Reinforcing construction method for foam core die precast hollow plate beam

A technology of hollow slab girders and construction methods, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of complicated procedures, inability to complete them at one time, and insufficient thickness of hollow slab roof and web, so as to ensure the quality of prefabrication and improve Work efficiency, the effect of ensuring the design thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

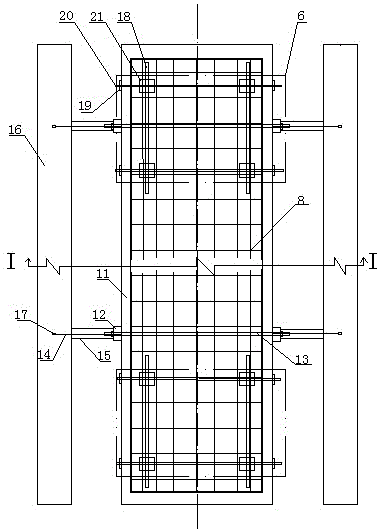

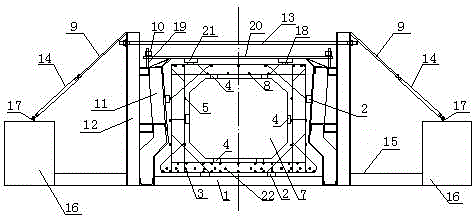

[0014] Depend on figure 1 and figure 2 The reinforcement construction method of a prefabricated hollow slab girder with foam mandrel shown includes the following process steps: (1). First fix the steel strand 22 on the prefabricated pedestal 1 and carry out the initial tension, and the double-layer reinforced mesh structure The base plate reinforcement layer 3 is placed above the prefabricated pedestal 1 and bound together with iron wires, and the steel strands 22 are interspersed between the double-layer reinforcement meshes of the base plate reinforcement layer 3, and the horizontally arranged base plate reinforcement layer 3 and the interval are erected on the base plate with iron wires. The two web reinforcement layers 5 on both sides of the reinforcement layer 3 are bound together, the bottom reinforcement layer 3 and the web reinforcement layer 5 are located above the prefabricated pedestal, and the outer concrete pads 2 are respectively bound on the lower side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com