Patents

Literature

72results about How to "Reliable reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

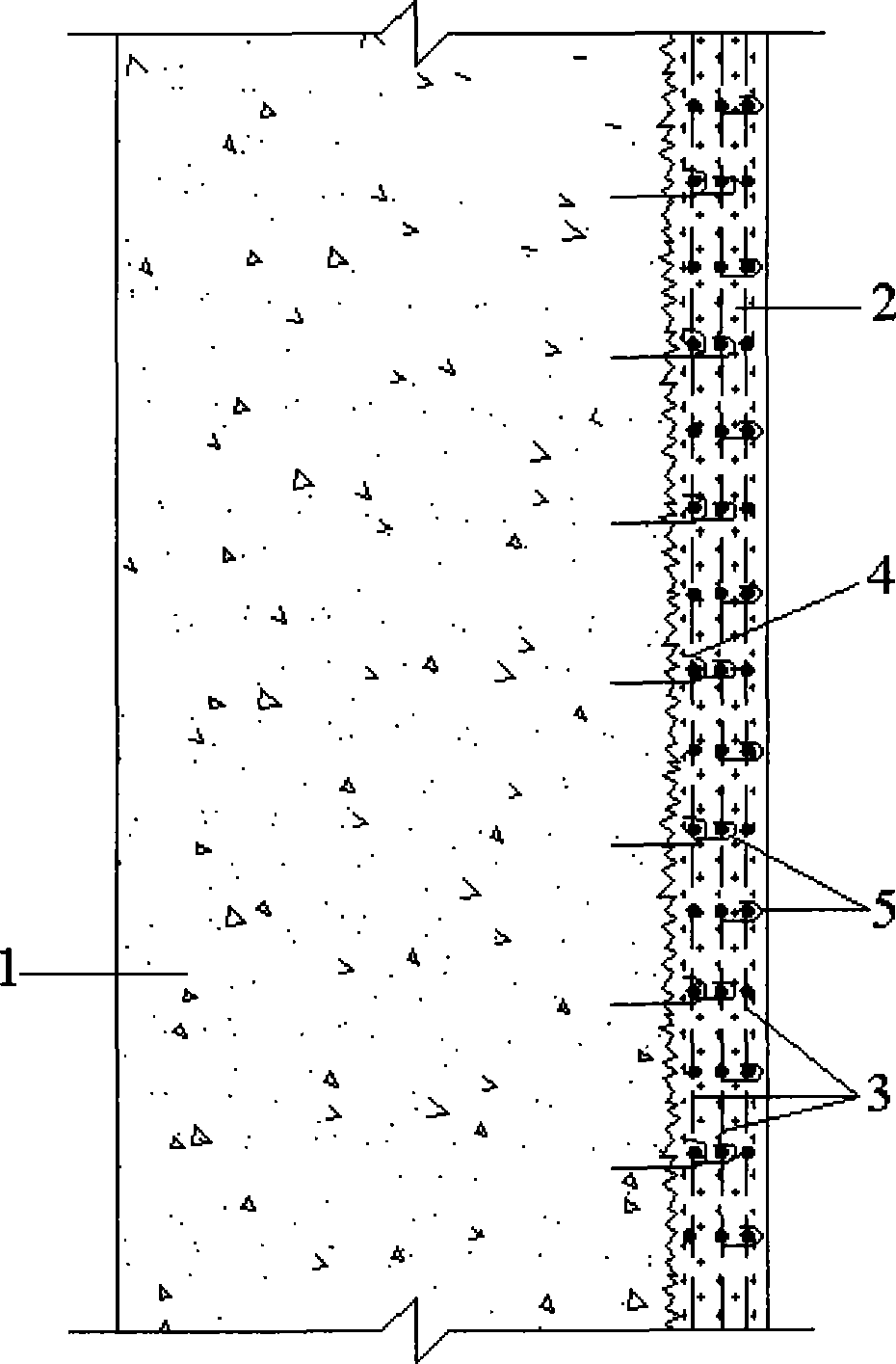

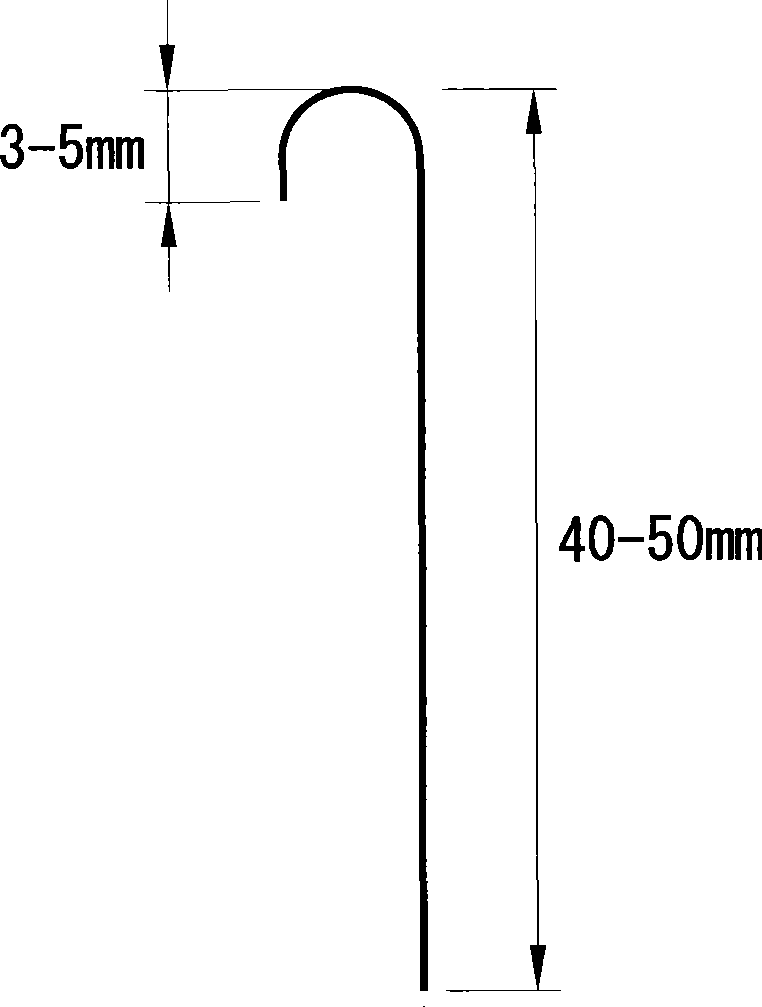

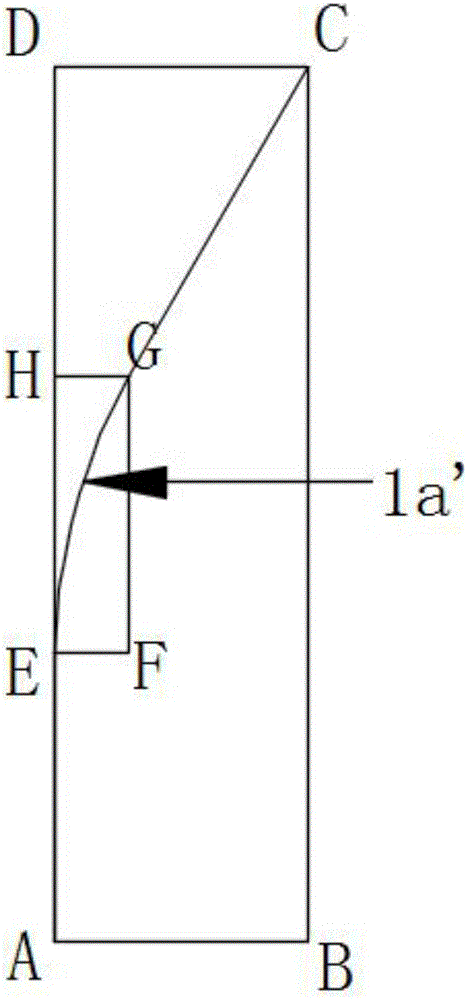

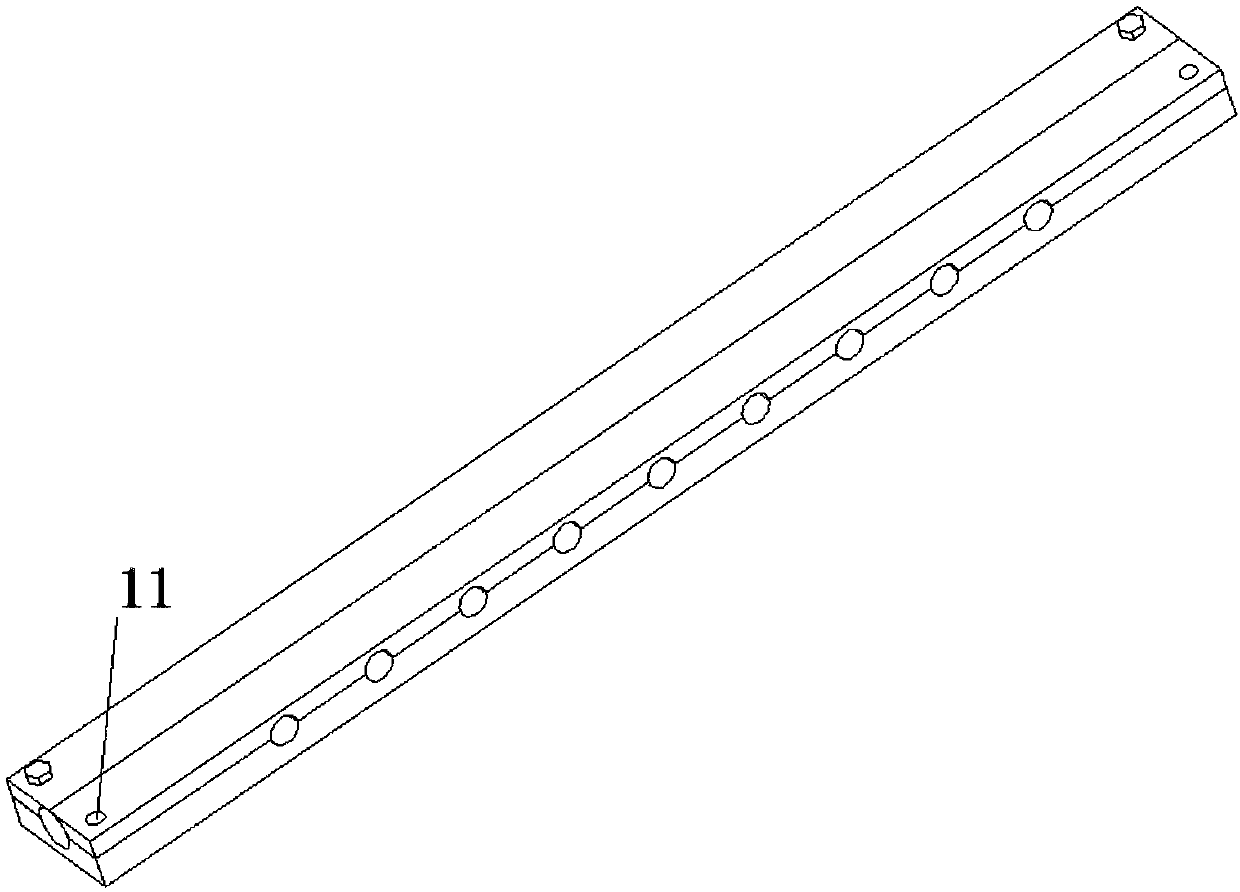

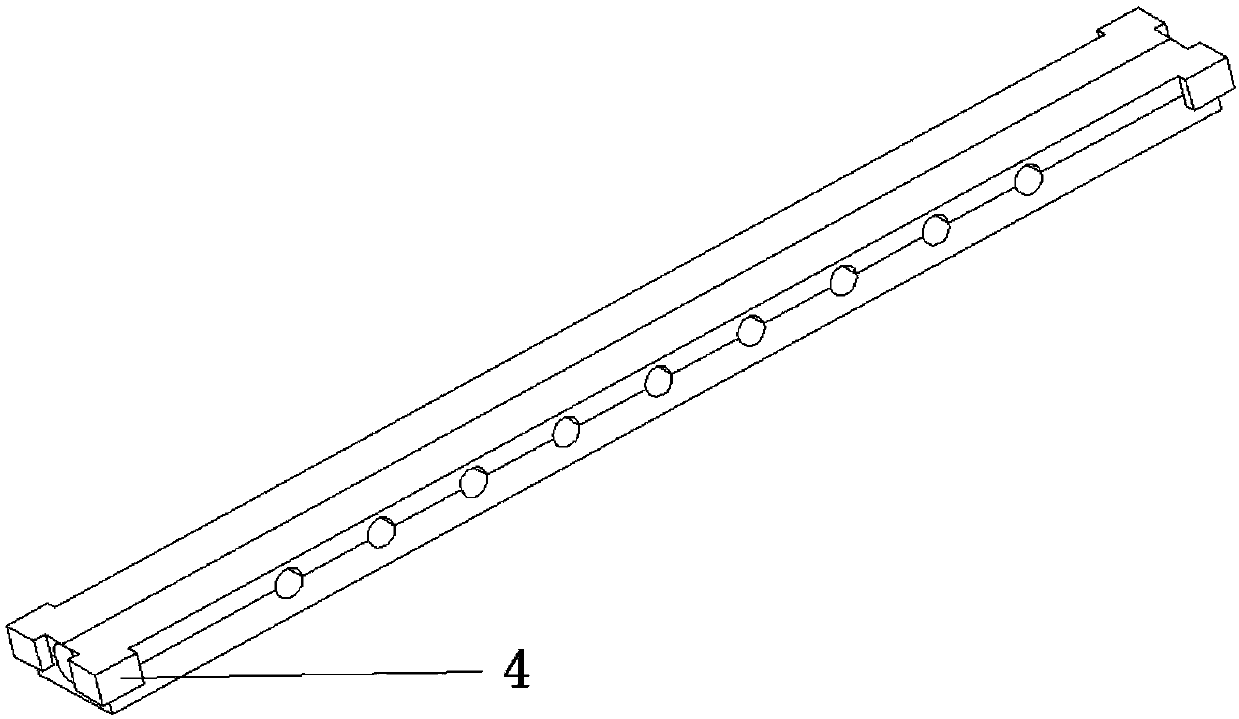

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

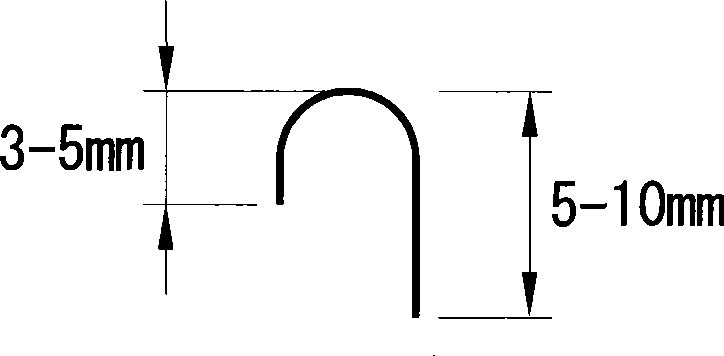

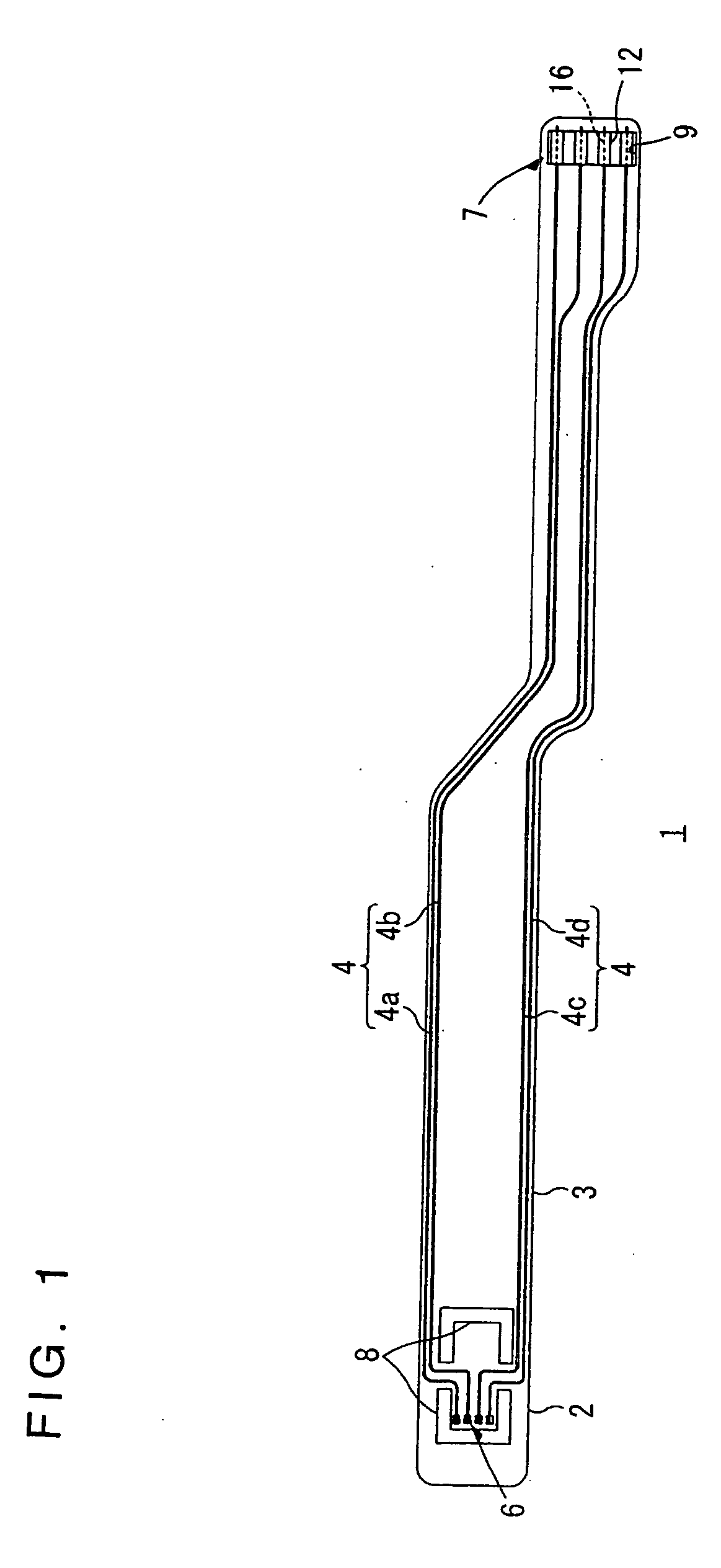

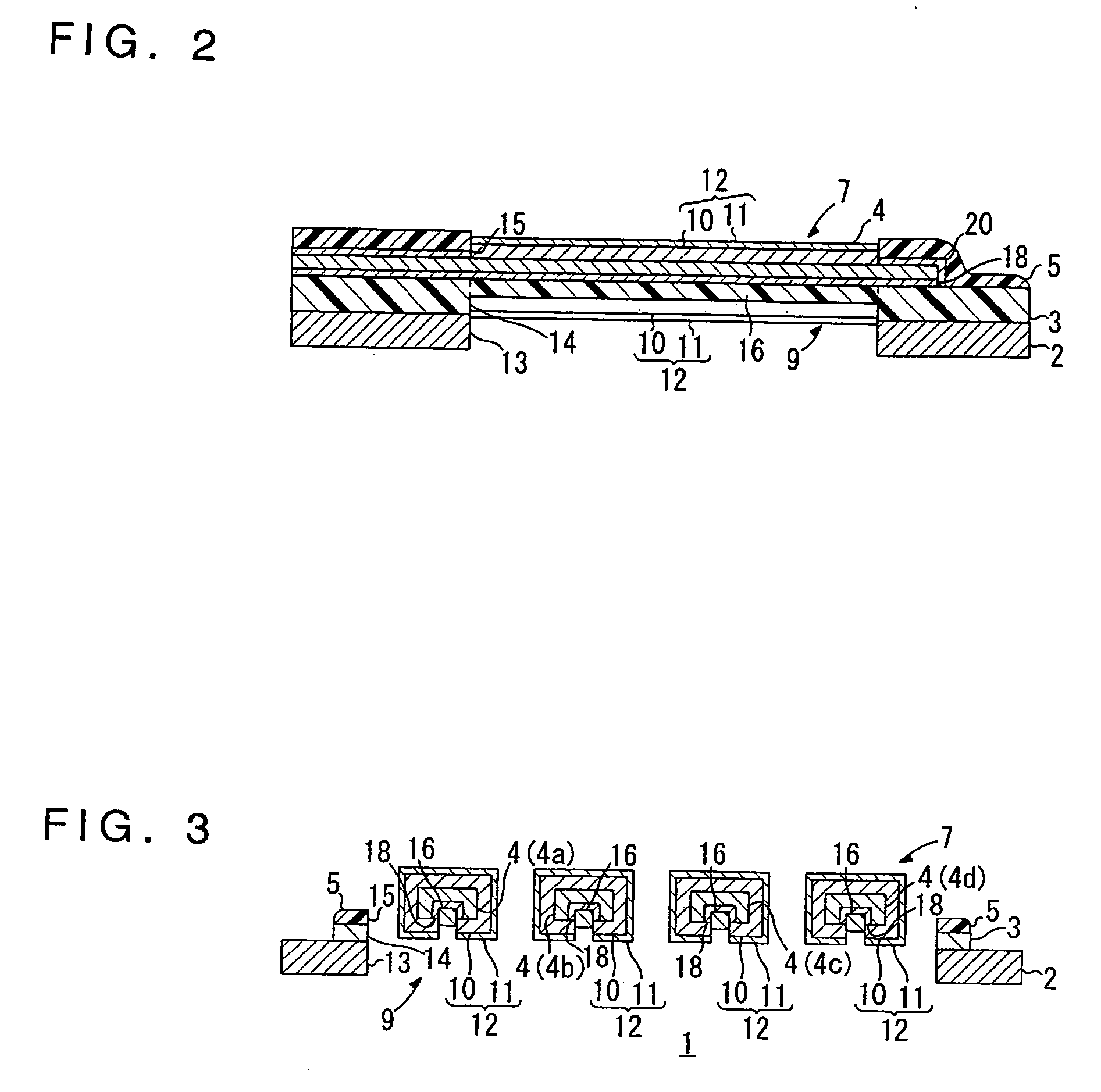

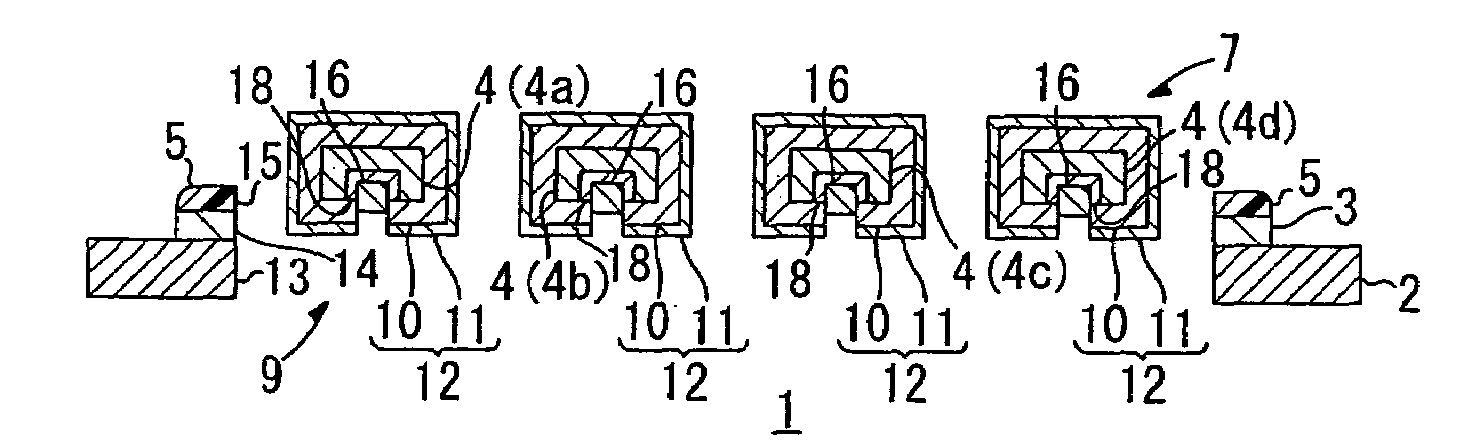

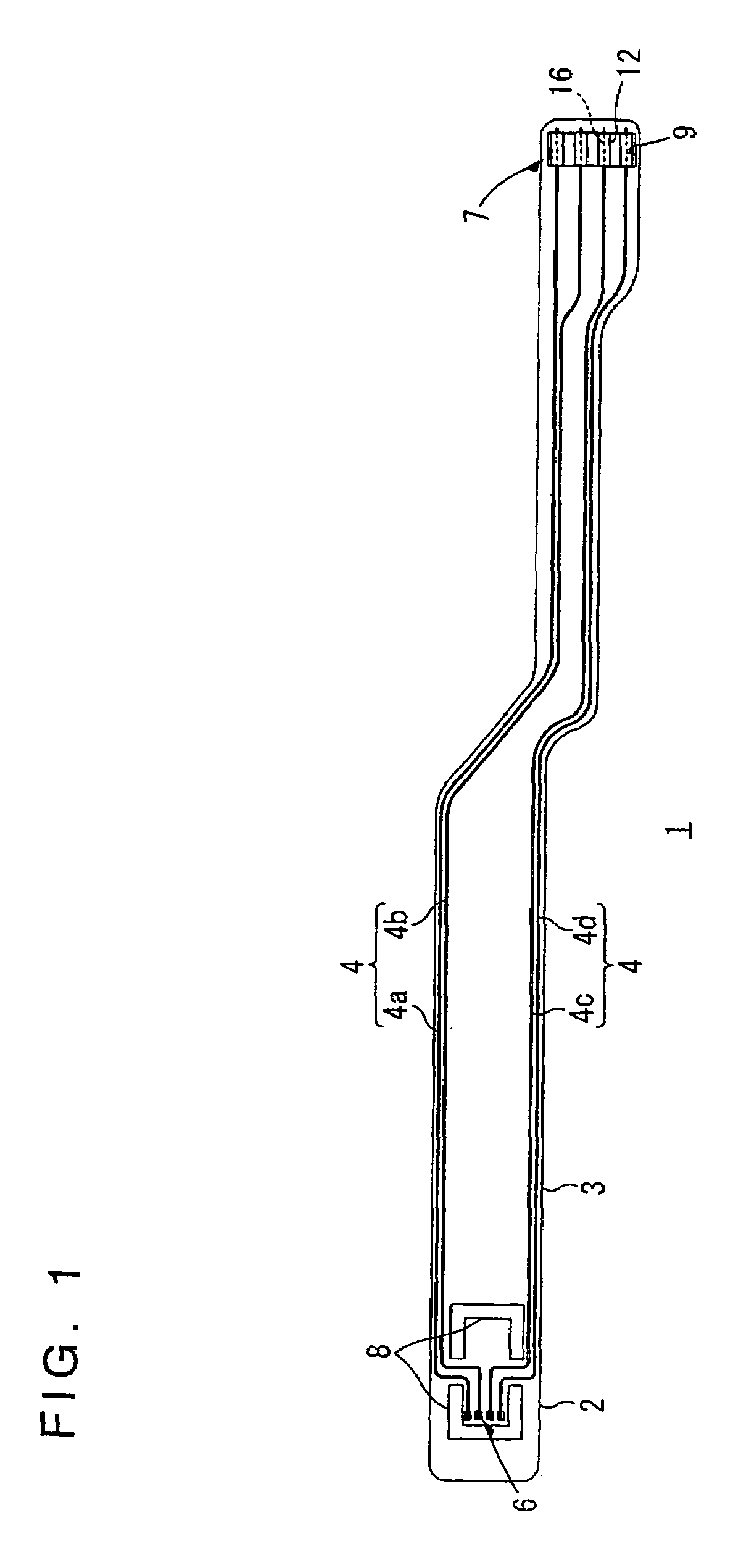

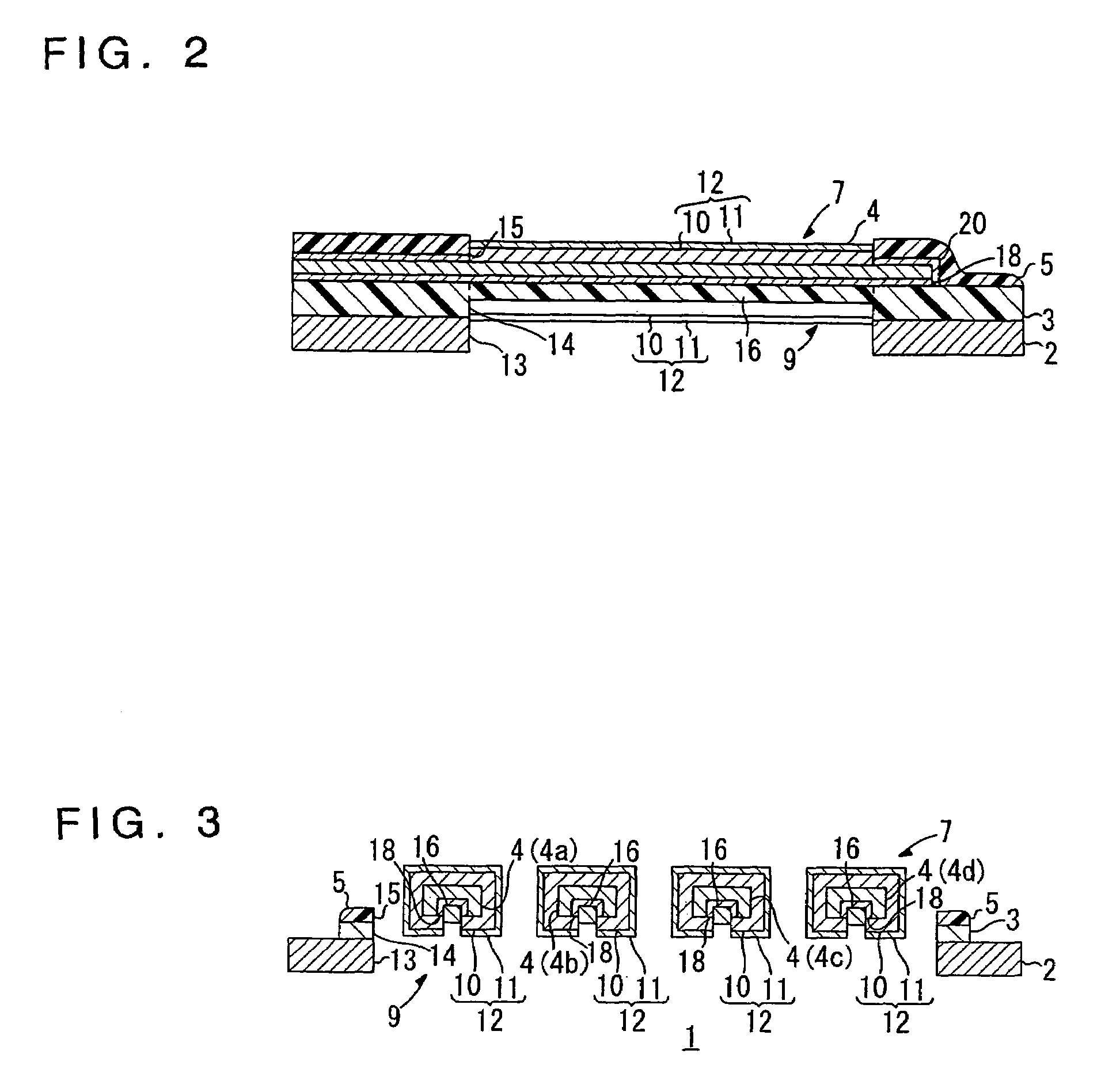

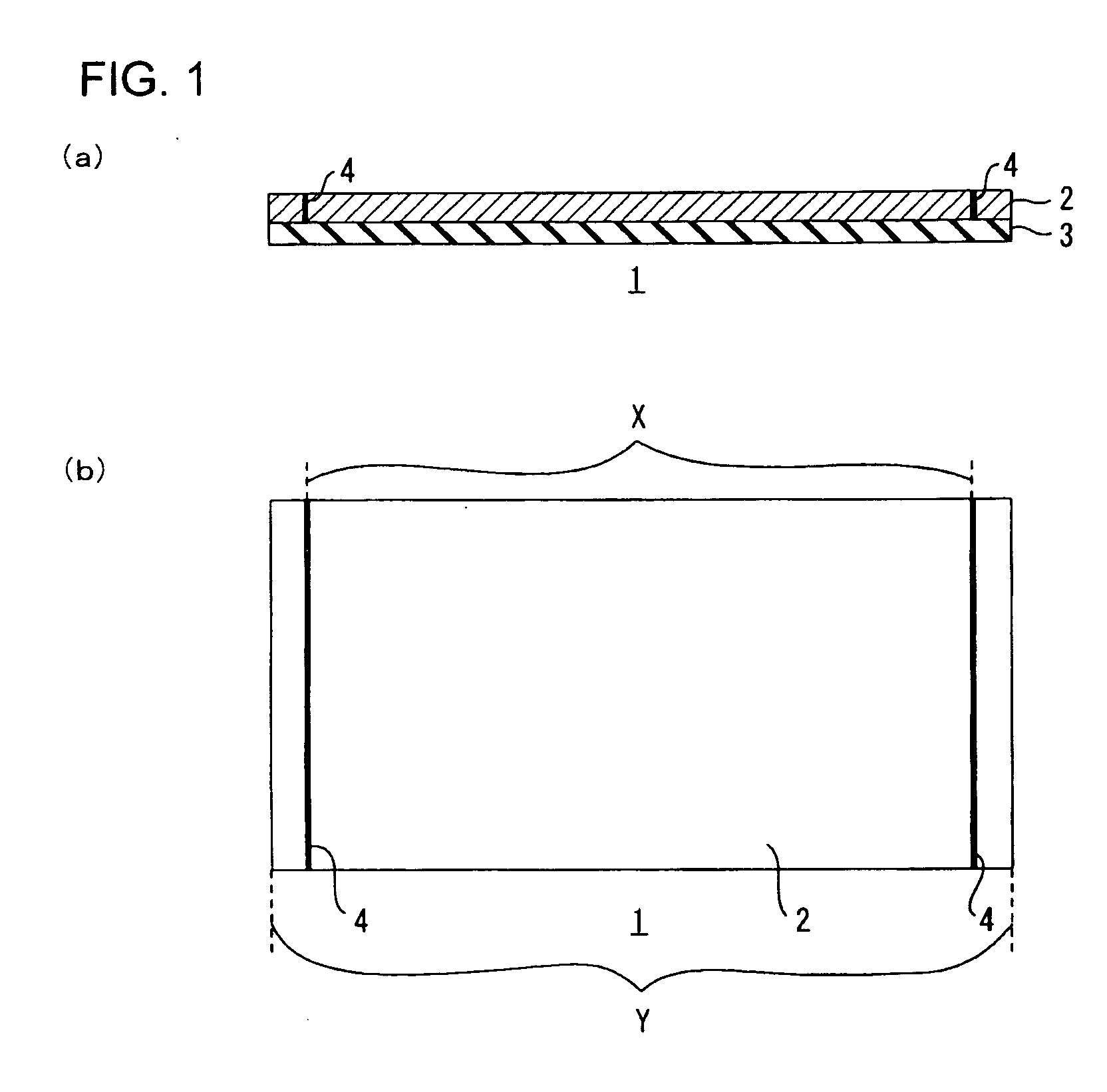

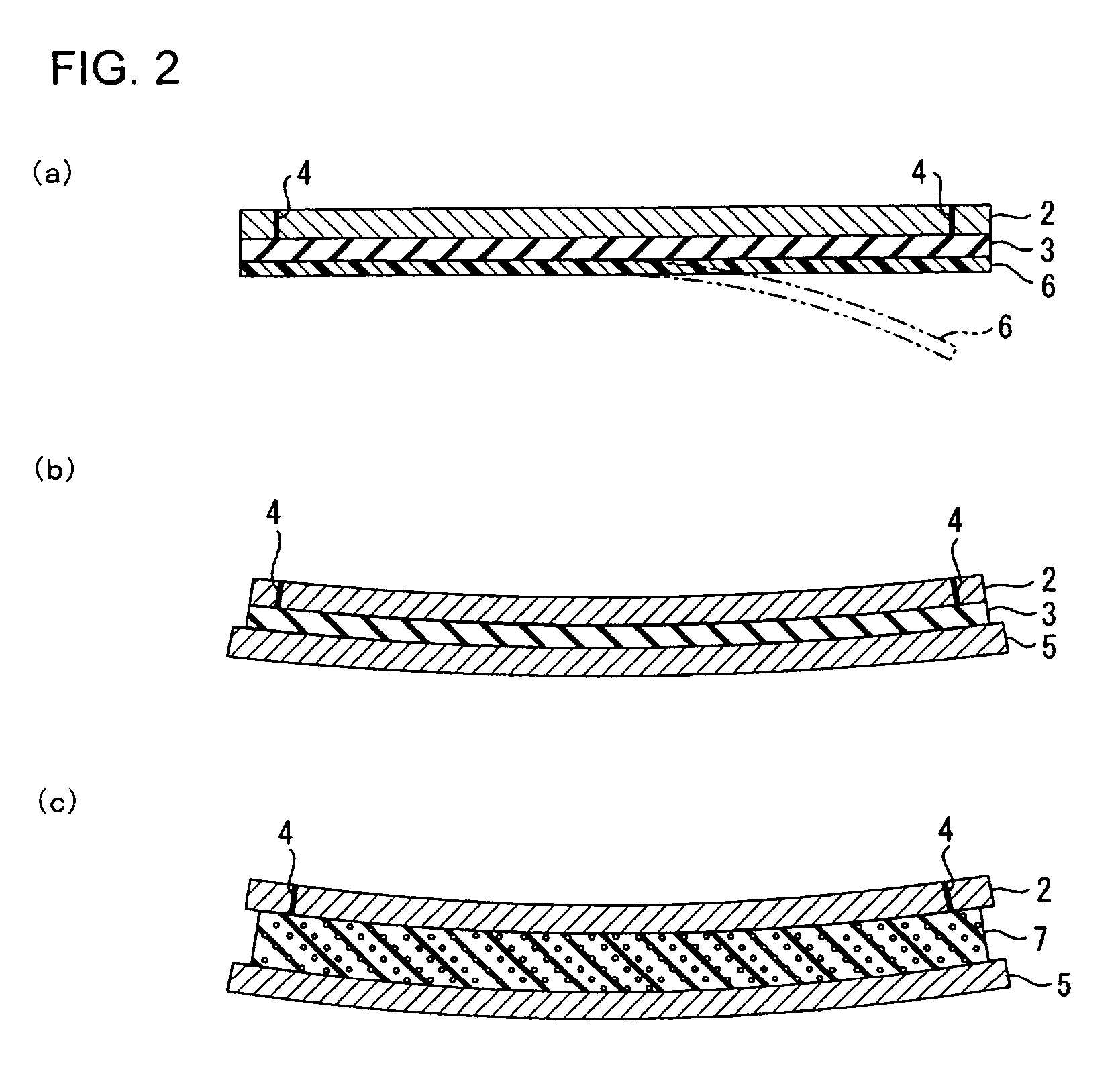

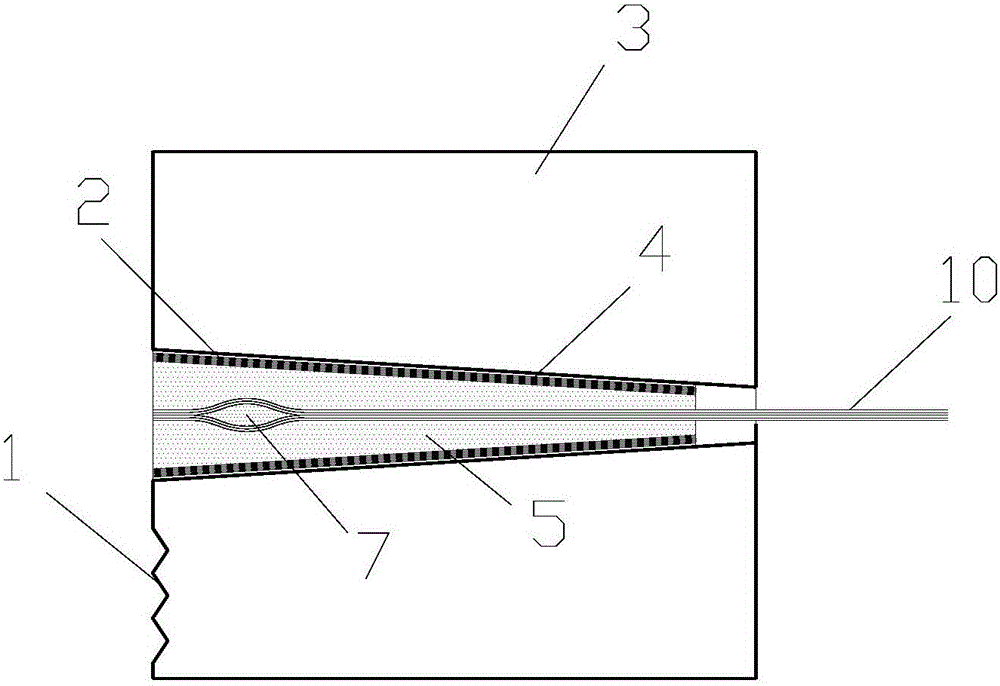

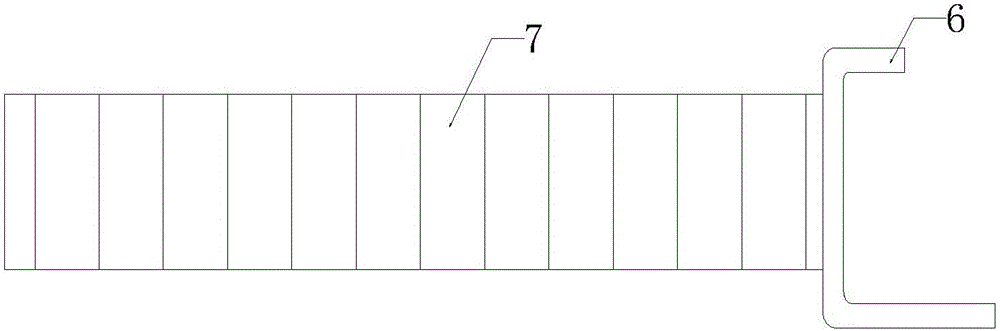

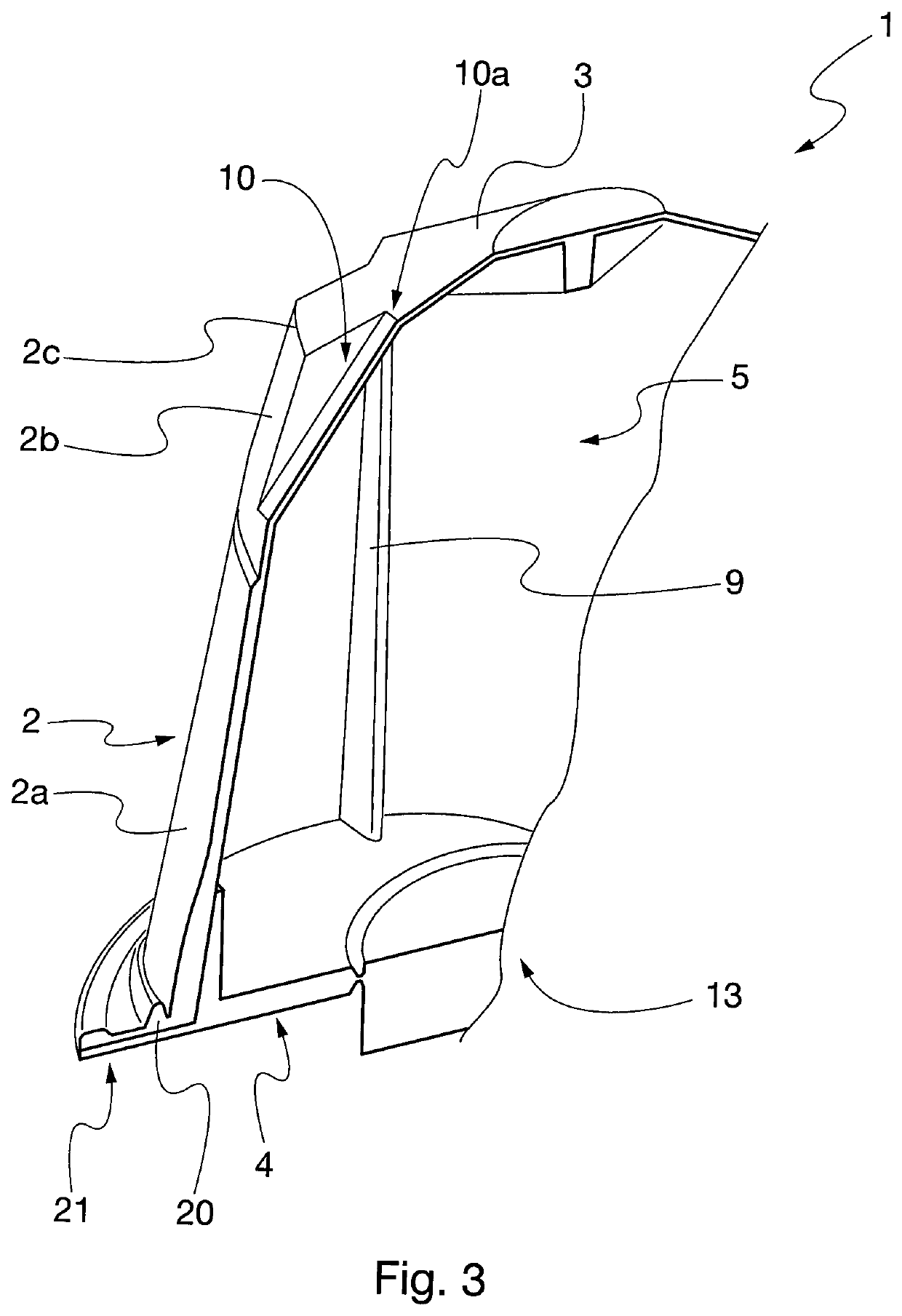

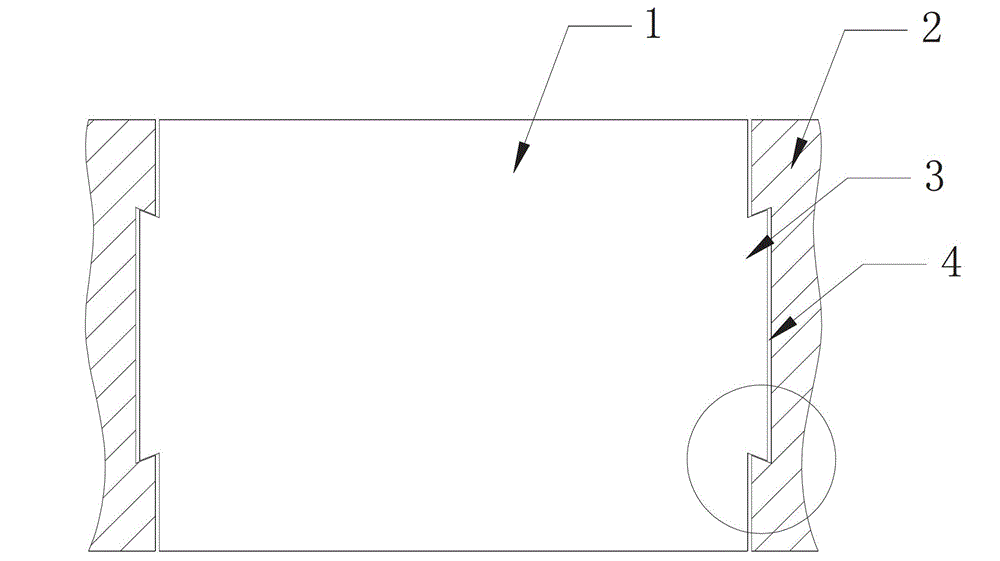

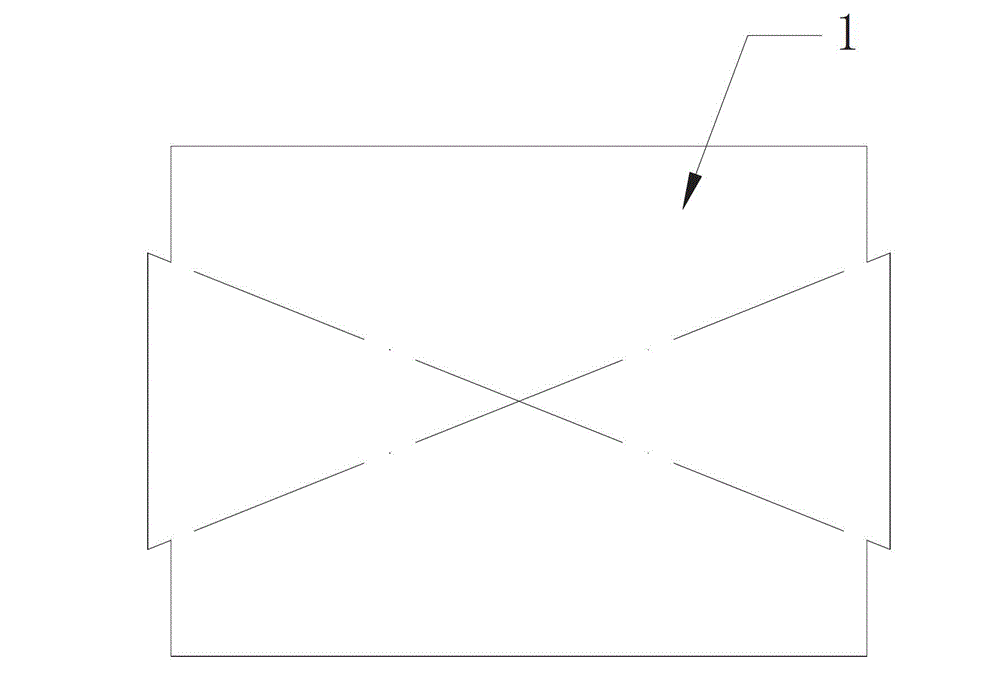

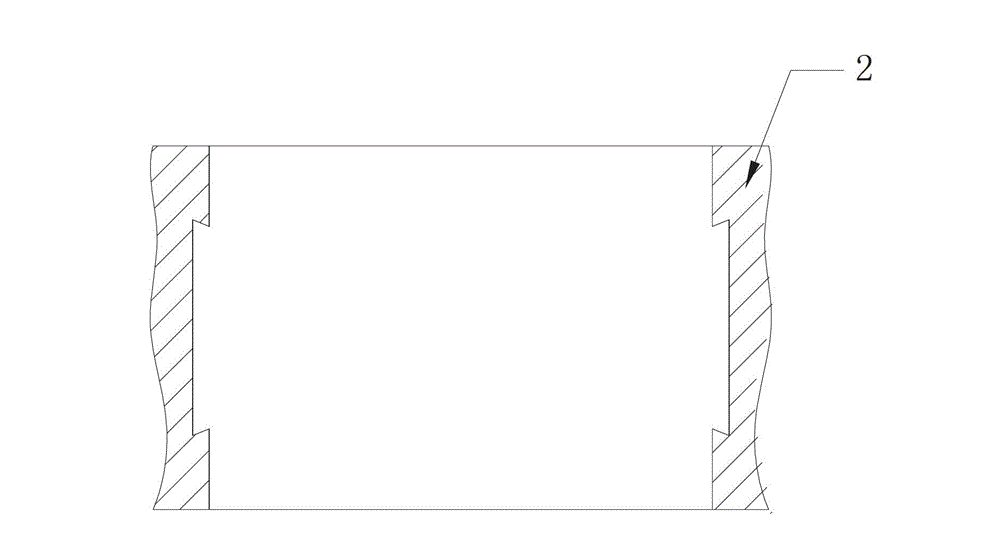

Suspension board with circuit

InactiveUS20050122627A1Reduce risk of damageImprove reliabilityDriving/moving recording headsPrinted circuit aspectsElectrical conductorAdditive process

A suspension board with circuit having a conductor layer formed in the form of a fine wiring circuit by an additive process, while providing a reduced risk of damage and breaking of the conductor layer in a flying lead portion. The suspension board with circuit comprises a supporting board 2, an insulating base layer 3 formed on the supporting board 2, a conductor layer 4 formed on the insulating base layer 3, an insulating cover layer 5 formed on the conductor layer 4, and a flying lead portion 9 in which a supporting-board-side opening 13, a base-layer-side opening 14, and a cover-layer-side opening 15 are formed so that both sides of the conductor layer 4 can be exposed therefrom. A reinforcing portion 16 or 23 for reinforcing the conductor layer 4 formed continuously from at least either of the insulating base layer 3 and the insulating cover layer 5 along the longitudinal direction of the conductor layer 4 is included in the flying lead portion 9.

