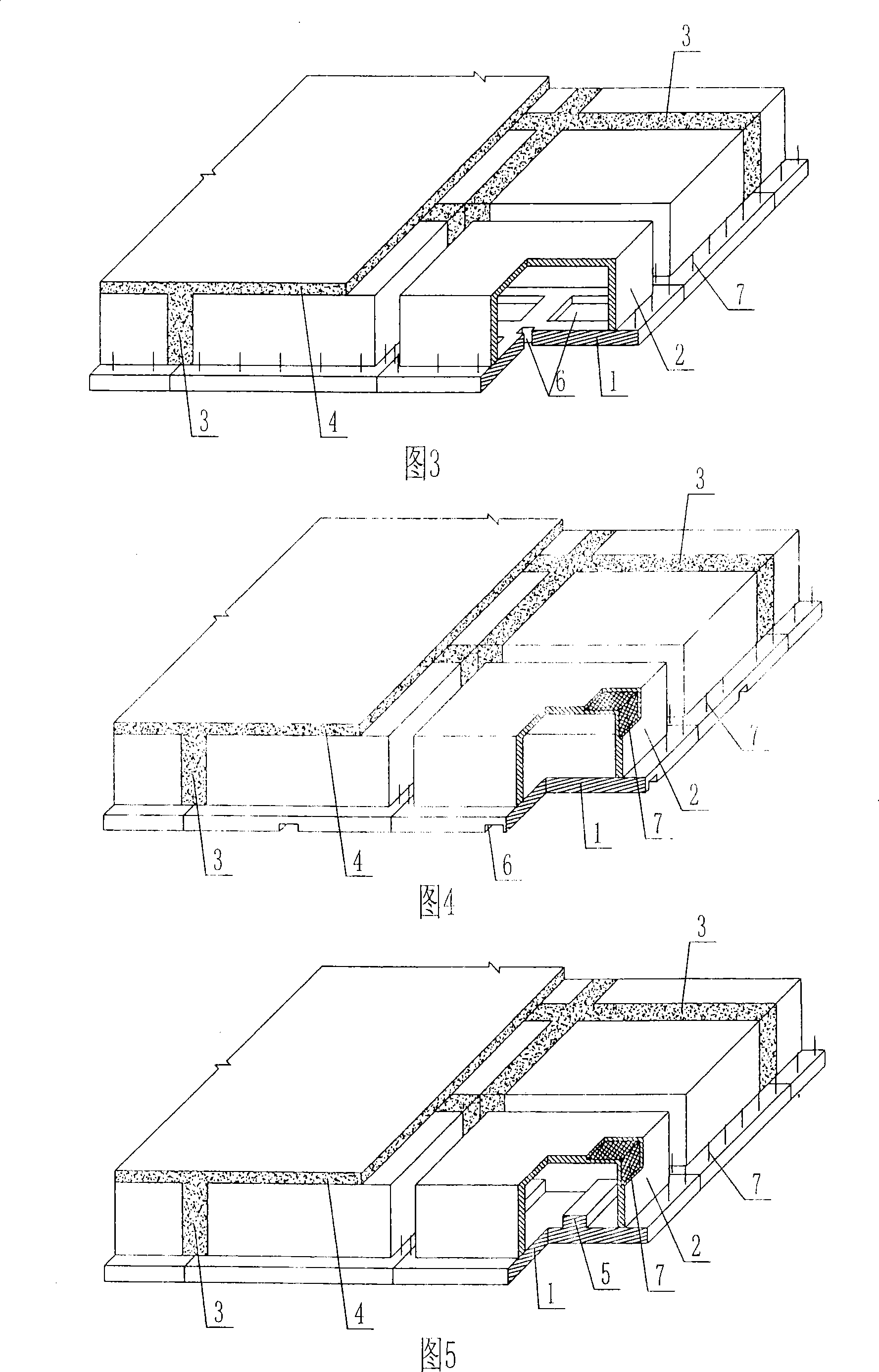

Hollow core slab for combined use of filling rods and filling boxes

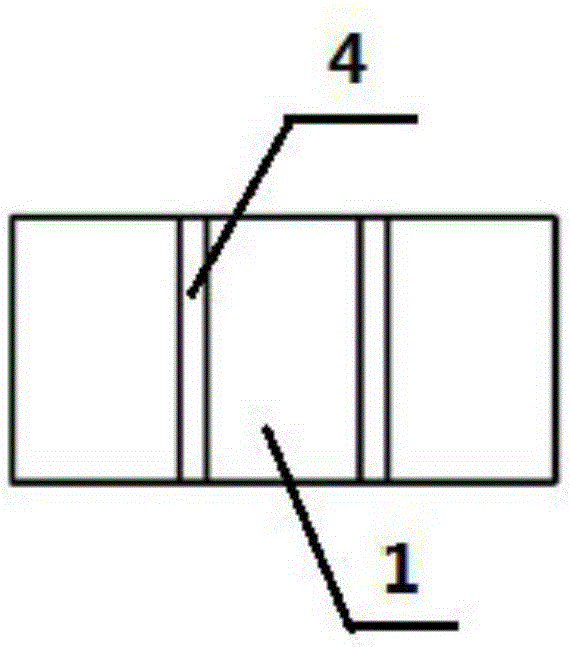

ActiveCN102031839AHigh hollow rateLow hollow rateFloorsBuilding material handlingCrack resistanceCombined use

The invention relates to a hollow core slab for the combined use of filling rods and filling boxes, and belongs to the field of construction of the common buildings. The hollow slab is a two-way slab and is divided into four peripheral hollow regions (1) and one central hollow region (2) on the plane, wherein filling rod combined blocks (3) and filling boxes (4) are embedded in the peripheral hollow regions (1) and the central hollow region (2) respectively; the central hollow region (2) is enclosed by four boundaries (7); each peripheral hollow region (1) is enclosed by one support edge (5), two oblique lines (6) and one boundary (7); each filling rod combined block (3) faces the direction vertical to the support edge (5) of the peripheral hollow region (1) where the filling rod combined block (3) is; and each filling rod combined block (3) arranged on the oblique line (6) faces the direction vertical to any one of support edge (5) adjacent to the oblique line (6). The hollow slab has large span and light weight in hollow floor system, has high reliability, shock resistance and crack resistance in a structure, and has high economy and applicability.

