Rotary kiln hook nail arrangement method

A rotary kiln and hook nail technology, applied in the field of rotary kiln, can solve the problems of loose lining castable structure, affecting the use of the rotary kiln, affecting the lining of the rotary kiln, etc., so as to reduce pollution, improve the ability to resist mechanical vibration, and save maintenance. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

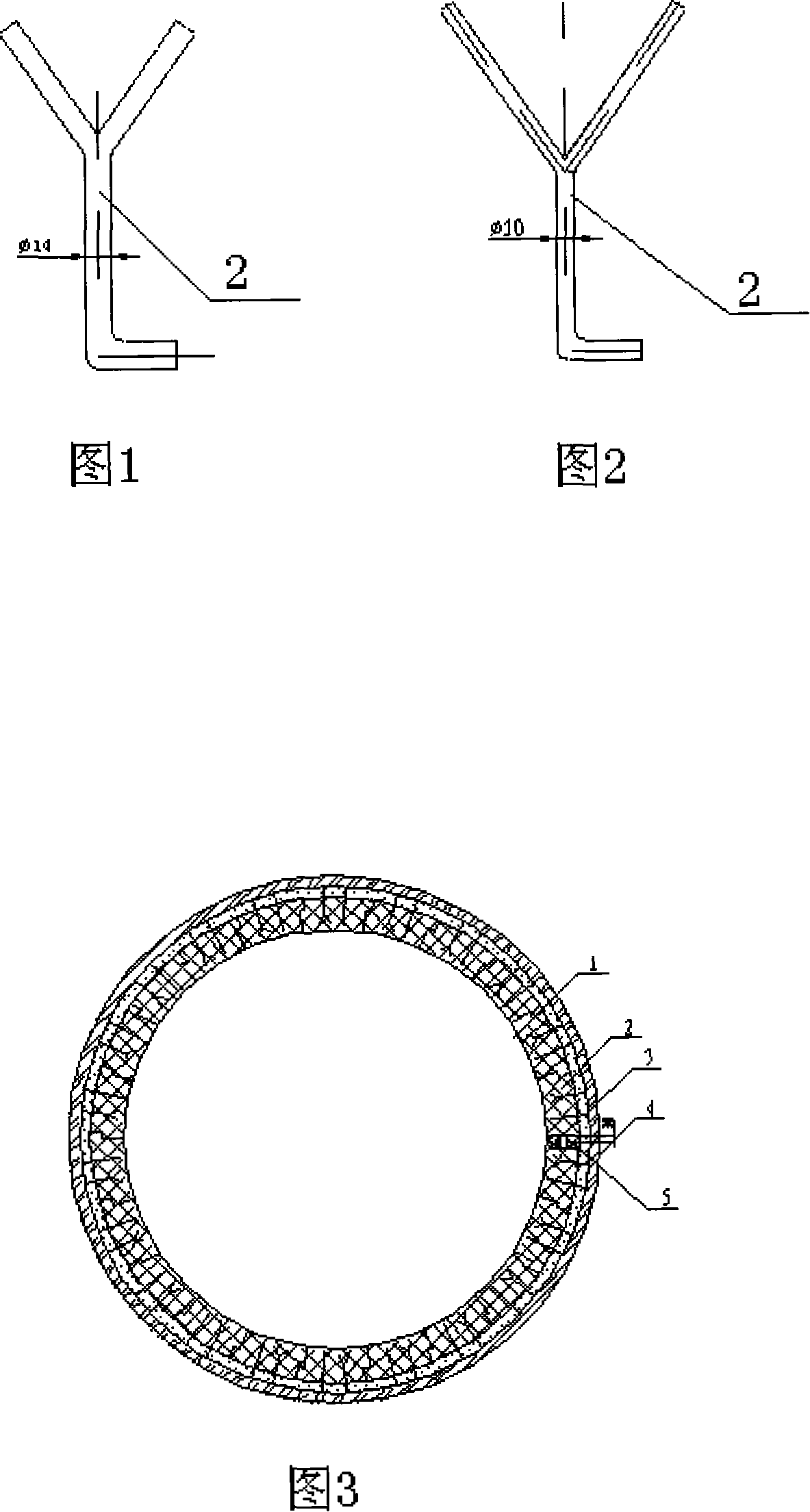

[0024] The root of the original stainless steel hook nail 2 is set to 40mm, which increases the welding strength of the root, and the welding length is 40mm. The maximum tensile force borne by the stainless steel hook nail 2 with a fully welded length of 40 mm is 1.6 times that of the stainless steel hook nail with a fully welded length of 25 mm.

[0025] Arrange Φ14 stainless steel hook nails 2 between the secondary air nozzle and the tertiary air nozzle of the rotary kiln cylinder 4 within 10.5 meters, and the longitudinal distance between the hook nails is set to 200mm; the other parts of the rotary kiln cylinder 4 are arranged Φ10 Stainless steel hook 2.

[0026] Use black tape to wrap the stainless steel hook nail 2, which not only ensures the design thickness, but also meets the expansion requirements; weld the stainless steel hook nail 2 on the rotary kiln shell 4 according to the direction of the root; then pour light castable material 3; make the formwork ; Pouring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com