A lead core corrugated steel tube restraining rubber bearing

A corrugated steel pipe and rubber bearing technology, which is applied in building types, buildings, building components, etc., can solve the problems of limited restraint effect of lead cores and inability to exert energy dissipation capacity stably, so as to improve seismic energy dissipation capacity and ensure horizontal isolation. Seismic and reset characteristics, guaranteeing the effect of restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

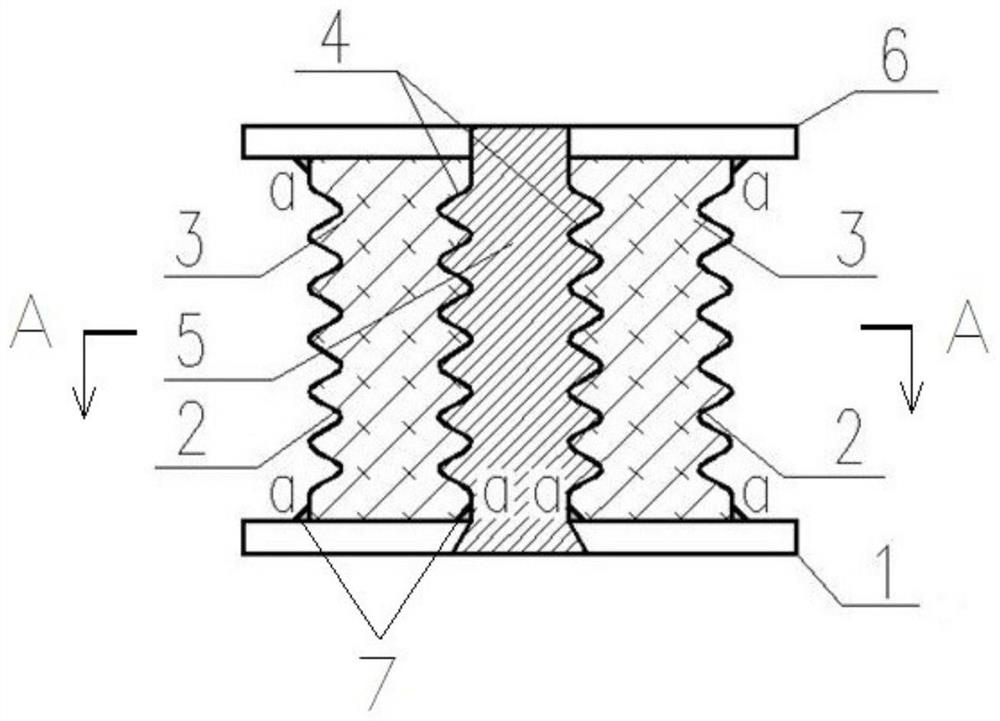

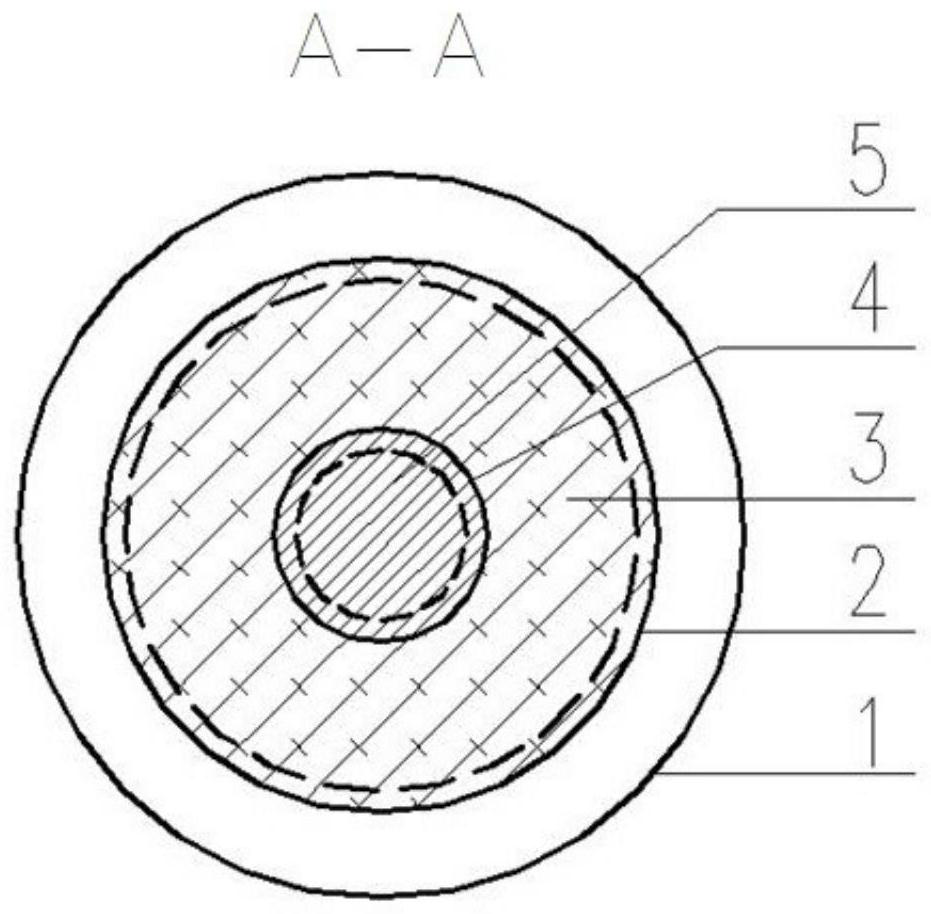

[0018] combine figure 1 and image 3 This embodiment will be specifically described. A lead-core corrugated steel pipe constrained rubber support in this embodiment is arranged between the foundation of the house, the bottom or the substructure and the upper structure, including the lower connecting steel plate 1, the outer corrugated steel pipe 2, the rubber interlayer 3, and the inner corrugated Steel pipe 4, lead core 5 and upper connecting steel plate 6. The lower connecting steel plate 1 is used to connect the support of the present invention with the structural foundation, the bottom or the lower structure. The inner corrugated steel pipe 4 is coaxially installed in the outer corrugated steel pipe 2, and the upper end of the