Bolt steel bar plug pin prefabricated wooden structure column base joint

A technology of prefabricated assembly and column foot joints, applied in building components, building structures, earthquake resistance, etc., can solve problems such as unsatisfactory seismic performance, and achieve the effect of ensuring structural performance, good deformation ability, and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

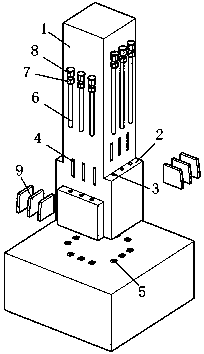

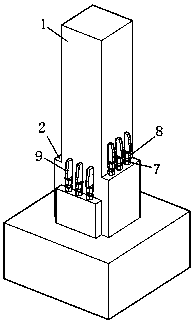

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-2 As shown: the four sides of the bottom of the prefabricated wooden structure column 1 are provided with protruding steps 2 .

[0023] A steel bar hole 3 is reserved in the protruding step 2 , and a latch plate slot 4 is reserved in the rear of the protruding step 2 .

[0024] The protruding step 2 and the latch plate groove 4 on the adjacent side of the prefabricated wooden structure column 1 have a certain height difference

[0025] The center of the embedded part 5 of the foundation is provided with a threaded hole, which is embedded on the foundation at the position of the column foot, and is opposite to the reserved steel bar hole 3 .

[0026] Both ends of the connecting steel bar 6 are provided with threaded sections, and the nut 7 and the end nut 8 are screwed on the upper end of the connecting steel bar 6 .

[0027] After the prefab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com