Owner:NITTO DENKO CORP

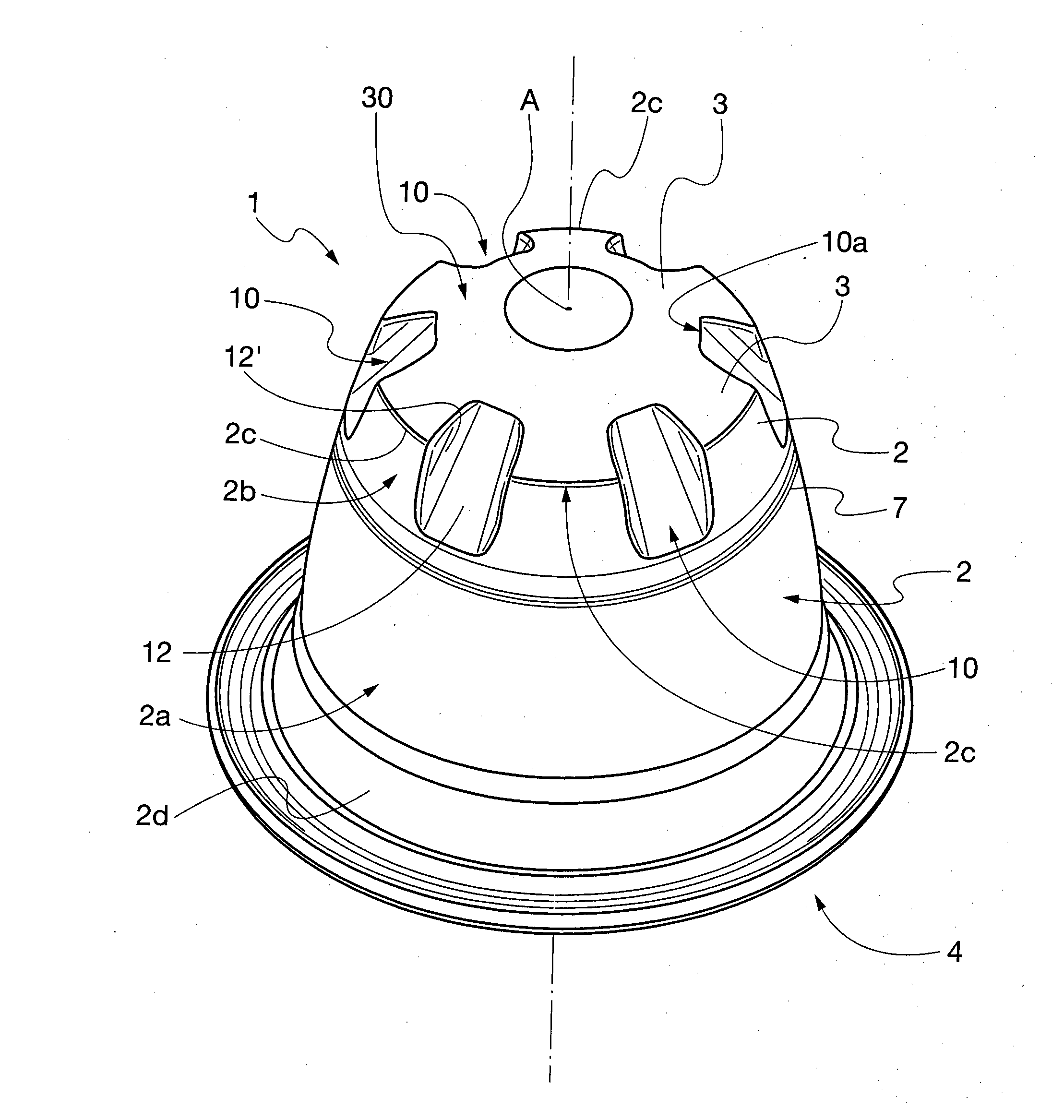

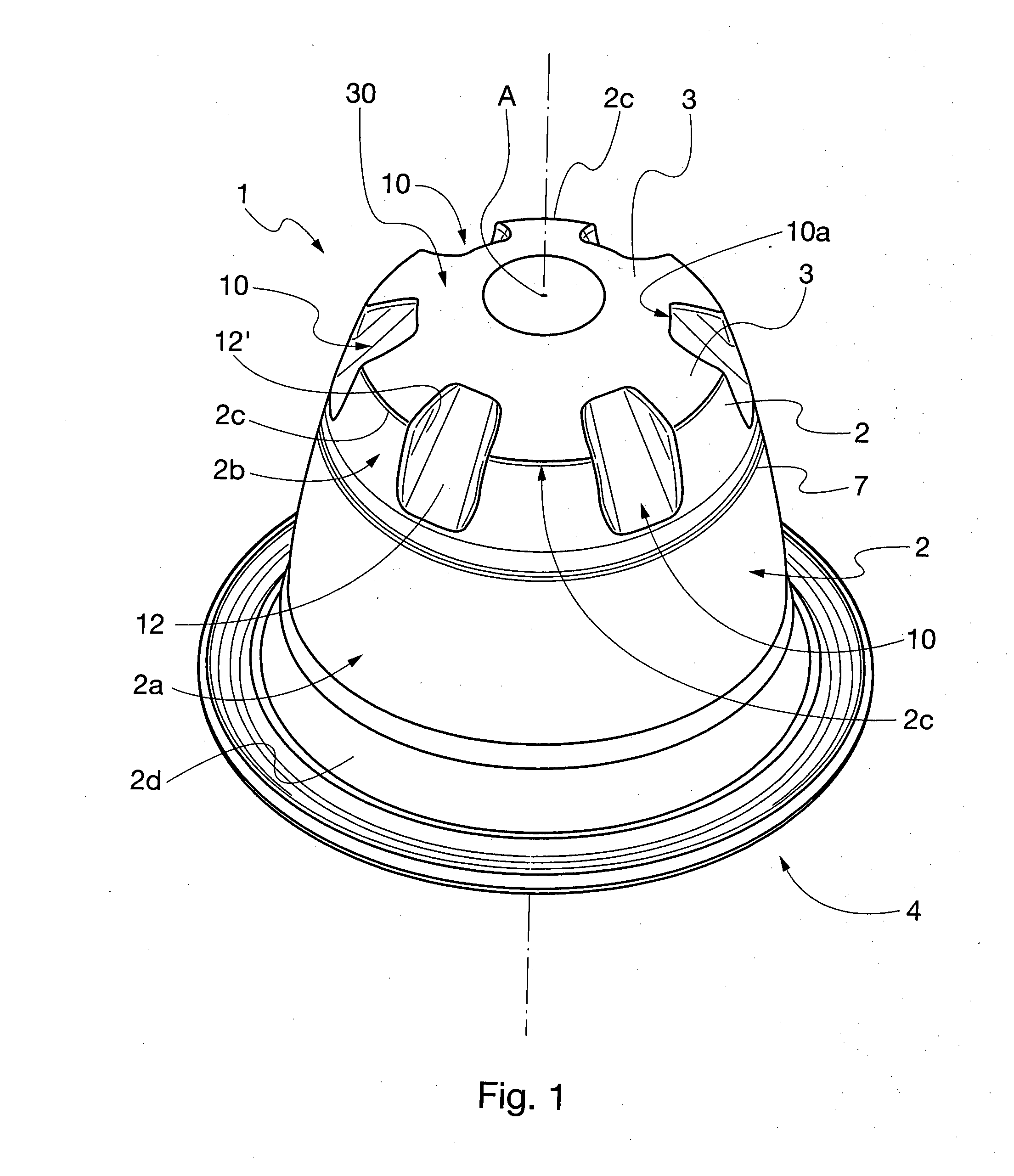

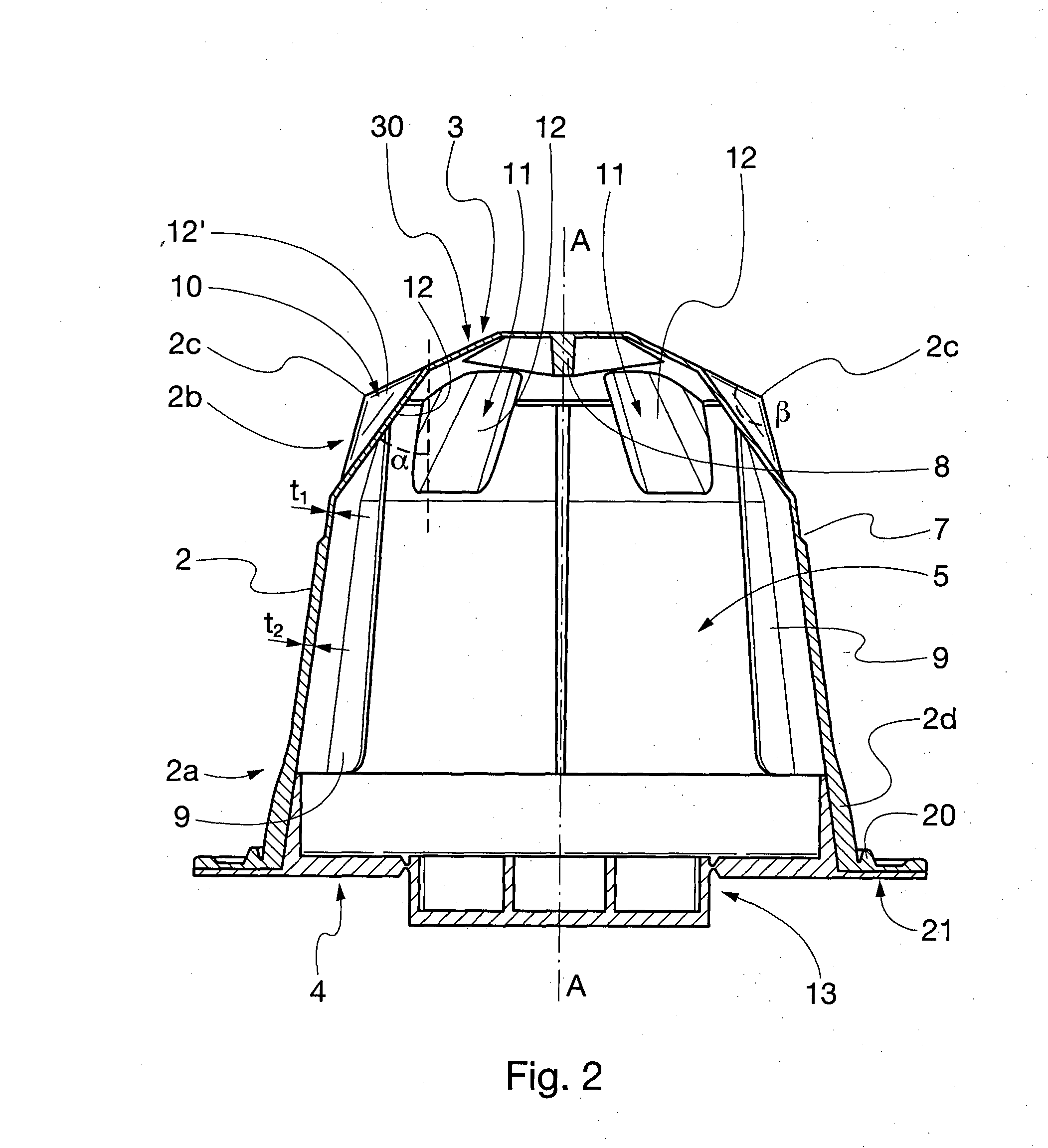

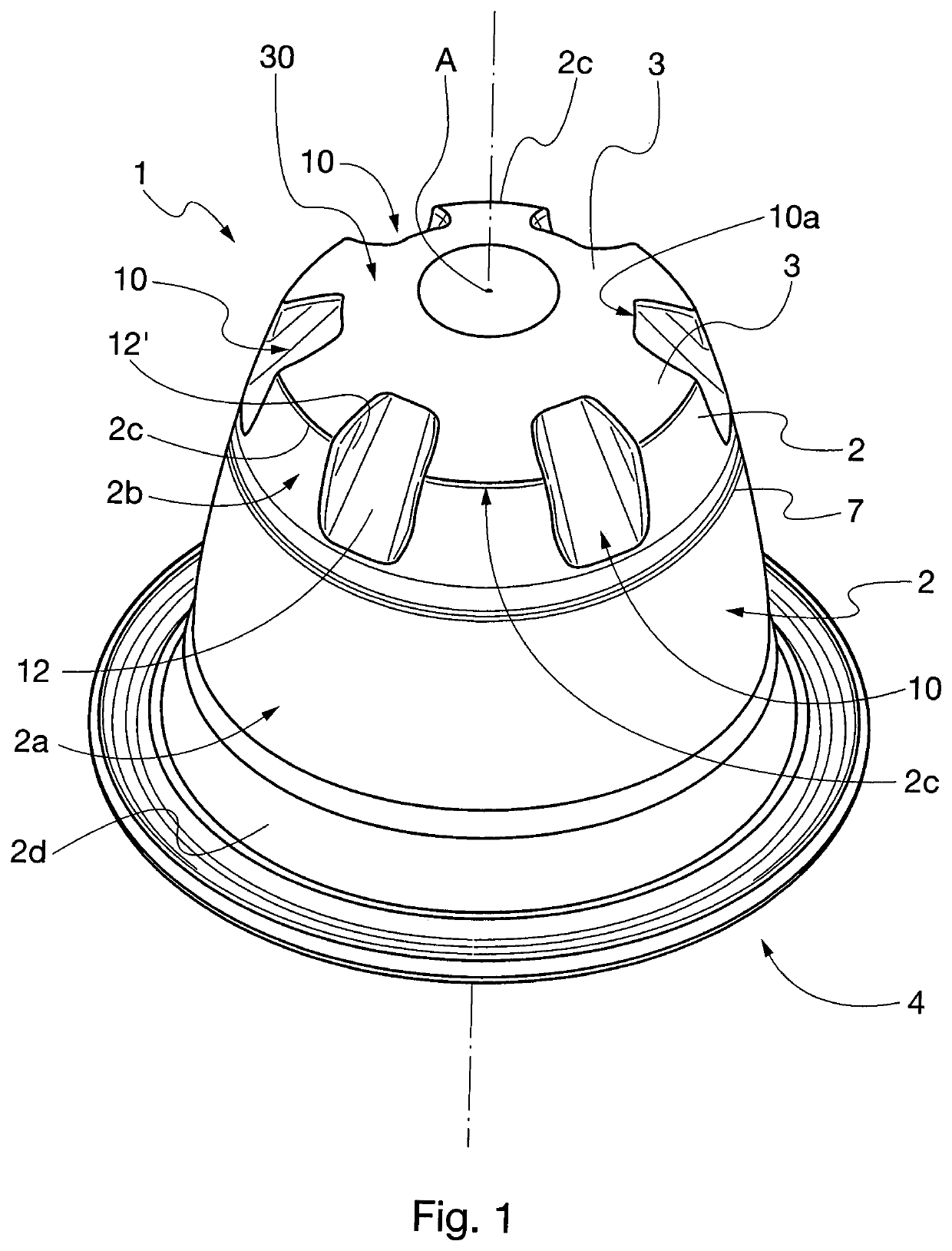

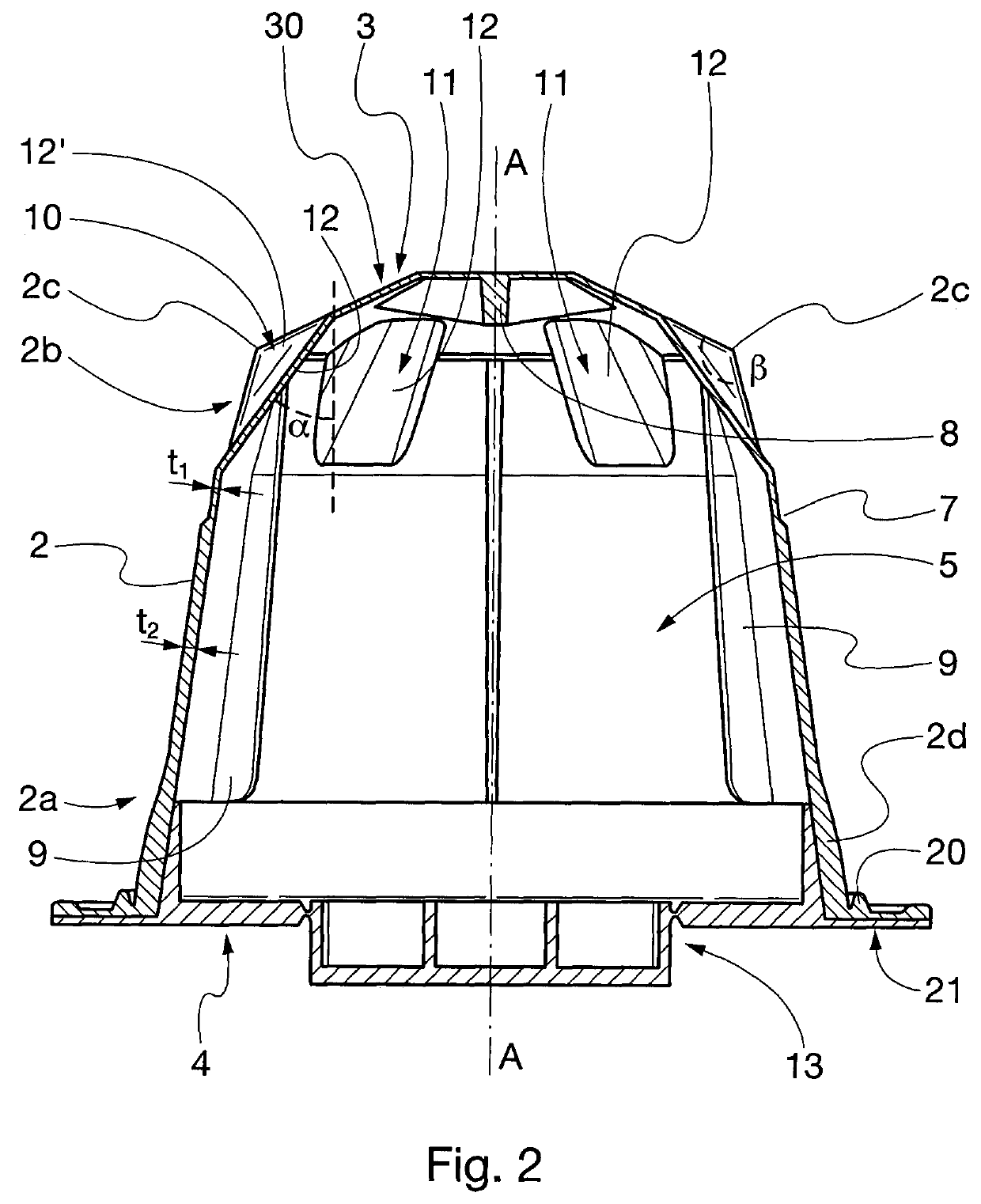

Capsule and system for beverage preparation

ActiveUS20140318380A1Easy feedingEfficient extractionReady-for-oven doughsBeverage vesselsEngineering

A capsule for the preparation of a beverage comprises a lateral wall, an inlet wall and a lower wall forming a hollow body having a substantially central axis, the inlet wall extends from a peripheral end of the lateral wall towards said central axis and a plurality of sunken portions are extending on both lateral and inlet walls across the edge between said walls each portion connecting together the lateral wall and the inlet wall.

Owner:TUTTOESPRESSO SRL

Suspension board having a circuit and a flying lead portion

InactiveUS7336446B2Reduce risk of damageImprove reliabilityDriving/moving recording headsPrinted circuit aspectsElectrical conductorAdditive process