Owner:徐焱

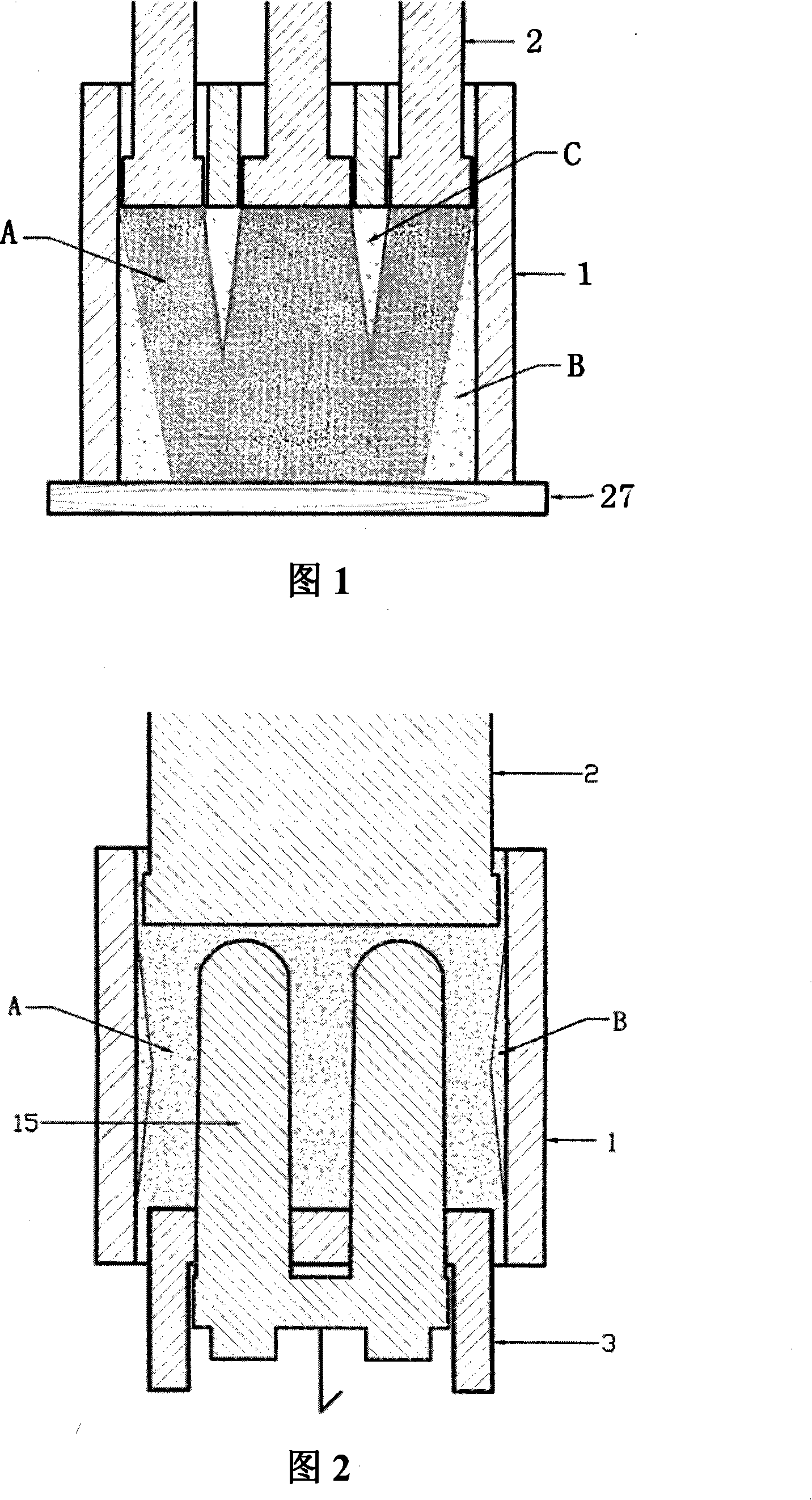

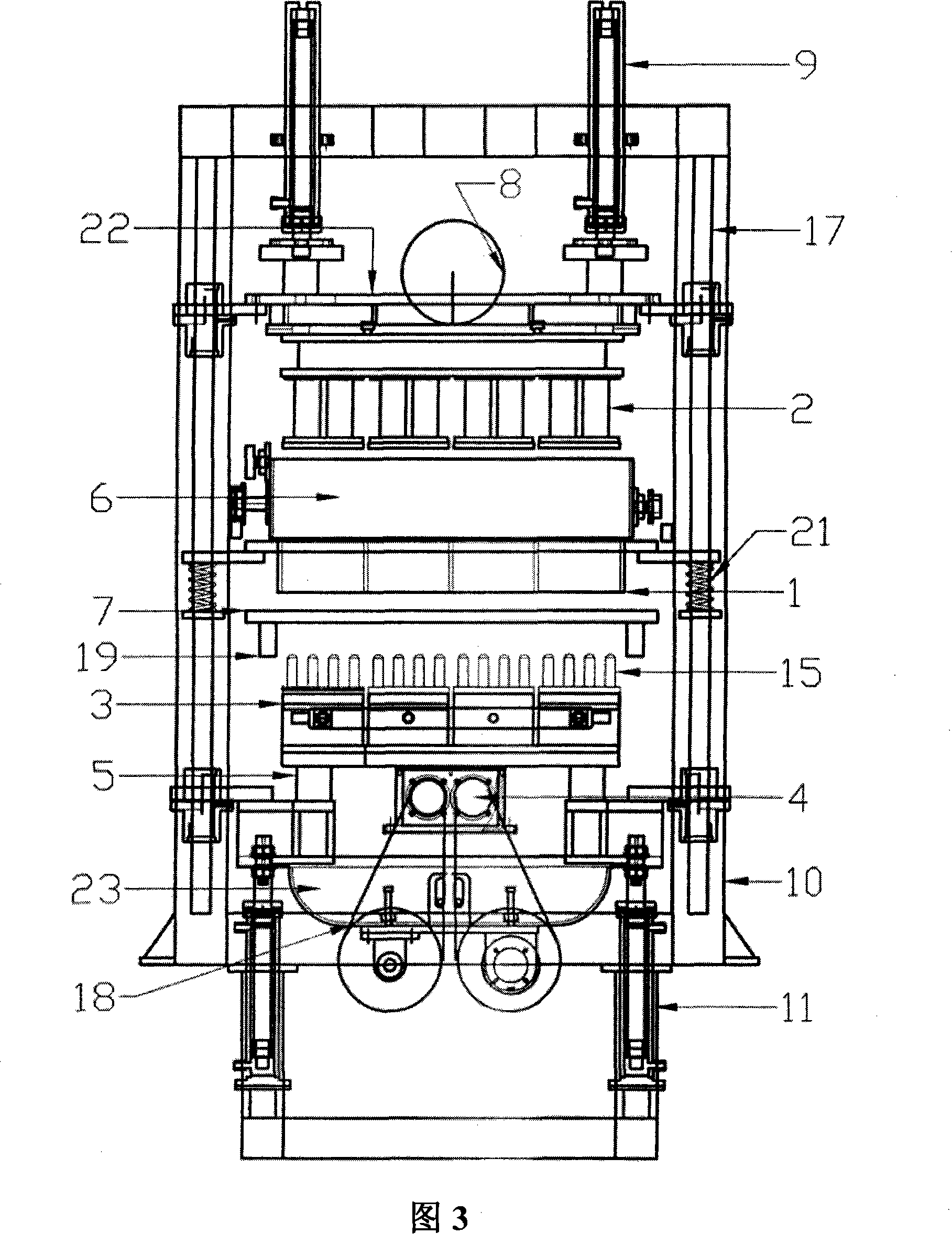

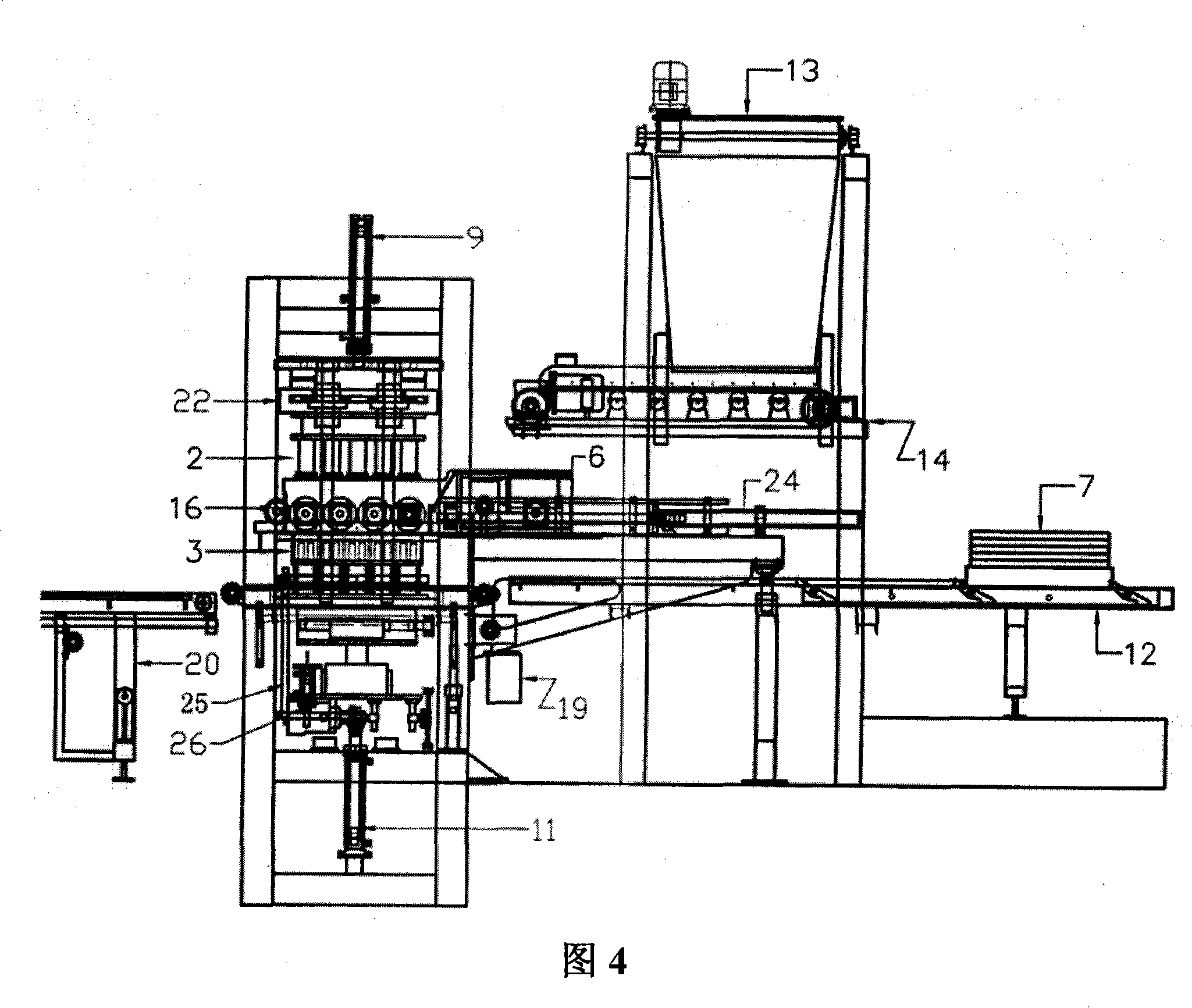

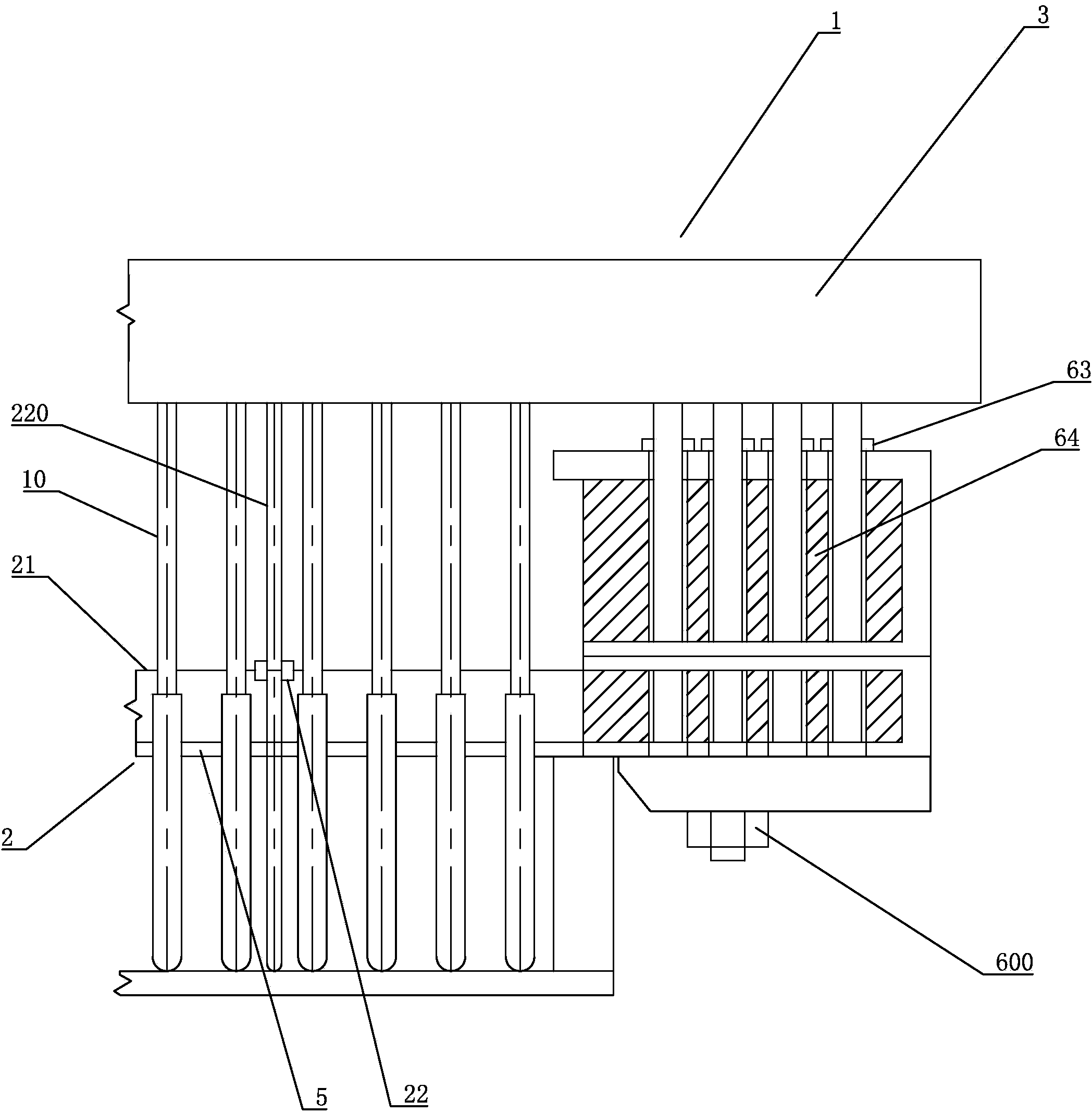

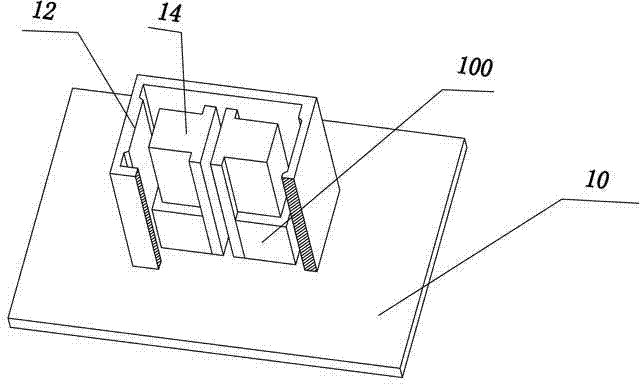

Bidirectional pressing-vibrating type building block shaping machine

InactiveCN101234509AReduce frictional resistanceLower recipe ratioCeramic shaping apparatusBrickThermal insulation

A bidirectional vibration block-forming machine belongs to a forming equipment of a building block or a brick. A molding box (1) is a framework cutting through from top to bottom; an outer framework of the molding box (1) is arranged on four columns (17) of a machine frame (10); a lower pressure head (3) is correspondingly arranged under the molding box (1) while an upper pressure head (2) is arranged above the molding box (1); the lower pressure head (3) is connected with a cylinder (11) of the lower pressure head through a lower excitation mechanism while the upper pressure head (2) is connected with a cylinder (9) of the upper pressure head. The molding box (1) adopts the suspension arrangement, which can greatly reduce the frictional resistance, add the density and overall strength, reduce the formulation ratio of cement gelling raw materials and the manufacture cost and improve the vibration efficiency with lower vibration force, and can be made into bricks or brick products with multi-row, be convenient for material-saving and thermal insulation with a high hollow ratio, improve the grade of the wall materials and create beneficial conditions for the development of heat-preservation and heat-insulation products.

Owner:武汉市快郑建材机械制造有限责任公司 +1

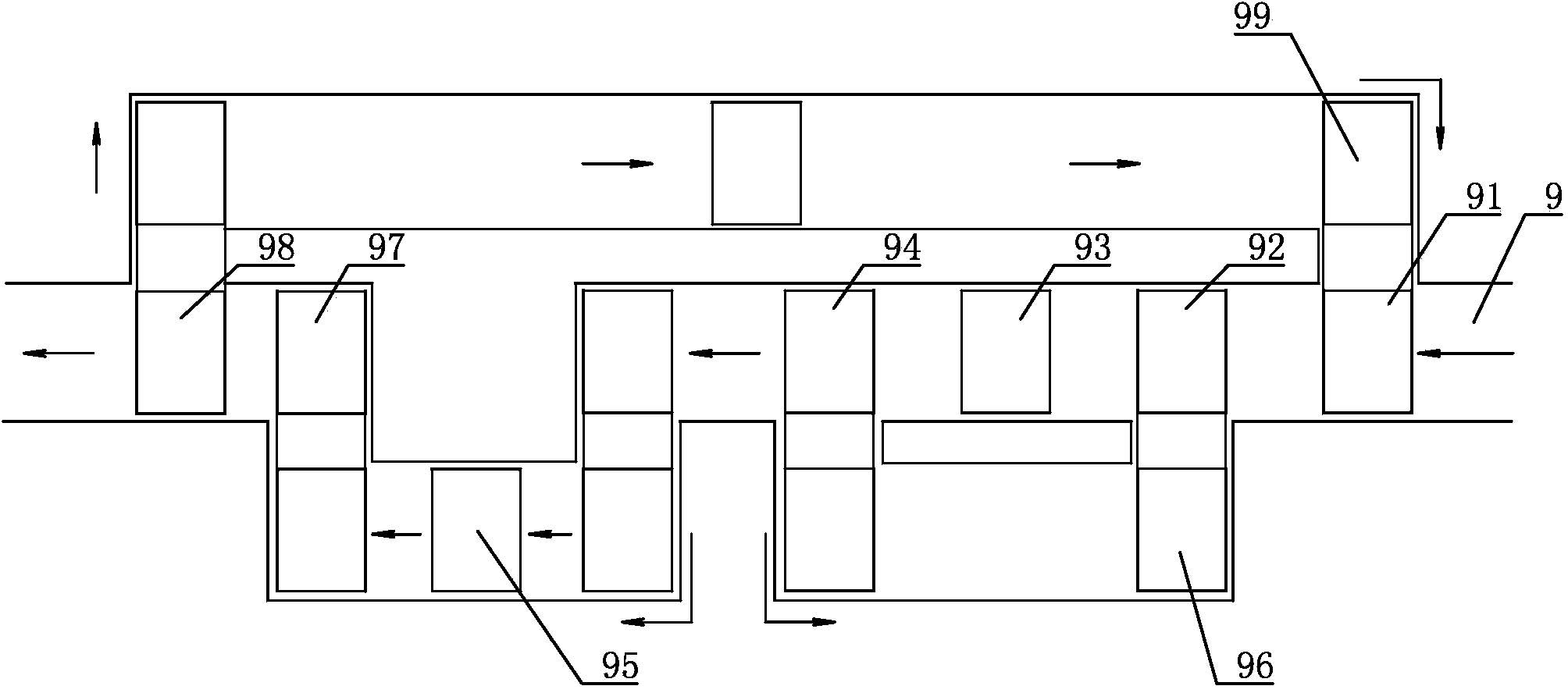

Split inserting type hole forming die and device and automatic manufacturing method of perforated brick of split inserting type hole forming die

The invention discloses a split inserting type hole forming die which comprises an upper die and a lower die. The upper die is formed by arranging a plurality of insertion rod beams which are provided with hole forming insertion rods. The lower die comprises an insertion hole board, the two ends of the lower die are provided with side boxes for supporting, and guide rods are arranged on the insertion rod beams. Annular grooves are formed in the guide rods, and guide tubes are arranged in the side boxes. The top ends of the guide tubes are fixedly connected with clamping springs, and the upper die is supported through the clamping springs and the side boxes. The insertion rod beams are divided into more than two groups according to a downwards-moving order, and each group of the insertion rod beams comprises the plurality of insertion rod beams, the insertion rod beams of the same group are driven by the same pressure vibration table, and the rods are inserted into materials in batches to form holes. The split inserting type hole forming die is combined with a pole pulling device, and therefore the hole forming process of inserting the rods and pulling the rods out of a perforated brick can be finished. According to the split inserting type hole forming die, perforated brick products are more diverse, perforated bricks with smaller holes and higher hollow rates can be obtained, and in addition, the production efficiency is high, and the shapes of the holes are complete.

Owner:桂林市城昌建材科技有限公司

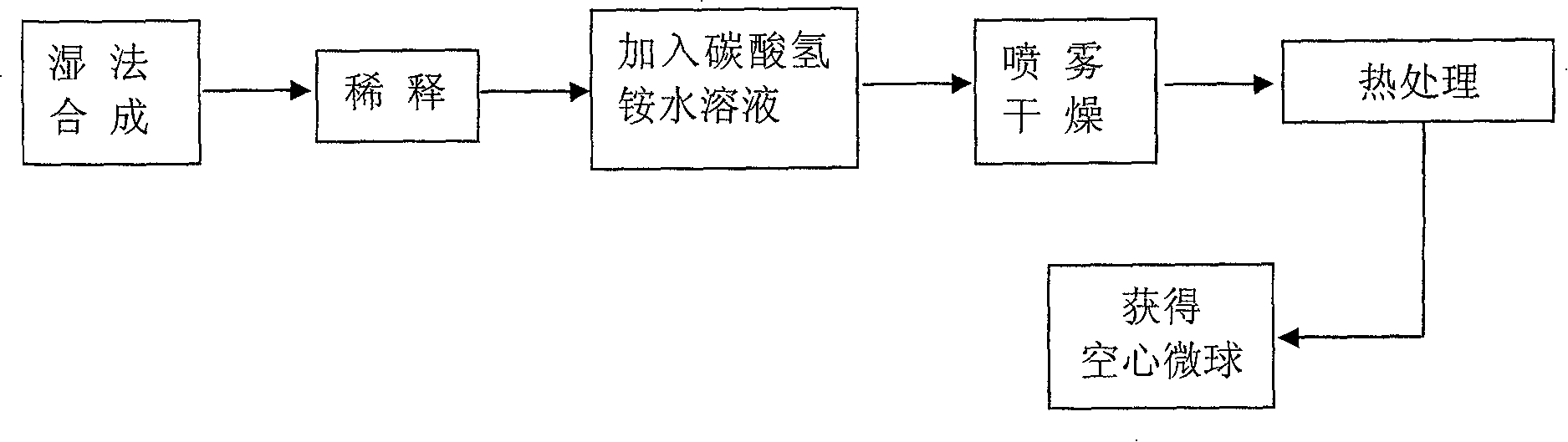

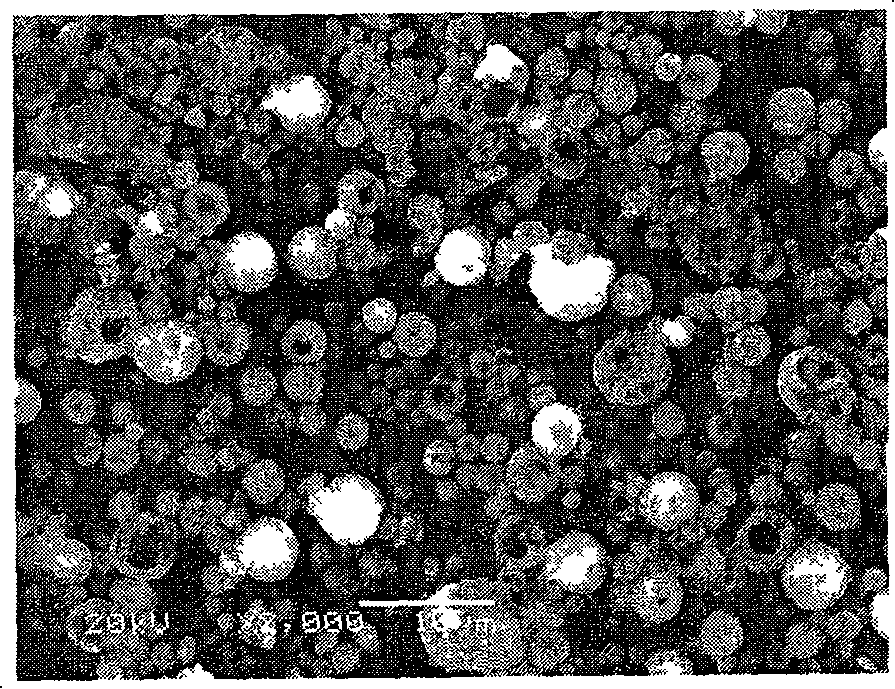

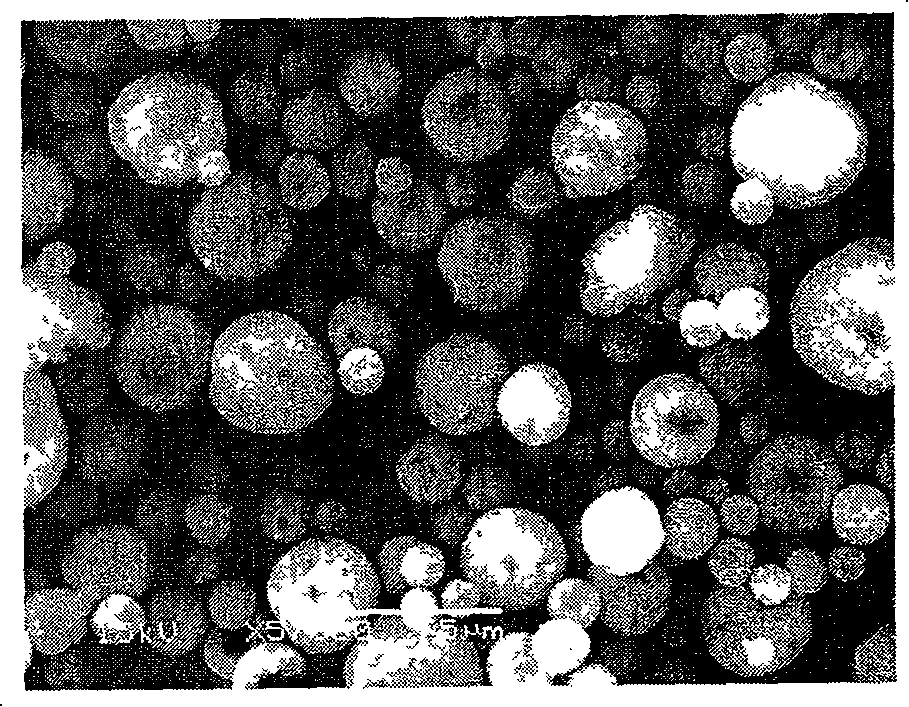

Preparation method of hydroxy phosephorite hollow microball

InactiveCN100398433CSmall sizeUniform particle sizePhosphorus compoundsProsthesisCalcium nitrate tetrahydrateApatite

The present invention discloses a method for preparing hydroxyapatite hollow microsphere. Said method includes the following steps: using tetrahydrate calcium nitrate and ammonium hydrogen phosphate as raw material, adopting chemical precipitation method to prepare hydroxyapatite slurry, then diluting said hydroxyapatite slurry by using distilled water, adding ammonium hydrogen carbonate as additive, uniformly stirring them, spray drying, making following heat treatment so as to obtain the hydroxyapatite hollow microsphere formed from nano grains.

