Multifunctional fast construction energy conservation bricks (building blocks) and dies therefor

A multi-functional, energy-saving brick technology, applied in molds, buildings, building components, etc., can solve the problems of poor sound insulation, no greening function, good air flow, etc., and achieve the effect of improving noise resistance and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

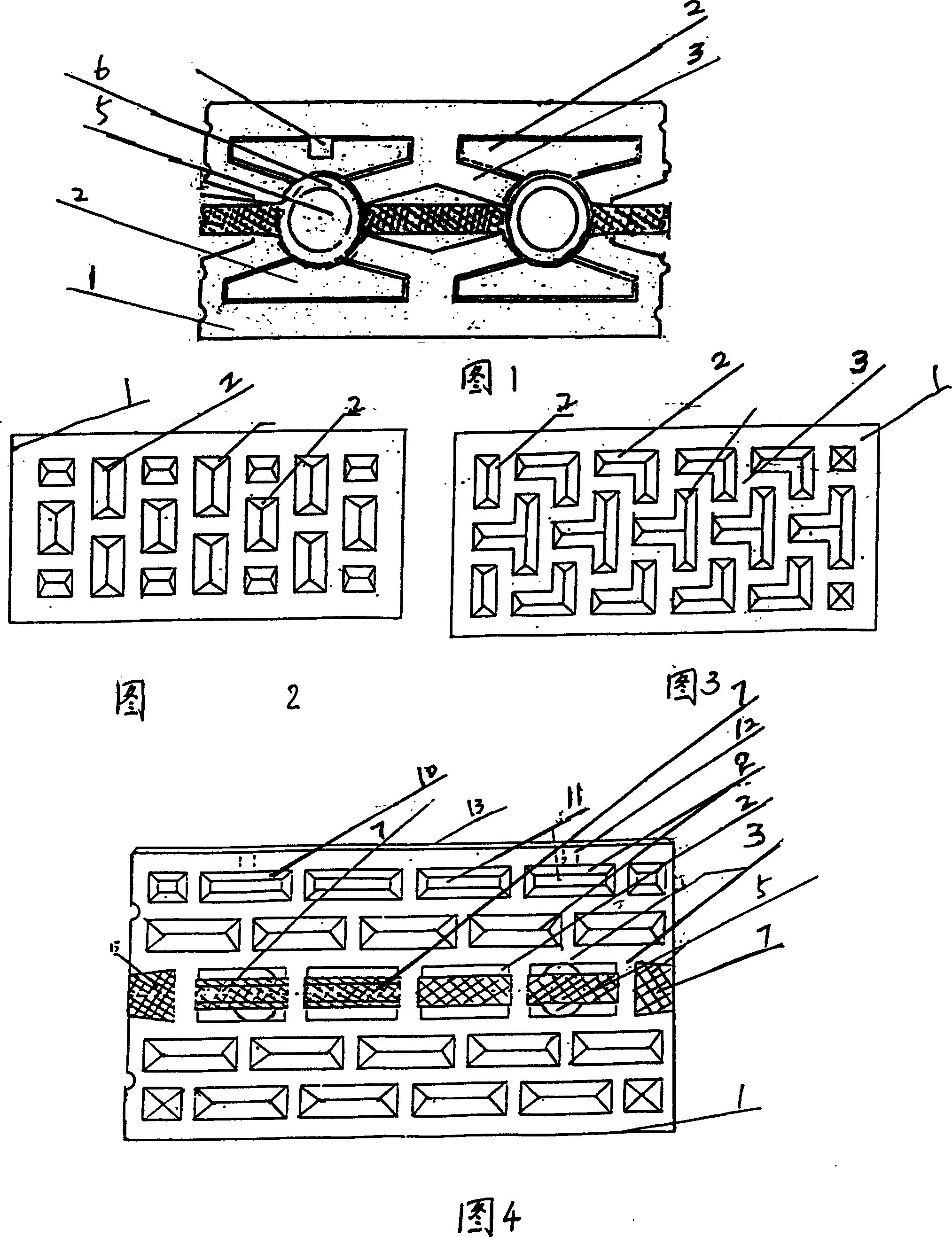

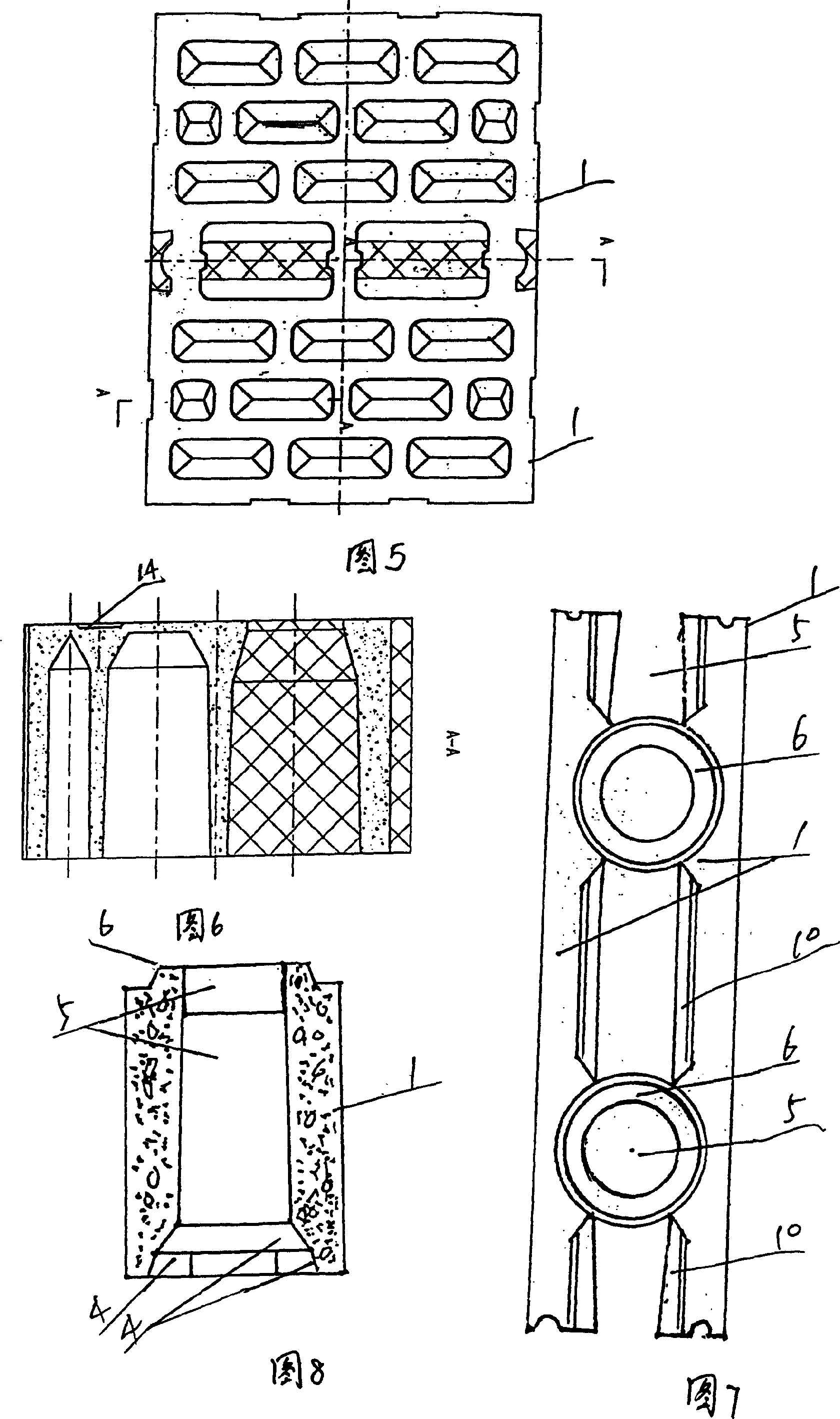

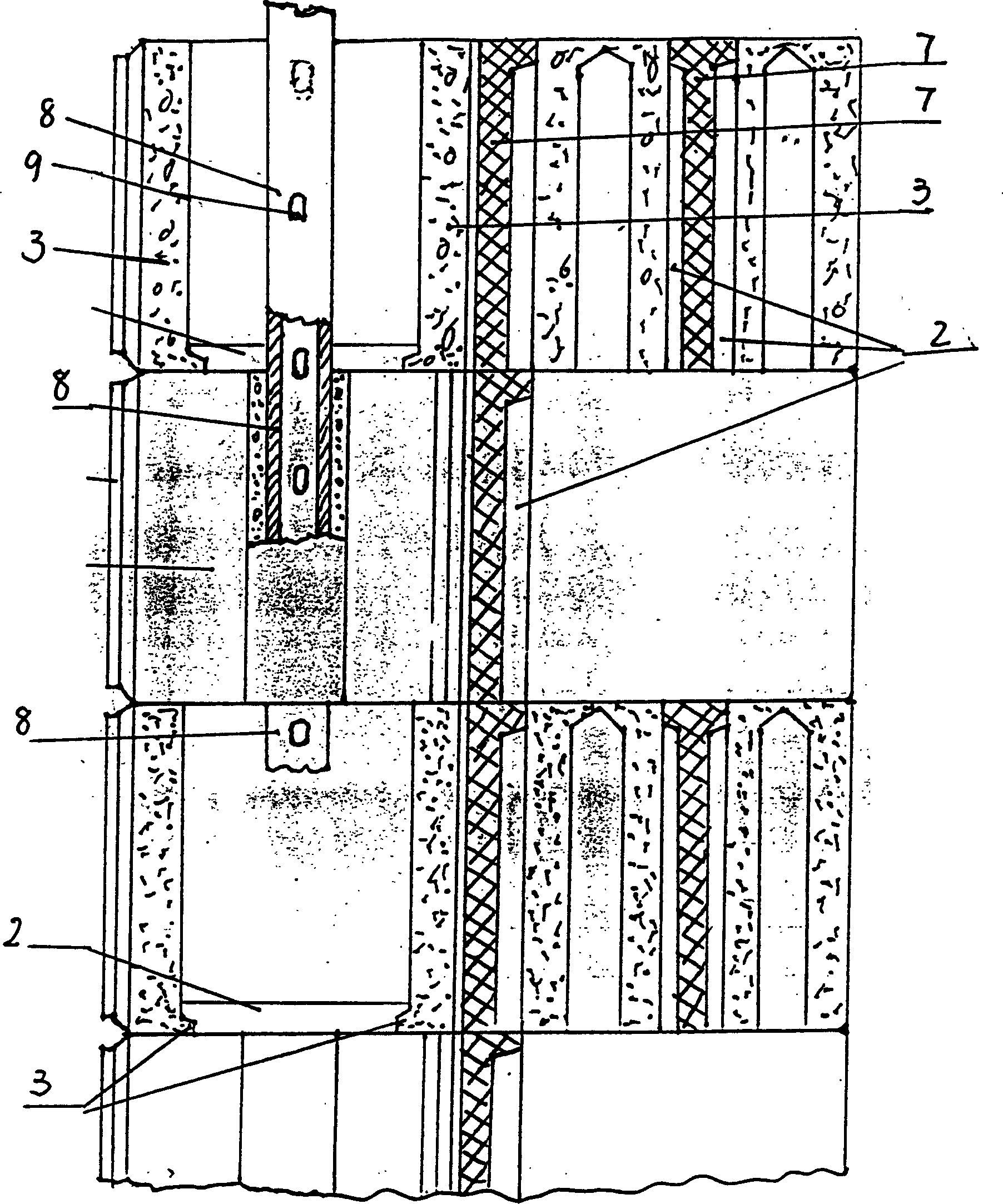

[0039] Figure 1- Figure 10Shown, the present invention comprises (block) body 1, is provided with the blind hole or semi-blind hole brick hole 2 of misplaced arrangement on brick (block) body 1, is blind hole on the end face of brick (block) body Or the capping surface of the semi-blind hole brick hole is provided with concave point 14. The concave point 14 can also become a mortise and tenon point, and the walls of each blind hole or semi-blind hole 2 in the brick (block) body 1 form scattering or cross-shaped internal ribs 3 . Concave-convex tenons 4 are provided on both sides of the bricks (blocks), and the left and right ends of each brick (block) body are engaged by the concave-convex tenons. Brick (block) body 1 is provided with steel pipe through-hole 5, and the two ends of steel pipe through-hole 5 are concave-convex tenon 6, and each brick (block) body 1 is meshed by concave-convex tenon 6 up and down. The steel pipe through-holes 4 in the brick (block) body 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com