One-step forming method for producing hollow light partion strip board and its flat mould

A technology of lightweight partition wall slats and molding methods, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting the strength and quality of the slats, unable to guarantee the bonding performance between the panel and the web, labor-consuming and time-consuming, etc. Achieve the effect of saving materials, facilitating the installation of water and electricity pipelines, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

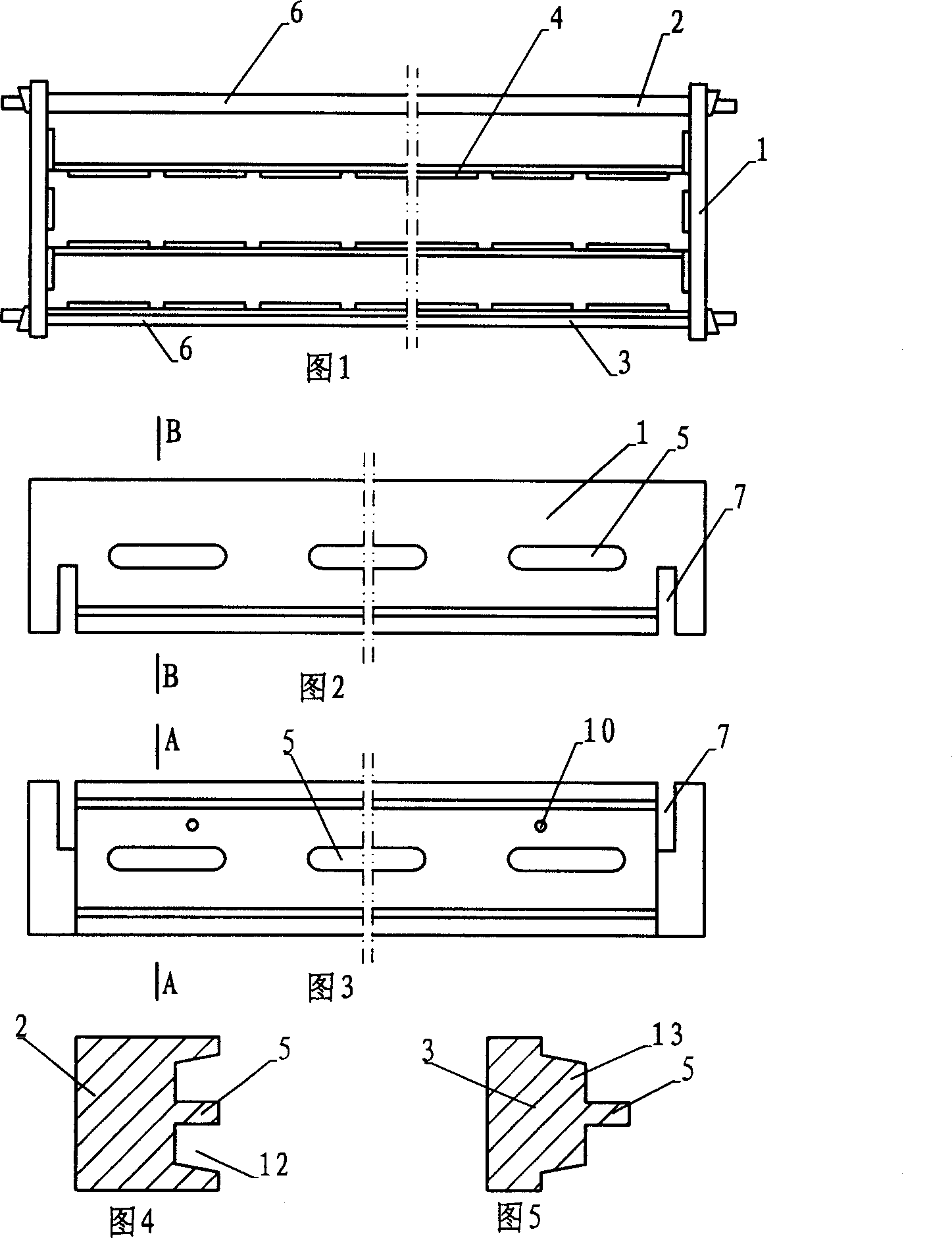

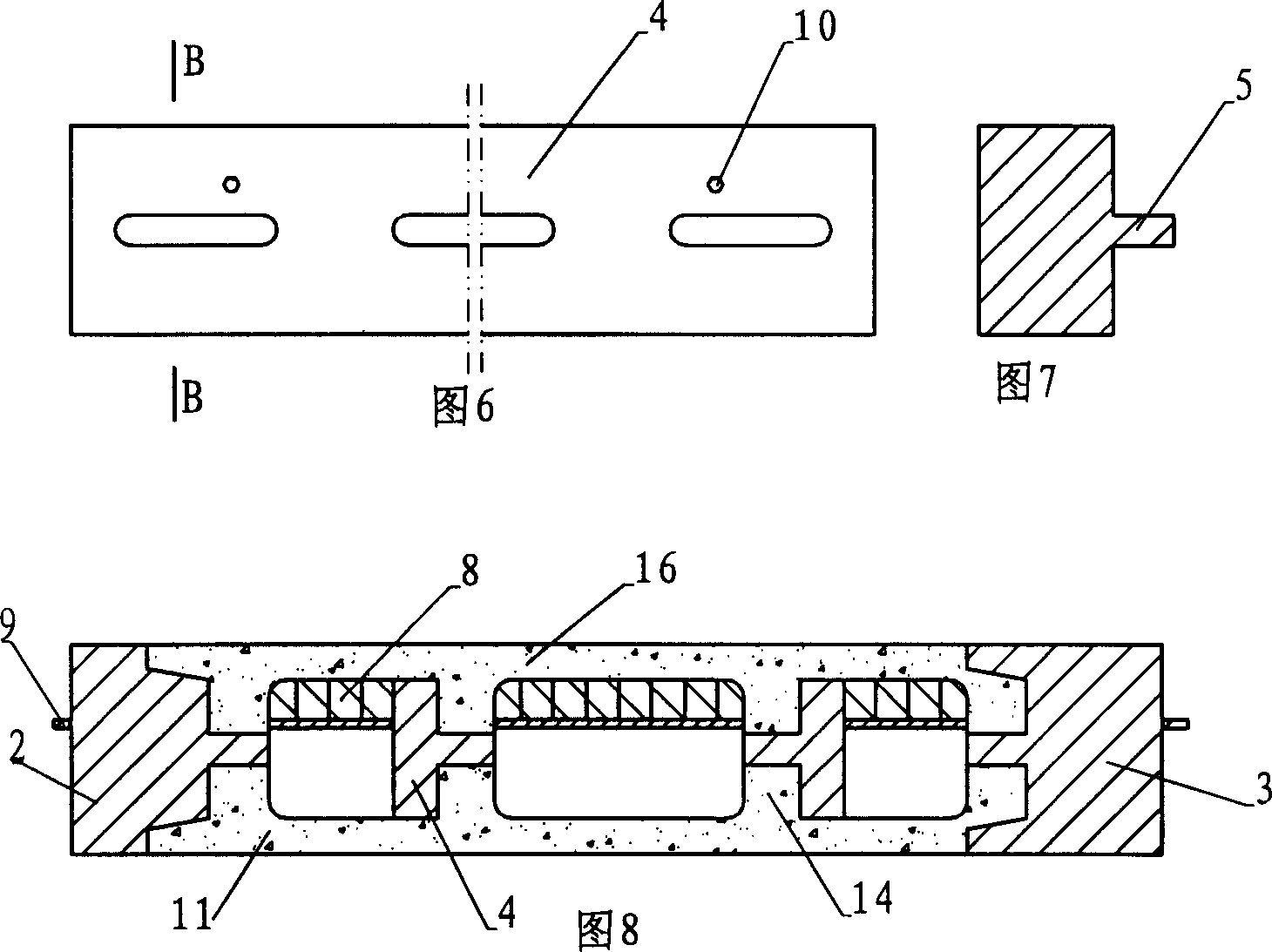

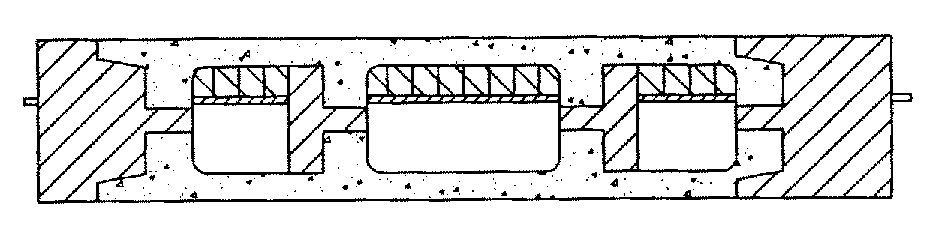

[0024] The flat mold of the present invention mainly includes: an end template 1 , a side template 6 , a partition template 4 and a hollow tire membrane plate 8 . Wherein the side formwork 6 includes a tenon formwork 2 and a grooved formwork 3 .

[0025] As shown in Figure 1, two end templates 1 and two side templates 6 are first combined into a quadrilateral mold frame, and the bayonet sockets 7 respectively arranged on the end template 1 and the side templates 6 are clamped up and down during assembly. To ensure that the frame is complete and firm, the two side formworks 6 are the tenon formwork 2 and the groove formwork 3 respectively. It can be seen from Fig. 4, Fig. 5 and Fig. 6 that a plurality of bosses 5 are arranged at a certain distance in the middle of one side of the longitudinal sides of the tenon formwork 2 and the groove formwork 3, and when the frame is assembled, the tenon The boss 5 on the formwork 2 and the grooved formwork 3 faces the inside of the frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com