Owner:NITTO DENKO CORP

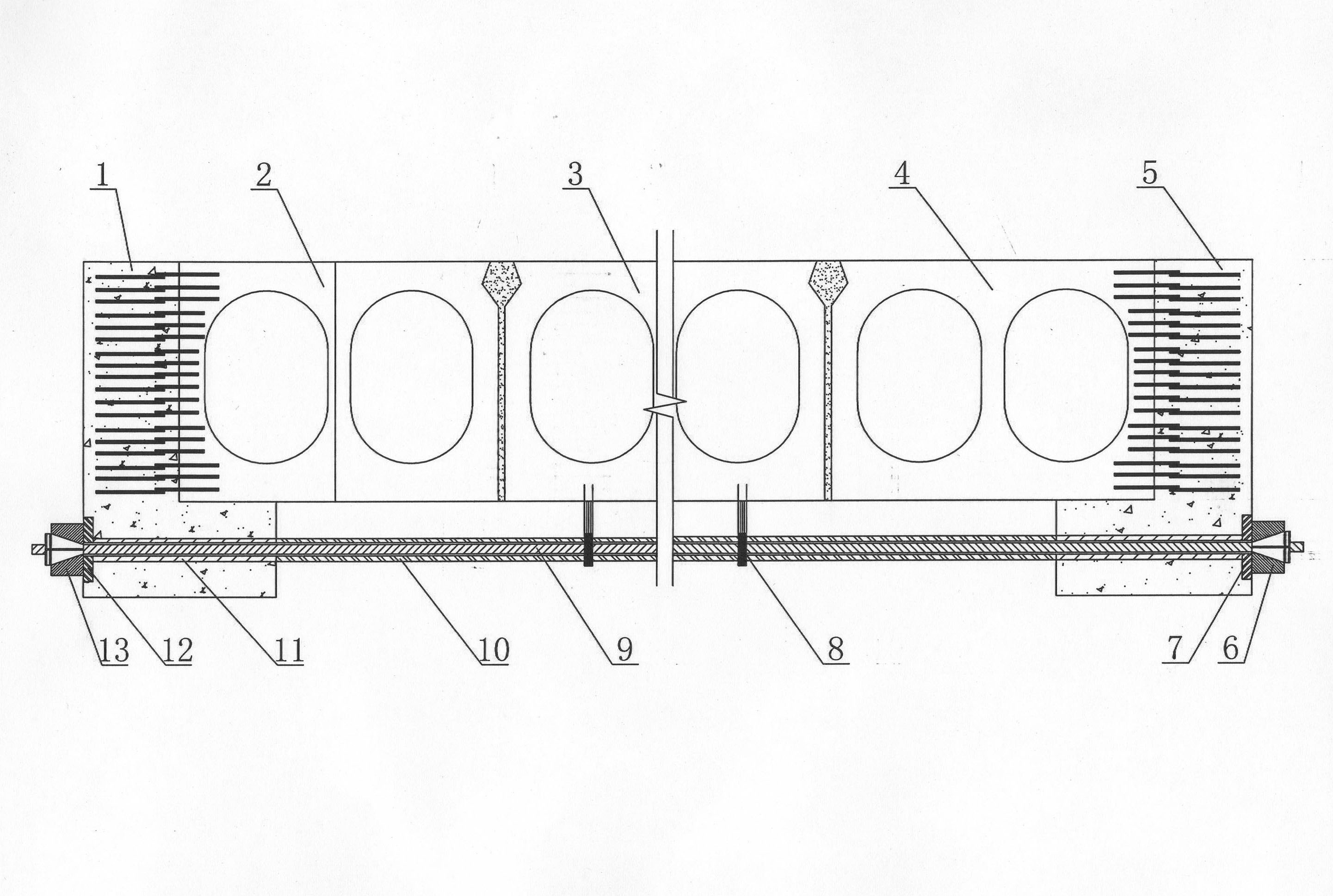

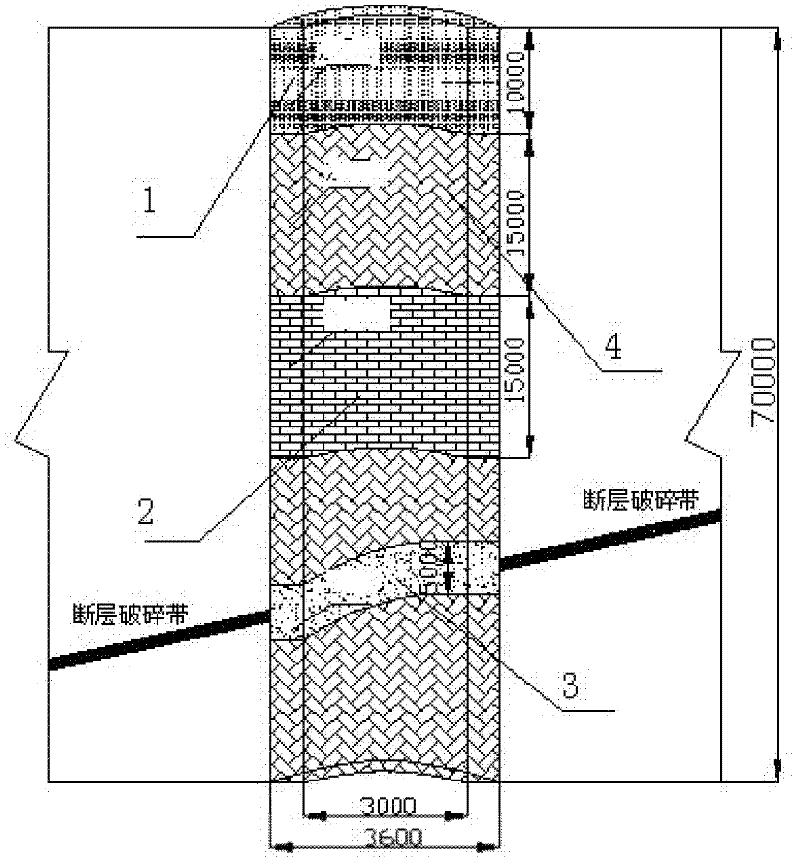

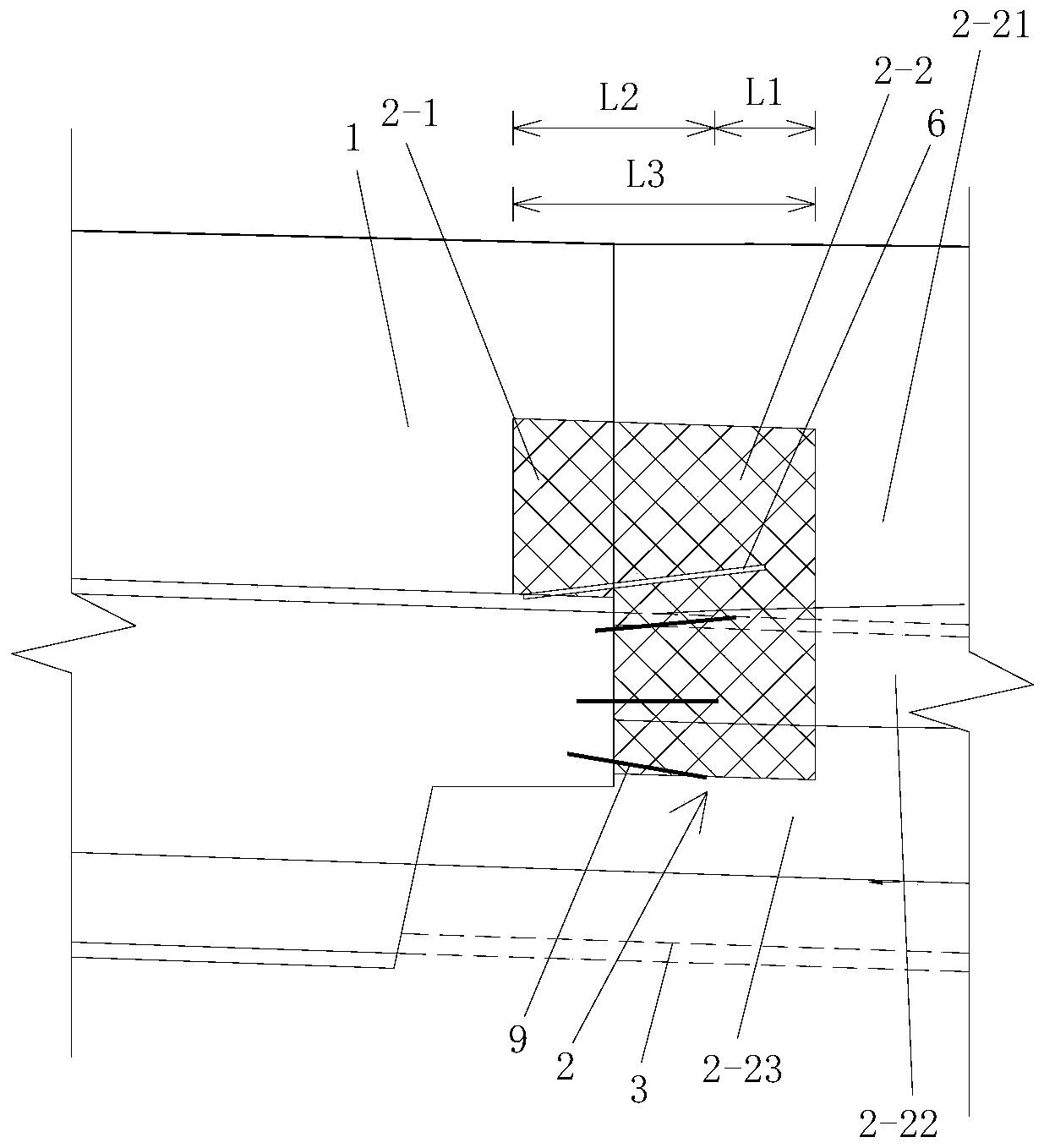

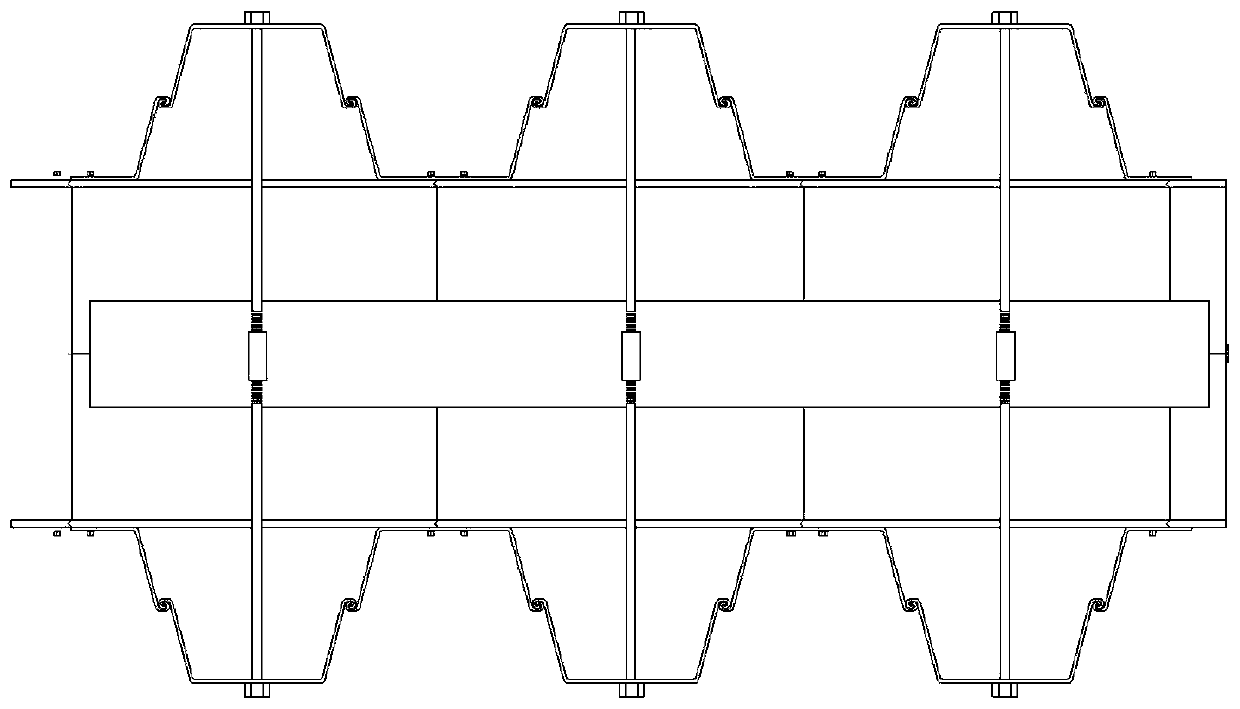

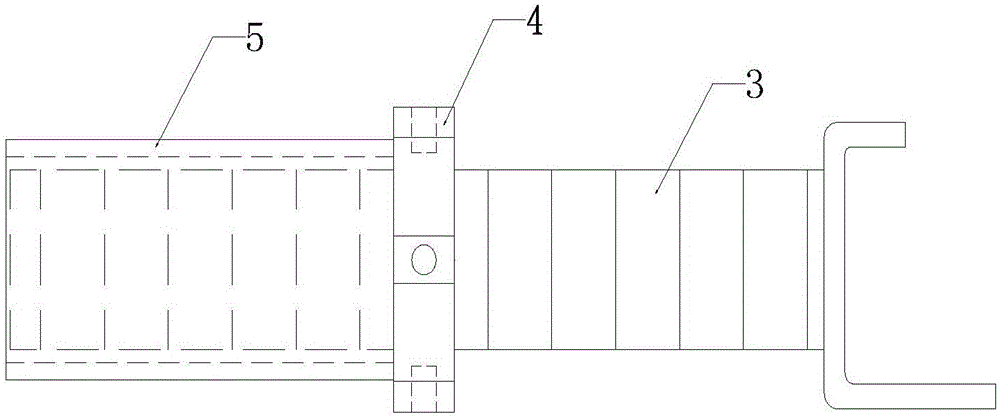

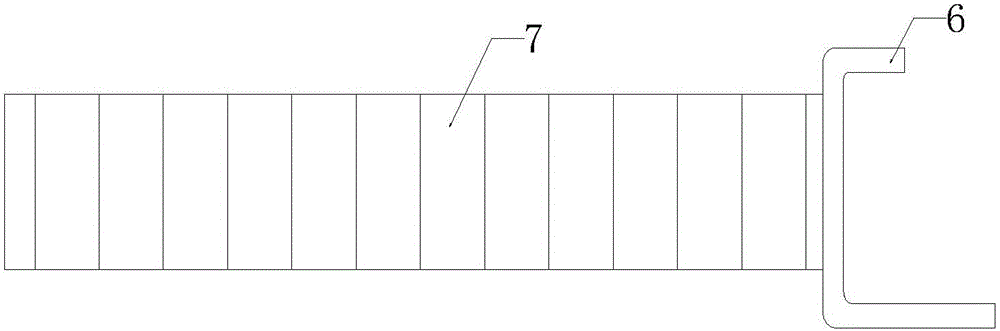

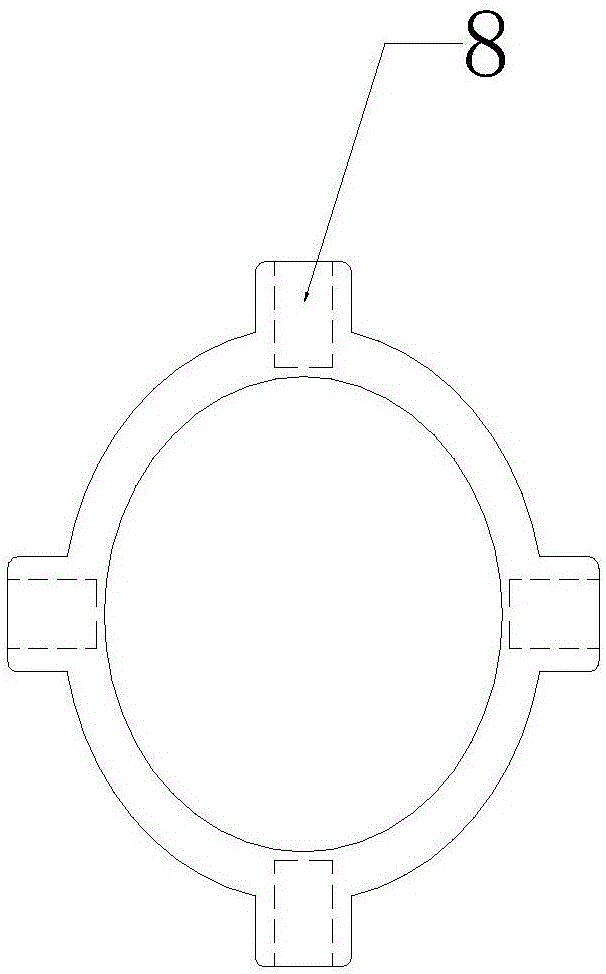

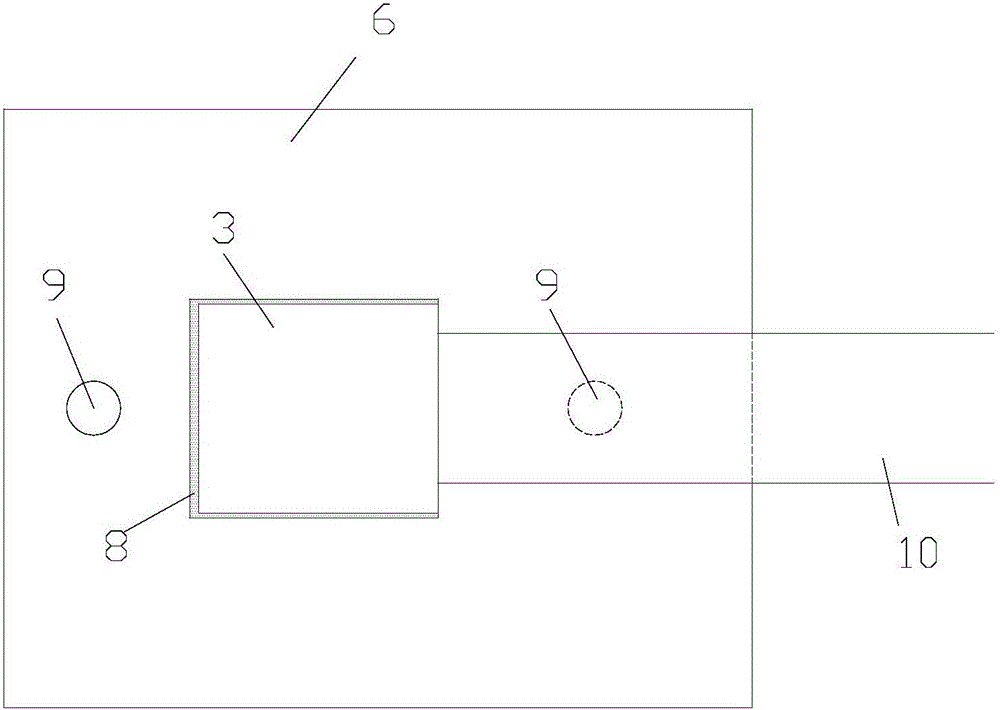

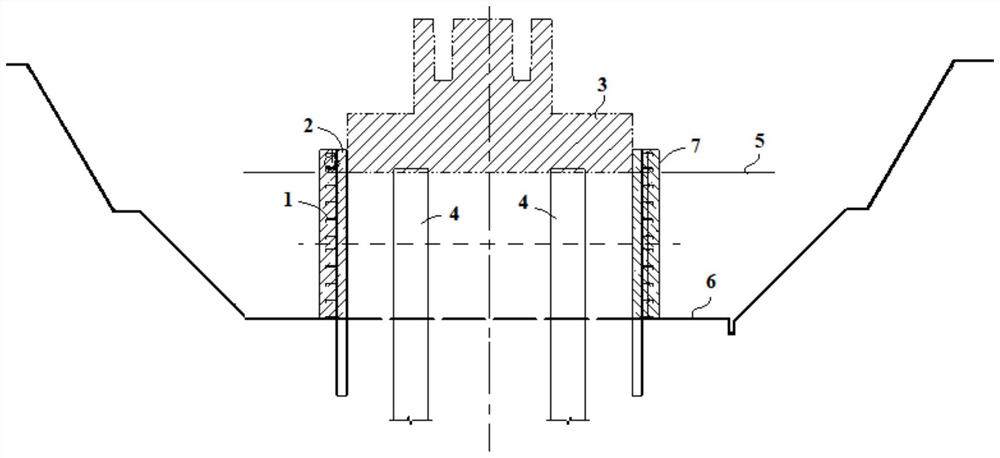

Transverse anchorage system outside hollow slab bridge body and construction process thereof

InactiveCN101949135AClosely connectedTo achieve the purpose of joint forceBridge structural detailsBridge erection/assemblyFatigue damageReinforced concrete

The invention relates to a transverse anchorage system outside a hollow slab bridge body and a construction process thereof. A left side slab of a hollow slab bridge is provided with a left corbel; a right side slab is provided with a right corbel; both the left corbel and the right corbel are provided with sylphon bellows; a prestressed cable penetratively arranged in each sylphon bellows; the left corbel and the right corbel are connected through the prestressed cable; the left end and the right end of the prestressed cable are respectively fixed by a left anchor device and a right anchor device; and the prestressed cable is connected with a middle slab through a flying ring. The transverse anchorage system is characterized in that the side slabs on both sides of the hollow slab bridge are respectively provided with a reinforced concrete corbel; the reinforced concrete corbels are cast together with the side slabs; the reinforced concrete corbels on both sides are connected with each other through the prestressed cable; and both ends of the prestressed cable are fixed to the reinforced concrete corbels by the anchor devices, and thus the structural rigidity and the integrity of the whole anchorage system are improved, the anchorage ends are guaranteed to be free from loosening, and the looseness of the prestressed cable is avoided. The invention solves the problems of easy looseness of a profile steel anchor lining plate, easy generation of fatigue damage, corrosion of a steel plate, and the like in the traditional anchorage system.