Owner:SHANDONG UNIV

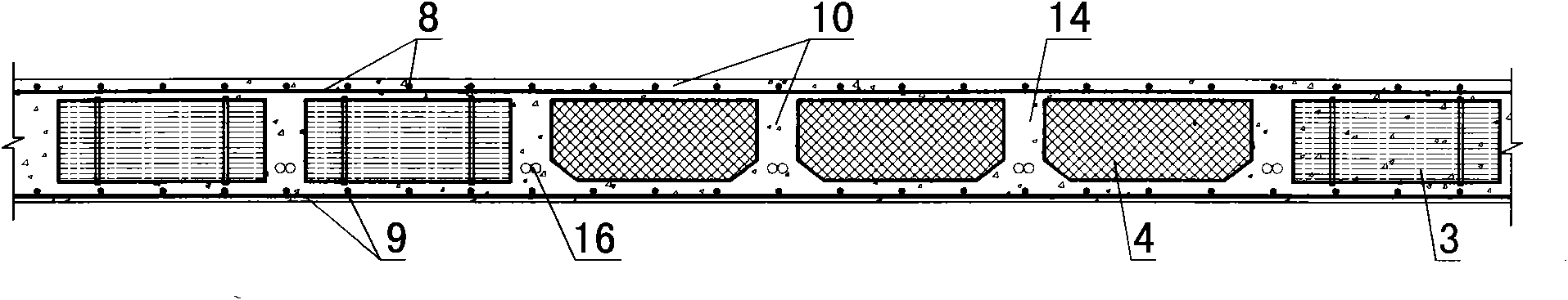

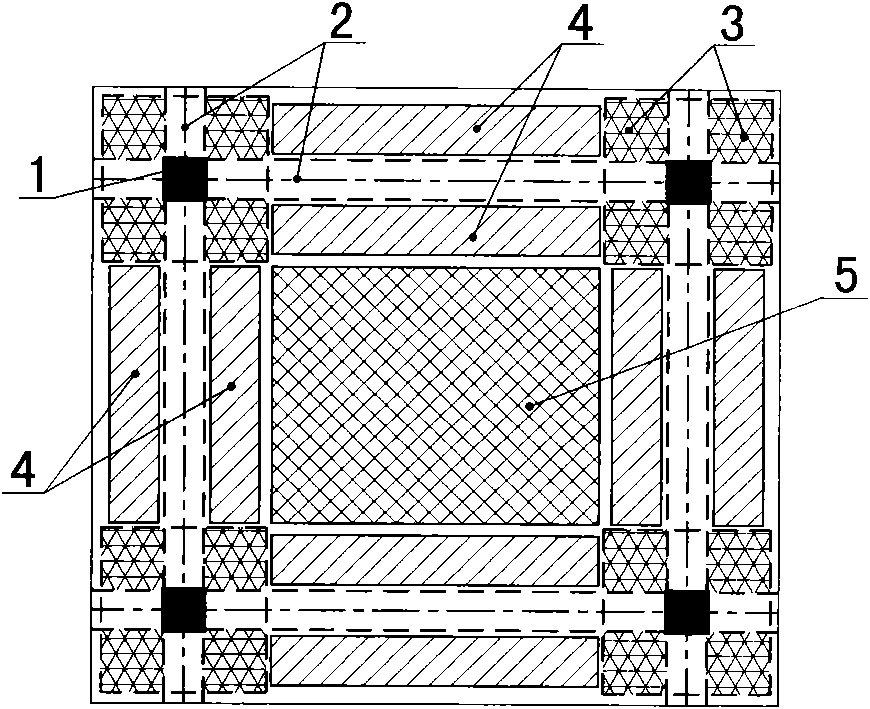

Slab-column structure hollow slap with mixed use of filling rod and filling box

The invention relates to a slab-column structure hollow slap with mixed use of a filling rod and a filling box, and belongs to the field of general building constructions. The hollow slap comprises a column (1), a beam (2), a column side solid area (3), a beam side hollow area (4) and a central hollow area (5), and is characterized in that: a filling rod combined block (6) is arranged in the beamside hollow area (4); the orientation of the filling rod combined block (6) in the beam side hollow area (4) is accordant with the direction of the beam (2) which is adjacent to the filling rod combined block (6); the filling box (7) is arranged in the central hollow area (5); and the filling rod combined block (6) and the filling box (7) are positioned between an upper layer steel bar (8) and a lower layer steel bar (9) and are permanently embedded in concrete (10). A hollow floor provided by the invention is reasonably stressed along with a high hollow ratio, and the structure of the hollowfloor also has high reliability, earthquake resistance and cracking resistance, so the hollow floor has high economical efficiency and practicability.

Owner:宁夏千弓预应力技术工程有限公司

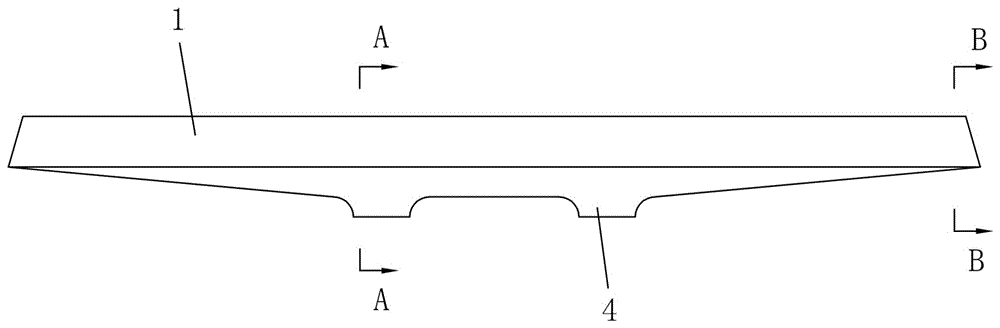

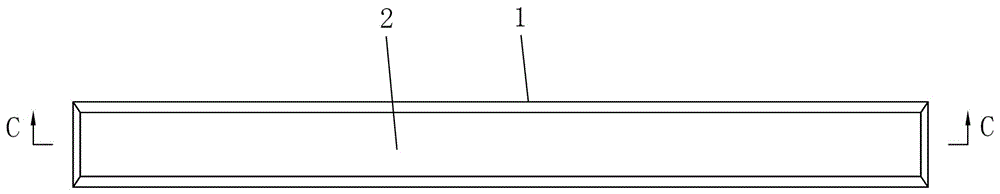

Steel and ultra-high performance concrete light combined box type cover beam and manufacturing method thereof

ActiveCN105803916AHigh hollow rateLose weightCeramic shaping apparatusBridge structural detailsMaterials scienceSteel plates

The invention discloses a steel and ultra-high performance concrete light combined box type cover beam and a manufacturing method thereof. The cover beam comprises a hollow box type body formed by pouring ultra-high performance concrete, a steel plate is pre-buried in the top face of the hollow box type body, and a plurality of shear connectors buried in the hollow box type body are arranged on the lower surface of the steel plate. The steel and ultra-high performance concrete light combined box type cover beam is of a fully-prefabricated structure. The manufacturing method comprises the steps of designing the structural form and dimension of the cover beam, manufacturing the steel plate with the shear connectors, carrying out pouring with an inversion prefabricating method, carrying out curing and disassembling a formwork. The steel and ultra-high performance concrete light combined box type cover beam has the advantages of being high in tensile property, light, convenient and fast to construct, easy to hoist, good in economy and the like.

Owner:邵旭东 +3

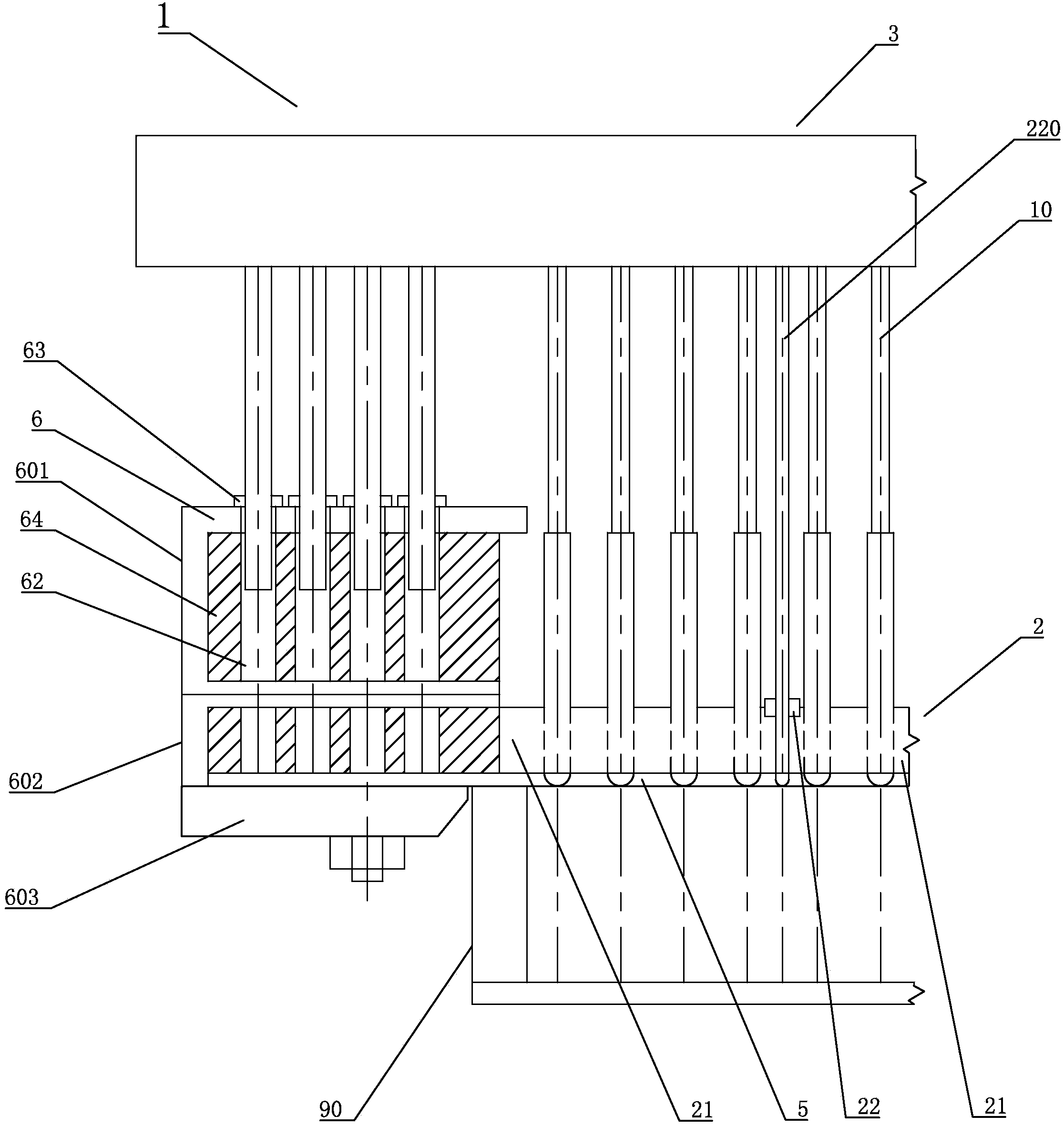

Multifunctional fast construction energy conservation bricks (building blocks) and dies therefor

InactiveCN1570317AImprove insulation performanceImprove noise immunityMouldsBuilding componentsSurface plateBlind hole

The present invention relates to a multifunctional fast construction energy conservation brick (building block) which includes brick (building block) body disposed with blind holes or meropia holes in malposition arrangement, the top end surface namely the top closing surface for the blind holes or meropia holes is disposed with pits. The die of the invention includes an upper die, a lower die and a drive oil cylinder, the drive oil cylinder is connected to the main top plate, the upper end of the oil drive rod disposed on the top of the main top plate is connected to a transition plate and the lower end is connected to the top plate. One end of a spring drive rod disposed on the transition plate passes through a core column connection plate and connected to the lower end of a spring disposed on a die frame, the upper end of the spring is connected to the panel of the die frame. One end of the lower die connection rod is connected to an auxiliary top plate disposed between the main top plate and the transition plate, and another end passes through the transition plate and the core column connection plate and is connected to the lower die. The die guide rods disposed at two ends of the dies are packing the guide rod connection plate, the die frame panel, the core column connection plate, the transition plate, the auxiliary plate, the main top plate and the two ends of the lower guide rod connection plate.

Owner:史世英

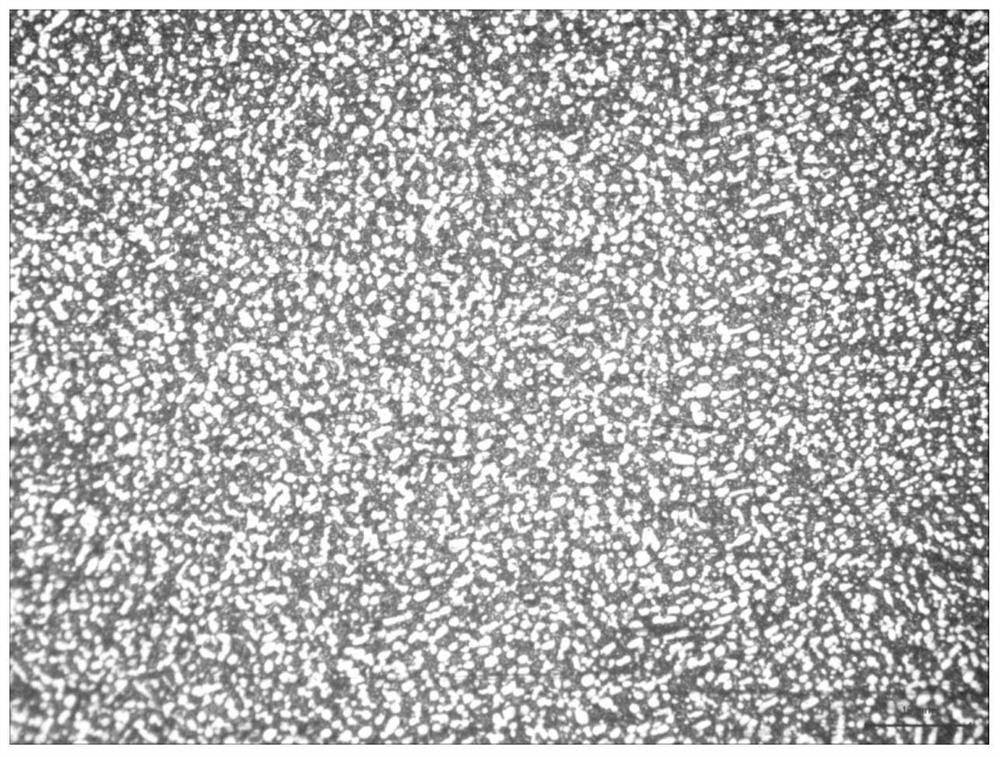

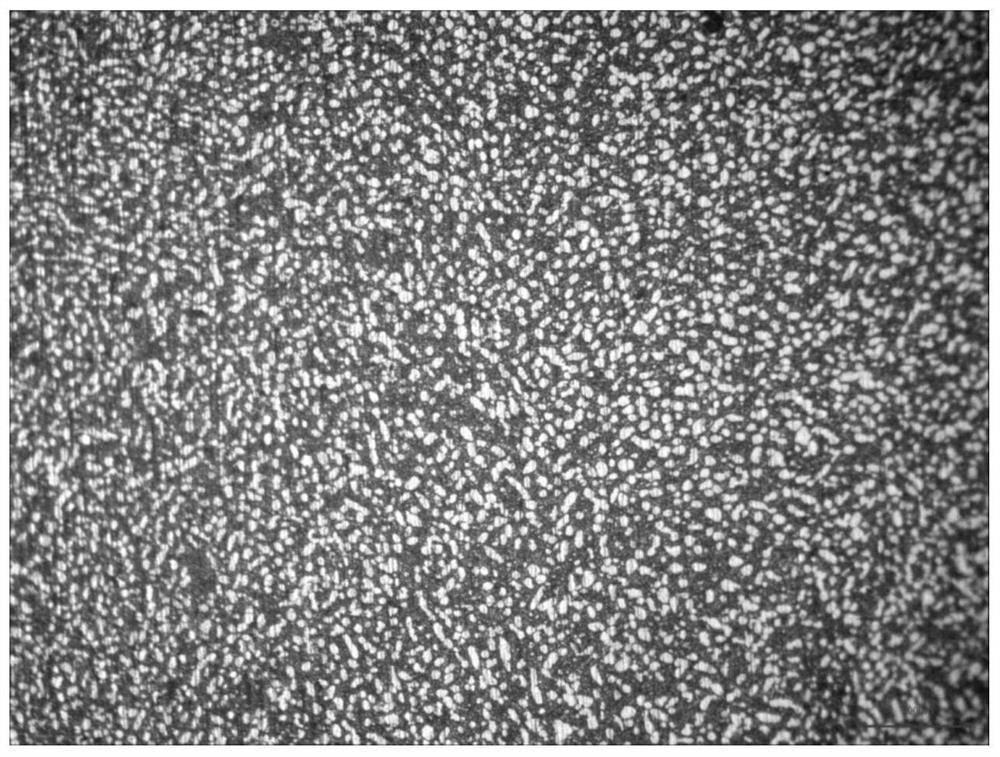

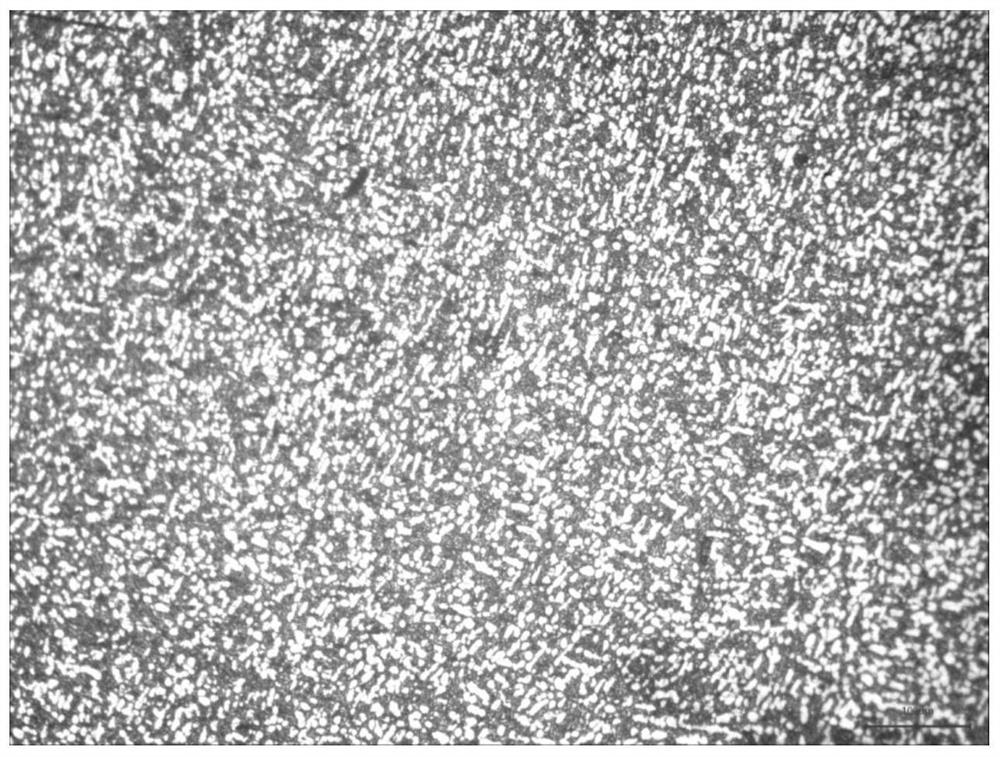

Alpha + beta type two-phase titanium alloy for aero-engine fan blade and preparation method of alpha + beta type two-phase titanium alloy

The invention relates to an alpha + beta type two-phase titanium alloy for an aero-engine fan blade and a preparation method of the alpha + beta type two-phase titanium alloy for the aero-engine fan blade. The preparation method of the alpha + beta type two-phase titanium alloy for the aero-engine fan blade comprises the following steps that S1, the following chemical components are obtained: 4.2%-5.6% of aluminum, 7.5%-8.8% of vanadium, 0.18%-0.24% of oxygen, less than or equal to 0.5% of iron, less than or equal to 1% of niobium, 0.4%-0.8% of silicon, less than or equal to 0.05% of carbon, less than or equal to 0.05% of nitrogen, less than or equal to 0.015% of hydrogen and the balance of titanium and impurity elements; S2, the titanium alloy cast ingot is subjected to first-stage upsetting and drawing; S3, under the conditions of the preset temperature and the preset deformation amount, after reversing is conducted, second-stage upsetting and drawing are conducted on the titanium alloy cast ingot; S4, the titanium alloy cast ingot is heated to the temperature above the phase transformation point, and then the titanium alloy cast ingot is subjected to third-stage upsetting and drawing; S5, the titanium alloy cast ingot is heated to the temperature below the phase transformation point, then fourth-stage upsetting and drawing are conducted on the titanium alloy cast ingot, and a titanium alloy material is obtained; and S6, the titanium alloy material is subjected to heat treatment. The preparation method is applied to the technical field of titanium alloys.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Preparation Method Of Hydrophobic Hollow Glass Micro Bead And Hydrophobic Hollow Glass Micro Bead Thereof

InactiveUS20120058343A1High strengthLow costSynthetic resin layered productsCellulosic plastic layered productsCalcium hydroxideLithium hydroxide

A preparation method of low cost hydrophobic hollow glass micro bead by means of spray drying includes the steps of adding an atomized mixed solution of boric acid, potassium hydroxide, lithium hydroxide, and calcium hydroxide into a high-speed stirred water glass solution, spray drying the solution, and then treating the surface of the micro bead with an organic silicon water repellent.

