High-speed turnout switch tie for speed of 350km per hour and manufacturing method thereof

A switch sleeper, high-speed technology, applied in the field of prestressed concrete switch sleeper and its manufacturing, can solve the problems of large precision error, short service life, insufficient bearing capacity of turnout sleeper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

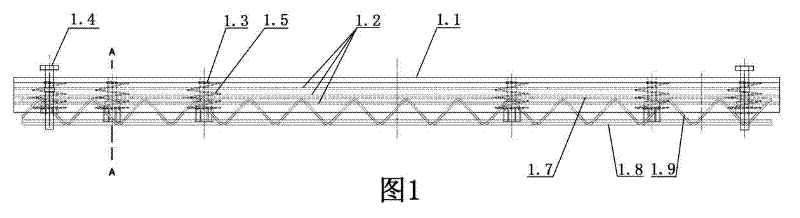

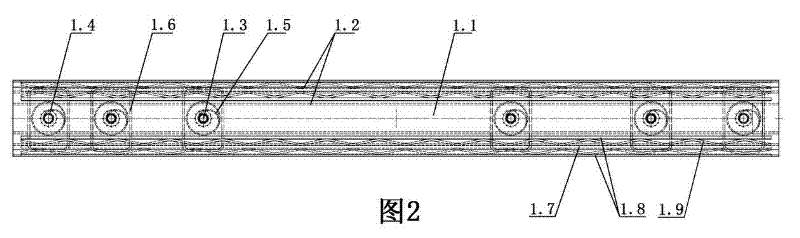

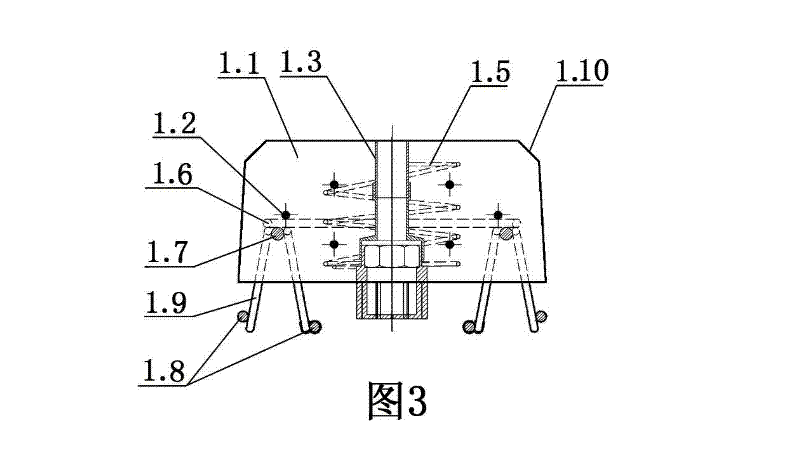

[0068] Examples see Figure 1-Figure 4 As shown, a high-speed turnout sleeper with a speed of 350km per hour includes a concrete slab body 1.1, a prestressed steel hinge line 1.2 embedded in the concrete slab body 1.1, a casing 1.3 and an adjusting bolt 1.4, and the lower part of the concrete slab body 1.1 is connected with Two rows of trusses, characterized in that: the concrete turnout sleeper 1.1 is a full-length integral type, and the cross-sectional shape is a trapezoid with a small top and a big bottom; the prestressed steel hinge line 1.2 is pre-embedded with 6 roots, and are distributed symmetrically in a triangle on the left and right sides of the central axis of the concrete turnout sleeper 1.1;

[0069] The concrete turnout sleeper 1.1 is pre-embedded with an upper chord 1.7 on the left and right sides respectively, and two lower chords 1.8 are arranged corresponding to the upper chord 1.7 in a triangle under the concrete turnout 1.1, the upper chord 1.7 and the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com