inner corrugated steel pipe 4 is cylindrical and inserted Set in the central hole of the upper connecting steel plate 6, the lower end of the inner layer corrugated steel pipe 4 and the upper and lower ends of the outer layer corrugated steel pipe ...

Embodiment 2

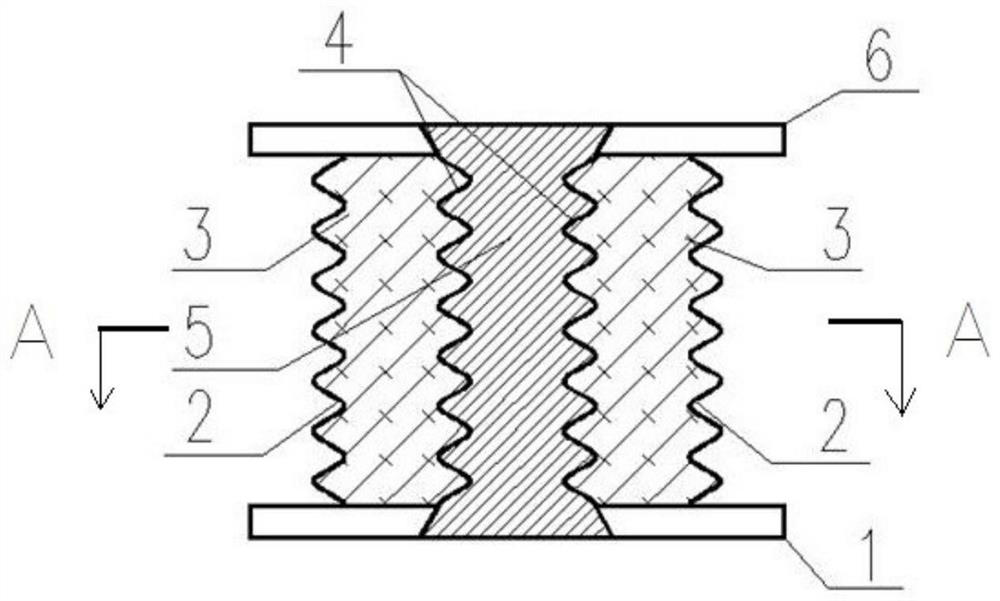

[0023] combine figure 2 and image 3 The difference between this embodiment and Embodiment 1 is that the upper and lower ends of the inner corrugated steel pipe 4 and the upper and lower ends of the outer corrugated steel pipe 2 are respectively positioned with the inner surfaces of the lower connecting steel plate 1 and the upper connecting steel plate 6 by spot welding. .

[0024] The difference in the manufacturing process is: after the outer layer corrugated steel pipe 2 and the inner layer corrugated steel pipe 4 are coaxially positioned at the center of the lower connecting steel plate 1, both are positioned by spot welding with the lower connecting steel plate 1, and then the inner layer corrugated The steel pipe 4 is filled with a lead core 5, and then rubber is added between the outer corrugated steel pipe 2 and the inner corrugated steel pipe 4, and then both the outer corrugated steel pipe 2 and the inner corrugated steel pipe 4 are spot welded to the upper connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com