Owner:ZHEJIANG TONGDA MACHINERY

Hollow glass microsphere prepared by soft template method and preparation method thereof

The invention relates to a hollow glass microsphere prepared by a soft template method and a preparation method thereof. The hollow glass microsphere comprises the following raw materials in parts by weight: 93 parts of tetraethoxysilane, 11-35 parts of n-amine, 1.5-3.5 parts of inorganic ionic salt and 8-20 parts of borax, wherein, the n-amine is at least one of n-octylamine, n-nonyl amine or n-decylamine; and the inorganic ionic salt is at least one of sodium chloride, potassium chloride, calcium chloride, sodium sulfate, sodium carbonate and potassium carbonate. The balling rate of the hollow glass microsphere exceeds 99% and the hollow rate thereof exceeds 99%; the hollow glass microsphere has uniform structure, and the particle size thereof can be self-regulated and controlled into 10-400mum as needed; the corresponding stacking density is 0.60-0.15g / cm<3>; and the hollow glass microsphere can be widely applied to fields such as automobile, building materials, heat insulation, sound insulation, deep-sea drilling, aerospace and the like.

Owner:南京龙驹科技实业有限公司

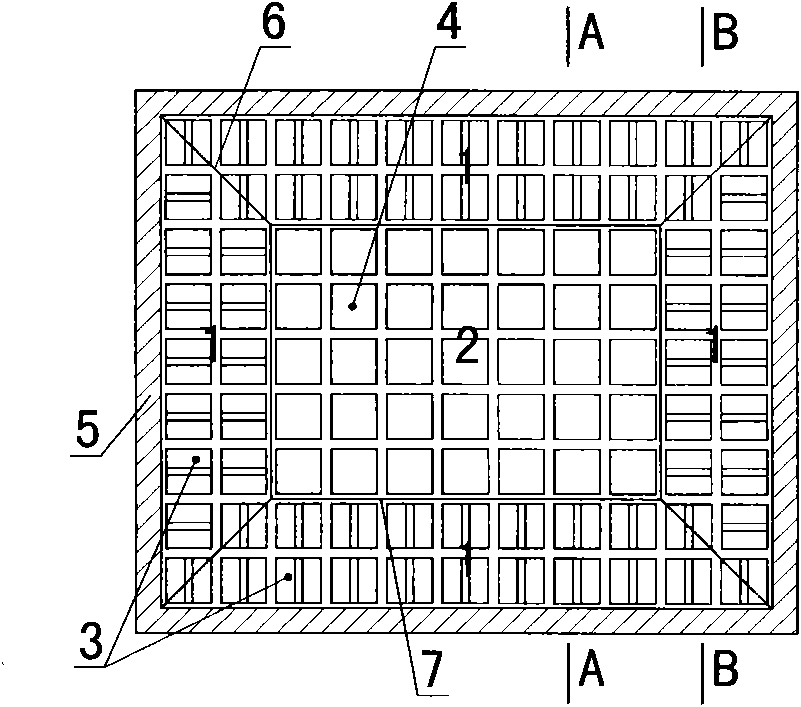

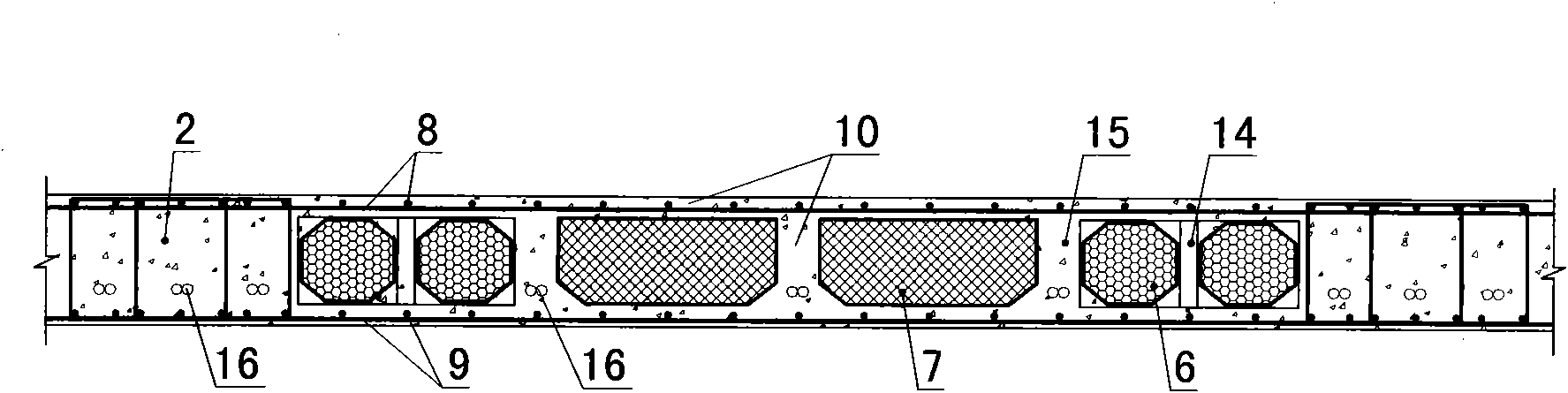

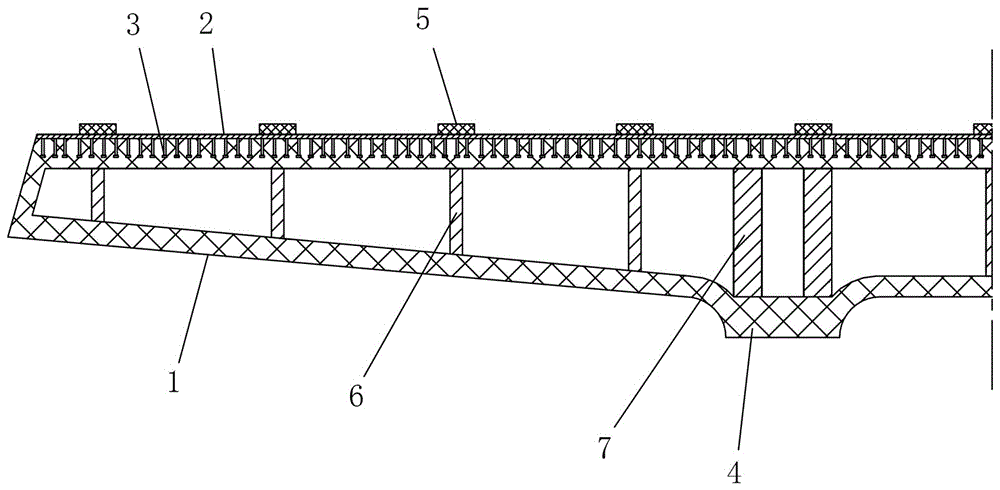

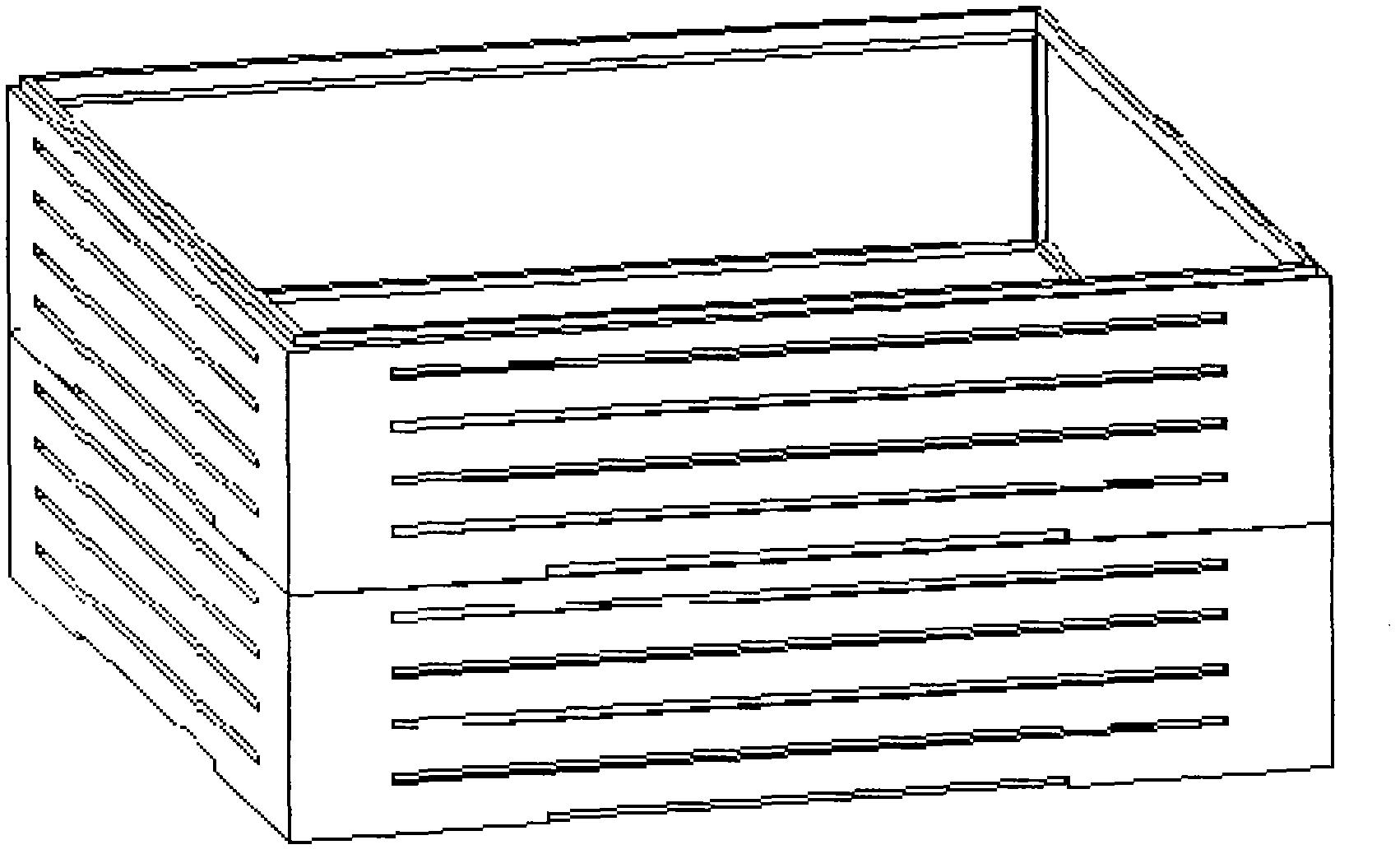

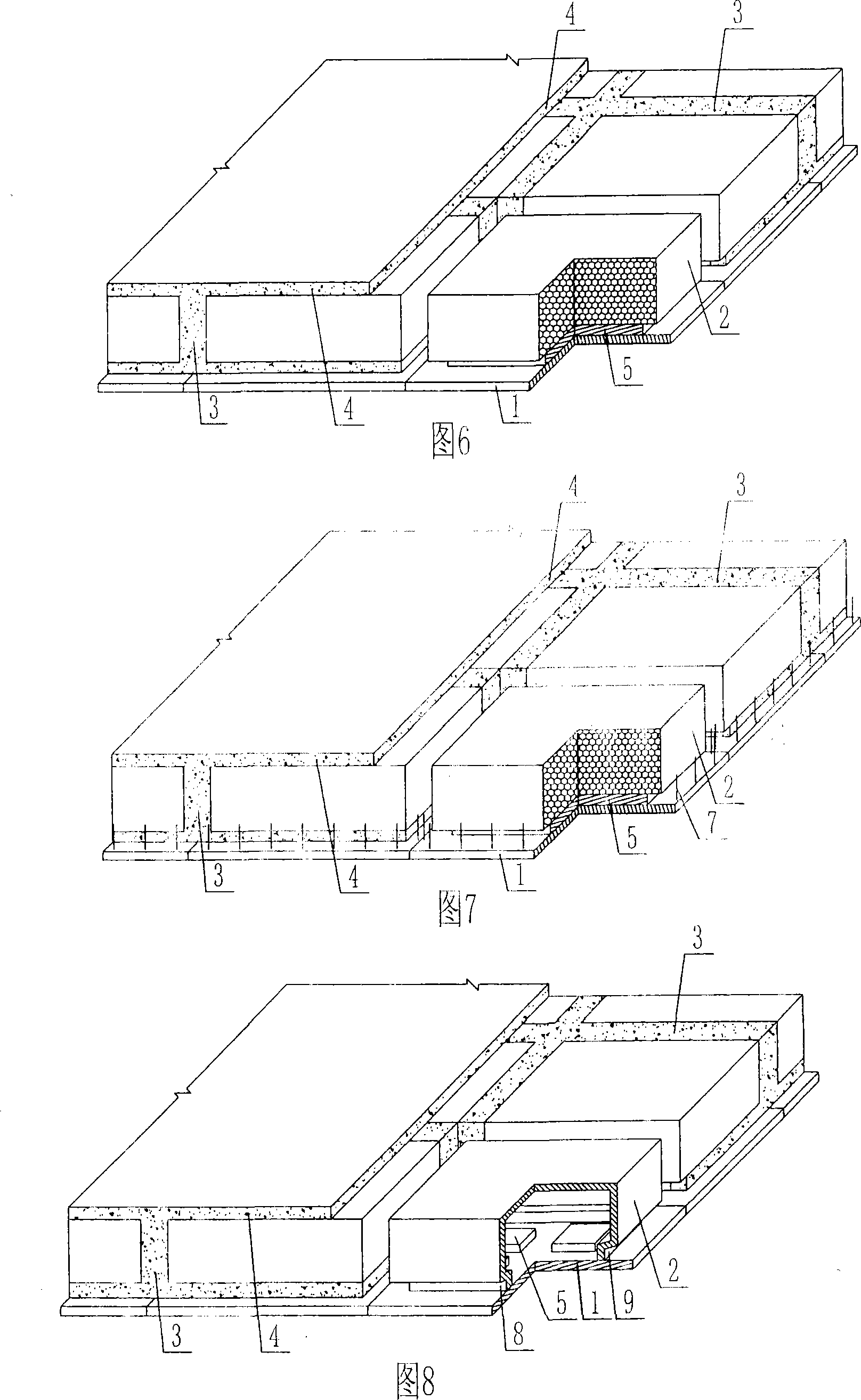

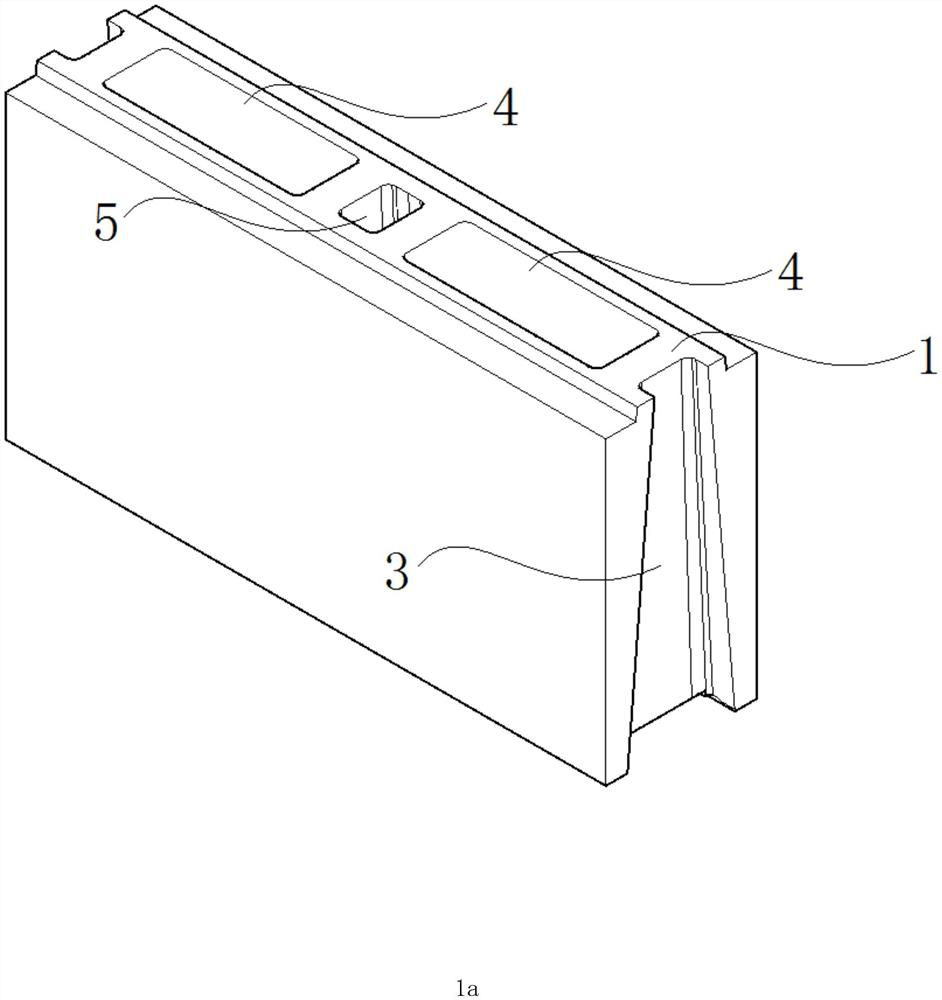

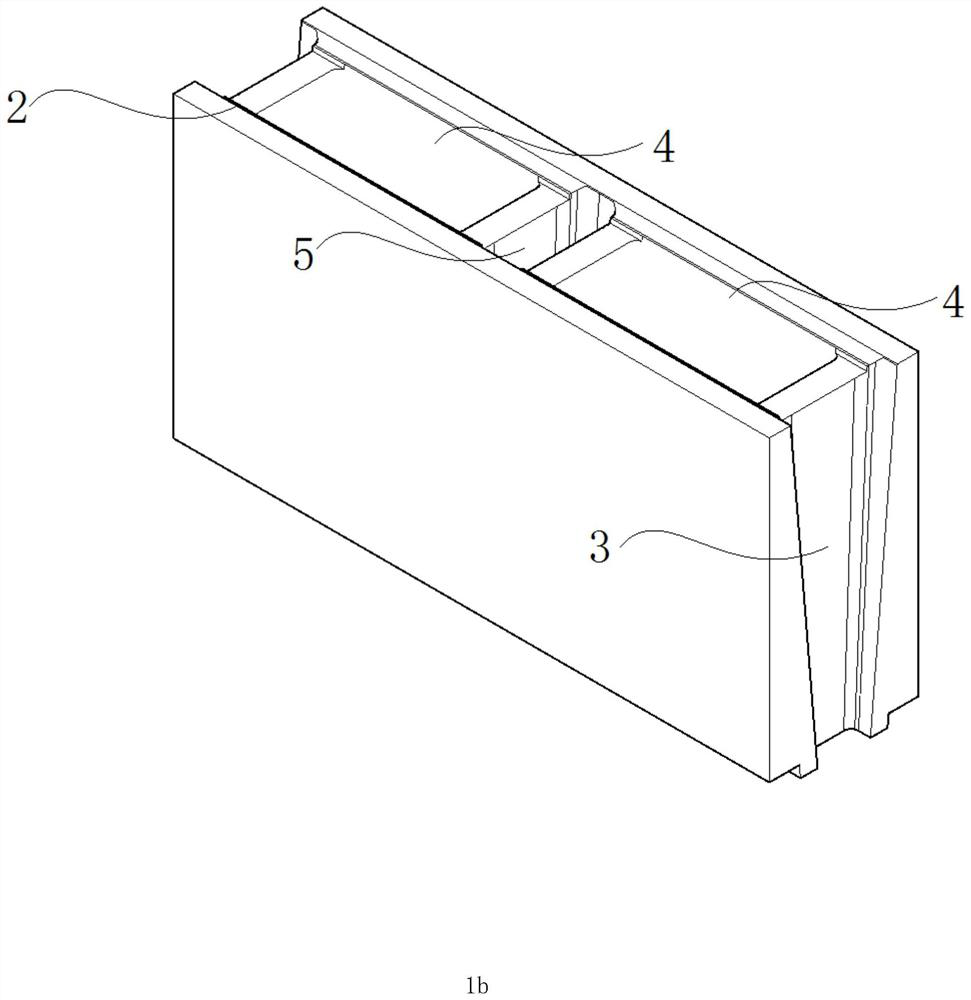

