Concrete with pumice waste residues as aggregates and preparation method of concrete

A technology of concrete and waste residue, which is applied in the field of building materials and can solve problems such as ineffective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

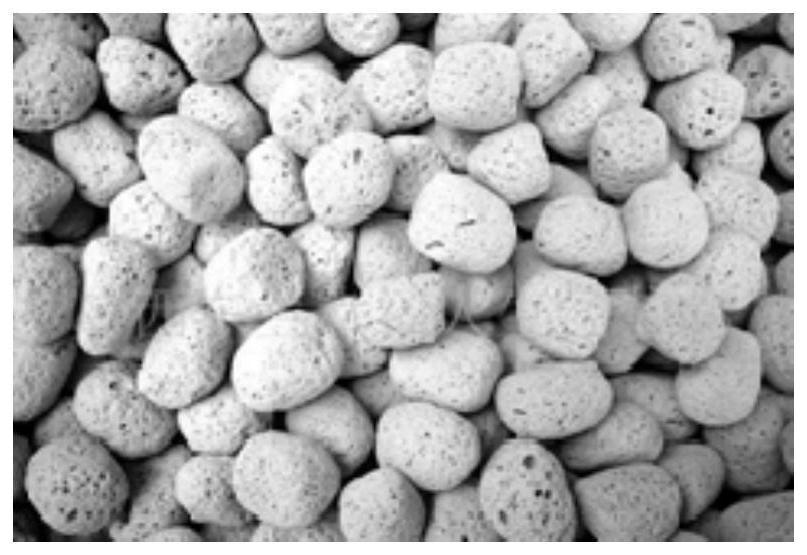

Image

Examples

Embodiment 1

[0052] Prepare raw materials according to the following composition ratio: cement 520kg / m 3 , fly ash 97kg / m 3 , silica fume 33kg / m 3 , pumice residue 900kg / m 3 , additive 73.5kg / m 3 , wherein, in terms of mass percentage, in the additive, the water-reducing component accounts for 4.22%, the water-retaining component accounts for 0.93%, the slump-preserving component accounts for 0.93%, the thickening component accounts for 1.21%, and the lubricating component accounts for 92.71%.

[0053] Stirring the pumice waste with part of the spare water for a first preset time to obtain pre-wet pumice waste; then, mixing the pre-wet pumice waste with other remaining spare components for a second preset time to obtain a pumice waste as aggregate concrete, wherein, the first preset duration and the second preset duration can be appropriately adjusted according to the amount of prepared concrete, which is not limited in this application, for example: the first preset duration can be 1mi...

Embodiment 2

[0055] It is basically the same as the above-mentioned embodiment one, the difference is that the raw materials prepared in embodiment two include: cement 350kg / m 3 , fly ash 100kg / m 3 , silica fume 50kg / m 3 , pumice residue 1000kg / m 3 , additive 18kg / m 3 , wherein, in terms of mass percentage, in the additive, the water-reducing component accounts for 4.98%, the water-retaining component accounts for 0.80%, the slump-preserving component accounts for 0.81%, the thickening component accounts for 1.41%, and the lubricating component accounts for 92.00%.

Embodiment 3

[0057] It is basically the same as the above-mentioned embodiment one, the difference is that the raw materials prepared in embodiment three include: cement 470kg / m 3 , fly ash 90kg / m 3 , silica fume 40kg / m 3 , pumice residue 950kg / m 3 , additive 45kg / m 3 , wherein, in terms of mass percentage, in the additive, the water-reducing component accounts for 4.06%, the water-retaining component accounts for 1.2%, the slump-preserving component accounts for 1.2%, the thickening component accounts for 1.06%, and the lubricating component accounts for 92.48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com