Owner:ZHENGZHOU UNIV +1

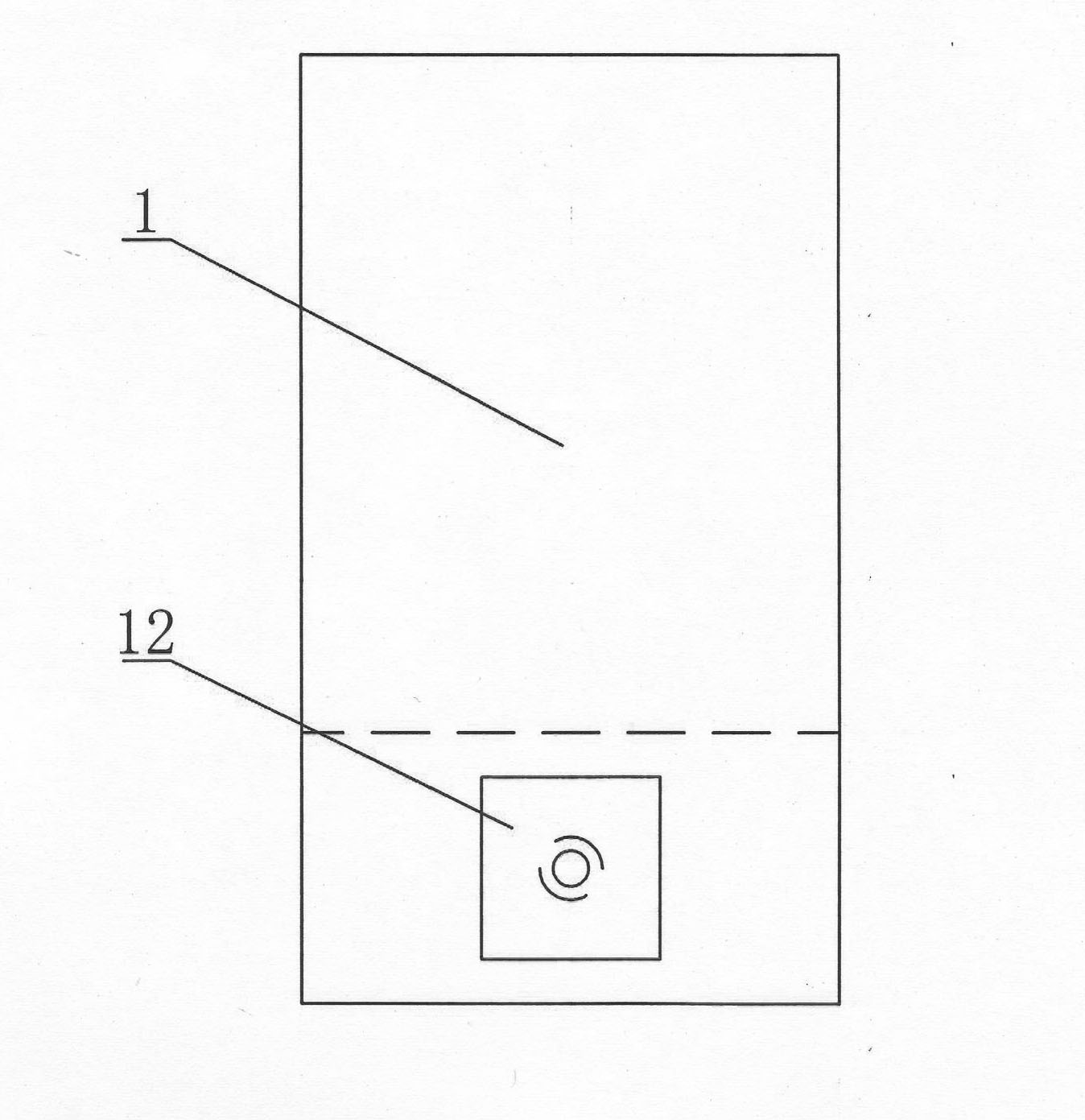

Method for reinforcing drop shaft in underground mine producing area

InactiveCN102226397AEasy to deform and shrinkShock absorbing effectAnchoring boltsShaft liningRock engineeringFracture zone

The invention relates to a method for reinforcing a drop shaft in an underground mine producing area and belongs to the field of metal mine and rock engineering reinforcement. The method is characterized in that the movement track of ores in the drop shaft during the ore discharge process is fully considered, model experiments and theoretical analysis method are adopted for determining the property of impact action and an impact failure region to the well wall generated by the ores according to the height of the drop shaft and the diameter of the drop shaft, the drop shaft is hereby divided into four stress regions, namely a first impact failure region, a second impact failure region, a fault fracture zone region and a wear-out failure region, and different forms are further adopted for reinforcement. The method is especially applicable to reinforcement of the drop shafts in the producing areas under soft and broken surrounding rock conditions, can be used for significantly prolonging the service life of the drop shaft and has the advantages of safety in construction, simpleness and low cost.

Owner:UNIV OF SCI & TECH BEIJING

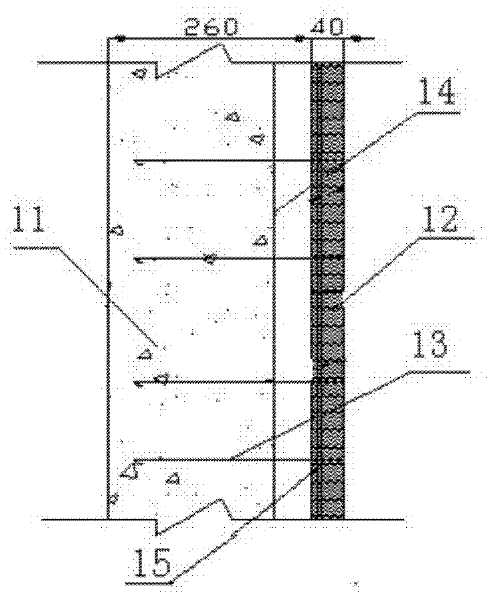

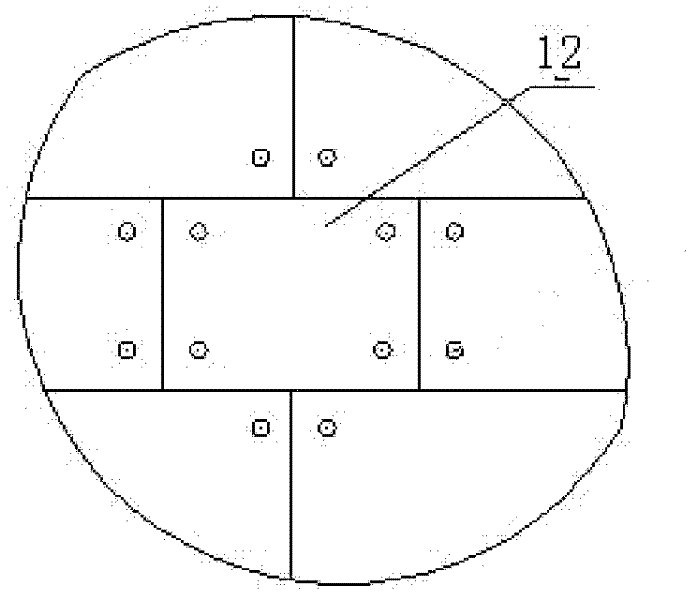

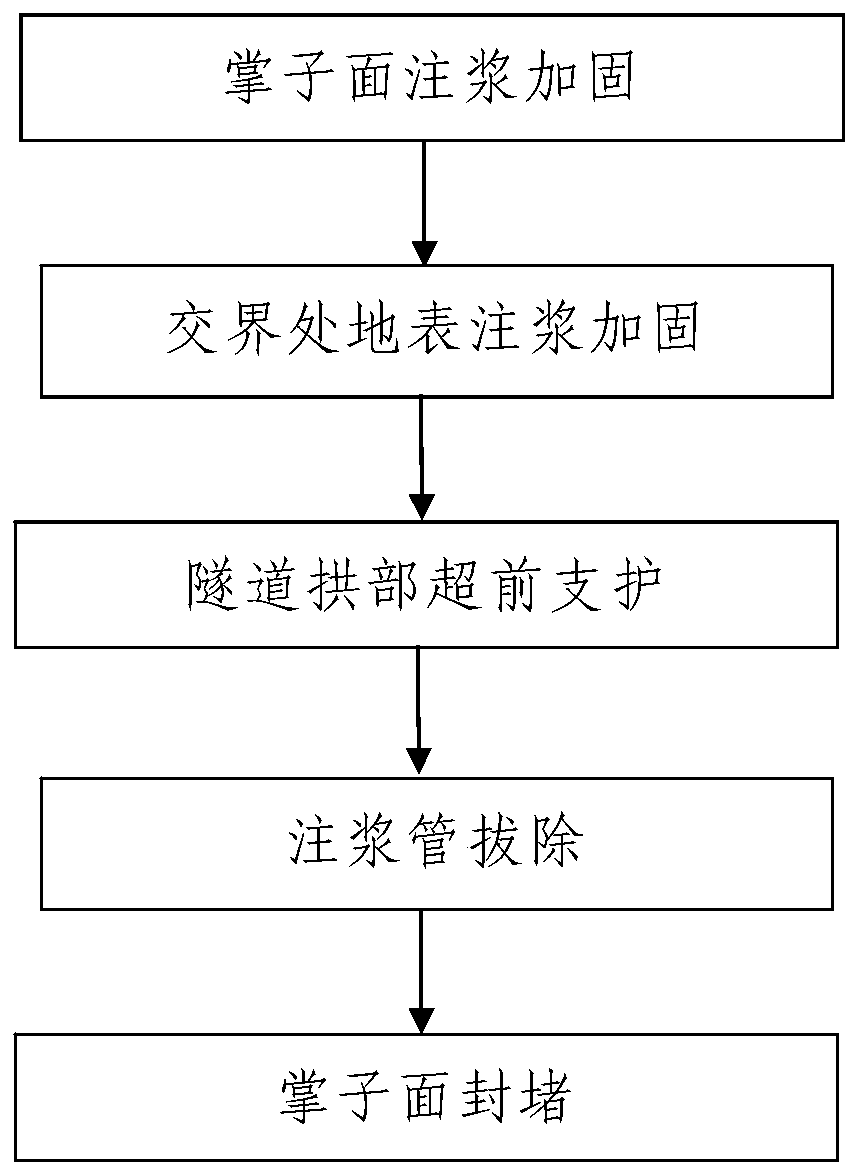

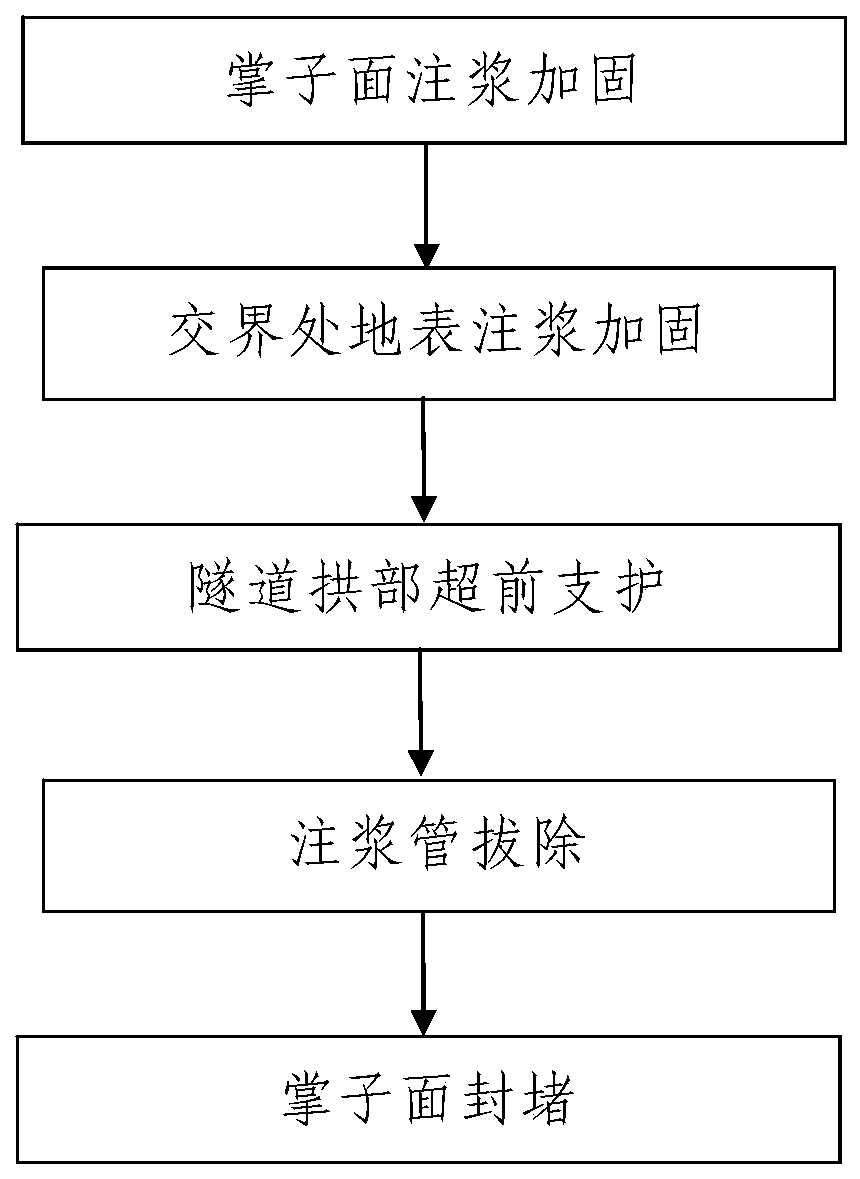

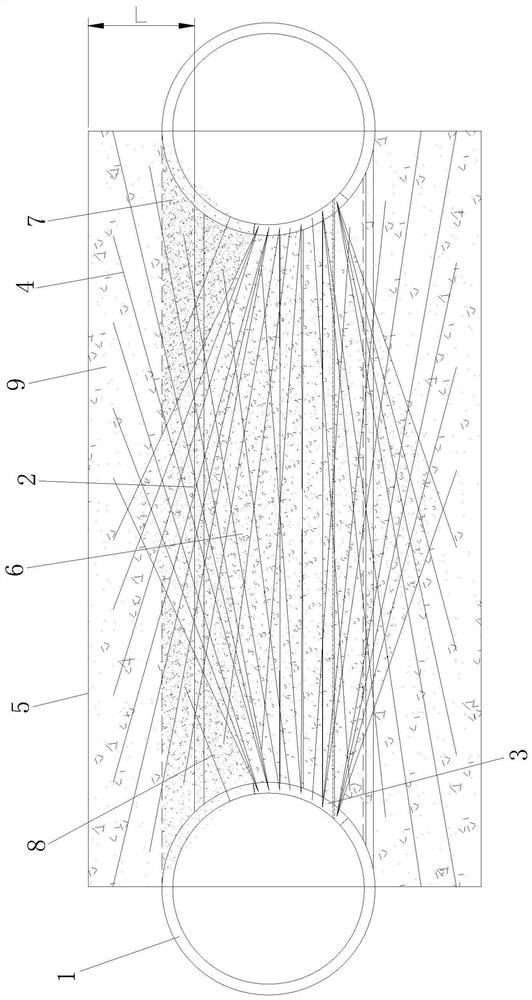

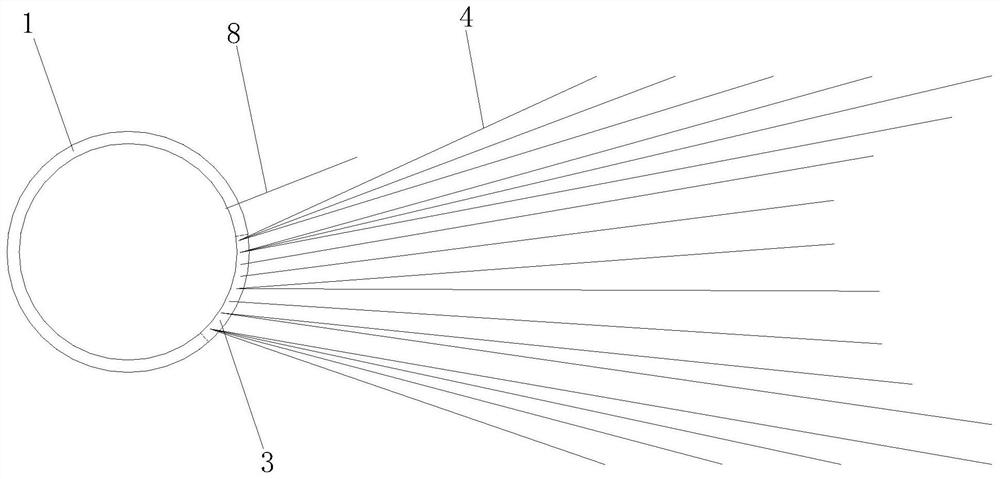

Surrounding rock reinforcement method for junction tunnel section in upper-soft lower-hard stratum constructed adopting shield method and mining method