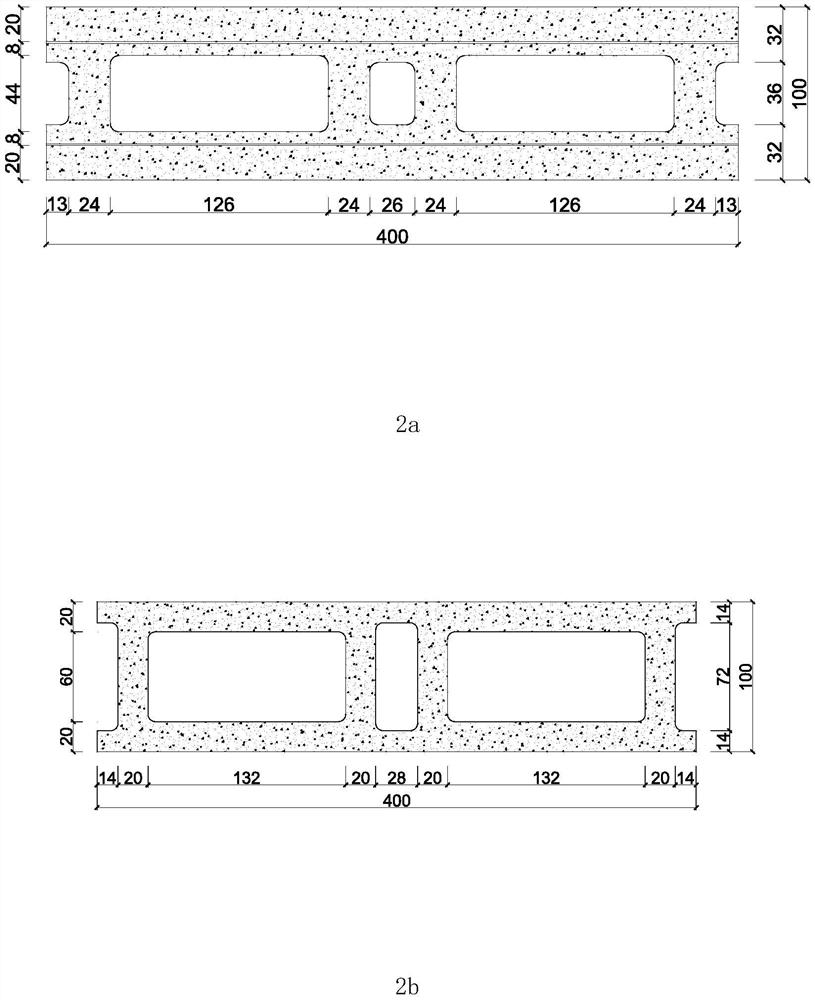

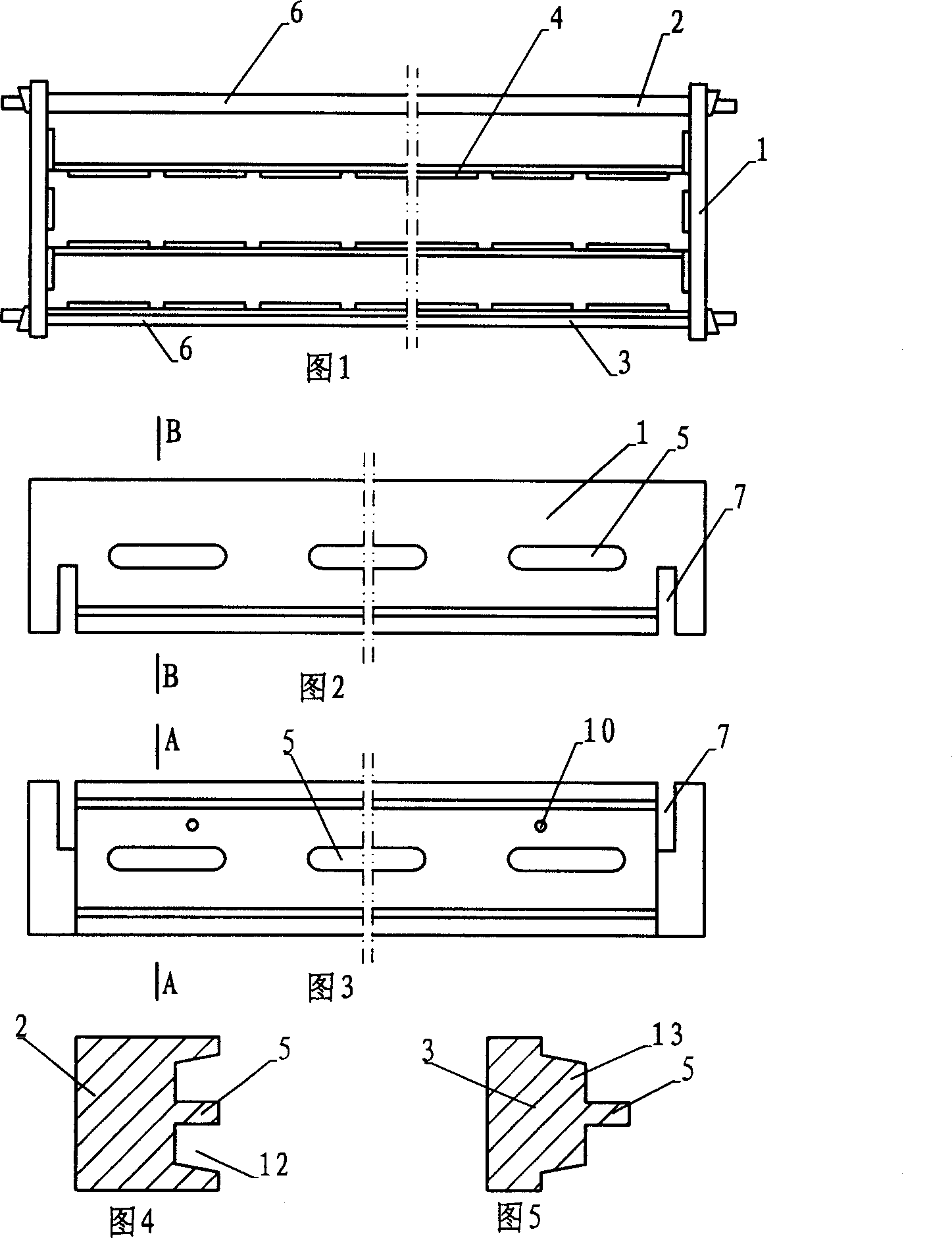

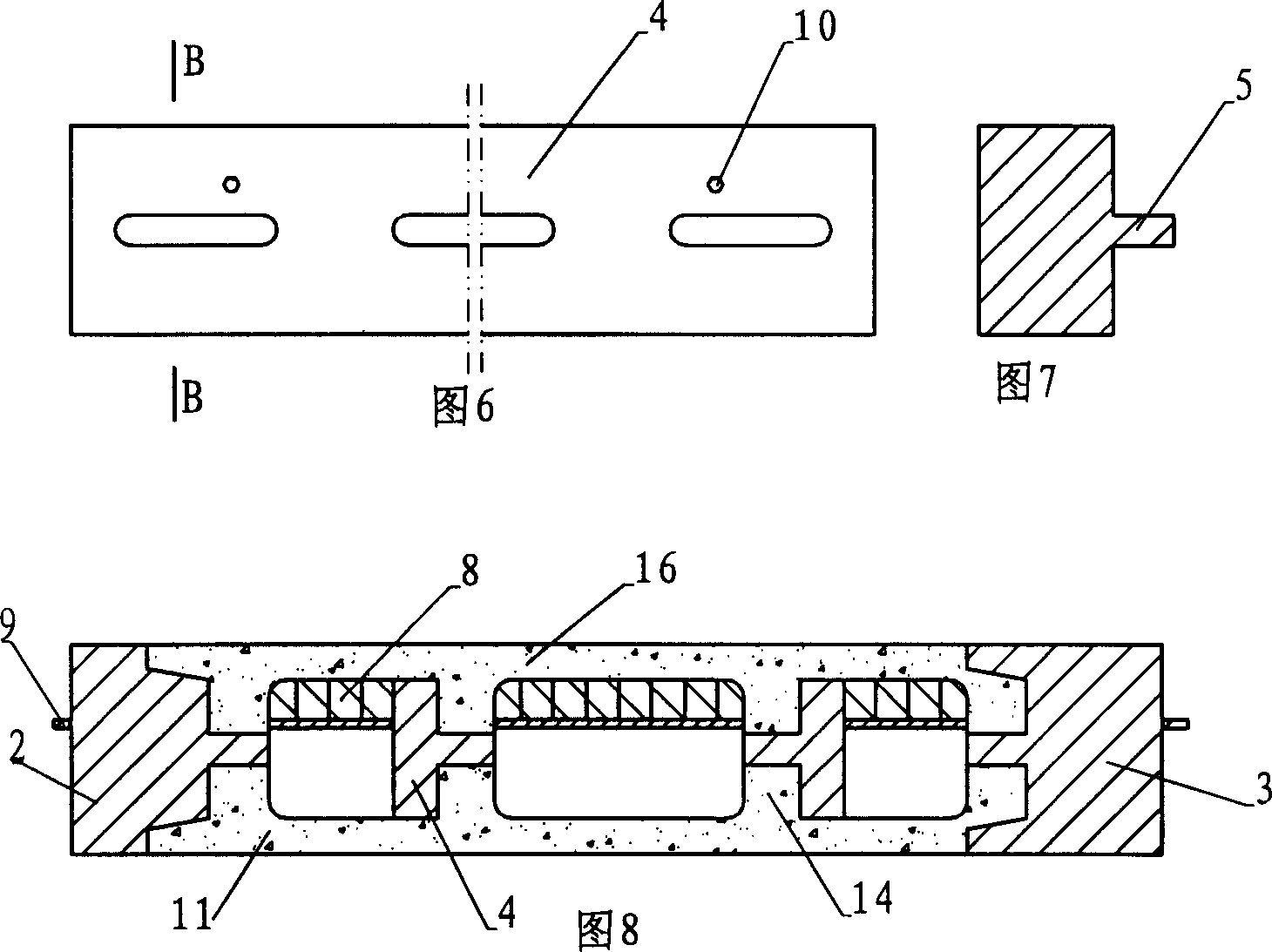

Assembled monolithic concrete ribbed hollow floor slab

InactiveCN102094481AHigh hollow rateLight weightFloorsForms/shuttering/falseworksFloor slabReinforced concrete

The invention relates to a floor slab, in particular to an assembled monolithic concrete ribbed hollow floor slab with combination of prefabrication and casting in place and joint stress, which comprises reinforced concrete rib beams (1), a reinforced concrete overlapping layer (2) and assembled box dies (3); each reinforced concrete rib beam is formed by casting in place between the adjacent assembled box dies; the reinforced concrete overlapping layer is formed by casting in place above the assembled box dies; each assembled box die (3) comprises a lattice reinforced composite slab (4) and an open box (5), and each lattice reinforced composite slab is a top slab of the open box (5); and protruding steel bars (6) are arranged in the lattice reinforced composite slabs (4), the protruding steel bars protrude into the peripheral rib beams for anchoring, longitudinal stressed steel bars (11) in the rib beams are hooked, and the rib beams (1) and the lattice reinforced composite slabs (4) are jointly stressed. The structural height of the floor slab can be greatly reduced, and higher using space for a building can be provided under the situation of same storey height.

