Alpha + beta type two-phase titanium alloy for aero-engine fan blade and preparation method of alpha + beta type two-phase titanium alloy

A technology for aero-engines and fan blades, applied in the field of titanium alloys, can solve problems such as poor superplasticity and difficult diffusion connection control, and achieve the effects of improving tissue uniformity, reducing weight and increasing efficiency, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An α+β type two-phase titanium alloy for aero-engine fan blades, comprising the following chemical components by mass ratio: 4.2% to 5.6% of aluminum, 7.5% to 8.8% of vanadium, 0.18% to 0.24% of oxygen, and iron≤0.5% , niobium ≤ 1%, silicon 0.4% to 0.8%, carbon ≤ 0.05%, nitrogen ≤ 0.05%, hydrogen ≤ 0.015%, and the rest are titanium and impurity elements.

[0039] A method for preparing an α+β type two-phase titanium alloy for an aeroengine fan blade, comprising the following steps:

[0040] S1, according to the mass ratio to obtain the following chemical composition: aluminum 4.2% ~ 5.6%, vanadium 7.5% ~ 8.8%, oxygen 0.18% ~ 0.24%, iron ≤ 0.5%, niobium ≤ 1%, silicon 0.4% ~ 0.8%, carbon ≤ 0.05%, nitrogen ≤ 0.05%, hydrogen ≤ 0.015%, the rest is titanium and impurity elements;

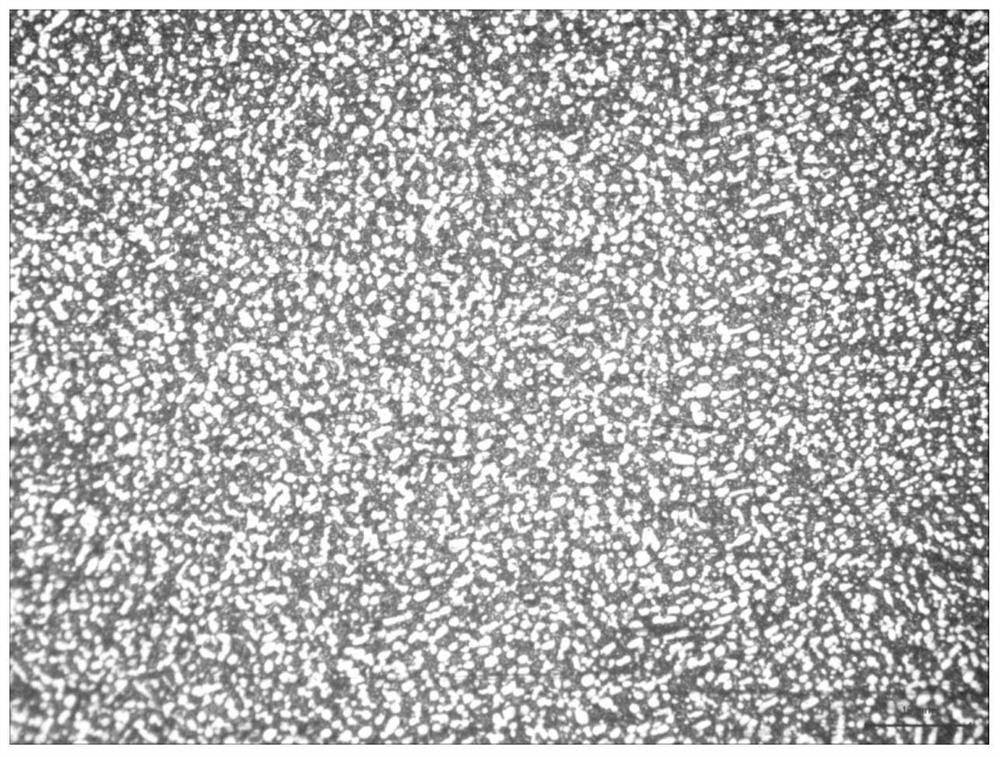

[0041] S2, the raw materials of each chemical composition are smelted three times by vacuum self-consumption to make titanium alloy ingots, and then measure the β transformation temperature of the...

