Hollow building block

A technology of hollow blocks and blocks, which is applied in the field of building wall materials, can solve problems such as wall cracking, filling wall damage, economic loss, etc., and achieve the effects of improving shear strength, facilitating masonry construction, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

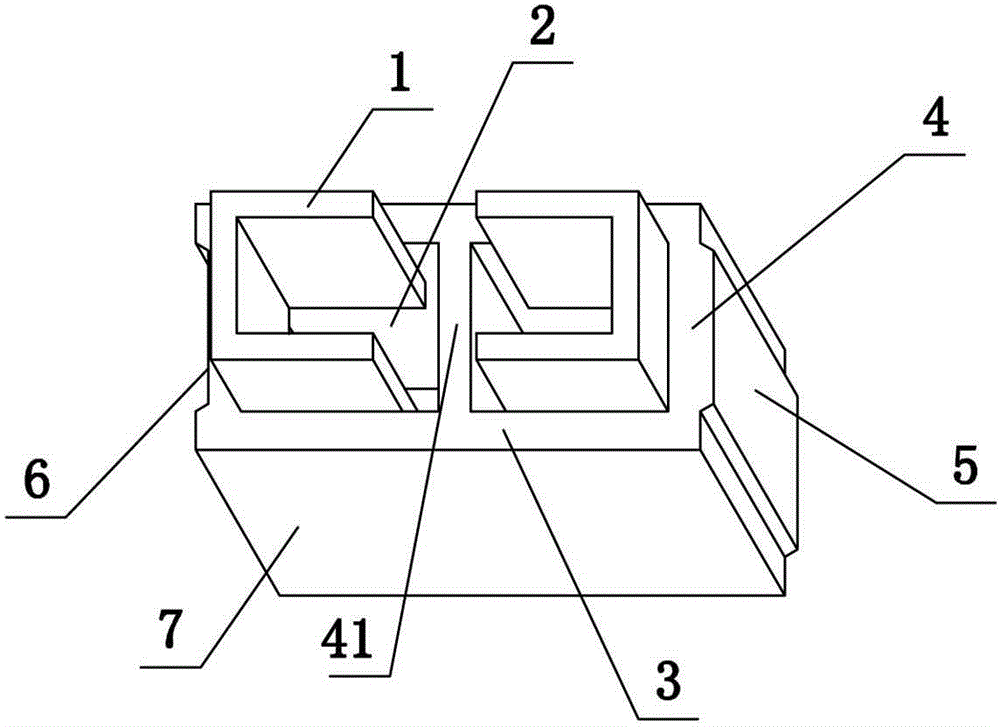

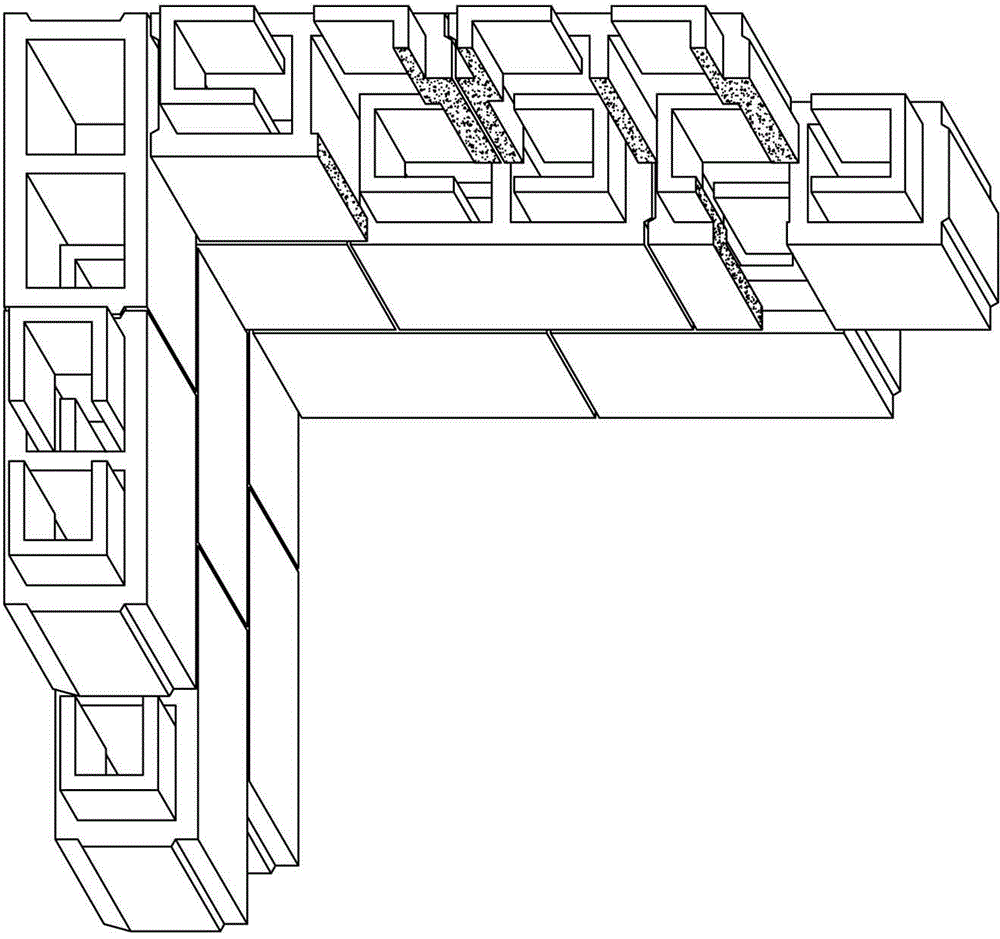

[0041] see attached figure 1 , the hollow block includes a rectangular block 7 with two holes in the shape of a "day" when viewed from above. The rectangular block 7 includes two vertical through holes 2, walls 3 on the front and rear sides, end ribs 4 on the left and right ends, and a middle rib 41. Including the protrusion 5 and the groove 6, the upper surface and the lower surface of the rectangular block are two planes parallel to each other. The hollow block also includes: a bolted part 1 respectively arranged in the two through holes 2 of the "day" shaped rectangular block, the bolted part 1 is arranged on the inner facade of the wall and the end rib, and the two bolted parts The horizontal sections