Owner:辛崇安

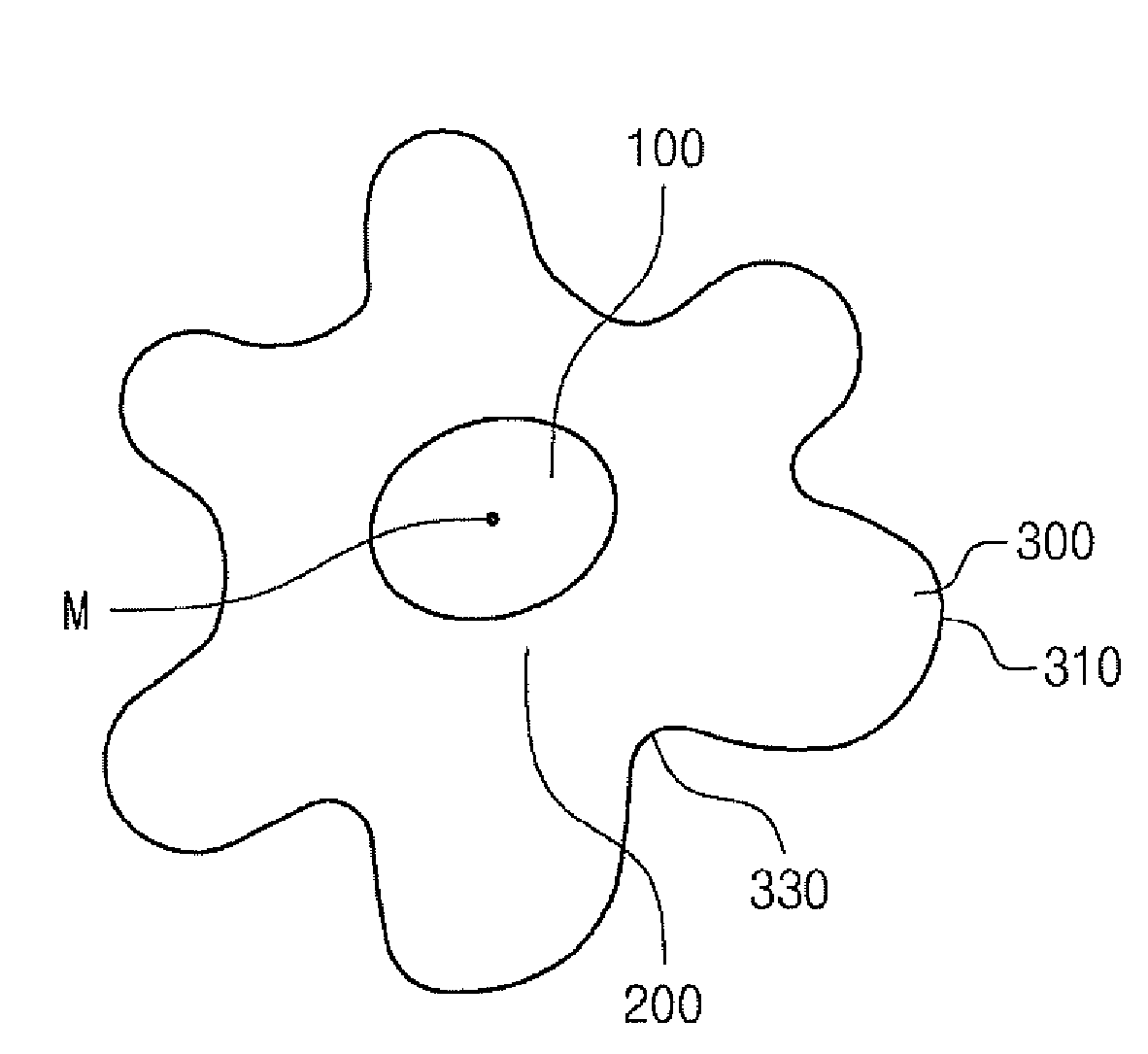

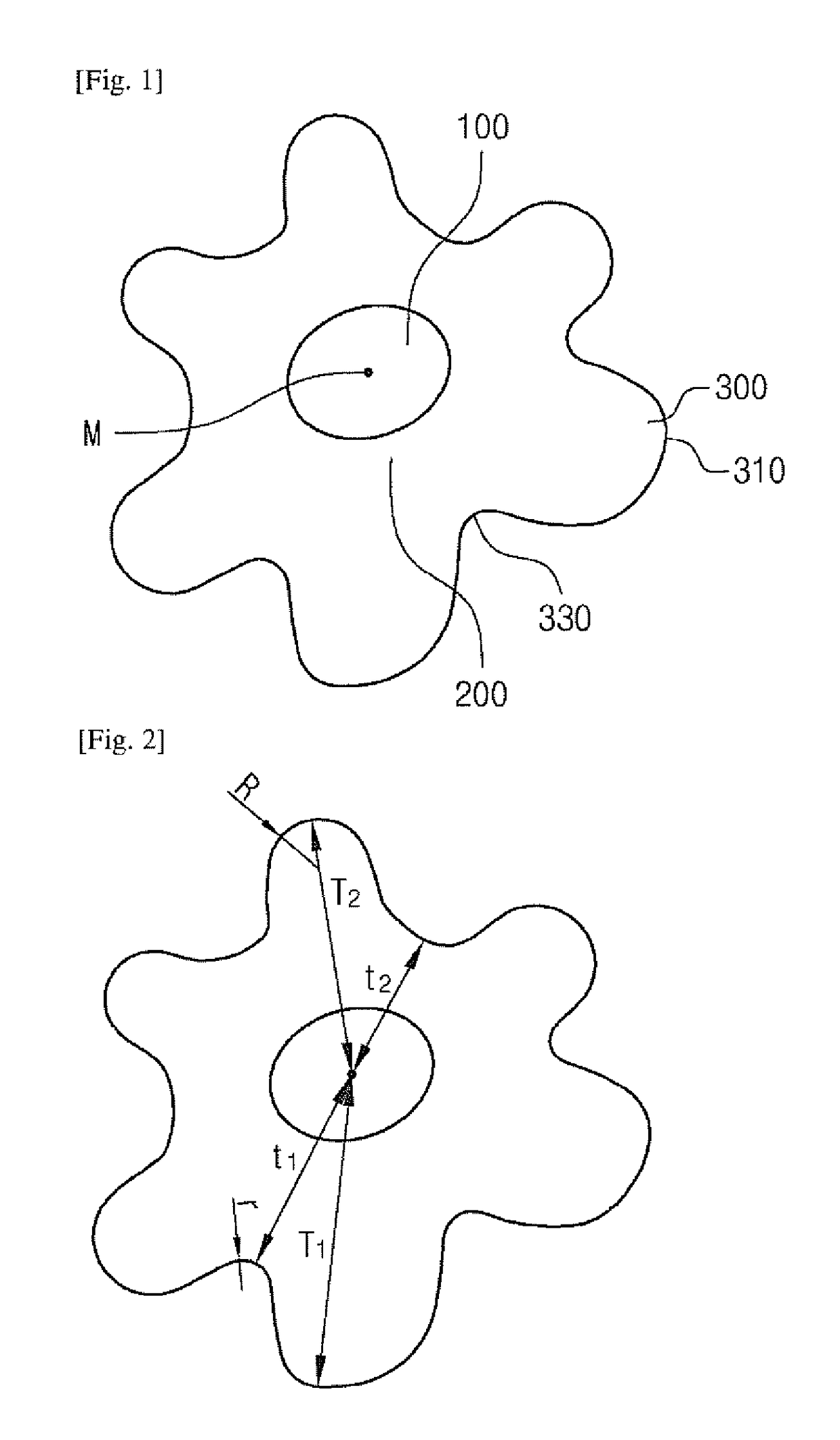

Modified cross-section hollow fiber, and fiber assembly using same

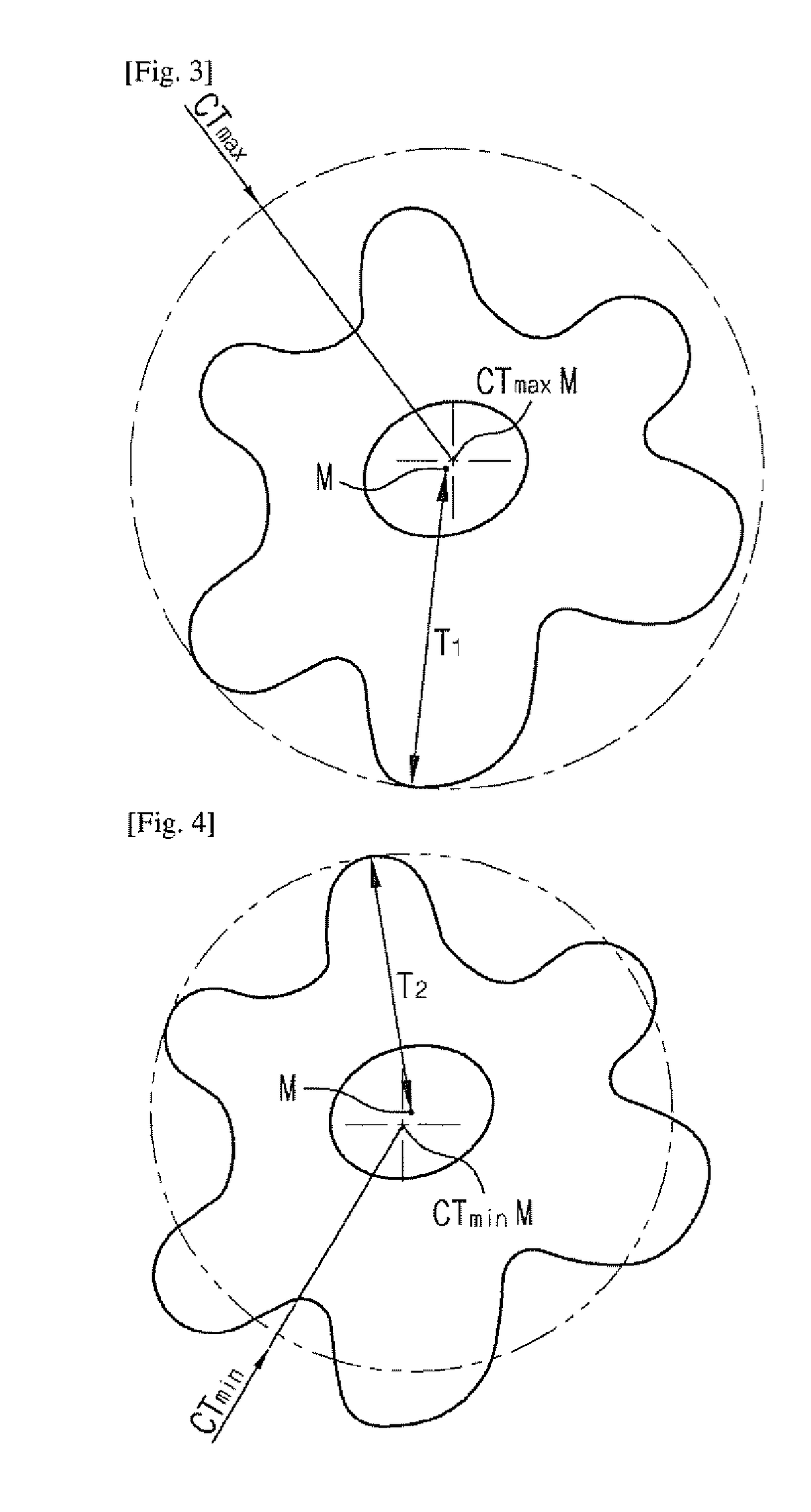

InactiveUS20170226673A1High hollow rateShape stableHollow filament manufactureFilament/thread formingFiberExtremity Part

The present invention provides a modified cross-section hollow fiber, wherein the fiber comprises a hollow part, a shape maintaining part and a volume control part, the volume control part can have a shape protruding in the direction opposite to the center of the fiber, and an end part has a round shape.

Owner:HUVIS CORP

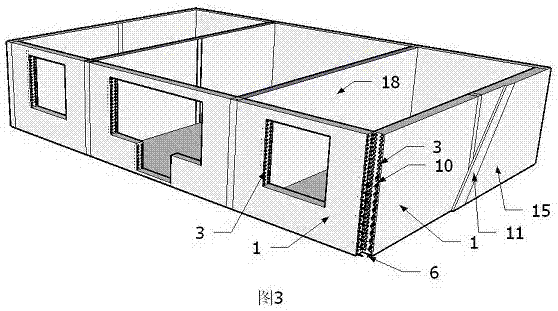

On-site concrete hollow floor construction method of LPM light filling embodies

InactiveCN110080454AReduce dosageSimple processConstruction materialFloorsStructure of the EarthEngineering

The invention discloses an on-site concrete hollow floor construction method of LPM light filling embodies. The construction method comprises the steps that a plate bottom formwork is erected, plate bottoms and hidden rib beam steel bar binding cushion blocks are installed, anti-floating drilling is conducted; and plate bottoms and hidden rib beam steel bars are bound, and a specially-assigned person is dispatched to punch holes in the bottom plate template according to the anti-floating distribution diagram, install water and electric pipelines, hoist LPM light filling pieces, place the filling pieces, bind plate surface reinforcing steel bars, reinforce anti-floating iron wires of the filling pieces, pour concrete, maintain, demold and the like. The method is simple in process, convenient to construct and easy to operate; by the adoption of the technology in a proper structure, the engineering quality is guaranteed, and meanwhile the beneficial effects of being small in concrete consumption, large in space, low in structural self-weight, small in earthquake acting force, good in structural heat insulation and sound insulation performance, capable of shortening the construction period and the like are achieved.

