Bidirectional pressing-vibrating type building block shaping machine

A block forming machine and a pressure-vibration technology, applied in the field of building block or brick forming equipment, can solve the problems of high power and energy consumption, insufficient uniform pressure, inconsistent strength, etc., to reduce the formula ratio and increase the density. degree, the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

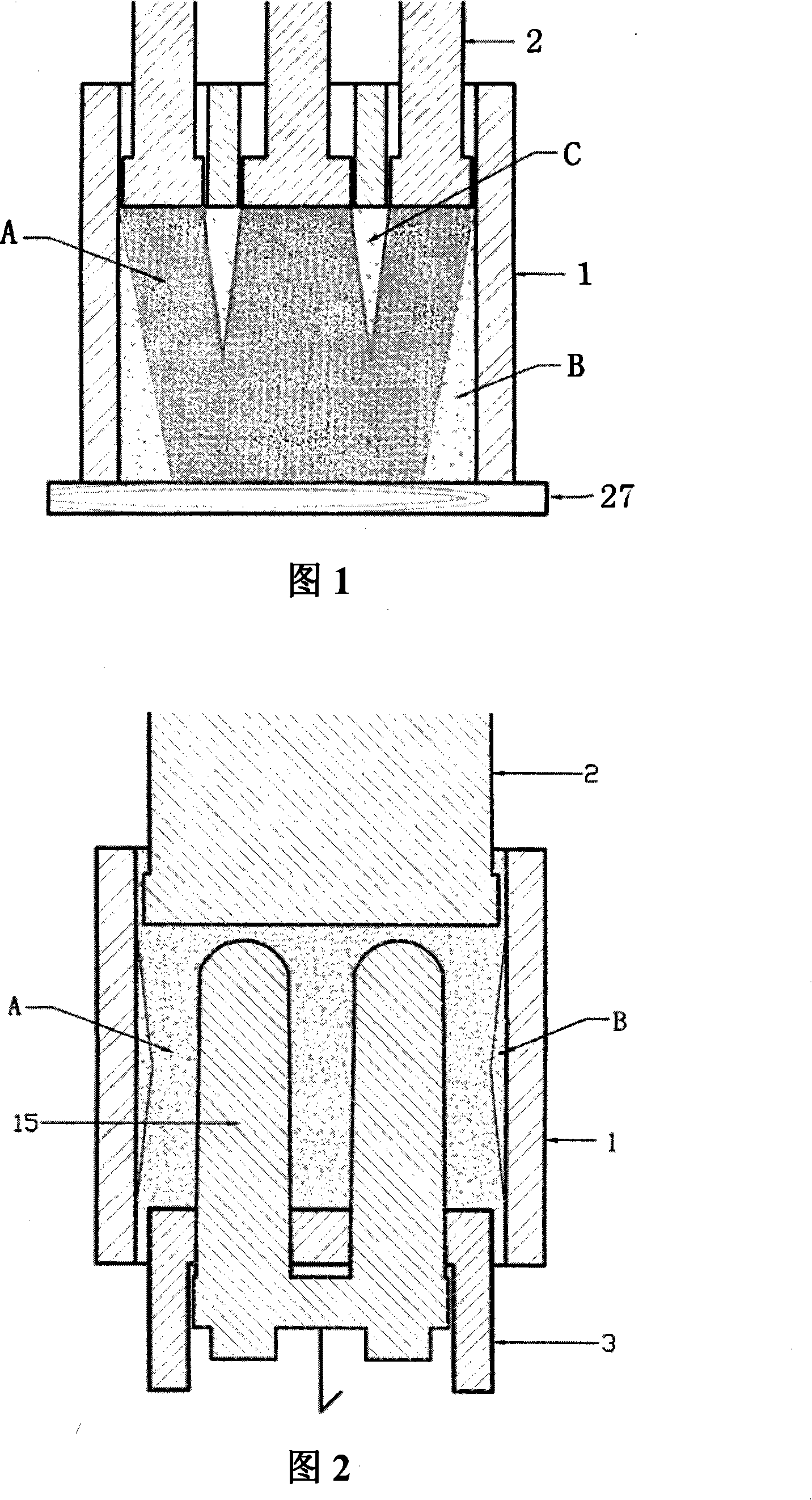

