Large horizontal hole overall prefabricated wall plate

A horizontal hole and assembled technology, applied in the direction of walls, building components, insulation, etc., can solve the problems of reducing the heat transfer coefficient of concrete walls, less stretching, and the self-heavyness of solid slabs, so as to reduce hoisting costs and foundation costs, Good waterproof ability, good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

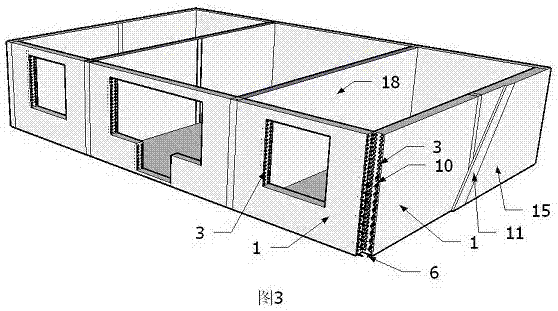

[0017] The present invention will be further explained below in conjunction with the drawings:

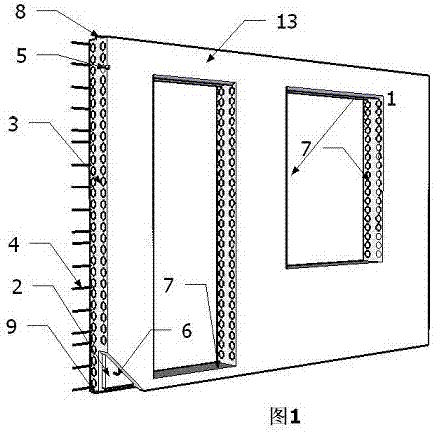

[0018] As attached figure 1 Shown: There are sandwich insulation board 2, double rows of horizontal holes 3 and prestressed steel bars 4 inside the large horizontal hole integrally assembled wall panel 1, and there are lifting gaps 5 at both ends of the large horizontal hole integrally assembled wall panel 1 , Doors and windows 7 are reserved on the wall panel, there are waterproof convex grooves 8 on the top surface of the wall panel, waterproof grooves 9 on the bottom and bottom of the wall panel, and ring beams 13 on the lower side of the wall panel.

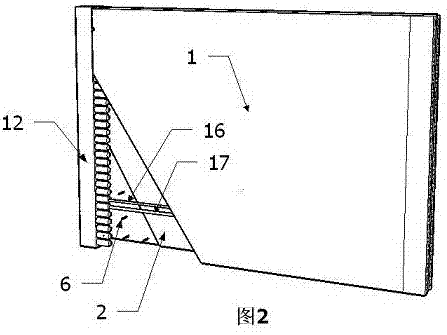

[0019] As attached figure 2 Shown: there is a sandwich insulation board 2 inside the large horizontal hole integrally assembled wall panel 1, and there are cast-in-place columns 12 and upper and lower ring beams 13 at both ends. Inside the inner horizontal hole 3 of the large horizontal hole integrally assembled wall panel 1, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com