Prefabricated composite steel tube concrete latticed column and construction method

A composite steel pipe, prefabricated assembly technology, applied in the direction of columns, piers, pillars, etc., can solve the problems that the material strength cannot be fully utilized, the construction technology is difficult to guarantee, and the concrete is not easy to pour, so as to save the amount of concrete, improve the durability, Weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

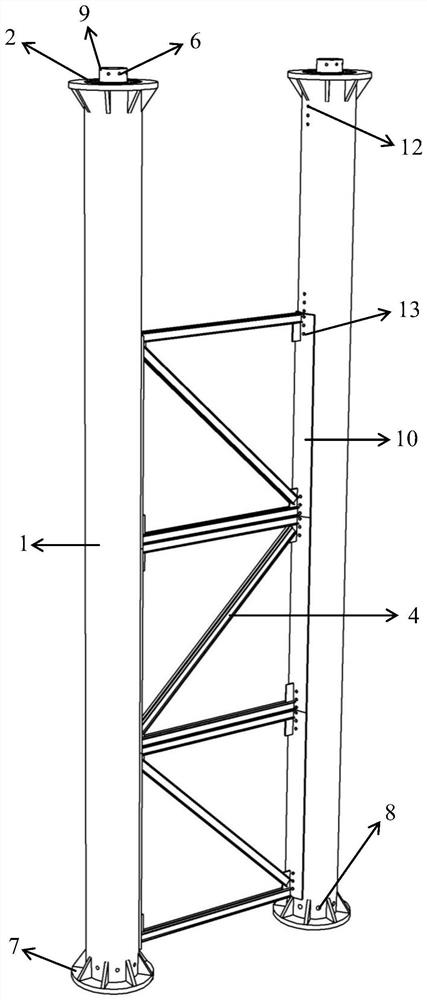

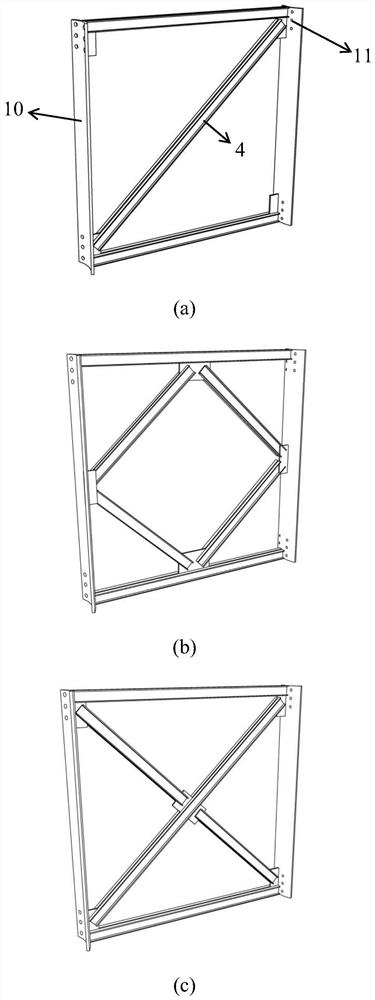

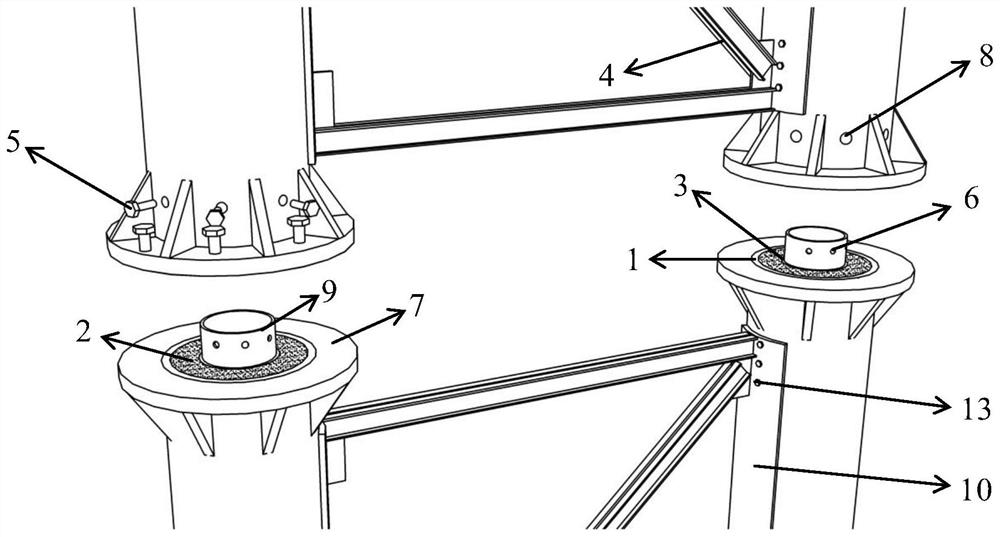

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0042] The present invention is a prefabricated equipped composite steel pipe concrete column, mainly including columns and grid-based connectors, and the grid-based connectors are mainly used in the connection between adjacent two column.

[0043] like figure 1 As shown, the state of the present invention includes: a prefabricated sandwiching high-performance concrete 2 between the column outer steel tube 1, the inner steel pipe 3 and the column outer steel tube 1 and the inner steel pipe 3 in the column.

[0044] Column outer steel pipe 1 and column in the column is generally a circular steel pipe, and the distance between the inner side wall of the column outer steel pipe 3 and the outer side wall of the steel pipe 3 can generally be 50 ~ 300mm, prefabricated sandwich high-performance concrete 2 According to the size of the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com