of the components are all "concave" shapes and the concave facades are opposite; the external surface of the bolted component 1 is seamlessly fitted to the wall and end ribs, and is seamlessly fitted to the connecting top corners of the walls and end ribs. The overall vertic...

Embodiment 2

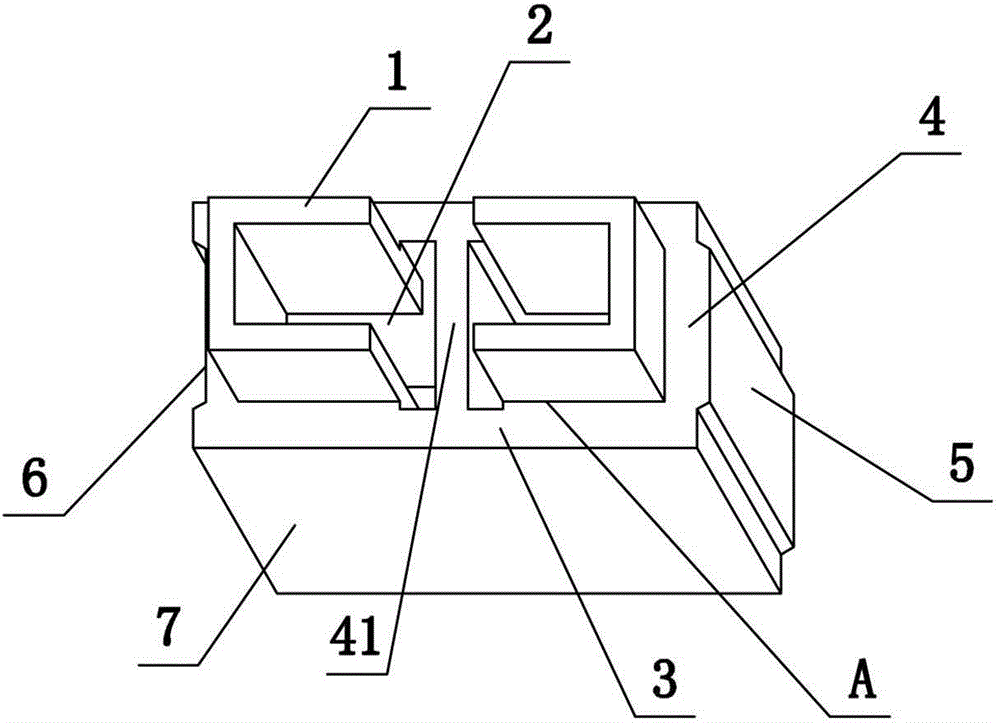

[0044] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the masonry structure is also the same. For details on the structure, see image 3 A guide position.

Embodiment 3

[0046] Such as Figure 4As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the masonry structure is also basically the same. The difference is that this embodiment does not include the structures of bumps 5 and grooves 6 in Embodiment 1. It is only necessary to find out the protruding parts of the upper ends of the bolted parts of the lower blocks and insert them into the through holes of the corresponding two adjacent blocks of the upper layer to nest the staggered joints and form a joint between the upper and lower blocks that are adjacent to each other. Just the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com