Cast-in-place concrete PVC hollow tube wallboard used for basement exterior wall

A basement external wall and hollow pipe technology, which is applied in the field of basement wall panels and building structures, can solve problems such as cracks, achieve the effects of preventing cracks, obvious economic benefits, and reducing the impact of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

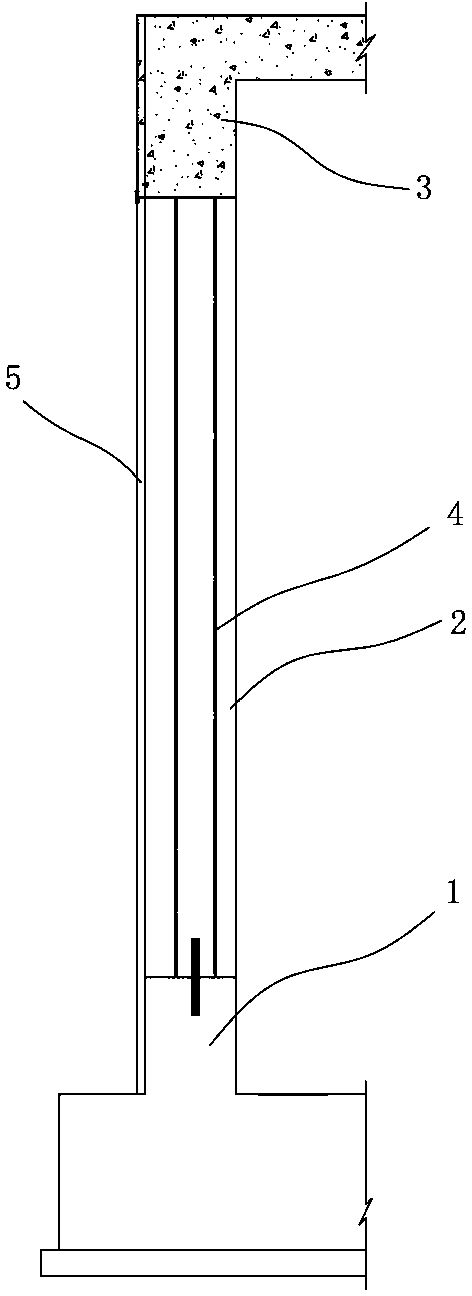

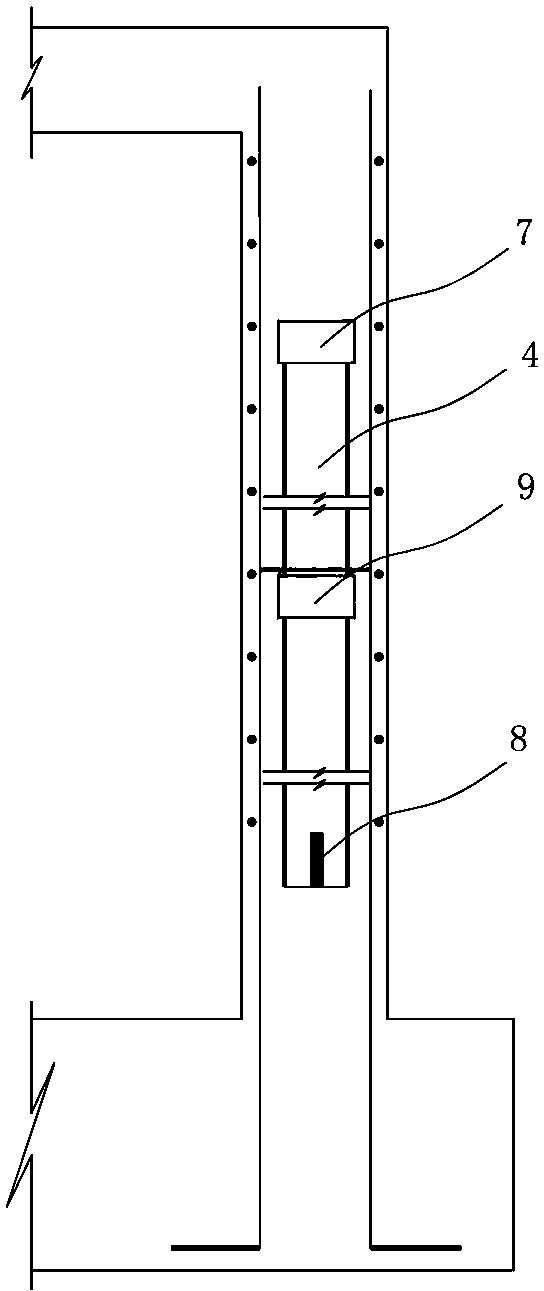

[0027] Example 1: See attached figure 1 As shown, a cast-in-place concrete PVC hollow tube wall panel for basement exterior walls is composed of a first solid section wall 1, a middle hollow tube wall 2 and a second solid section wall 3 on the top. The hollow tube wall 2 in the middle is mainly composed of a plurality of plastic tubes 4 arranged in the vertical direction and connected to the solid section of the wall, steel bars, and concrete poured around the plastic tube 4, which are distributed in the wall body. A steel wire mesh anti-cracking layer 5 is provided on the water facing surface of the wall.

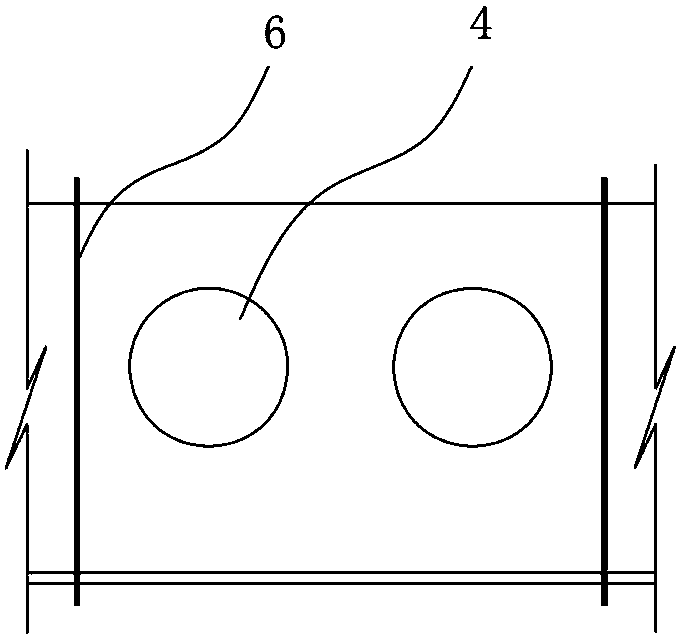

[0028] See attached figure 2 As shown, the wall formwork used during construction is multi-layer plywood, which is usually 1820 mm × 910 mm. In order to match the position of the wall formwork bolt 6 (horizontal spacing 460 mm), the axial distance between adjacent plastic pipes 4 is 230 Mm, the distance between the plastic pipe wall and the wall surface is not less than 100 ...

Embodiment 2

[0042] Example 2: 1. Wall panel design

[0043] The original design of the first underground floor of a project: the floor height is 4.15m, the bay size is 8.10m, the outer wall is 350mm thick, and the 30mm thick steel wire mesh anti-cracking layer is set on the waterfront; now a plastic hollow pipe is added to the wall, which is the existing underground floor. Design of pouring concrete light-weight pipe column wall panel.

[0044] Wall structure:

[0045] The 450mm height at the bottom end is a solid section, which is convenient to conform to the adjacent solid wall structure; the wall load is transmitted directly to the raft; it is convenient for the processing of construction joints.

[0046] The uppermost 700mm height is a solid section, which provides an anchorage length for the floor reinforcement; the upper wall and floor loads are evenly transmitted to the lightweight tubular column wall panel through this section; at the same time, it provides an anchoring area for the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com