A post-processing method and post-processing device for a 3-methylthiopropionaldehyde reaction mixture

A technology of methionaldehyde reaction and methionaldehyde, which is applied in the field of preparation of chemical intermediates, can solve problems such as increased operational complexity, increased process control points, complex process routes, etc., and achieves a reduction in material loss rate, The effect of shortening the process route and increasing the rectification yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

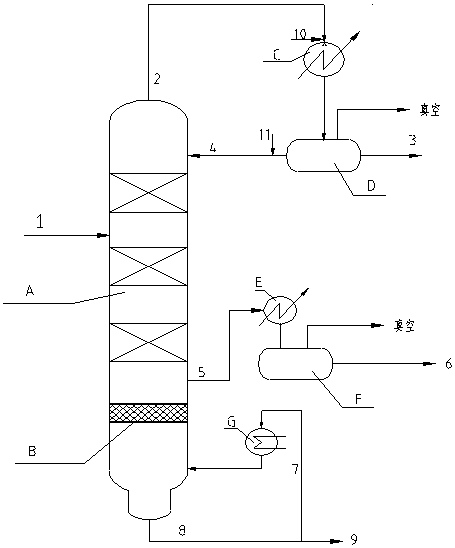

[0052] Example 1 A 3-methylthiopropionaldehyde aftertreatment device

[0053] It mainly includes rectification tower A, tower top condenser C, tower top condensation receiving tank D, side line condenser E, side line condensation receiving tank F, and tower still reboiler G.

[0054] The internal structure of rectification tower A consists of two parts, including packing section and demister B equipment, wherein the upper end of rectification tower A is packing section, and the lower end is equipped with demister B; demister B is located below the packing section, and the tower still Boiler G discharges into the upper end of the inlet at the bottom of the column.

[0055] In the packing section, the packing can be random packing or structured packing, and the number of theoretical plates is 20-25;

[0056] In the packing section, the packing type is common packing, and the specific type is not limited;

[0057] Described demister B, adopts the one in general type such as wire ...

Embodiment 2

[0064] Embodiment 2 A kind of aftertreatment method of 3-methylthiopropanal

[0065] Include the following steps:

[0066] (1) Feed

[0067] The 3-methylmercaptopropionaldehyde reaction mixture 1 prepared from methylmercaptan and acrolein is fed to the 10th tray of rectification tower A. The mixture components mainly include 89% of 3-methylmercaptopropionaldehyde and 0.303% hydrogen sulfide. %, methyl mercaptan 0.648%, allyl alcohol 0.227%, acrolein 0.479%, acetic acid 0.288%, acetaldehyde 0.193%, methanol 0.026%, dimethyl benzylamine 0.086%, dimethyl sulfide 0.158%, dimethyl Disulfide 0.292%, allyl acrylate 0.069%, water 5.301%, acrolein polymer, 3-methylthiopropionaldehyde polymer and other impurities 2.93%.

[0068] The first polymerization inhibitor 10 is a saturated solution of hydroquinone in methanol, and the active ingredient of the polymerization inhibitor, hydroquinone, accounts for 0.001% of the total mass of the 3-methylthiopropionaldehyde reaction mixture 1, and...

Embodiment 3

[0077] Embodiment 3 A post-treatment method of 3-methylthiopropanal

[0078] Include the following steps:

[0079] (1) Feed

[0080] The 3-methylmercaptopropionaldehyde reaction mixture 1 prepared from methyl mercaptan and acrolein is fed to the 11th tray of rectification tower A, and the mixture components mainly include 91% of 3-methylthiopropionaldehyde and 0.103 hydrogen sulfide %, methyl mercaptan 0.448%, allyl alcohol 0.027%, acrolein 0.019%, acetic acid 0.188%, acetaldehyde 0.043%, methanol 0.126%, dimethyl benzylamine 0.016%, dimethyl sulfide 0.158%, dimethyl Disulfide 0.212%, allyl acrylate 0.029%, water 4.901%, acrolein polymer, 3-methylthiopropionaldehyde polymer and other impurities 2.73%.

[0081] The first polymerization inhibitor 10 is a water-saturated solution of hydroquinone, and the active ingredient of the polymerization inhibitor, hydroquinone, accounts for 0.005% of the total mass of the 3-methylthiopropionaldehyde reaction mixture 1, and is fed from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com