Hollow glass microsphere prepared by soft template method and preparation method thereof

A technology of hollow glass microspheres and soft template method, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low compressive strength, inability to form balls, high water permeability, etc., and achieve high ball forming rate, Good for forming balls and improving the hollow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

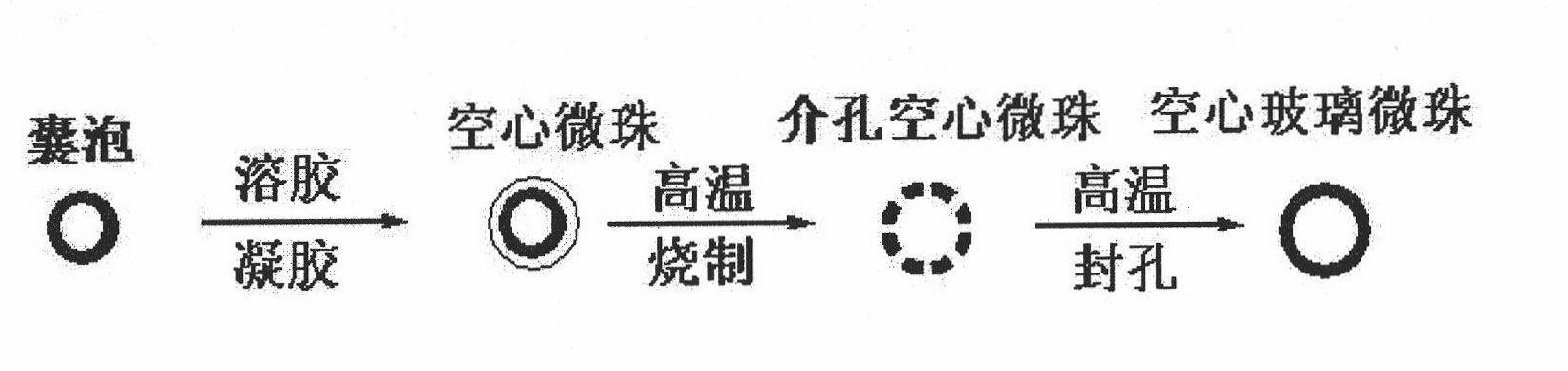

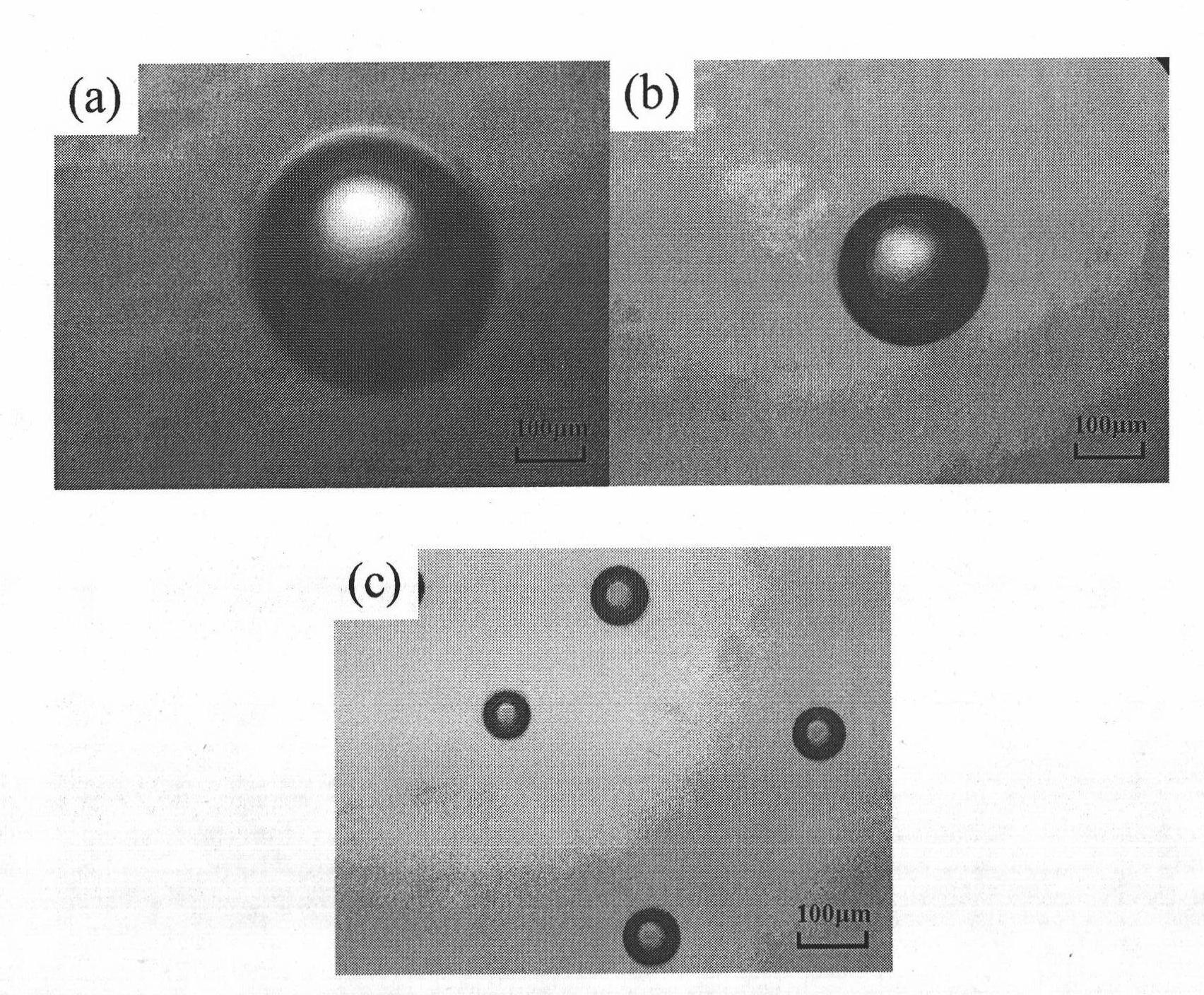

[0024] figure 1 It is a schematic diagram of the principle of preparing hollow glass microspheres according to the present invention. It can be seen from the figure that when n-octylamine and other n-octylamines are mixed with tetraethyl orthosilicate, microvesicles are first formed, and when the mixed solution containing ions is added to it, , (Earlier reports must add dilute acid solution to cause sol-gel reaction. In this example, it is found that replacing dilute acid with a small amount of ionic compound can not only make the reaction happen quickly, but also add other elements to the product) orthosilicic acid Ethyl ester rapidly undergoes a sol-gel reaction on the surface of the vesicles to form a layer of borosilicate compound with uniform thickness. The spherical shell of the microbeads has not undergone glass transition and has very low strength, so the stirring time should not be too long to avoid breaking. Then add the thick hollow microspheres from the top of the ...

example 1

[0026] Example 1: Mix 100ml of tetraethyl orthosilicate, 15ml of n-nonylamine and 10ml of n-decylamine, stir for 4 minutes and set aside, while fully dissolving 1.0g of sodium chloride, 0.5g of calcium chloride and 8g of borax in water at 80°C Then quickly pour the above mixed solution, stir at a constant speed, the stirring rate is 100 rpm, and the stirring time is 5 minutes. After the stirring is stopped, the product is filtered and dried to obtain the hollow borosilicate microbeads containing the soft template. The beads are added to a high-temperature vertical glass bead molding furnace at a temperature of 1100°C (manufactured by Wuhan Yahua Electric Furnace Co., Ltd., model: KY-30-6) for refining, and the hollow glass beads with spherical shells in a molten state are directly introduced into the circulation system. Quenched in the water tank of cooling water, the density is less than 1g / cm 3 The hollow glass microspheres float on the water, and the floating beads are coll...

