Shear wall-support structure system

A support system and support structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of limited coupling beam size and energy consumption capacity, limited energy consumption capacity, inconvenient construction, etc., to improve the seismic fortification standard, Easy-to-repair, easy-to-construct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

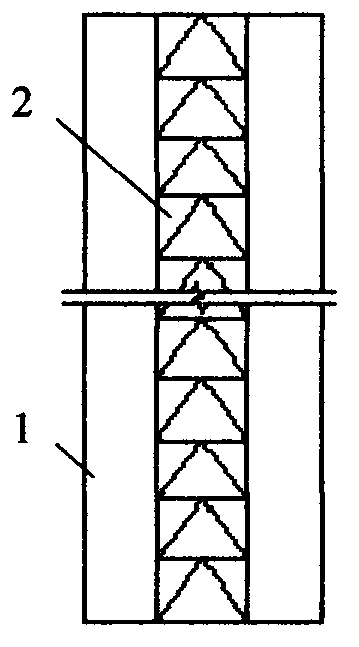

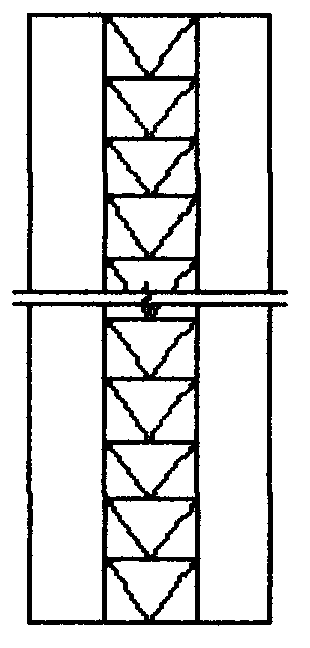

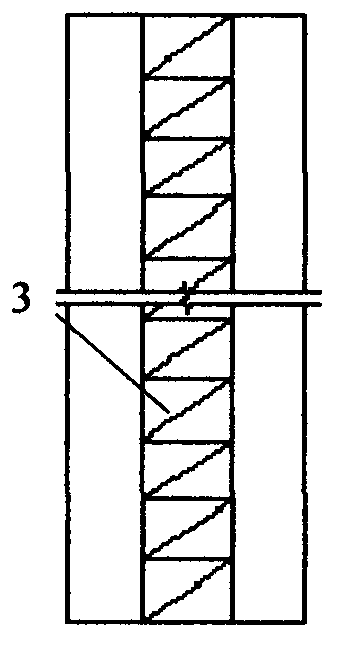

[0009] A support system is set between the concrete shear wall limbs, and the support members can use members with high bearing capacity, high rigidity, and good energy dissipation capacity, such as steel members, steel pipe concrete members and FRP-confined concrete members. Damping components or devices can be set in the support system, such as anti-buckling supports and frictional energy dissipation dampers. The connection between the support system and the shear wall can be welded, bolted or embedded in the shear wall. The type, material, size and setting form, type, material and size of the shear wall can be determined according to the bearing capacity, stiffness, energy consumption requirements and service conditions of the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com