Owner:中联世纪建设集团有限公司

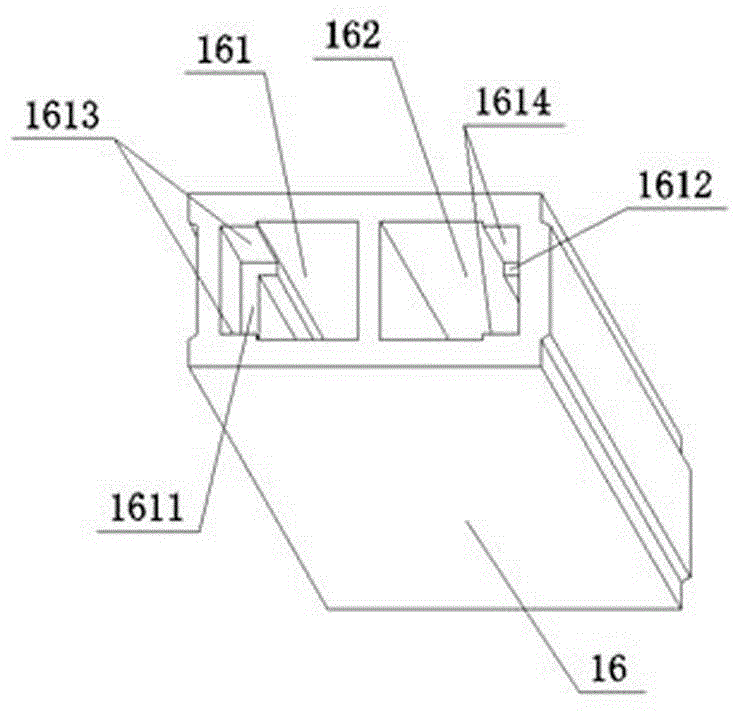

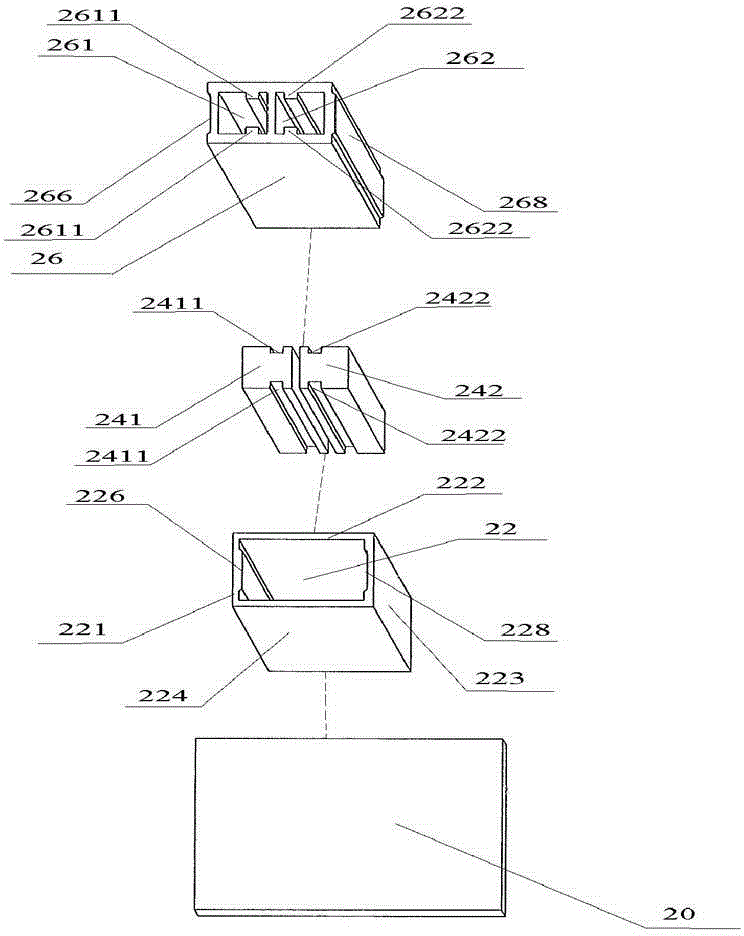

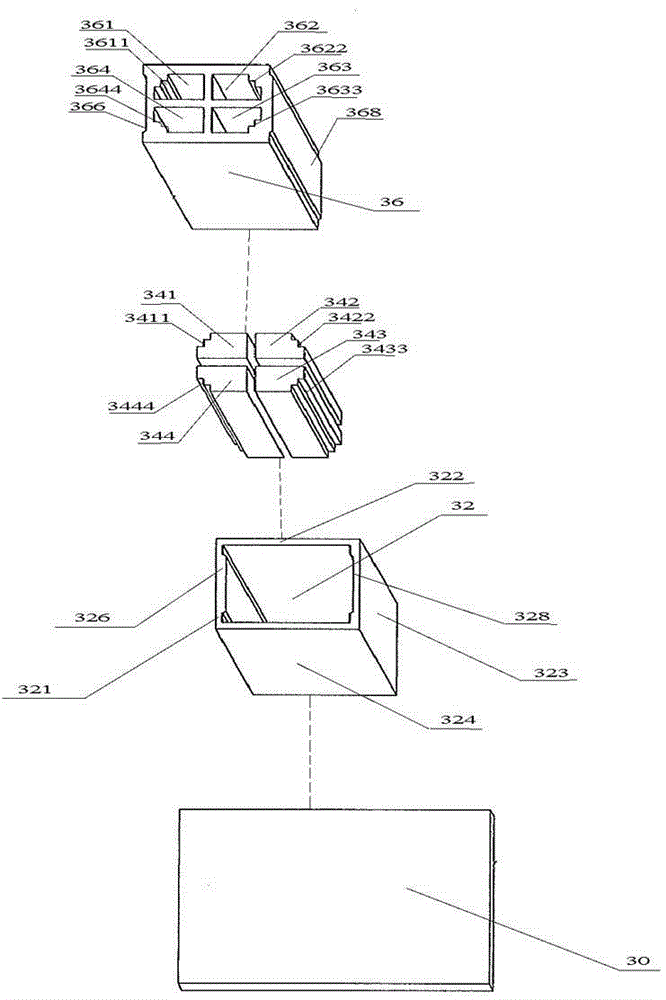

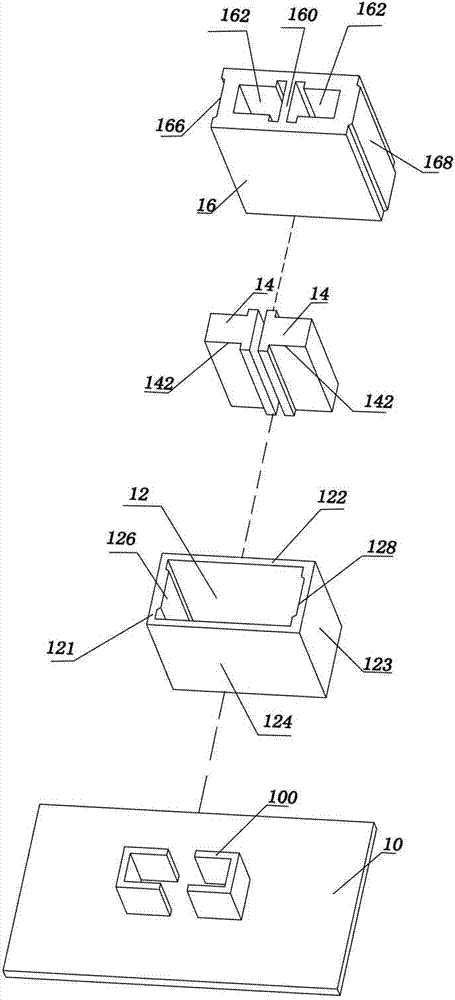

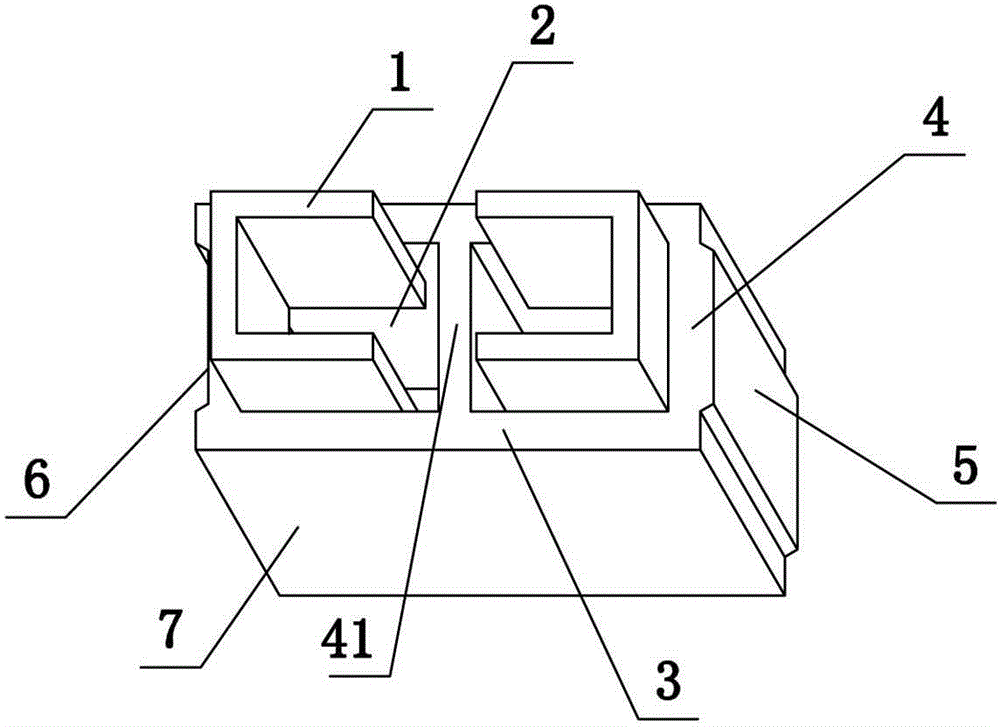

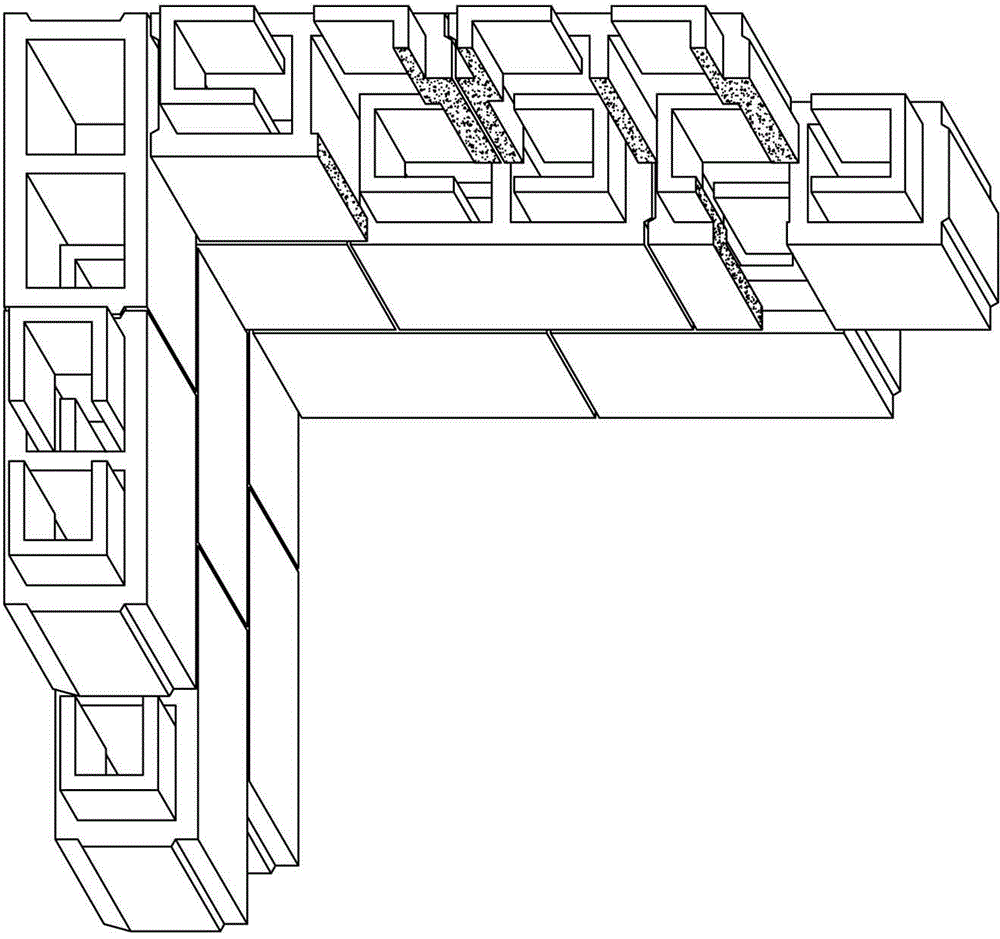

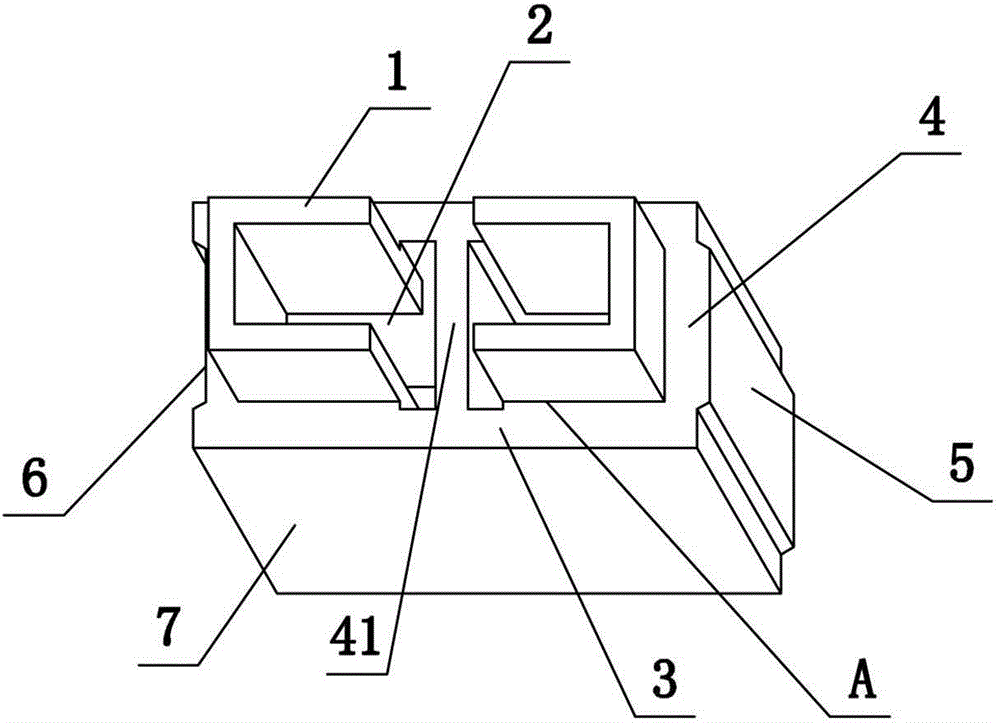

Building block die and method of carrying out pressing to form building block by utilizing same

The invention provides a building block die. The building block die is formed by horizontally arranging and combining at least one die unit. Each die unit comprises a supporting plate, a die box arranged on the supporting plate, a die core unit arranged in the die box and a pressure head which is inserted between the die box and the die core unit and is provided with a vertical hole structure. The building block die is used for forming an anti-seismic anti-cracking building block with a convex bolting part; the outer wall of the pressure head with the vertical hole structure is attached to the inner wall of the die box in a seamless manner; the pressure head with the vertical hole structure is a of a shape of a Chinese character 'ri' or 'tian'. The invention also provides a method for forming the building block by utilizing the building block die. The building block die is used for carrying out extrusion forming of the anti-seismic anti-cracking building block with the convex bolting part and the formed building block has excellent mechanical properties such as shear strength and the like.

Owner:段炼山

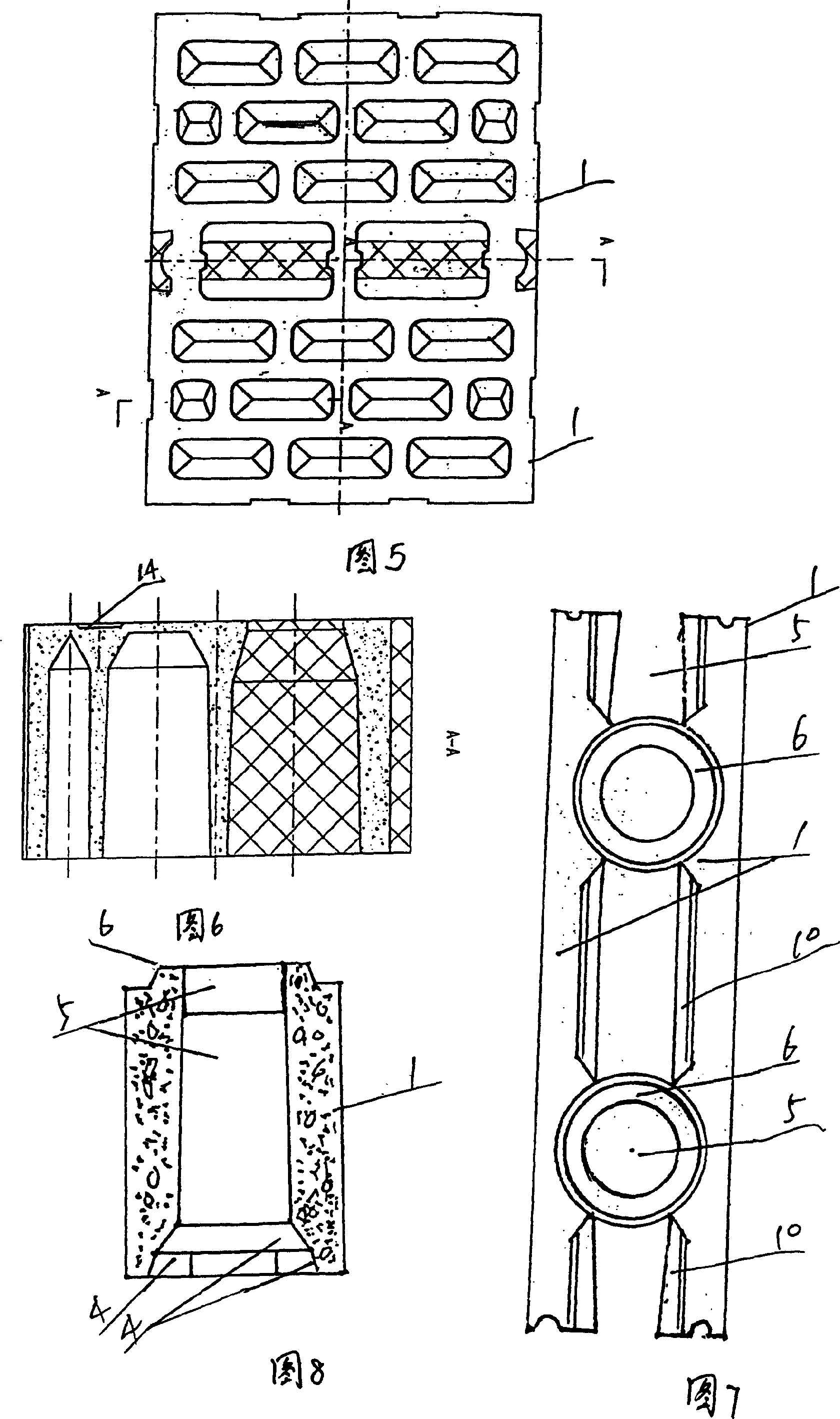

Assembled reinforcing steel bar concrete hollow floor slab

InactiveCN101240597AHigh hollow rateImprove shear resistanceFloorsConvex structureReinforced concrete

A combined reinforced concrete hollow floor plate comprises a prefabricated thin plate (1), a formwork (2), a concealed rib (3) and an upper plate (4), the prefabricated thin plate (1) is fixed with a formwork (2), a concealed rib (3) is arranged between the adjacent prefabricated thin plates (1) or the formworks (2), the upper plate (4) covers the formwork (2) and is connected to the concealed rib (3) to a whole, and the invention is characterized in that the prefabricated thin plate (1) is arranged with at least one in convex structure (5) or / and concave structure (6), and the prefabricated thin plate (1) is exposed. In this way the hollow floor plate is suitable for various building roofs, building covers, walls, base plates and empty bridges using the cast-in-situ reinforced concrete or prestressed reinforcement concrete, especially suitable for the hollow beamless floor and multi-ribbed floor.

Owner:湖南邱则有专利战略策划有限公司

Building block mold and method for pressing and forming building block by using building block mold

Owner:段炼山

Hollow polymer particle and manufacturing method thereof

ActiveCN103372409AReduce the generation of concave particlesImprove insulation effectThermographyMicroballoon preparationHollow coreOrganic solvent

Disclosed are a hollow polymer particle and a manufacturing method thereof. The invention provides a method for producing hollow polymer particles, capable of reducing generation of recessed particles low in hollow rate and increasing the particles high in hollow rate. The method is characterized in that, in water medium, a mixture of polymer monomers for forming housings of the polymer particles and organic solution is emulsified and scattered, the polymer monomers are floated and polymerized under the presence of a polymerization initiator to form polymer particles containing organic solution, and the organic solution in the polymer particles is gasified and removed through the housings of the particles so as to produce hollow polymer particles. In the method, the organic solution in the polymer particles is gasified and removed through the housings of the particles, when the polymer particles are scattered in the water medium, so as to produce hollow polymer particles.

Owner:SANKO CO LTD

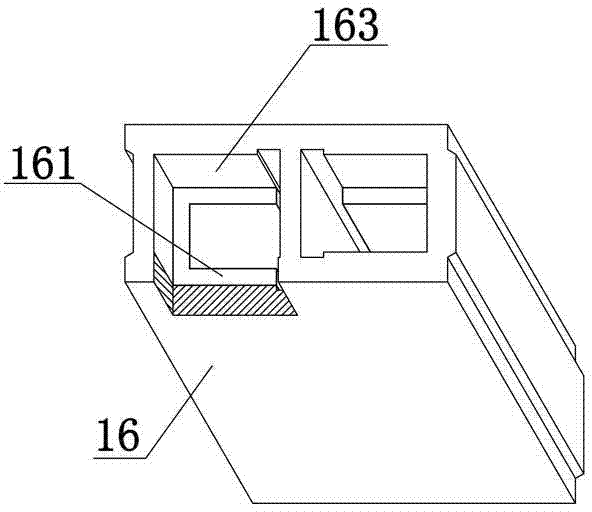

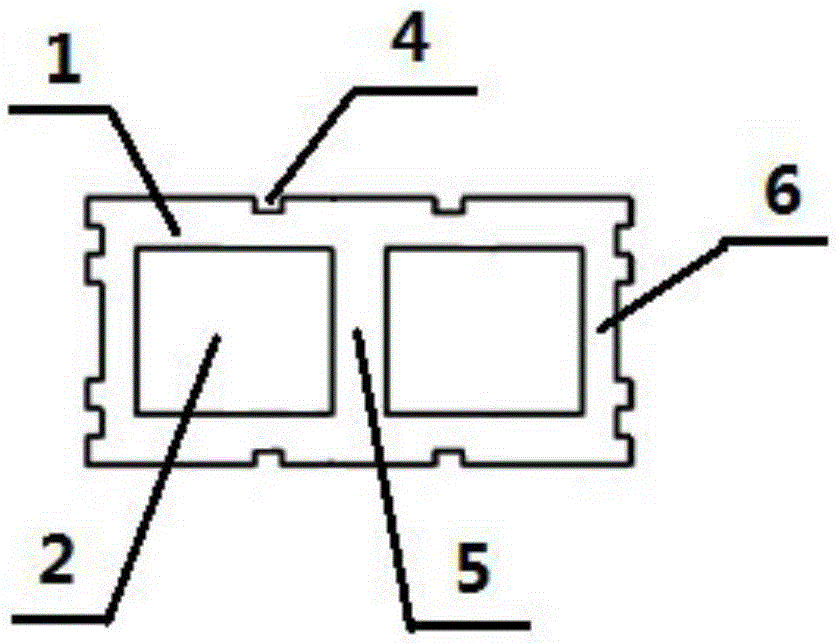

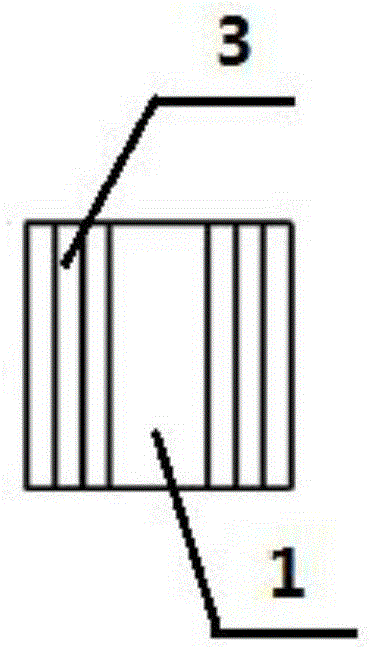

Hollow building block

InactiveCN104453063AImprove tensile propertiesImprove bending resistanceConstruction materialWallsEngineeringMechanical property

The invention relates to a hollow building block. The hollow building block is a rectangular block with through hole structures shaped like a Chinese character 'ri' or 'tian'; the rectangular block is provided with bolting components; one bolting component is attached to the inner wall of each through hole shaped like a Chinese character 'ri' and the inner vertical surface of an end rib, wherein one horizontal cross section of the bolting component is shaped like a Chinese character 'ao', or two horizontal cross sections of each bolting component are both shaped like 'L'; one bolting component is attached to the inner walls of each through hole shaped like a Chinese character 'tian' and the inner vertical surface of an end rib, wherein the horizontal cross section of the bolting component is shaped like 'L'; the vertical surfaces of each bolting component, which are shaped like a Chinese character 'ao', are arranged opposite to each other, the outer vertical surface and the walls of each bolting component and the end rib are in seamless fit like steps; the upper end of each bolting component protrudes out of the through hole, and the height of the exposed part of the bolting component is less than that of the through hole; the lower end surface of each bolting component keeps a distance from the lower surface of the rectangular block, wherein the distance is greater than the height of the upward exposed part of the bolting component. Due to the unique bolt-hole connection structure, the wall formed by laying the hollow building blocks has unique mechanical properties such as shearing strength and an inner structure with anti-seismic and anti-cracking functions. The hollow building block provided by the invention is easy to lay and is easy to popularize.