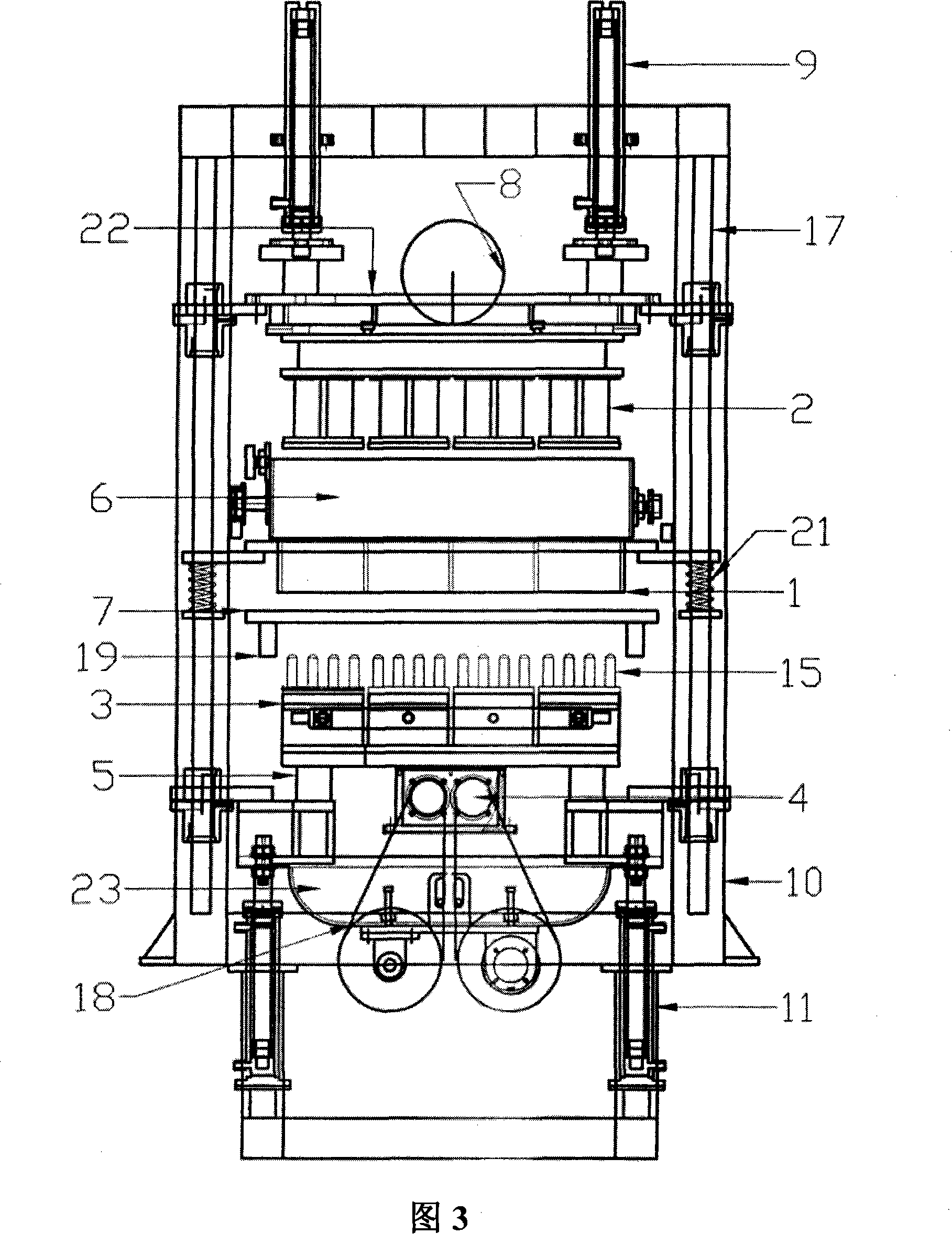

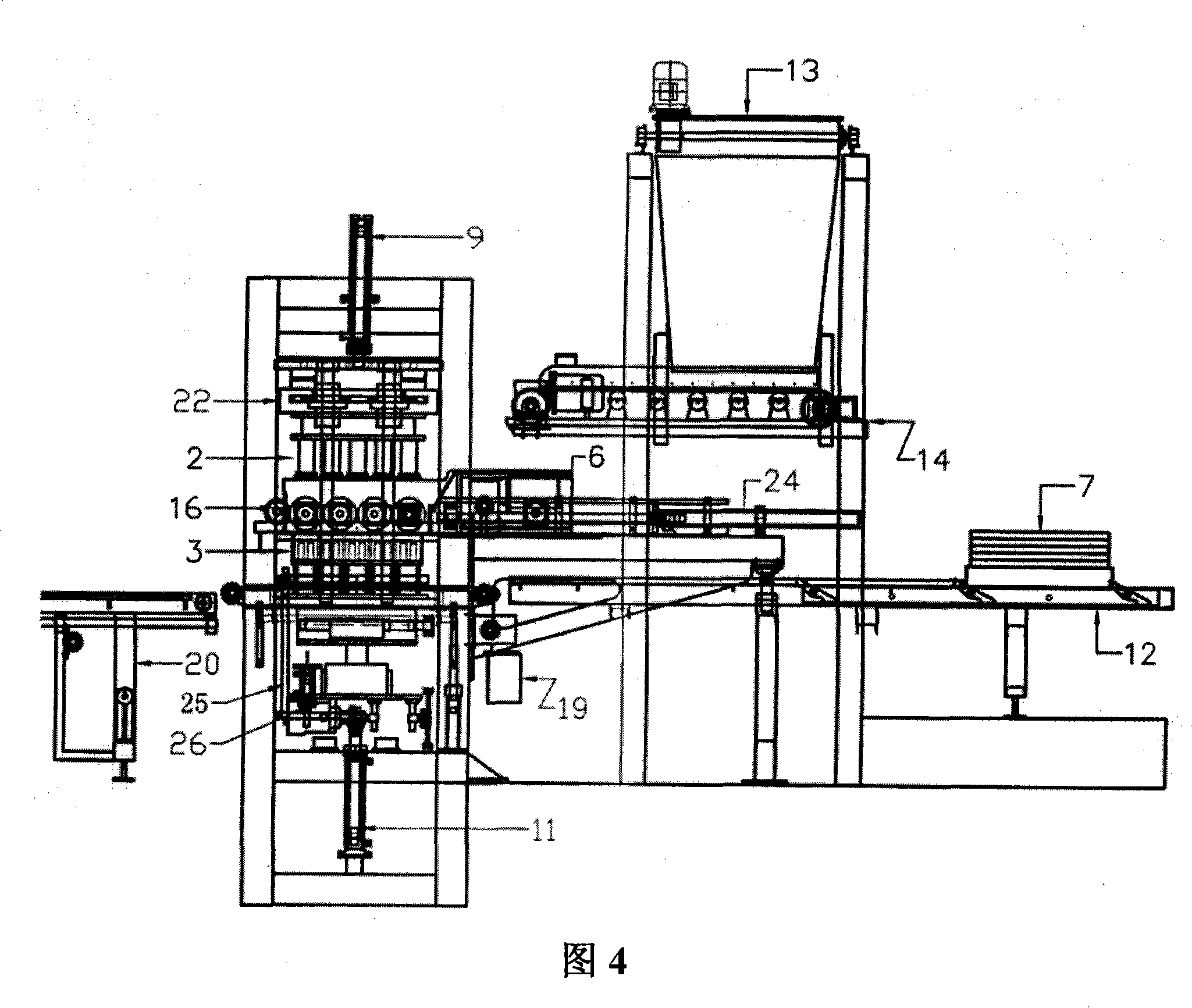

[0022] Referring to Fig. 2 and Fig. 3, the two-way vibratory pressure mechanism of the present invention is respectively provided with an upper indenter 2 and a lower indenter 3 above and below the mold box 1 which penetrates up and down, and the die heads on the two indenters 2 and 3 are opposed to the mold box. The material in 1 is subjected to two-way vibration extrusion. First, the compression distance is halved, the compression vibration force is reduced, and the cross-sectional area of the denser area B is also reduced, ensuring the uniformity of the upper and lower strength of the product; The mold beam on box 1 prevents serious loose area C from appearing on the product. The 3rd, mold box 1 is improved into suspension type by original fixed type, and promptly described mold box 1 and the connecting position of frame 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com