Hollow core slab for combined use of filling rods and filling boxes

A technology of filling rods and filling boxes, which is applied to floors, building materials processing, building components, etc., can solve problems such as large hollow ratio, and achieve the effect of large hollow ratio, convenient construction and installation, and saving concrete and steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is realized in the following manner:

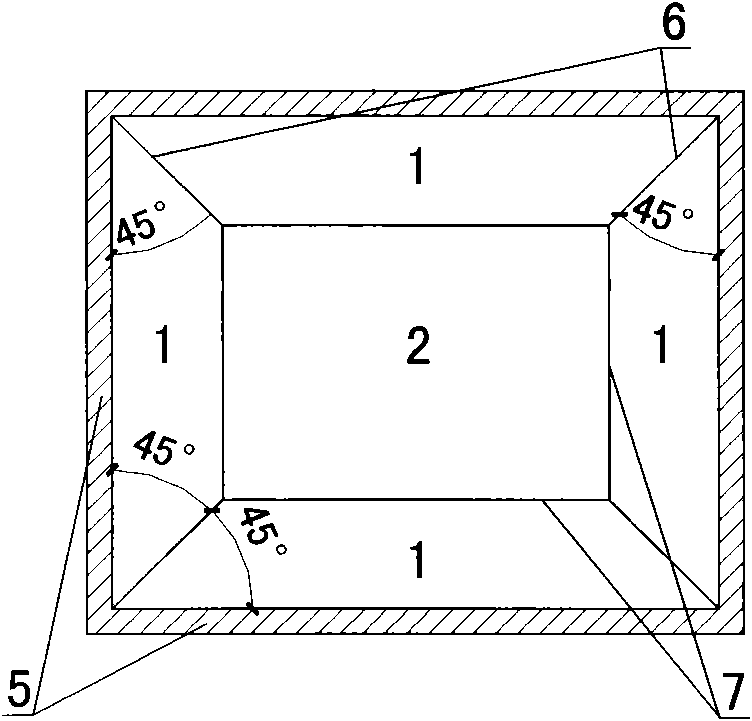

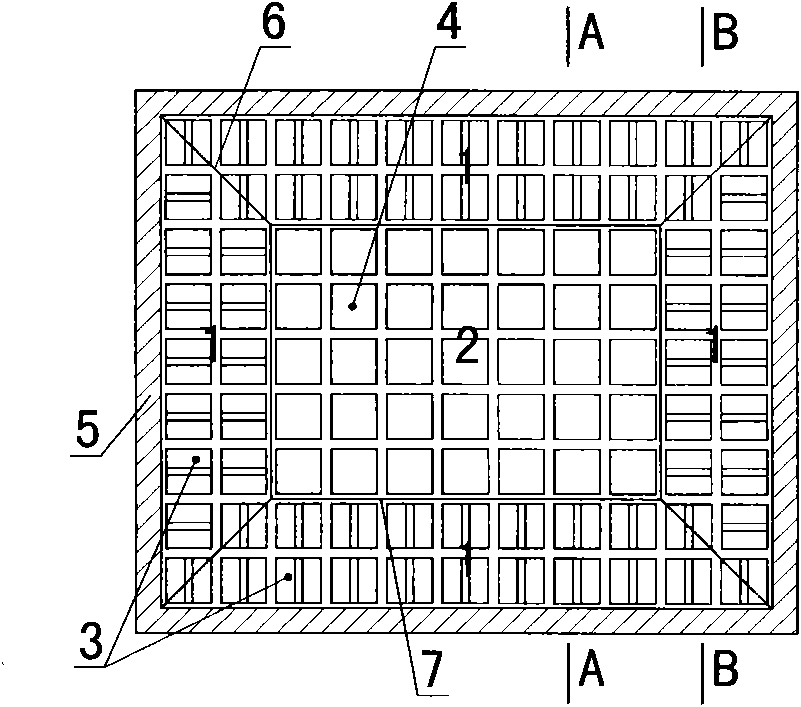

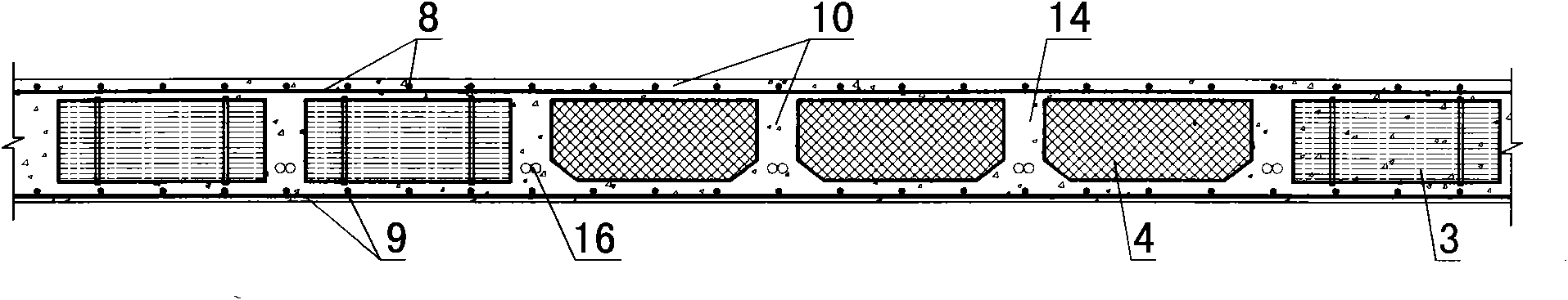

[0031] exist figure 1 , figure 2In the shown embodiment, a hollow plate mixed with filling rods and filling boxes is used. The hollow plate is a two-way plate, and the plate is divided into four peripheral hollow areas (1) and a central hollow area (2) from the plane. The filling rod combination block (3) and the filling box (4) are respectively buried in the peripheral hollow area (1) and the central hollow area (2), which is characterized in that four corners of the plate are connected with adjacent supports The side (5) forms an oblique line (6) of 45 degrees, and then makes 4 dividing lines (7) corresponding to the support side (5). The dividing line (7) intersects with the oblique line (6). The area enclosed by the boundary line (7) is the central hollow area (2), and the area enclosed by one support edge (5), two oblique lines (6) and one boundary line (7) is a peripheral hollow area (1), the orienta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com