example 2

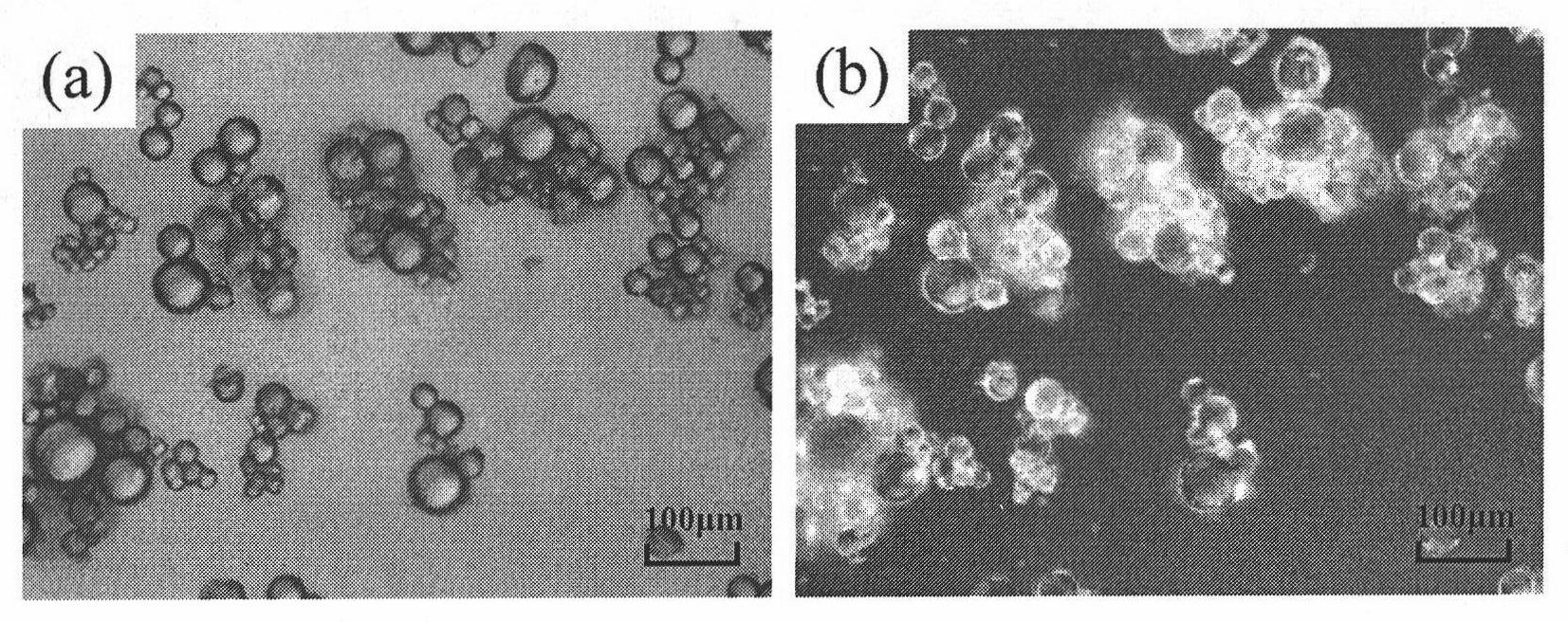

[0027] Example 2: Mix 100ml tetraethyl orthosilicate and 25ml n-octylamine, stir for 3 minutes and set aside, at the same time fully dissolve 2.5g potassium chloride and 10.0g borax in water at 80°C and quickly pour into the above mixture at a constant speed Stirring, the stirring rate is 800 rpm, and the stirring time is 10 minutes. After the stirring is stopped, the product is filtered and dried to obtain hollow borosilicate microbeads containing soft templates. The hollow microbeads are added to a refining furnace at a temperature of 1500 ° C. Refined, hollow glass microspheres with spherical shells in a molten state are directly introduced into a water tank with circulating cooling water for quenching, and the density is less than 1g / cm 3The hollow glass microspheres float on the water, and the floating beads are collected through a filter screen and dried at a constant temperature (80°C) to obtain the finished product. The bulk density is 0.54g / cm 3 .

[0028] image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com