ActiveCN110878696AThe method steps are simpleReasonable designUnderground chambersTunnel liningStructural engineeringGround settlement

The invention discloses a surrounding rock reinforcement method for a junction tunnel section in an upper-soft lower-hard stratum constructed adopting a shield method and a mining method. The method comprises the steps that 1, tunnel face grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on stratum in front of an excavation face of an upper tunnel body by adopting grouting pipes; 2, junction surface grouting reinforcement is carried out, specifically, grouting reinforcement is carried out on the reinforced stratum by adopting sleeve valve pipes; 3, tunnel arch part advanced support is carried out, specifically, advanced support is carried out on an arch part of the junction tunnel section; 4, grouting pipe removal is carried out; and 5, tunnel faceplugging is carried out, specifically, a tunnel face is plugged through concrete backfilling, and a tunnel face plugging structure is obtained. The method is reasonable in design, simple and convenient to construct and good in use effect, and surrounding rock of the junction tunnel section is effectively reinforced by the method of combining the surface grouting reinforcement with the in-tunnel reinforcement so that the mechanical property of the surrounding rock can be effectively improved; and the tunnel face of the junction tunnel section is reliably plugged before and after reinforcement so that tunnel safety construction can be effectively guaranteed, and ground settlement caused by excavation can be effectively reduced.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Steel plate reinforcing sheet

InactiveUS20050276984A1Reduce distortion problemsRelieve pressureLayered product treatmentSynthetic resin layered productsSheet steelDistortion

Owner:NITTO DENKO CORP

Anti-cracking waterproof construction method for post-poured strip

InactiveCN109057338AReduce gapGuarantee the construction qualityBuilding material handlingBuilding insulationsEconomic benefitsRebar

The invention discloses an anti-cracking waterproof construction method for a post-poured strip. The method comprises the following steps of pouring of fine-stone waterproof concrete strips; binding of plate bottom reinforcing steel bars; installation of a lower-layer dense-hole steel wire mesh frame; installation of water-stopping steel plates; installation of an upper-layer dense-hole steel wiremesh frame; binding of plate top reinforcing steel bars; formwork hanging; pouring of concrete at the two sides of the post-poured strip; die removing and maintenance; removal of dense-hole steel wire meshes; pouring of concrete in the post-poured strip. The construction method is reasonable in design and convenient to operate, the anti-cracking and waterproof effects of the post-poured strip after construction are good, the economic benefits are increased, and meanwhile the construction quality of the post-poured strip is effectively ensured.

Owner:CHINA MCC17 GRP

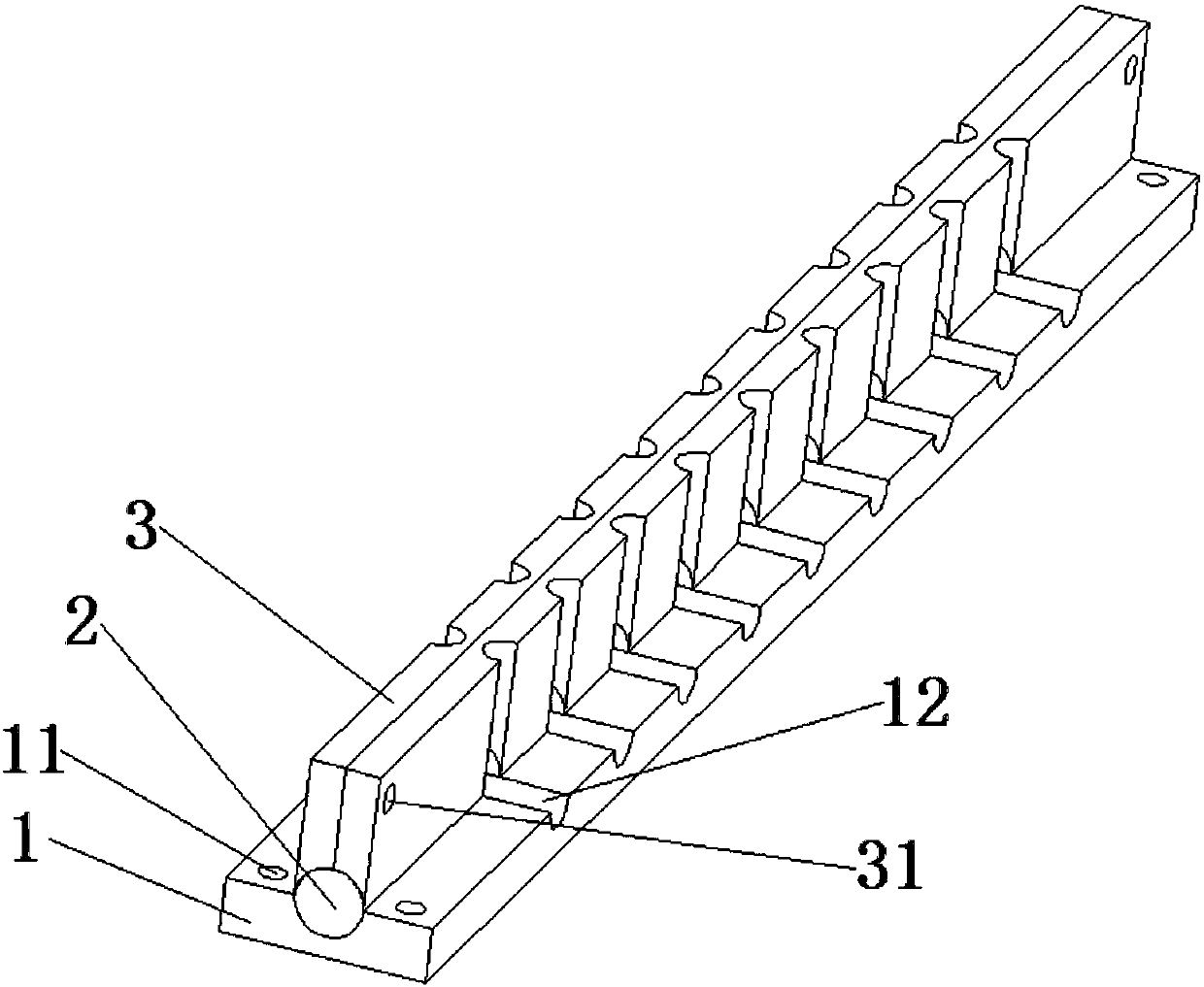

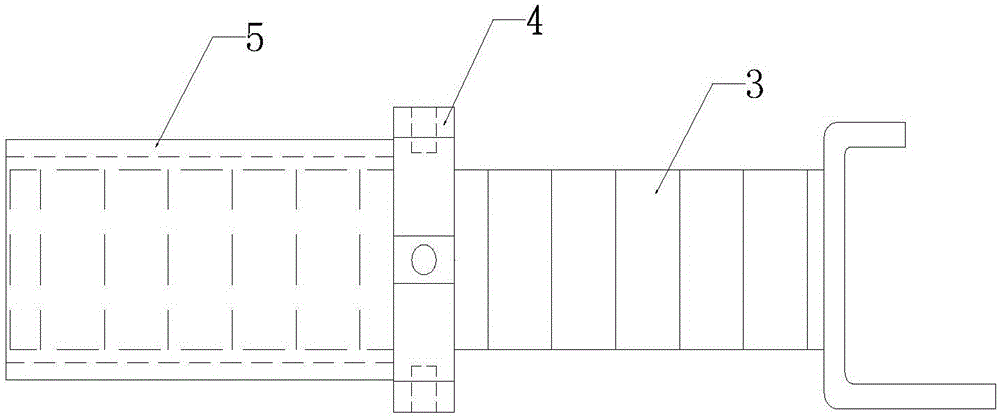

Construction method and installation accuracy control method of rack systems of high-lift rack climbing type ship lift

The invention relates to a construction method and installation accuracy control method of rack systems of a high-lift rack climbing type ship lift. The four sets of rack systems can be installed by adopting the rack system construction method. According to the installation method, the installation quality and installation efficiency of the rack systems can be improved and the safety and reliability of the whole construction can be further ensured. According to the rack installation accuracy control method, the accuracy requirements in a rack installation process can be improved and the installation accuracy of racks can meet requirements.

