Hydrophobic hollow glass microsphere preparation method and prepared hydrophobic hollow glass microsphere thereof

A technology of hollow glass microspheres and water glass, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of surface modification, high cost of imported products, environmental pollution, etc., and achieve good industrial application Foreground, high altitude, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

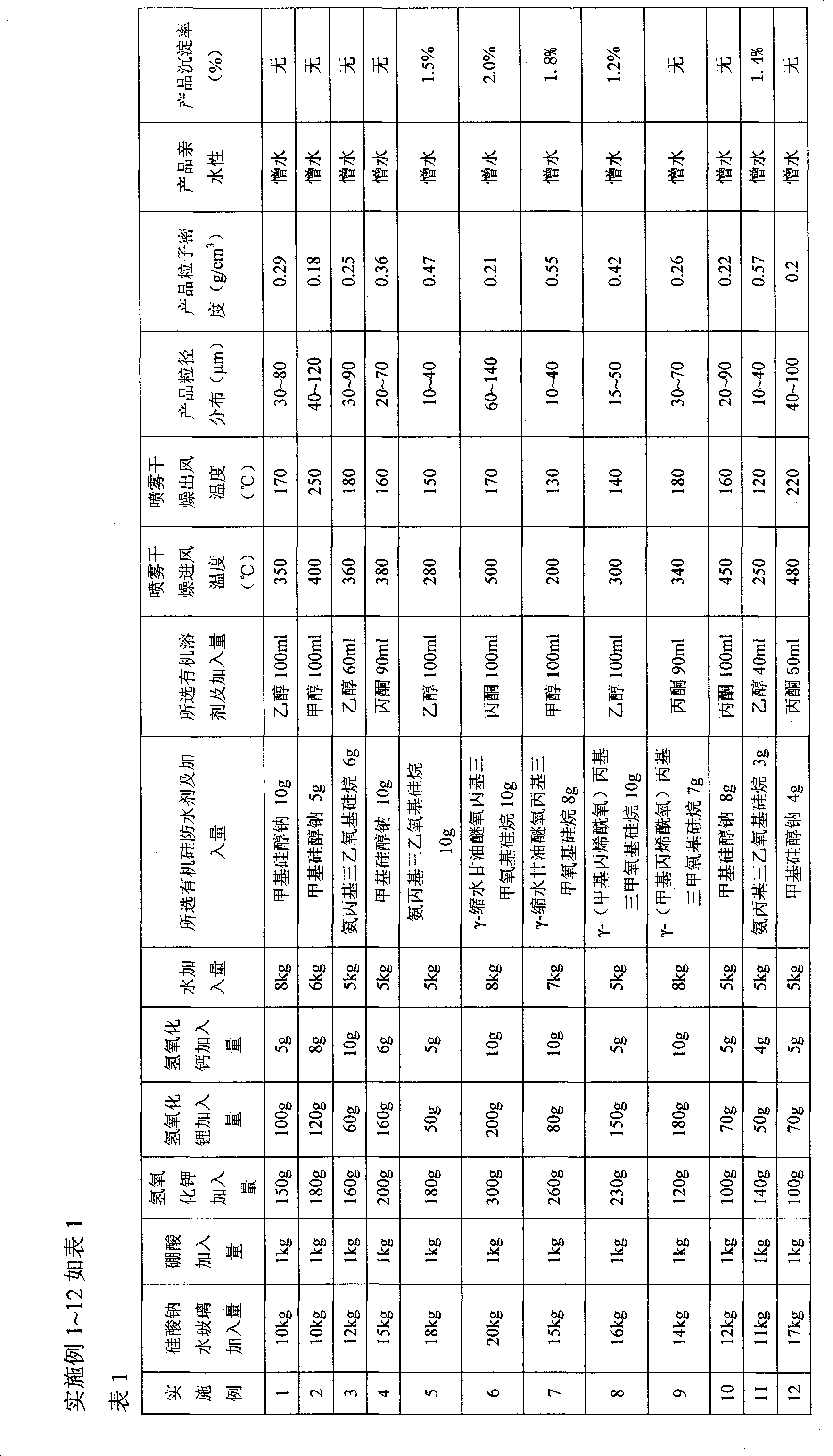

Examples

Embodiment Construction

[0013] The boric acid, potassium hydroxide, lithium hydroxide and calcium hydroxide weighed in proportion are dissolved in water to obtain a clear and transparent auxiliary material mixed solution. Sodium silicate water glass is placed in a magnetic stirring tank at the bottom and stirred at a high speed, and the auxiliary material mixture is sprayed into the water glass with an atomizing nozzle on the top of the mixing tank to obtain a precursor solution. The precursor solution is transported to the spray drying equipment with a peristaltic pump for drying treatment. Dissolve the silicone water repellent in a low-boiling organic solvent, and spray it into the delivery pipeline before the cyclone separator at a uniform speed. The silicone water repellent should be delivered synchronously with the precursor solution. The product of hydrophobic hollow glass microspheres can be obtained after the bottom receiving cylinder of the cyclone separator is naturally cooled. The product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com