Tenon-and-mortise hollow building block and laying method thereof

A hollow block and block technology, which is used in construction, building components, building materials, etc., can solve the problems of prone to cracks, poor horizontal shear resistance and shear resistance, and achieve improved seismic performance, improved shear resistance, The effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

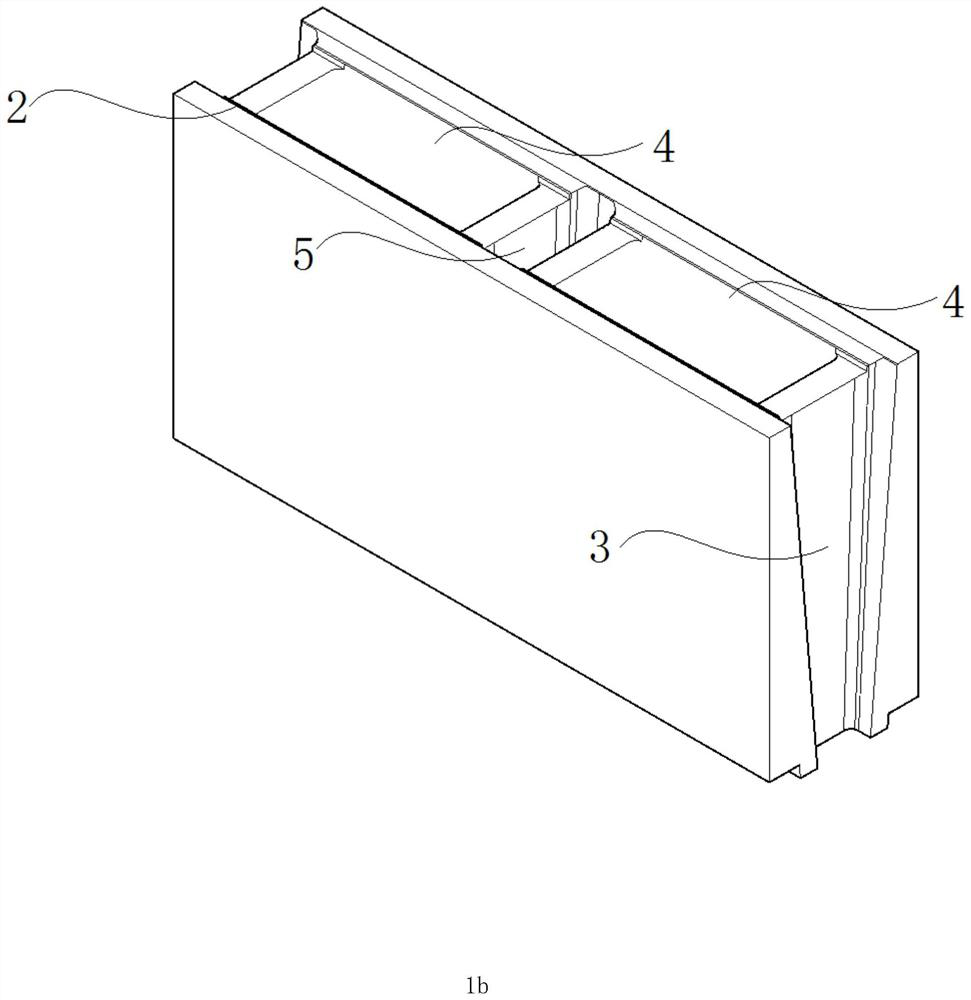

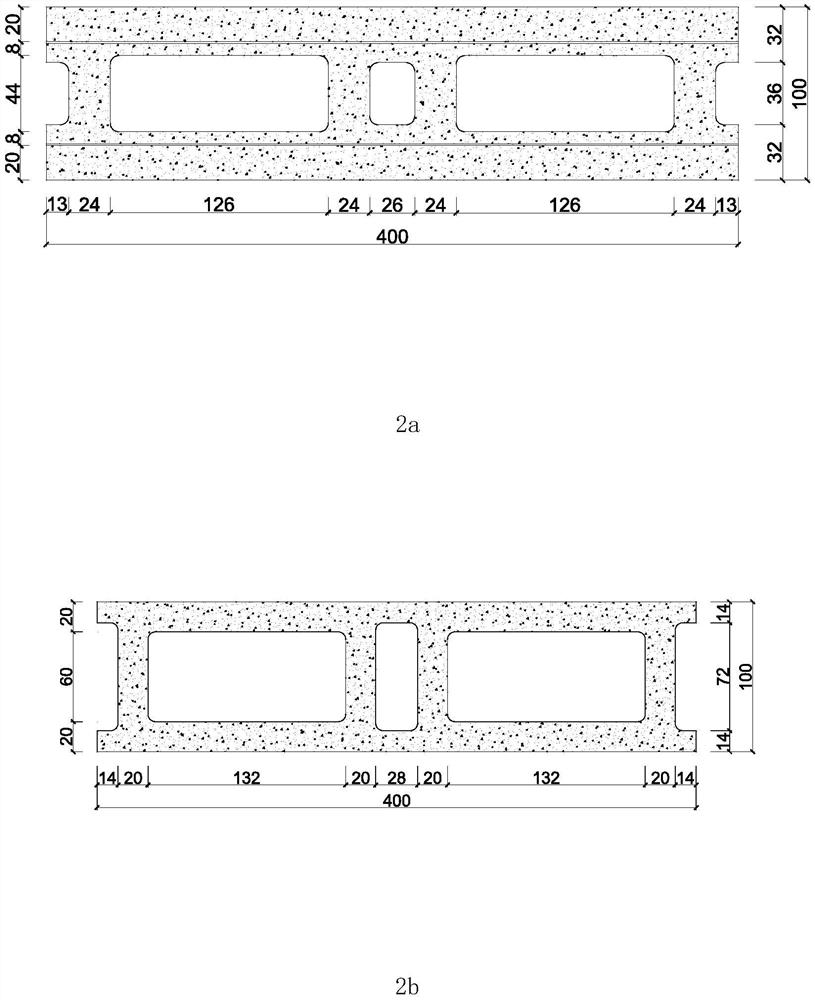

[0038] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

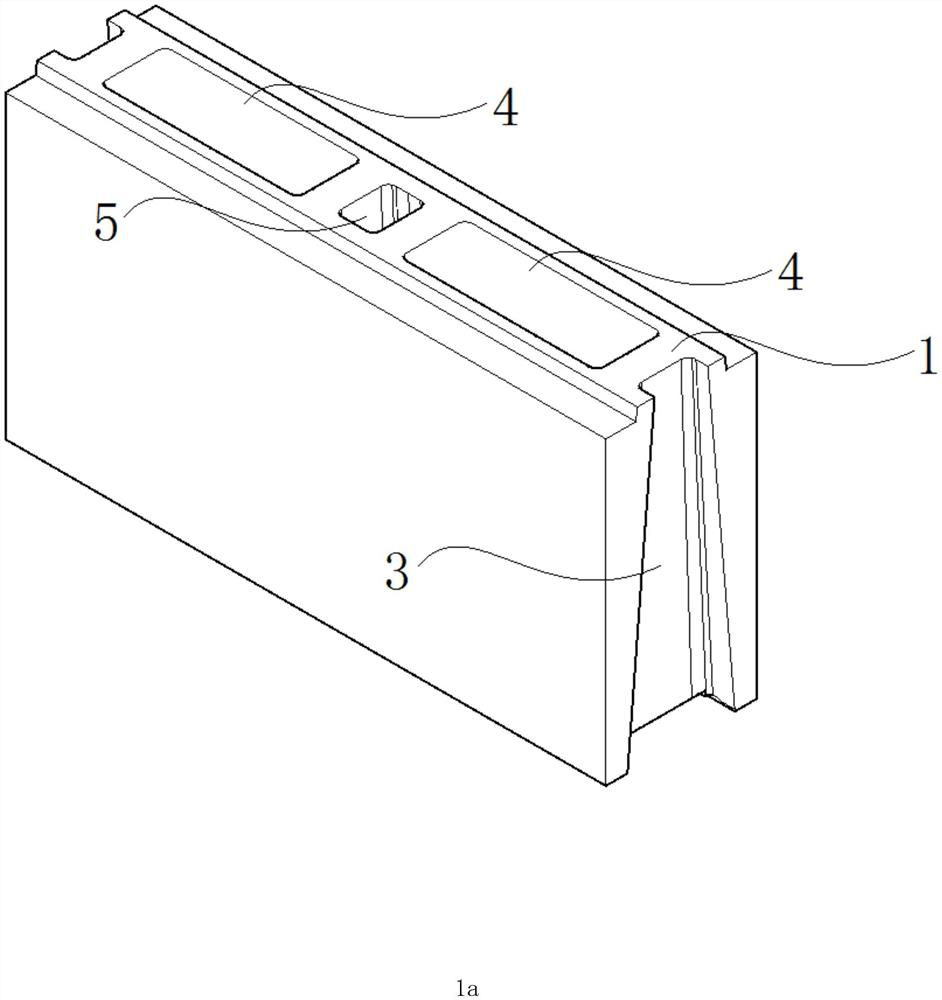

[0039] In the case of common use of concrete hollow blocks, it is prone to poor shear resistance in the vertical wall direction and cracks in the wall. In order to better improve the performance of concrete block masonry, this application provides a The new hollow block structure has modified the masonry itself and introduced the form of tenon and tenon structure, as shown in Figure 1, including the block body. In 1a, the top of the block body is provided with convex ribs, and in 1b , the bottom of which is provided with a groove 2. During the masonry process, several block bodies need to be superimposed or arranged side by side. A certain distance is require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com