Owner:CHINA THREE GORGES CORPORATION +1

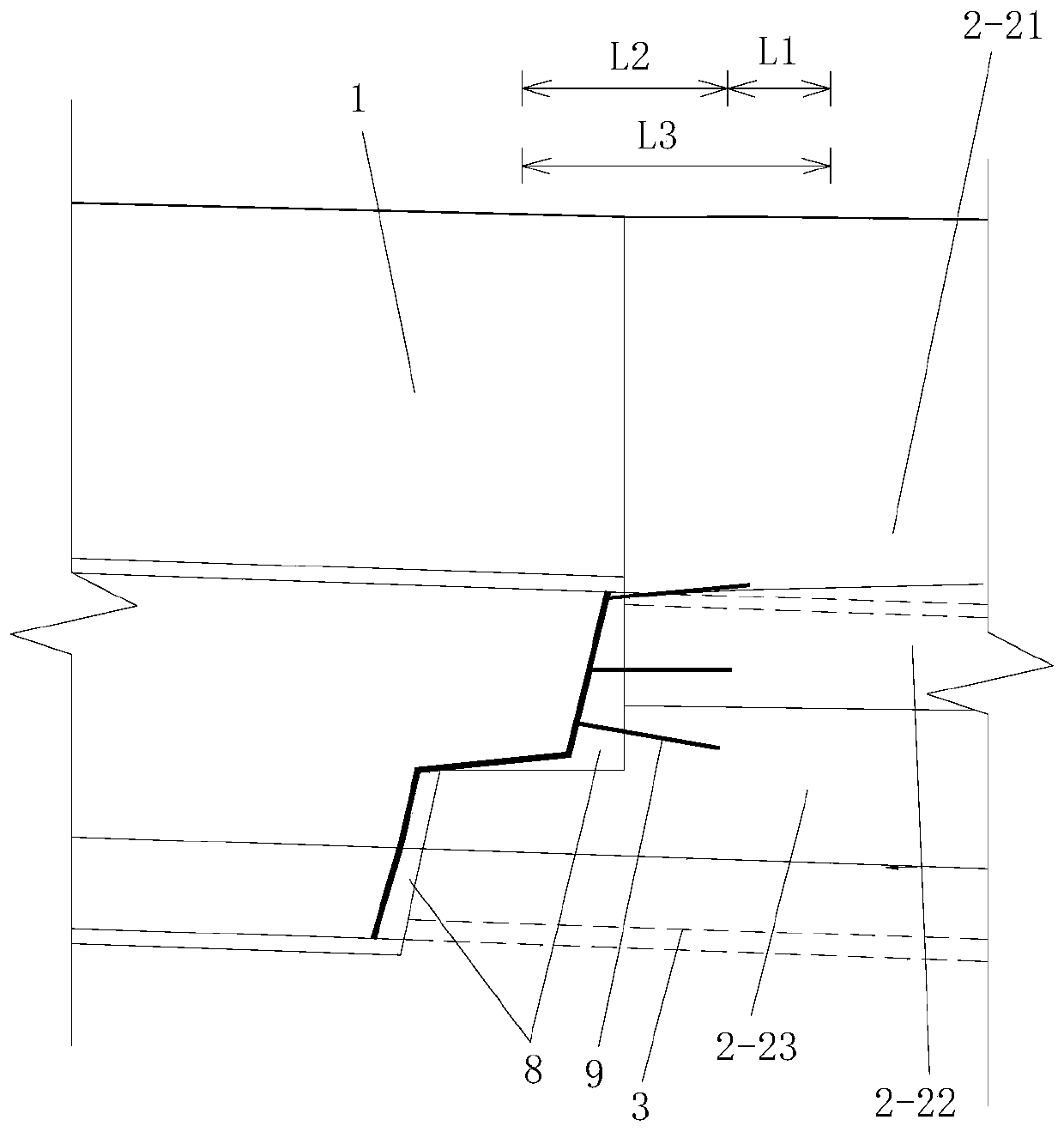

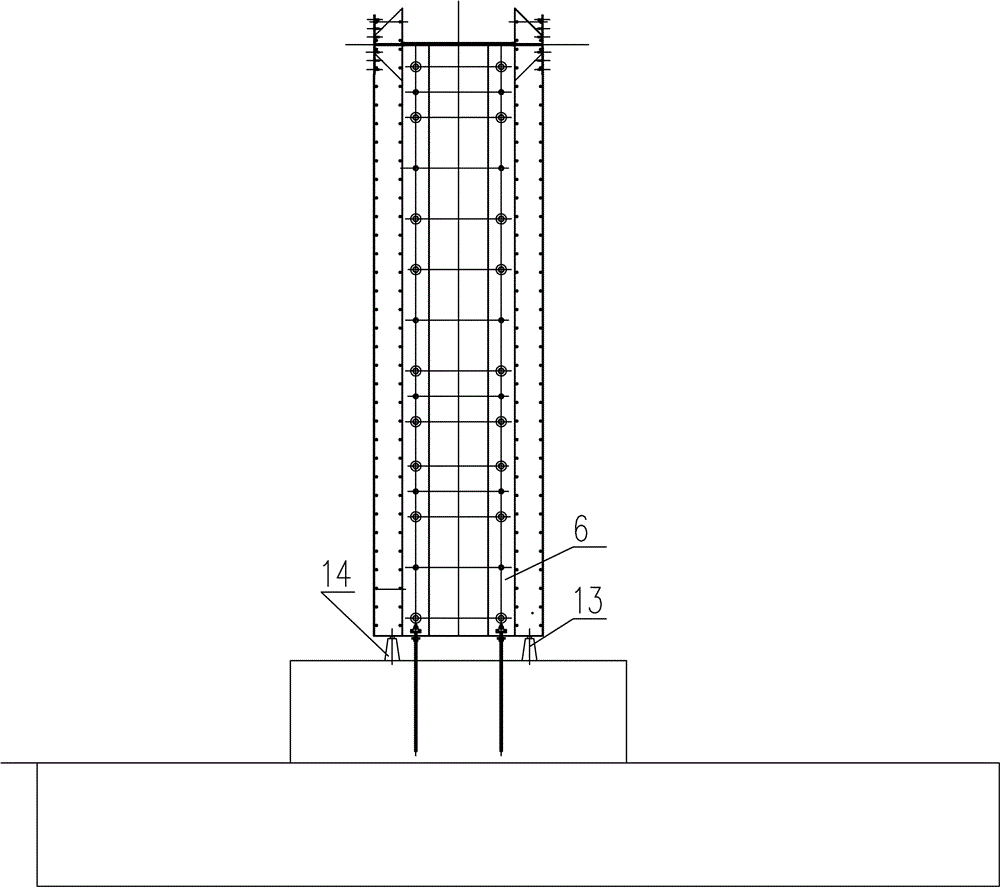

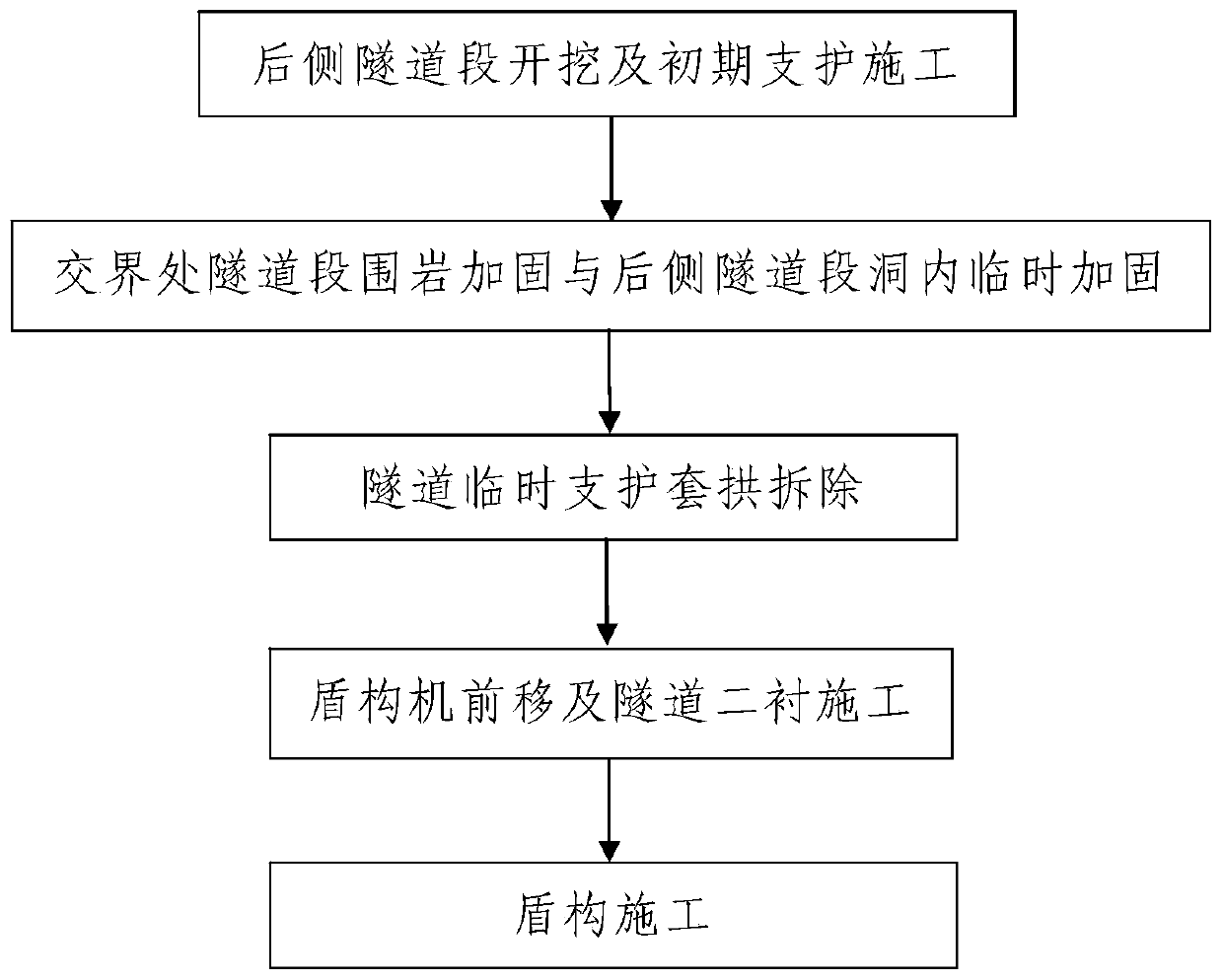

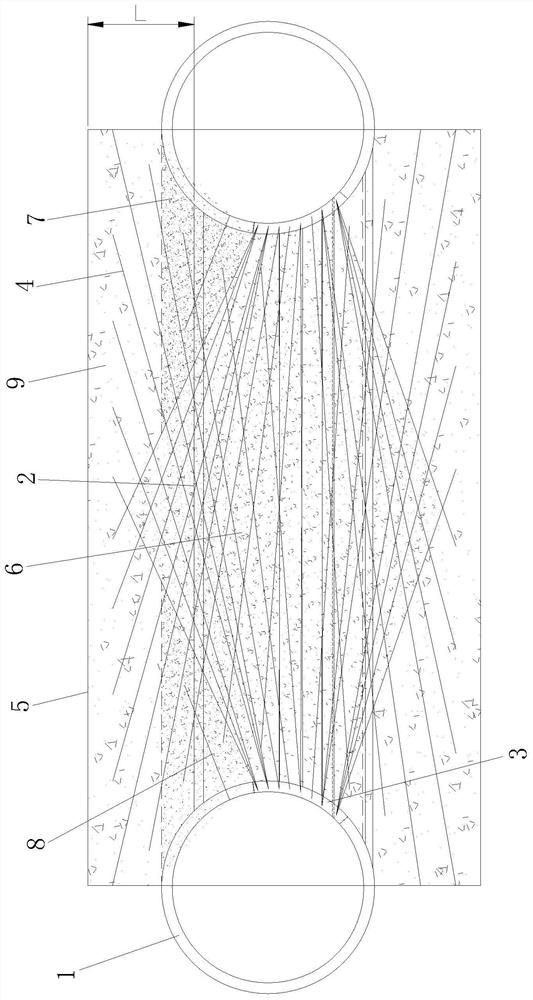

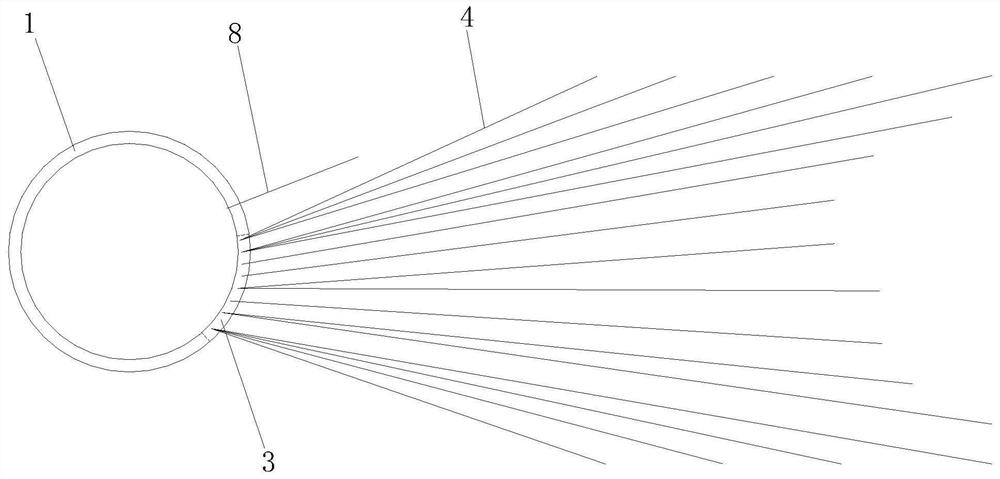

Tunnel construction method for formation with upper soft part and lower hard part

ActiveCN110905527AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringShield tunneling

The invention discloses a tunnel construction method for a formation with an upper soft part and a lower hard part. During construction of any one of to-be-constructed tunnels of the construction tunnel, the method comprises the following steps: 1, performing back side tunnel segment excavation and preliminary bracing construction; 2, performing junction tunnel segment surrounding rock reinforcement and back side tunnel segment in-cavity temporary reinforcement; 3, disassembling a tunnel temporary supporting cover arch; 4, enabling a shield tunneling machine to move forwards and performing tunnel secondary lining construction; and 5, performing shield tunneling construction. The method is reasonable in design, simple and convenient to construct and good in use effect; the stability of theback side tunnel segment is guaranteed by a tunnel temporary supporting cover arch; the junction tunnel segment surrounding rock is effectively reinforced by a mode of combining ground surface grouting reinforcement with in-cavity reinforcement, so that the mechanical property of the surrounding rock can be effectively improved, the safe construction of the tunnel can be effectively guaranteed andsurface subsidence caused by excavation can be effectively reduced; and after the junction tunnel segment surrounding rod reinforcement is completed, the tunnel temporary supporting cover arch is disassembled and the shield tunneling machine moves towards in place to perform construction on the front side tunnel segment, so the construction process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

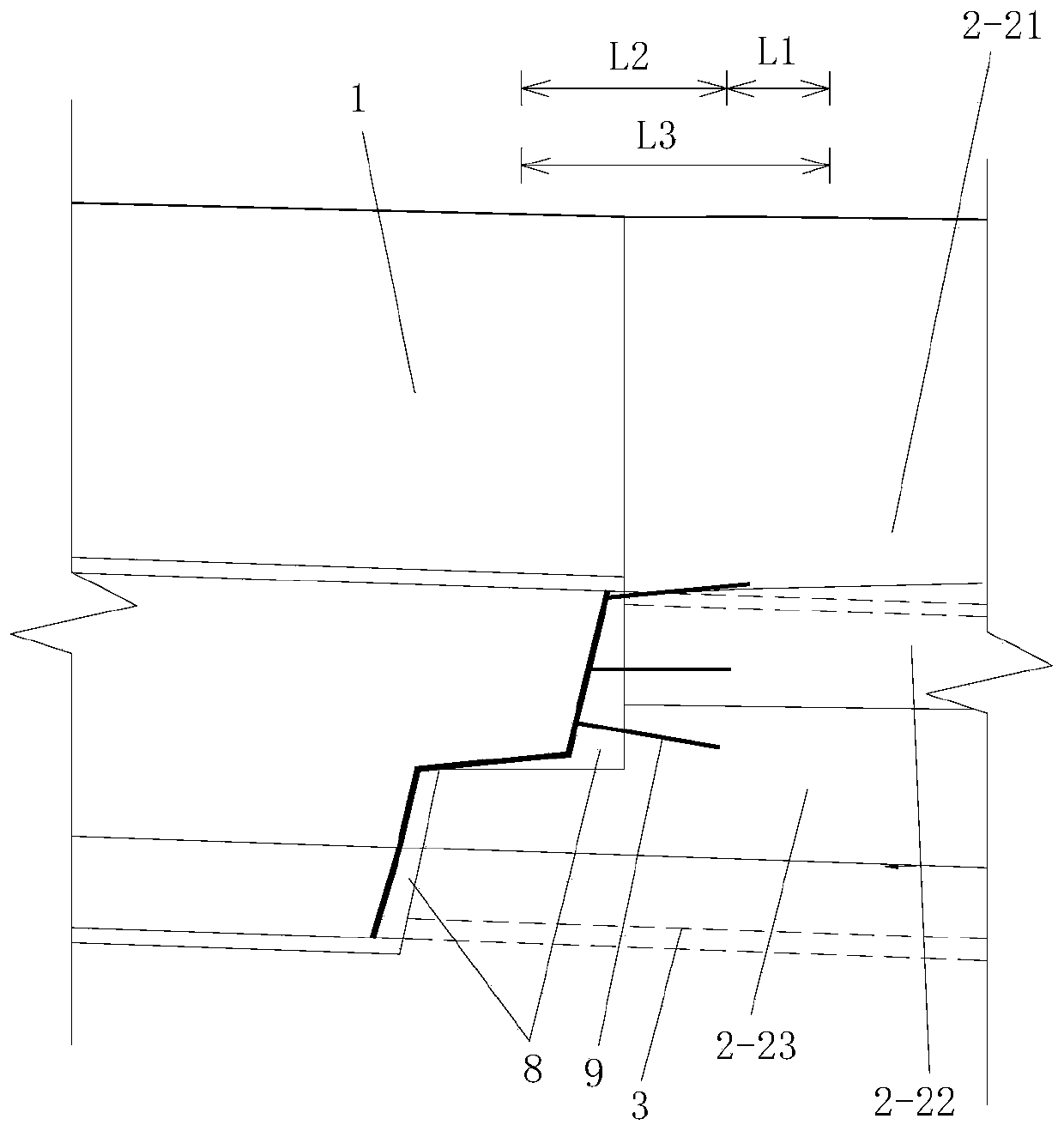

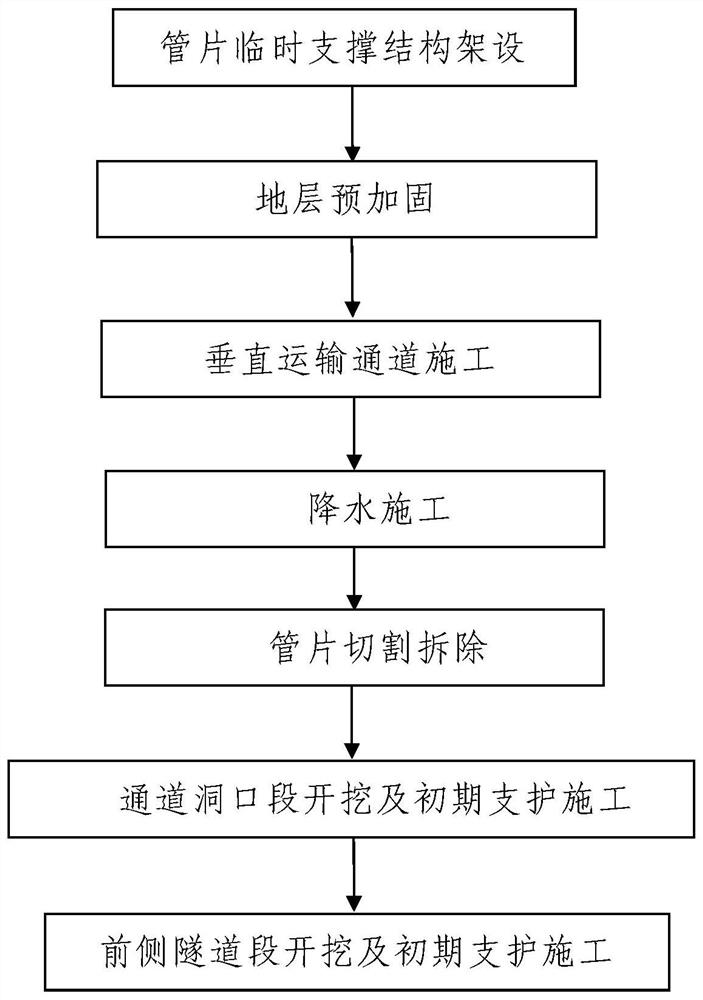

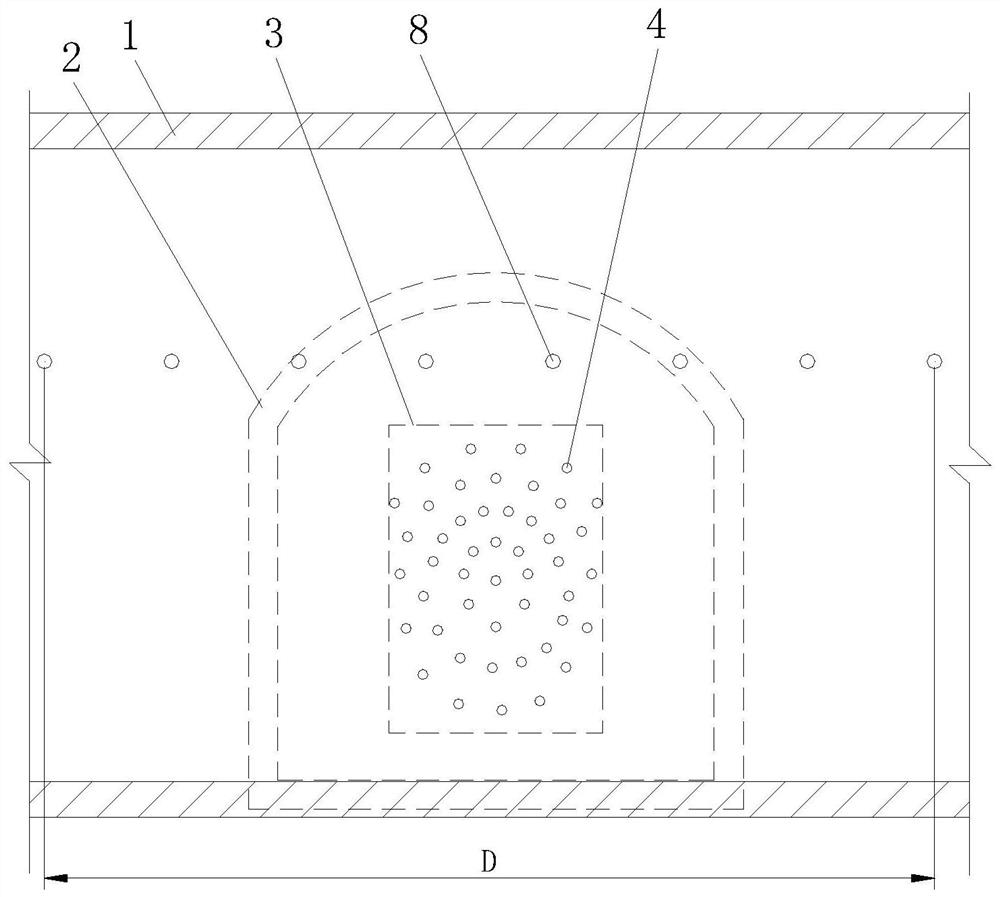

Construction method of water-rich sand layer shield interval contact channel

ActiveCN112502734ASimple stepsReasonable designUnderground chambersHydro energy generationEngineeringShield tunneling

The invention discloses a construction method of a water-rich sand layer shield interval contact channel. The construction method comprises the steps that 1, a segment temporary supporting structure is erected; 2, stratum pre-reinforcement is conducted; 3, precipitation construction is conducted; 4, cutting and dismantling are conducted on a segment; 5, a channel opening section is excavated, andprimary support construction is conducted; 6, a front side tunnel section is excavated, and primary support construction is conducted. The method is simple in step, reasonable in design, easy and convenient to construct and safe and reliable in construction process, and the segment temporary supporting structure is erected at the joint of the shield tunnel and the contact channel before stratum pre-reinforcement. Then stratum advanced small guide pipe grouting reinforcement at the end of the channel and overall grouting reinforcement of a sleeve valve pipe of the stratum where the channel is located are combined for stratum pre-reinforcement, the stratum is further reinforced through rainfall after the stratum pre-reinforcement, the construction process of the water-rich sand layer shieldinterval contact channel can be easily and conveniently completed, and the construction process is safe and reliable.