Embodiment 2

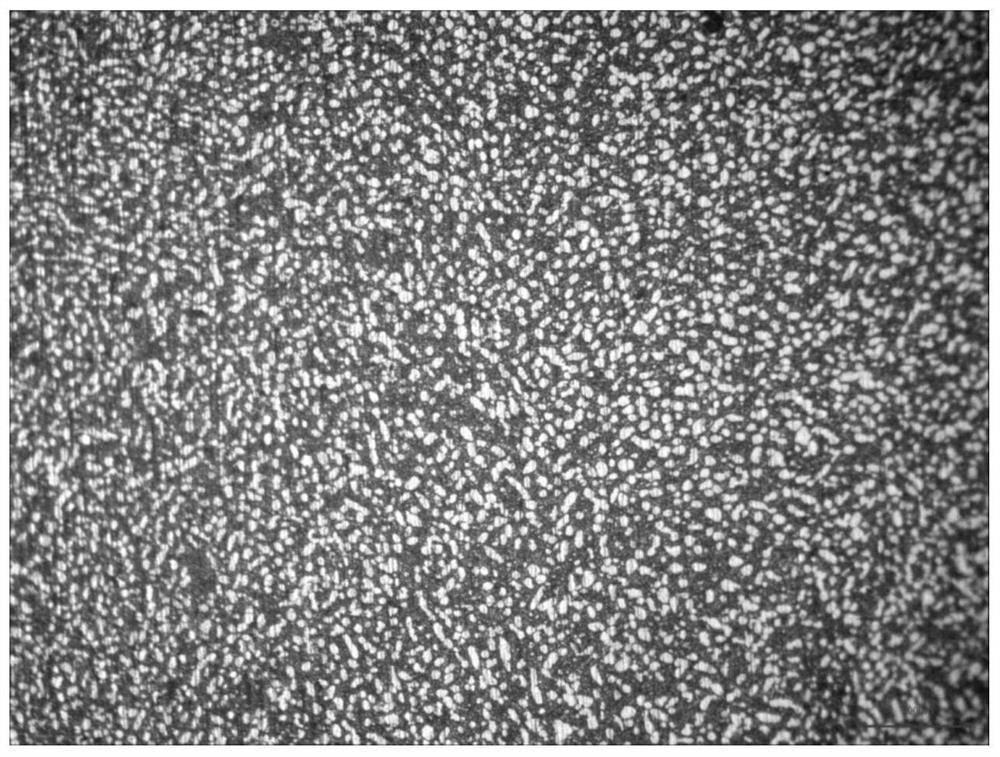

[0057] The difference between this embodiment and Embodiment 1 is that in step S3, the titanium alloy ingot is heated to the range of 30°C to 50°C below the β transformation point, and under the condition of preset deformation amount, after reversing, the The titanium alloy ingot is subjected to five times of upsetting in the second stage, so that the edge and center of the billet of the titanium alloy ingot are deformed evenly. The improvement of step S3 in this embodiment is an alternative to step S3 in embodiment 1. Please refer to figure 2 , the test results show that its tensile strength, yield strength, elongation, reduction of area and elastic modulus are 1137MPa, 1063MPa, 12.3%, 46.9% and 116GPa respectively, and its plasticity and rigidity are comparable to Ti-6Al-4V alloy, And the tensile strength is greater than 1100MPa. The research on the adaptability of blade forming process shows that its superplasticity and diffusion bonding performance also meet the require...

Embodiment 3

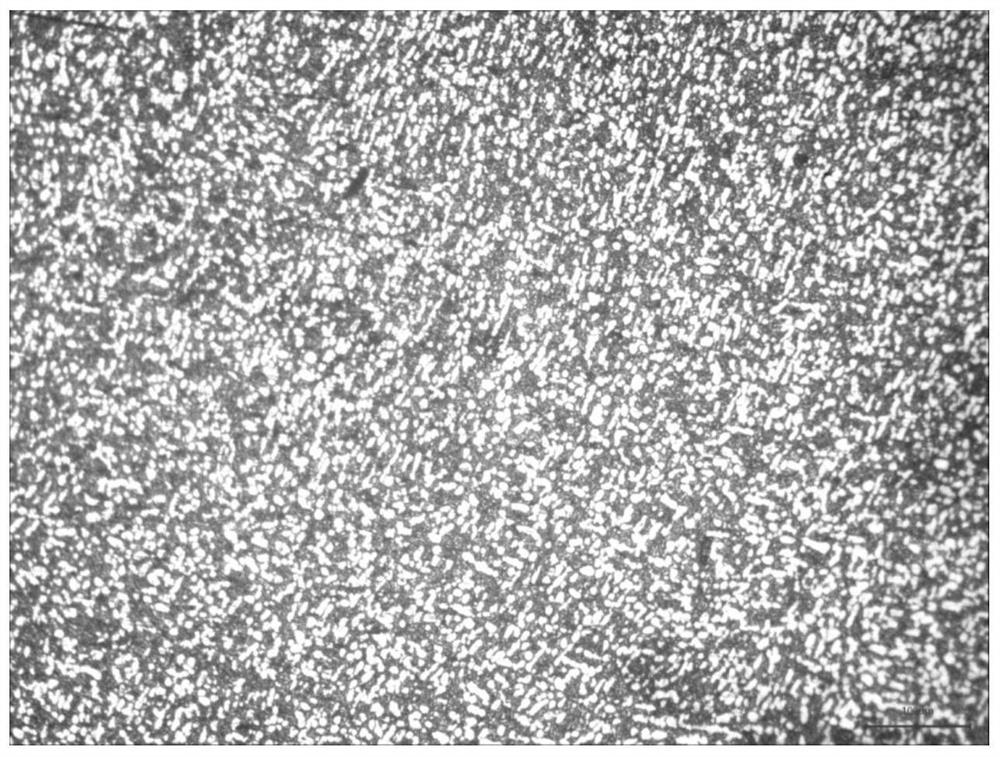

[0059] The difference between this example and Example 1 is that in S5, the titanium alloy ingot is heated to the range of 50°C to 80°C below the β transformation point, and the fourth-stage upsetting is performed six times in the α+β two-phase region. , so that the fine and uniform blank structure is completely broken, and the titanium alloy material is obtained. The improvement of step S5 in this embodiment is an alternative to step S5 in embodiment 1. Please refer to image 3 , the test results show that its tensile strength, yield strength, elongation, reduction of area and elastic modulus are 1121MPa, 1033MPa, 13.6%, 44.7% and 112GPa respectively, and its plasticity and rigidity are comparable to Ti-6Al-4V alloy, And the tensile strength is greater than 1100MPa. The research on the adaptability of blade forming process shows that its superplasticity and diffusion bonding performance also meet the requirements of superplastic forming / diffusion bonding process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com