Steel truss support capable of windowing and steel truss barrel structure including same

A technology of steel truss and window opening, applied in the direction of building structure and construction, can solve problems such as opening, and achieve the effects of improving economic benefits, shortening construction time, and eliminating shear lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

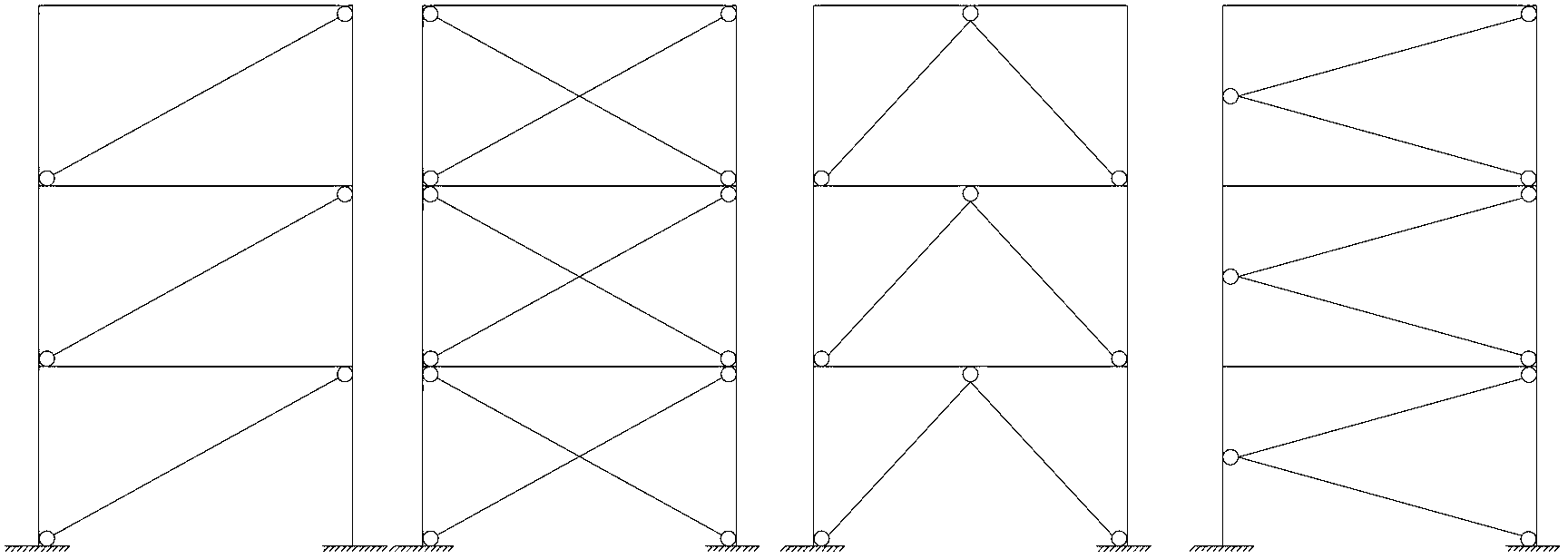

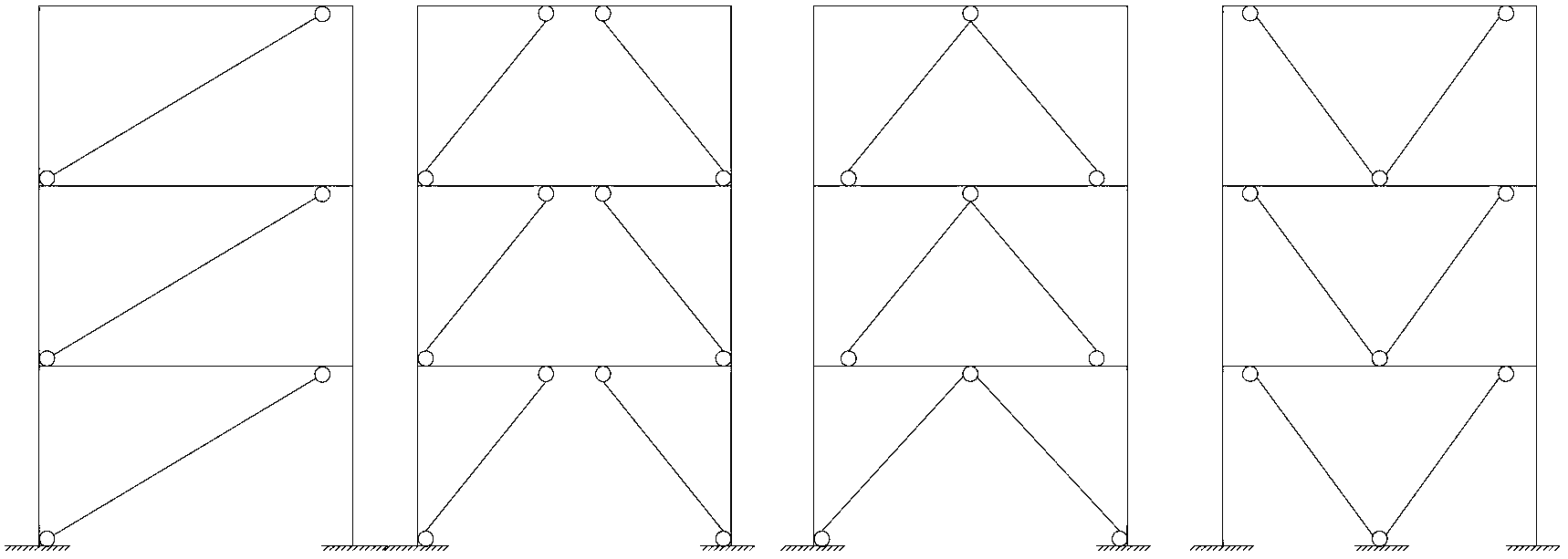

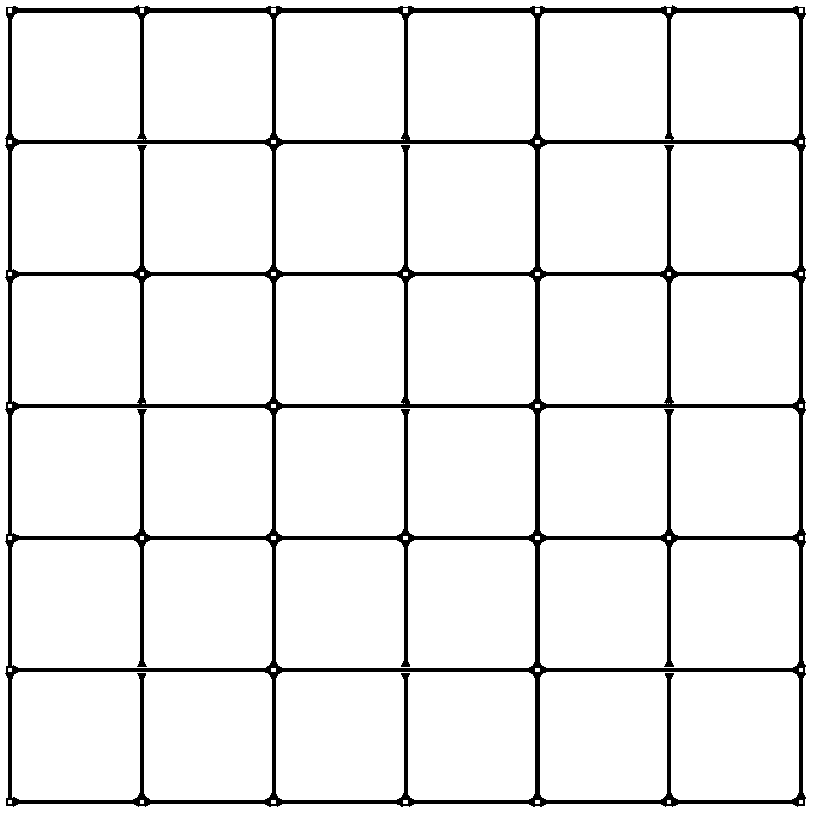

[0019] A steel truss support capable of opening windows and a steel truss cylinder structure system containing the support, a schematic diagram of a window opening in a steel frame, as shown Figure 5 As shown, it is composed of frame beam 5, frame column 6, short diagonal brace 1, long diagonal brace 2, horizontal support 3, vertical support 4, gusset plate 7, support rod 8 and end plate 9. Among them, the frame beam 5 is made of H-shaped steel, the frame column 6 is made of square steel pipe, and the short brace 1, the long brace 2, the horizontal brace 3 and the vertical brace 4 are all made of H-shaped steel. The frame beam 5 and the frame column 6 are rigidly connected by bolts, and the connection of the short brace 1, the long brace 2, the horizontal brace 3, the vertical brace 4, the support rod 8 and the end plate 9 is factory prefabricated. One end of the gusset plate 7 is connected to the lower flange of the frame beam 5 and the inside of the frame column 6 at the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com