Lightweight material combination unit filled prestressed concrete cast-in-situ hollow slab

A technology of combining units and lightweight materials, used in floors, building components, buildings, etc., can solve problems such as poor handling, low hollowness of hollow slabs, and time-consuming pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

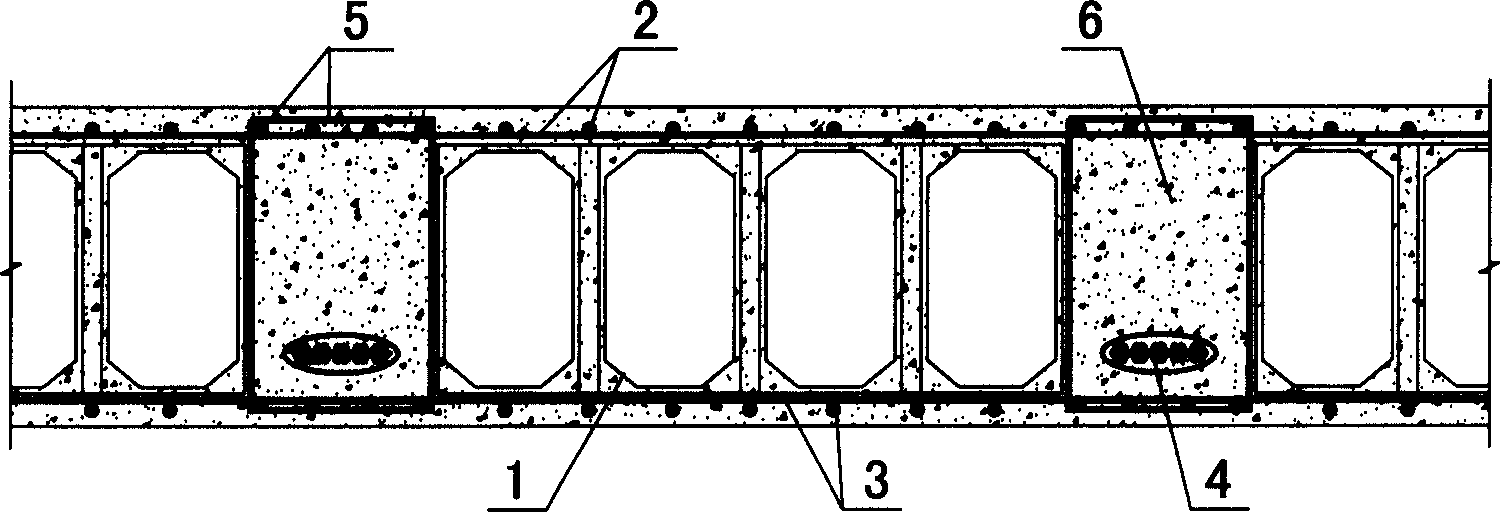

[0013] The present invention is realized in the following manner:

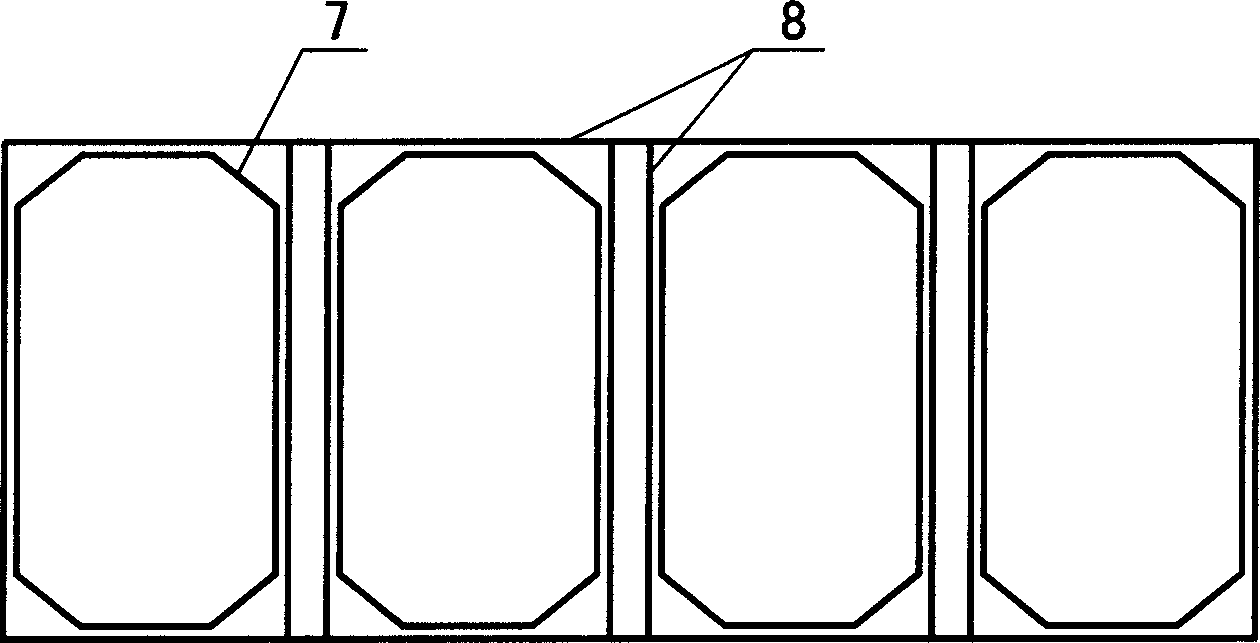

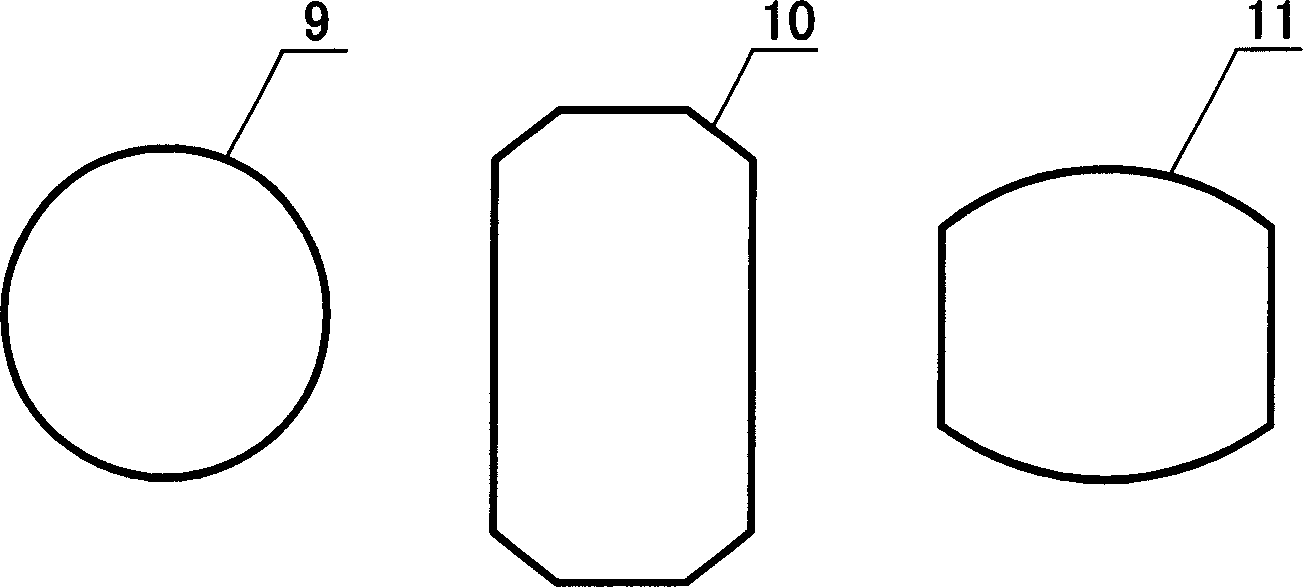

[0014] 1. To produce light-weight material pipes (7), the light-weight material must have a small unit volume weight and no pollution, and can be solid or hollow. The cross-sectional form of the lightweight material pipe (7) can be a circle (9), a broken line (10), or a combination of a rectangle and an arc (11). The height and width of the section are close to each other, and the aspect ratio range is 0.6 -2.0. Several pipes are connected by connecting steel bars (8) around the circumference of the light material pipes (7) to form a lightweight material composite unit (1), and the connecting steel bars (8) fix the position of the light material pipes (7) , and at the same time, the spacing between adjacent pipes in the same combined unit should meet the requirements to ensure the quality of concrete pouring.

[0015] 2. Binding the lower steel bars (3) of the hollow slab; setting hidden beams in the slab, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com