Adjustable fireless return device for locomotive

A non-fire loopback and adjustable technology, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve the problems of safety accidents and complicated setting of non-fire loopback, and achieve the effects of reducing costs, facilitating locomotive piping, and having a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

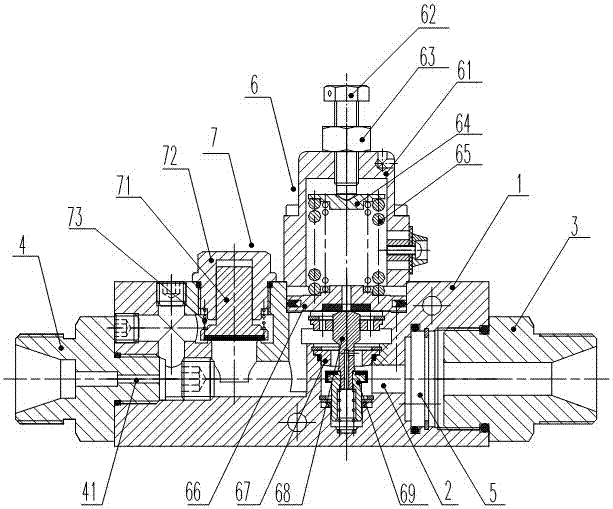

[0021] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

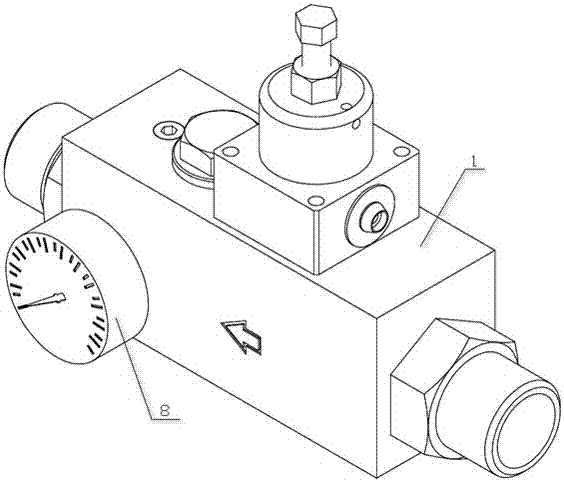

[0022] like Figure 1 to Figure 4 As shown, an adjustable fire-free return device for locomotives includes a valve body 1, a transverse channel 2 is opened on the valve body 1, a joint 3 is installed at one end of the channel 2, and a choke plug 4 is installed at the other end, from the joint 3 to the choke flow In the direction of the plug 4, the filter element 5, the pressure regulating valve assembly 6 and the one-way valve assembly 7 are sequentially installed in the channel.

[0023] The blocking hole 41 of the blocking plug 4 has a diameter of 3 mm. The valve body 1 is also provided with a pressure gauge 8 for measuring the gas pressure in the channel after pressure regulation.

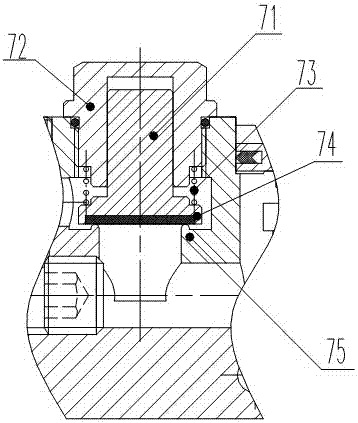

[0024] see image 3 , the one-way valve assembly 7 includes a valve core 71, a one-way valve housing 72 and a spring-1 73, a one-way valve assembly hole that commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com