Owner:段炼山

Tenon-and-mortise hollow building block and laying method thereof

InactiveCN112177233AHigh hollow rateImprove thermal insulationConstruction materialWallsEarthquake resistanceBrick

Owner:SOUTHEAST UNIV

One-step forming method for producing hollow light partion strip board and its flat mould

The present invention discloses an one-step forming method for producing hollow light-wt. partition panel and its flat-die. The said method includes the following steps: pouring mortar material into the die frame assembled by using end face die plate and side die plate to obtain bottom surface of the panel; then utilizing end face die plate, die plate with tenon, die plate with slot and projection on dividing panel die plate to form internal projection and through hole; and utilizing the hollow form die plate to form top surface of the panel. This invention also discloses the structure of thesaid invented flat-die. It can be extensively used in building industry.

Owner:成都市金橙环保轻质建材有限公司

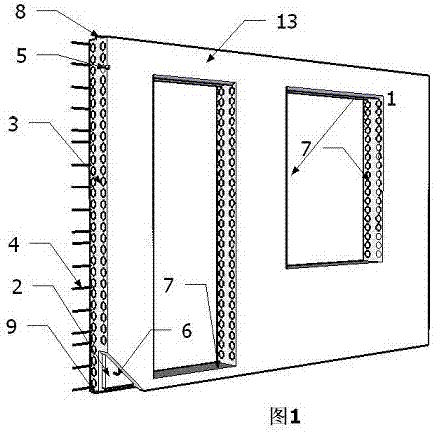

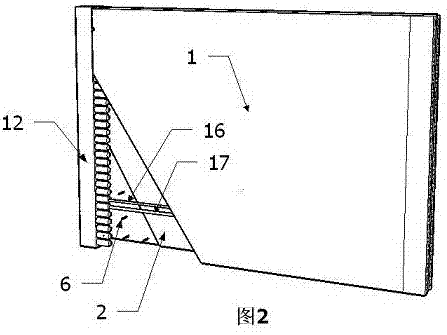

Large horizontal hole overall prefabricated wall plate

InactiveCN106930433AFirmly connectedImprove bindingWallsHeat proofingHeat transfer coefficientWall plate

The invention discloses a large horizontal hole overall prefabricated wall plate. In terms of a house assembled from wall plates, a wall body of each standard room is formed by building the large horizontal hole overall prefabricated wall plate (1) in the mode that internal horizontal holes are kept horizontal. After the wall body is built, a plurality of long hollow horizontal holes (3) which are horizontal are formed between every two top end stand columns (12). According to the large hollow overall prefabricated wall plate developed by the invention, the problems that the self weight is large, the thermal insulating performance is poor, the cost is high, hoisting is impossible, pulling is difficult and the like are solved, and the hollow structure reduces the heat transfer coefficient of the concrete wall body, a building foundation load and the foundation treatment cost.

Owner:张宗楼

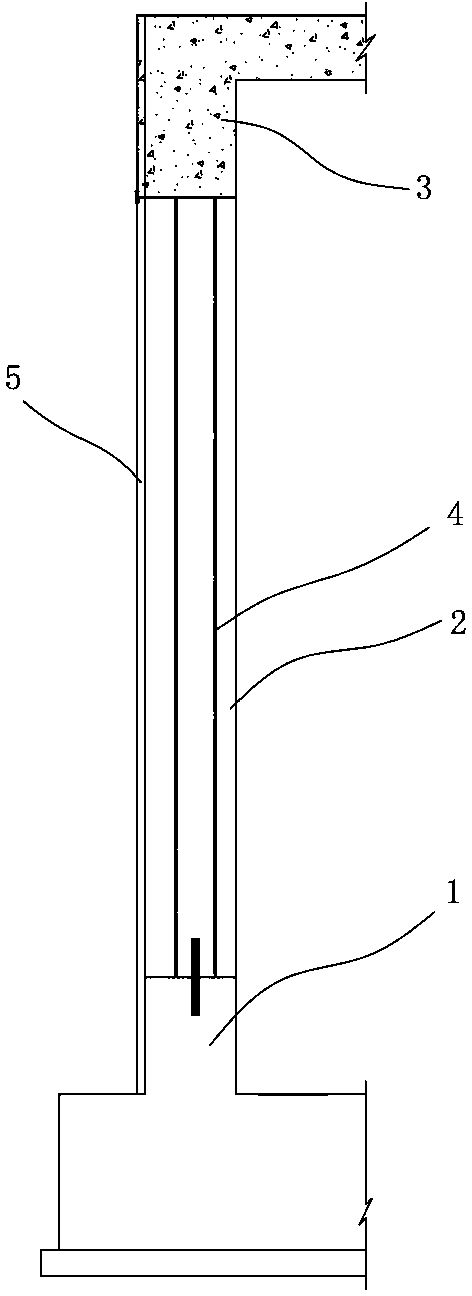

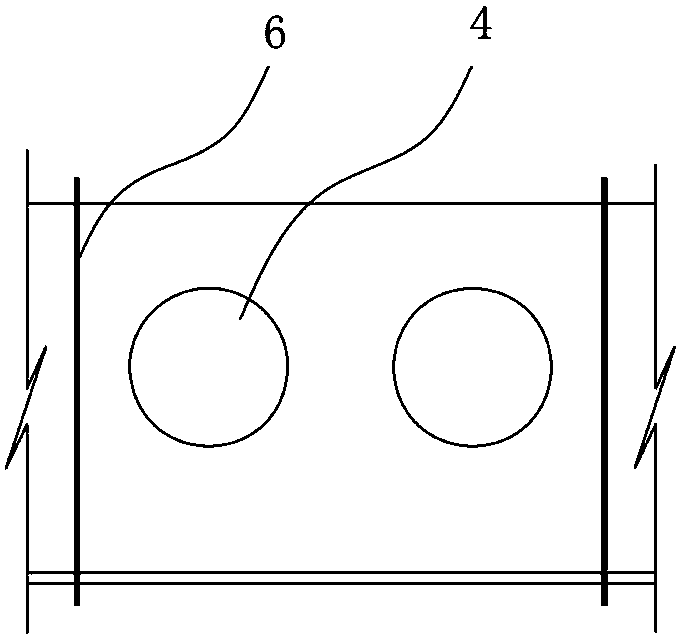

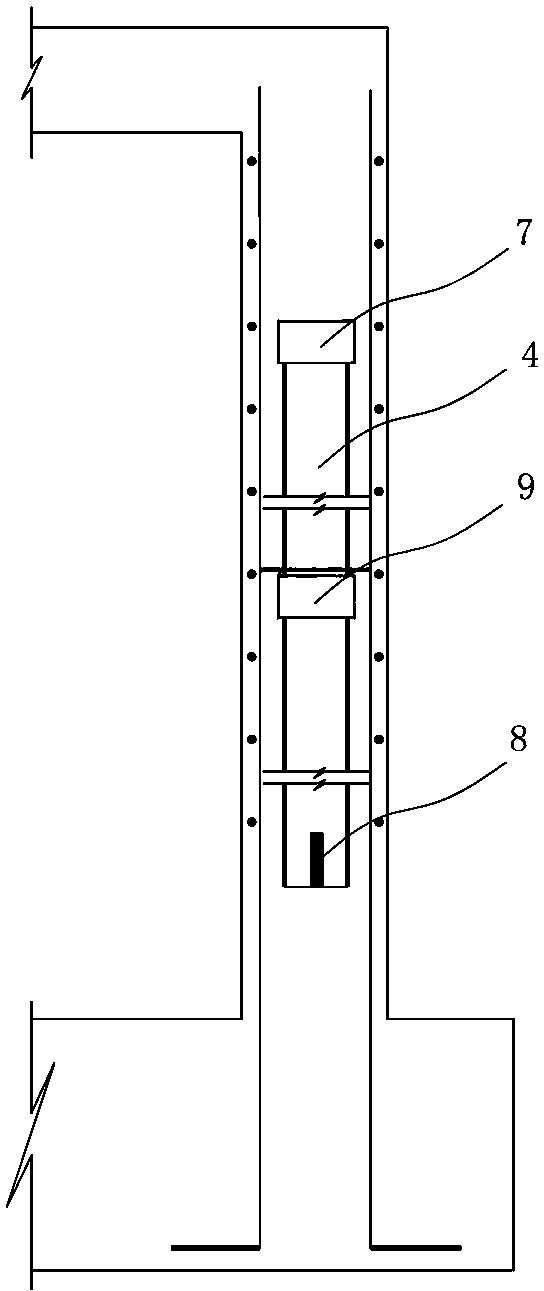

Cast-in-place concrete PVC hollow tube wallboard used for basement exterior wall

InactiveCN103590423AReduce dosageSmall shear stiffness weakenedArtificial islandsUnderwater structuresBasementSolid wall

The invention discloses a cast-in-place concrete PVC hollow tube wallboard used for a basement exterior wall. The cast-in-place concrete PVC hollow tube wallboard is characterized by comprising a first solid section wall body at the bottom, a hollow tube wall body in the middle and a second solid section wall body at the top, wherein the hollow tube wall body in the middle is mainly composed of a plurality of plastic tubes, steel bars and concrete poured surrounding the plastic tubes, the plastic tubes, the steel bars and the concrete are distributed in the wall body in the longitudinal direction and connect the solid section wall bodies in the longitudinal direction, the distance between the axes of the adjacent plastic tubes is 200-300 millimeters, the distance between each plastic tube wall and the surface of the wall body is not smaller than 100 millimeters, and the wall thickness of each plastic tube is 1-2 millimeters. The anti-bending bearing capacity of the exterior wall is not smaller than a solid wall, the anti-shearing rigidity is seldom weakened, concrete amount is substantially reduced, and meanwhile the problem that a basement enclosure wall cracks is solved.

Owner:SUZHOU JINXIN CONSTR GRP

Building board and method for producing building board

InactiveUS20140287220A1Good thermal insulation propertiesImprove design qualitySolid waste managementSynthetic resin layered productsSolid contentCoating

A building board includes an inorganic board having a surface covered by an insulating coating film containing a coating film forming material and organic hollow particles, wherein the organic hollow particles have an average particle size in the range of 5 to 50 μm and an average hollow ratio of 80% or more, and the insulating coating film contains 0 01 to 5.0 parts by mass of the organic hollow particles per 100 parts by mass of solid content thereof, and has an average thickness of 5 to 500 μm. The method for producing a building board includes: applying, onto a surface of an inorganic board, an insulating coating material containing a coating film forming material and organic hollow particles; and drying the insulating coating material to form an insulating coating film.

Owner:NICHIHA CORP

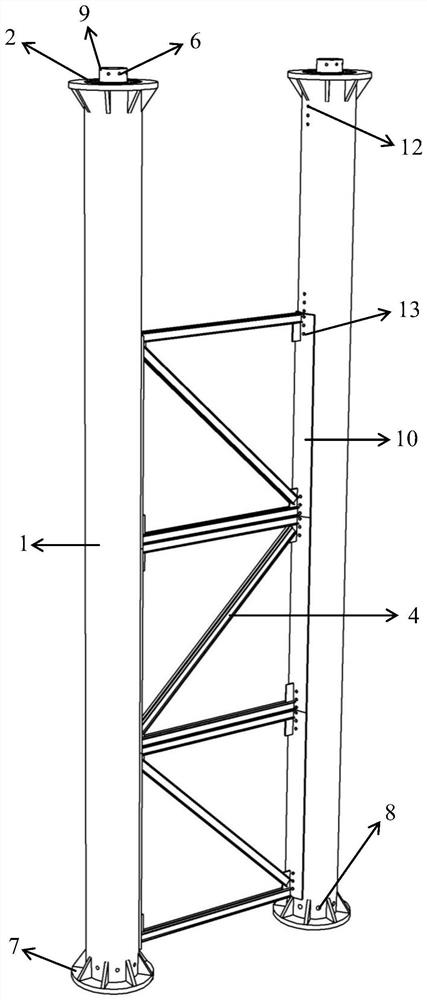

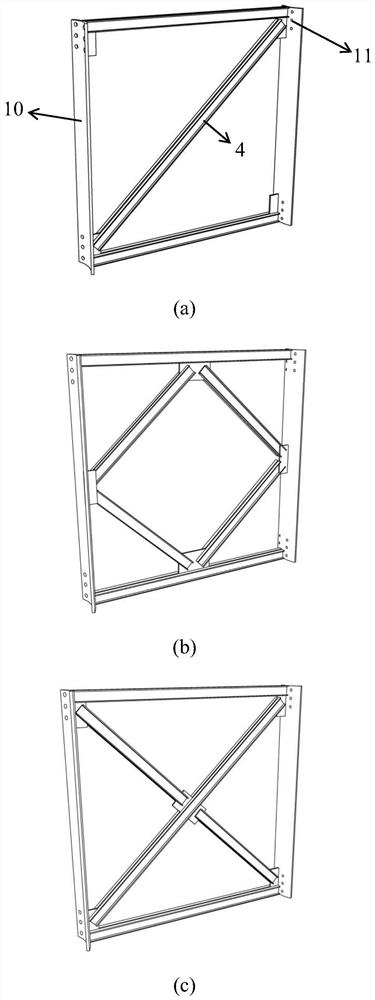

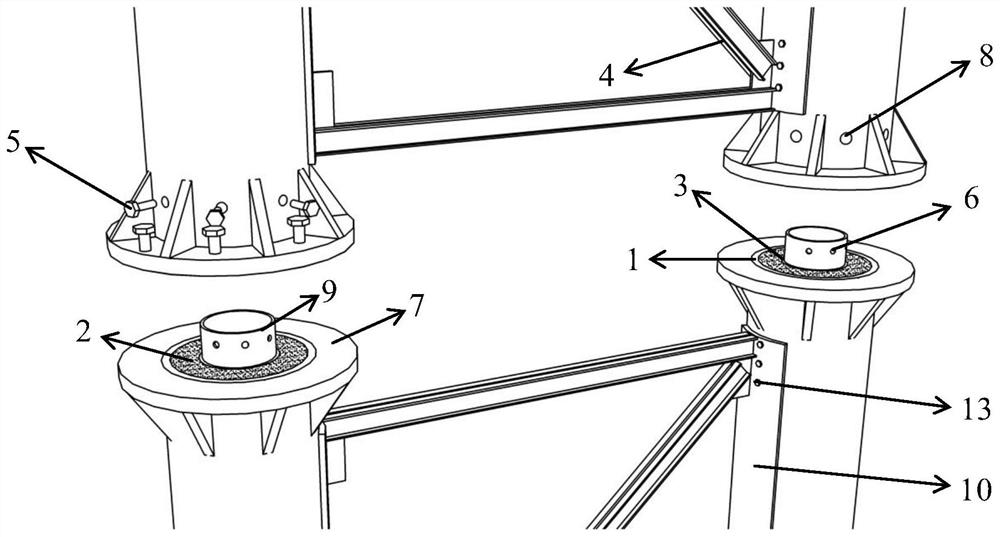

Prefabricated composite steel tube concrete latticed column and construction method

InactiveCN113445670ALow costDifficult to pourStrutsPillarsEarthquake resistanceArchitectural engineering

A prefabricated composite steel tube concrete latticed column is composed of prefabricated double-steel-tube interlayer concrete column limbs and lattice type connecting pieces between the column limbs. Steel tubes at the outer sides of the prefabricated column limbs are connected with the lattice type connecting pieces through bolts, and interlayer concrete between steel tubes at the inner sides and the outer sides of the column limbs is ultra-high-performance concrete. The upper-layer prefabricated column limbs and the lower-layer prefabricated column limbs are connected through flanges and connecting pipes. The double-steel-tube interlayer confined concrete can effectively reduce the steel distribution rate of column components, save the concrete consumption and reduce the self weight. The latticed column adopts a full-assembly manner, site construction is simple and convenient, and wet operation is not needed. A hollow part of the inner steel tube serves as strength reserve, and the purposes of crane upgrading and plant transformation in the using process can be achieved through secondary pouring of concrete in the hollow part. Based on the characteristics of simple and convenient design and flexible application, the latticed column can be widely applied to medium-sized industrial factory buildings, and the durability, the fire resistance and the anti-seismic property of the latticed column are effectively improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Recycled aggregate mountain flour anti-seismic hollow block for masonry frame filled wall and preparation method thereof

ActiveCN105384398AImprove shear resistanceImprove ductilitySolid waste managementBuilding componentsDuctilityConstruction aggregate

The invention discloses a recycled aggregate mountain flour anti-seismic hollow block for a masonry frame filled wall. The hollow block comprises a rectangular shell, wherein two rectangular holes are formed inside the shell; first grooves are formed in the top and bottom surfaces of the shell; and second grooves are formed in four side surfaces of the shell. The invention also discloses a method for preparing the recycled aggregate mountain flour anti-seismic hollow block for the masonry frame filled wall. The recycled aggregate mountain flour anti-seismic hollow block for the masonry frame filled wall prepared by the previous method is tested by referring to 'concrete block and brick test method' (GB / T 4111-2013), and the compressive strength, breaking strength and shear strength can respectively reach 8.60MPa or more, 1.30MPa or more and 0.10MPa or more. The recycled aggregate mountain flour anti-seismic hollow block disclosed by the invention is used for the frame filled wall, is full in hysteretic curve, high in ductility and high in energy-dissipating capacity and has good anti-seismic property.

Owner:LIMING VOCATIONAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com