Owner:CHINA RAILWAY 20 BUREAU GRP

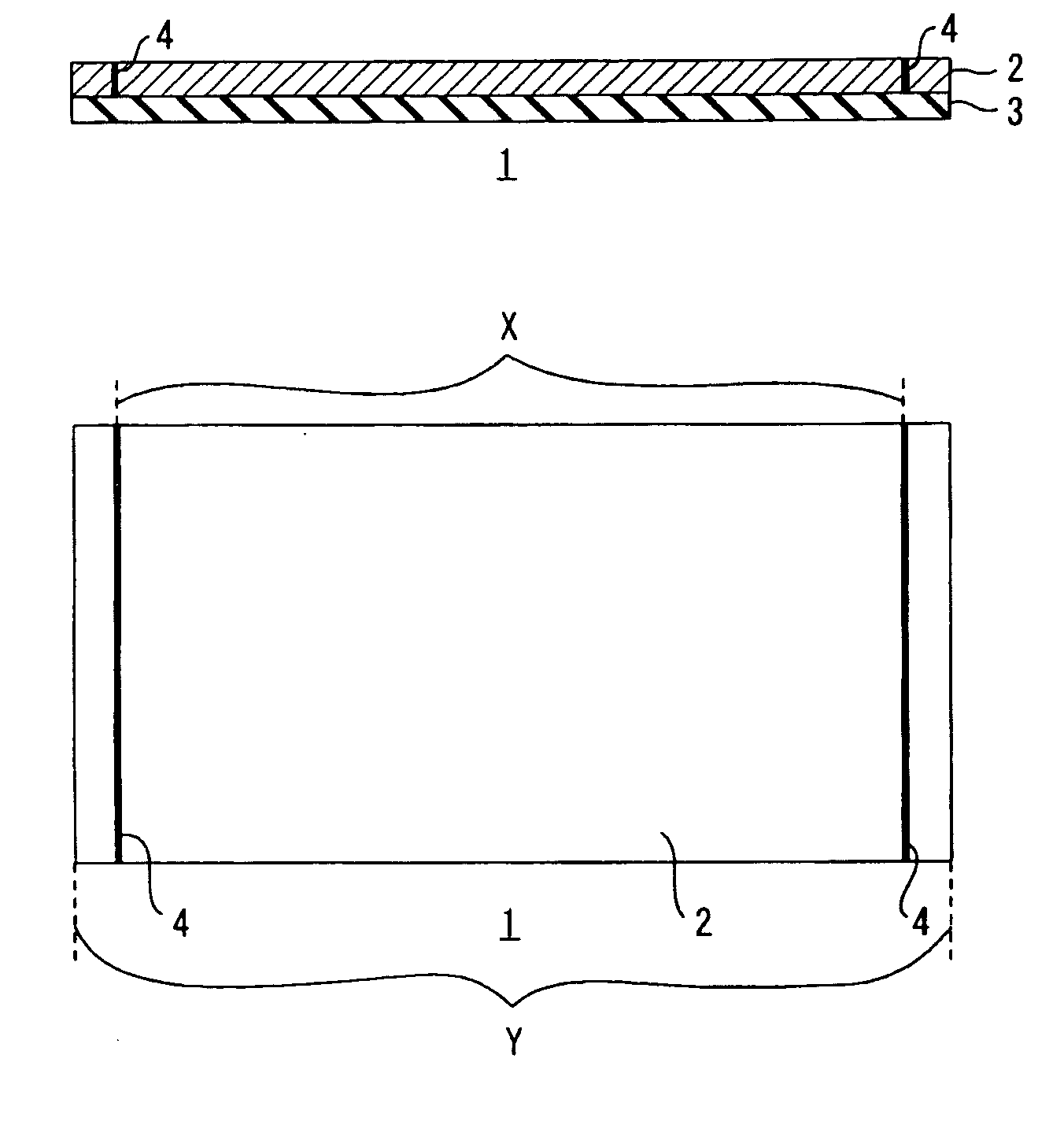

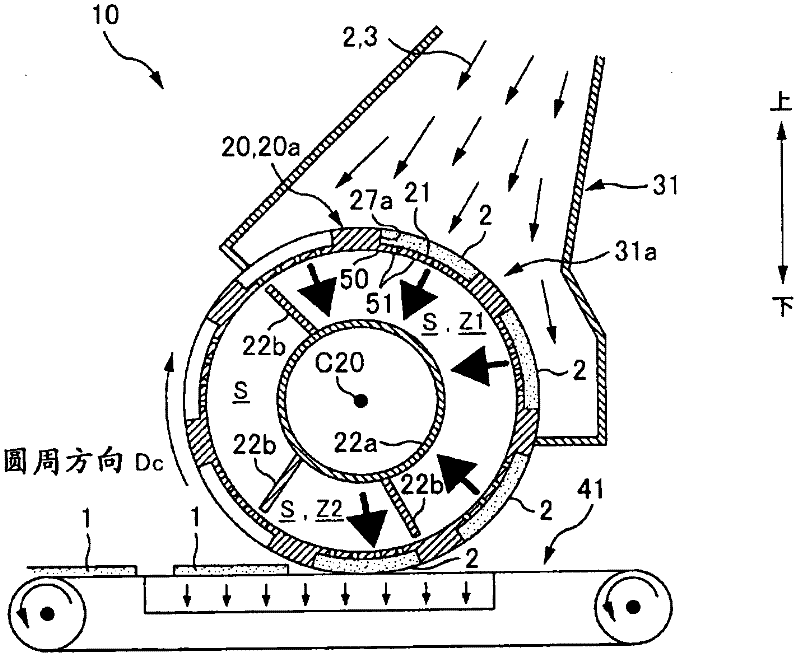

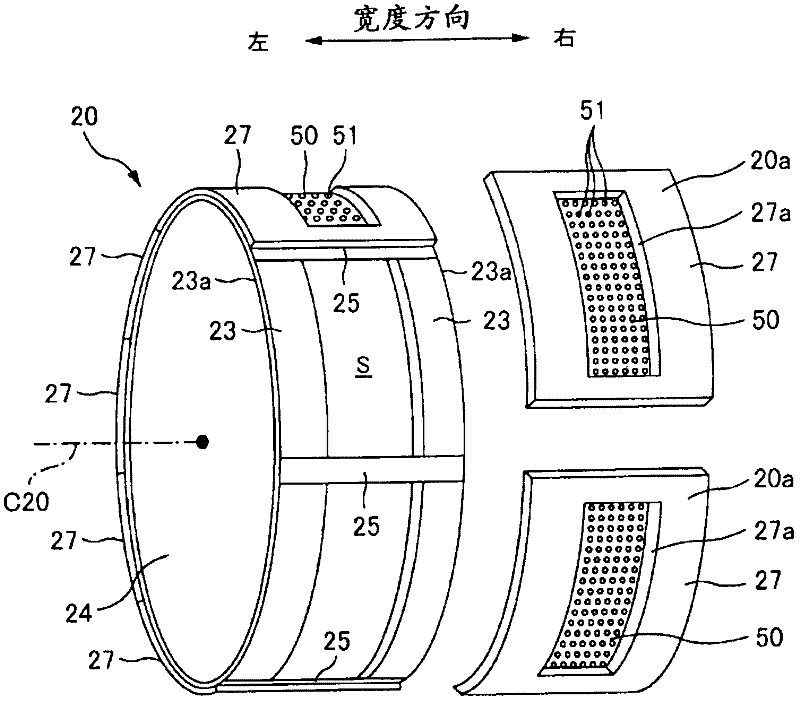

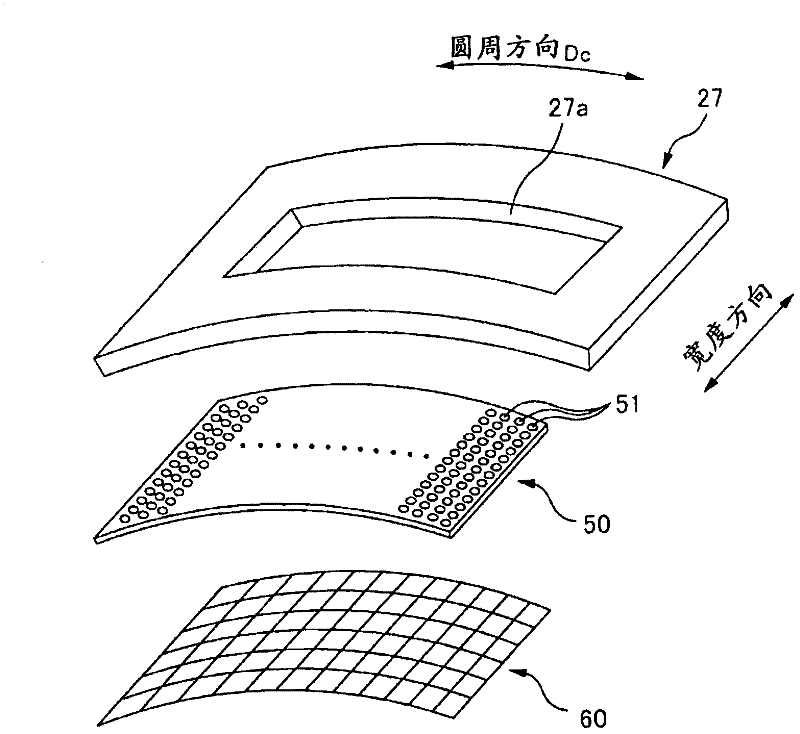

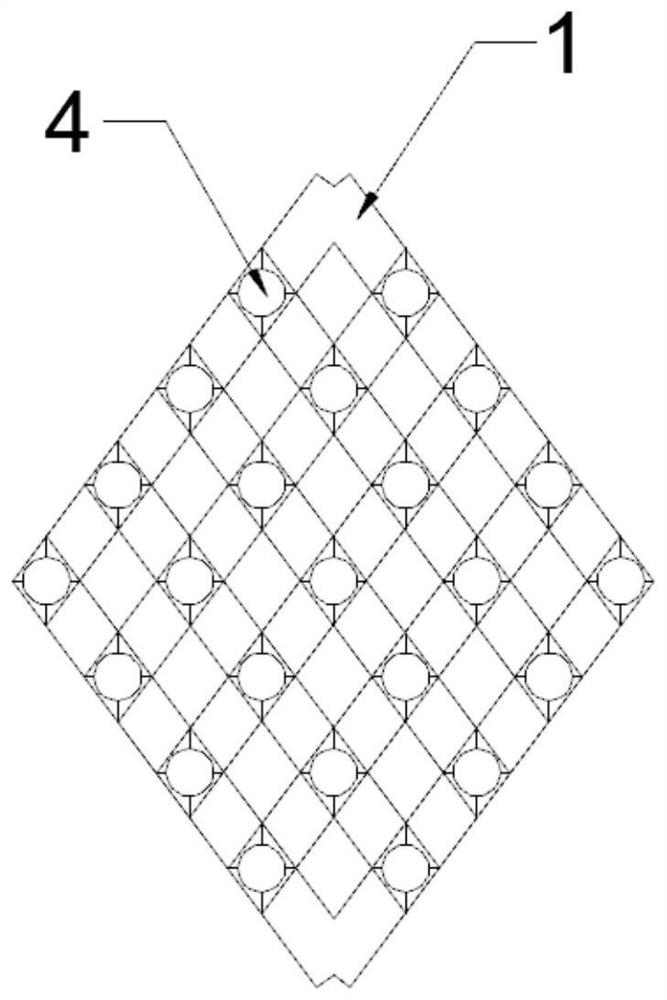

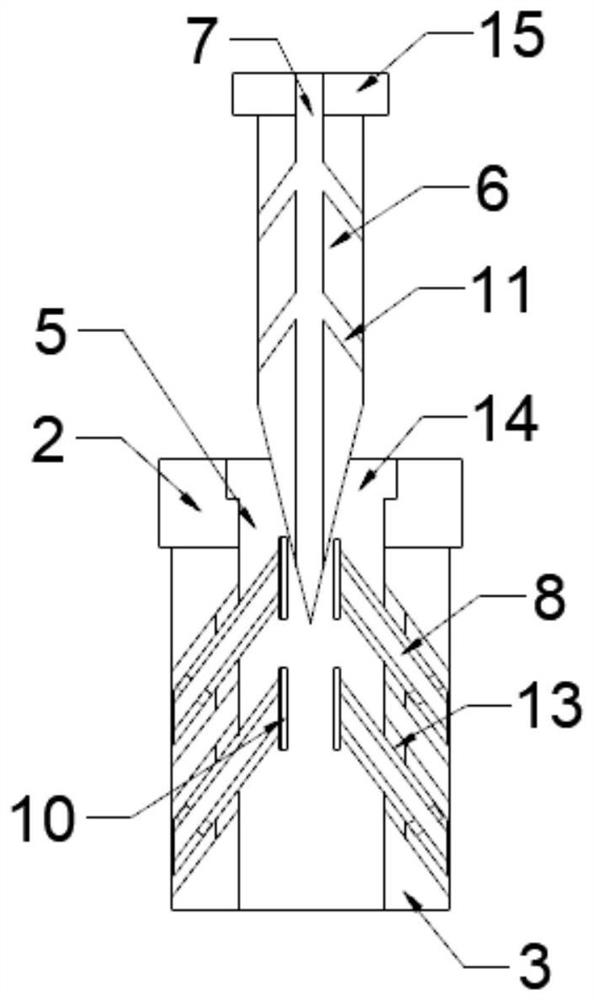

Device for manufacturing absorbing body and method of manufacturing gas permeable member

ActiveCN102355877AReliable reinforcementAvoid deformationLaminationLamination apparatusMechanical engineeringManufactured gas

A device (10) for manufacturing an absorbing body (1) relating to an absorptive article, the device (10) manufacturing the absorbing body (1) by causing gas (3) which contains a liquid absorptive raw material (2) to pass through a gas permeable member (50), which covers the opening (27a) of a mold member (27), in the thickness direction thereof to layer the liquid absorptive raw material (2) on the gas permeable member (50). The device (10) has a reinforcing member (60) superposed on the gas permeable member (50) in the thickness direction to reinforce the gas permeable member (50). The reinforcing member (60) is a meshed body formed by first wires (61) and second wires (62) in such a manner that each of the first wires (61) and each of the second wires (62) intersect each other at the intersection (CP60) at which the first and second wires (61, 62) are connected together. At the intersections (CP60), the reinforcing member (60) is joined to the gas permeable member (50).

Owner:UNI CHARM CORP

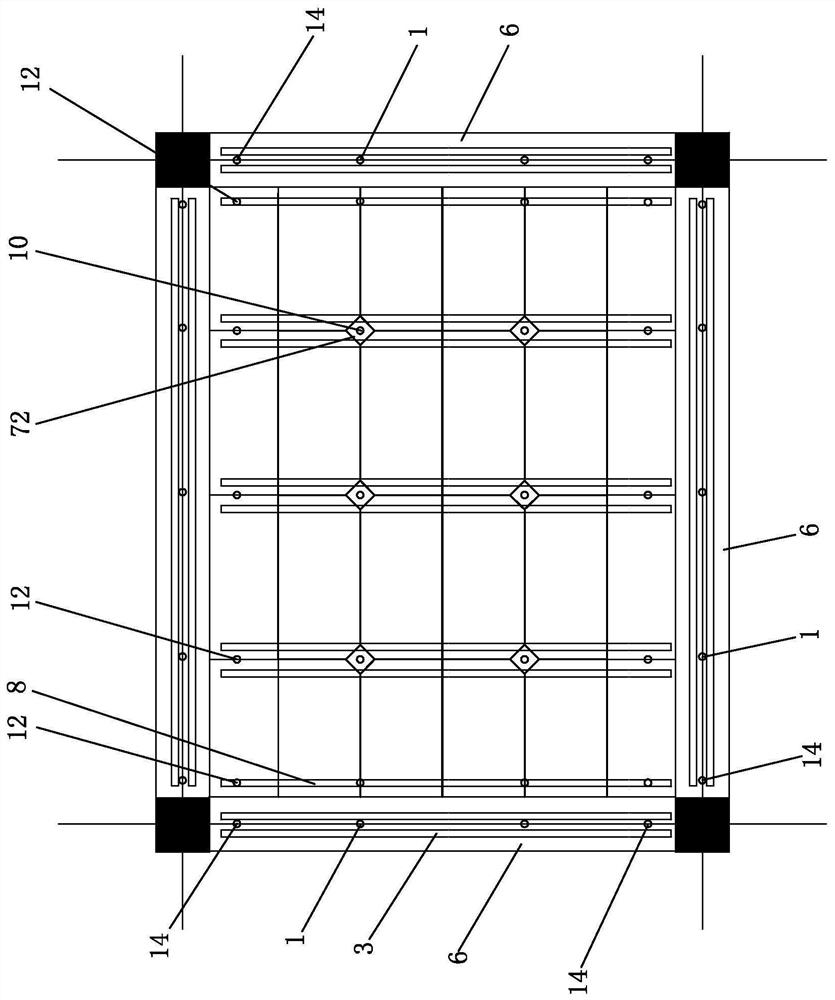

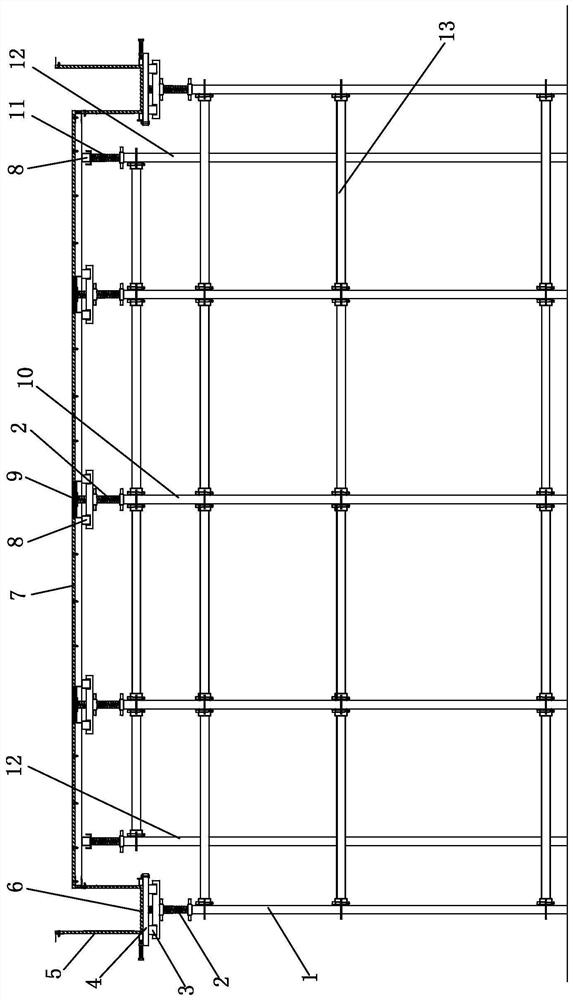

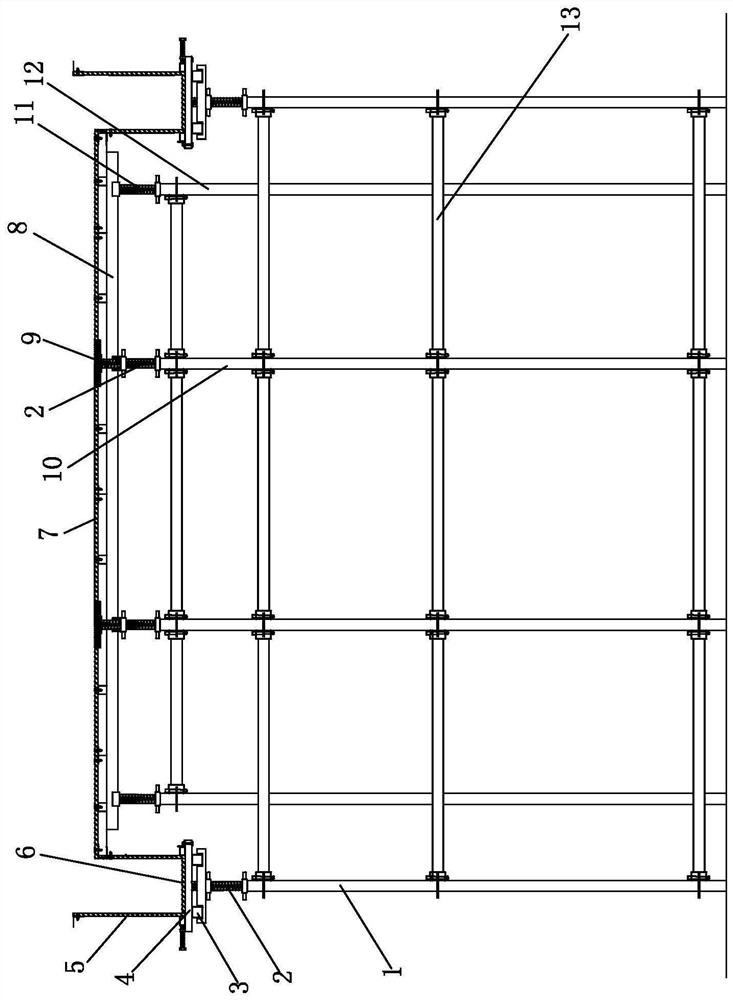

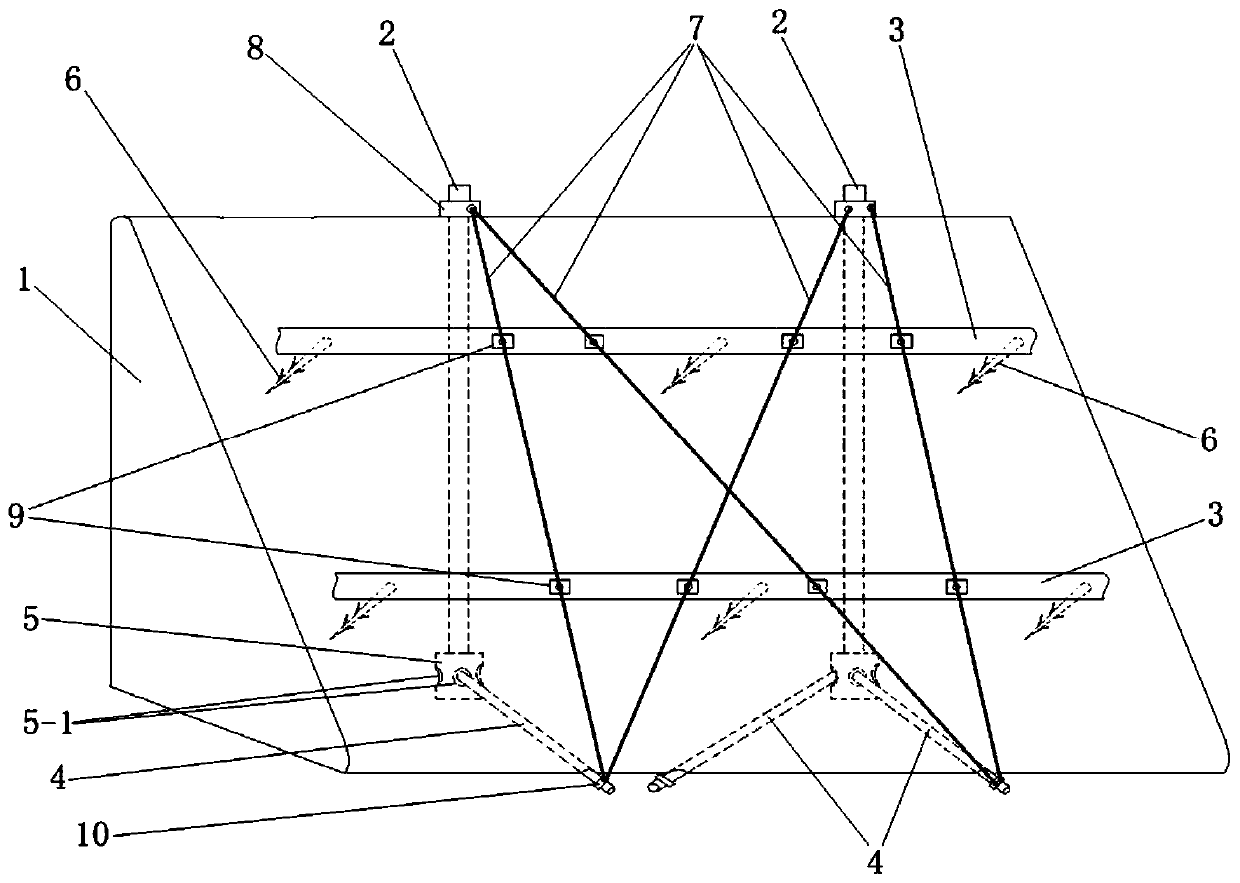

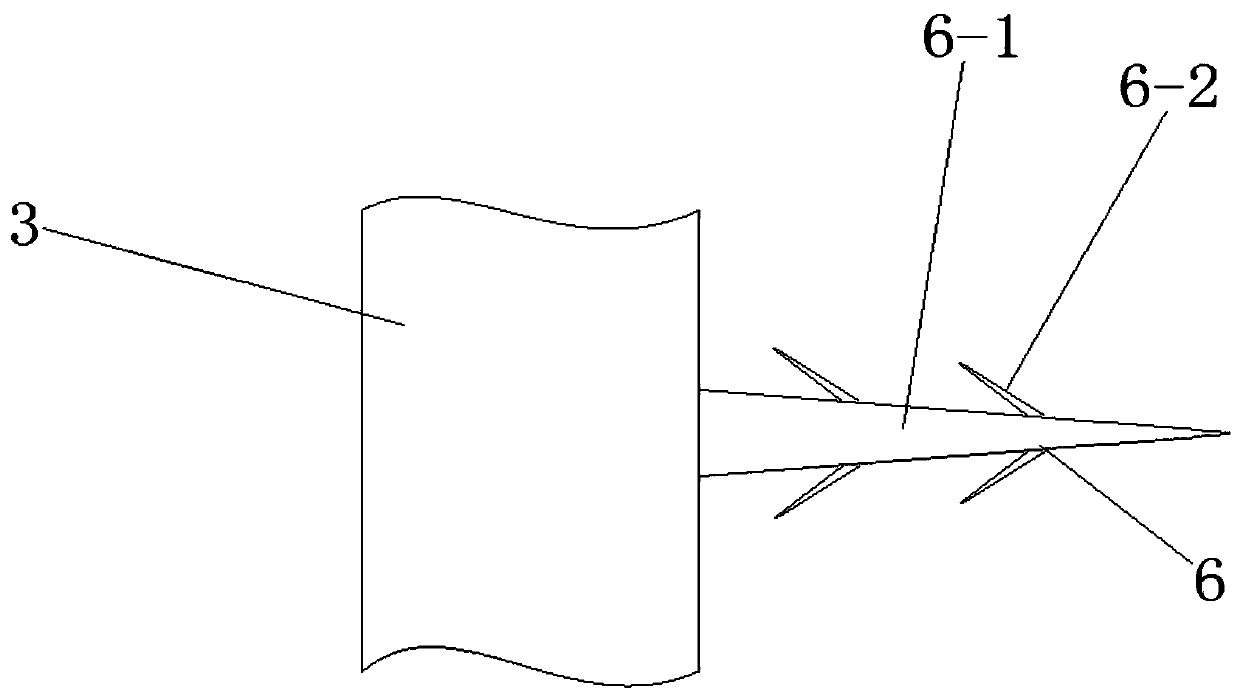

Pre-supporting and post-mounting shaping early-dismantling form system and construction method thereof

PendingCN111749457AReduced strength and stiffness requirementsReduce weightForms/shuttering/falseworksSteel tubeFloor slab

The invention relates to a pre-supporting and post-mounting shaping early-dismantling form system. The pre-supporting and post-mounting shaping early-dismantling form system comprises a supporting system and a form system; the supporting system comprises a supporting frame body, a jacking, a supporting beam and a beam bottom supporting device; the supporting frame body is an integral bracket formed by erecting scaffold steel pipes; the jacking comprises an early-dismantling jacking and a common jacking; the supporting beam comprises a plate bottom supporting beam and a beam bottom supporting beam; the form system comprises a floor form, a rear dismantling base plate, beam side forms and a beam bottom form, the floor form is located on the plate bottom supporting beam; and the beam bottom form is located on the upper side of the beam bottom supporting device, and the beam side forms are located on the two sides of the beam bottom form correspondingly. According to the pre-supporting andpost-mounting shaping early-dismantling form system, the strength and rigidity requirements of the shaping form are greatly reduced, so that the weight, the manufacturing cost and the processing difficulty of the shaping form are reduced, the problem that the shaping form is difficult to adapt to an integral supporting system is effectively solved, and the pre-supporting and post-mounting shapingearly-dismantling form system has wider application range.

Owner:吴贤情

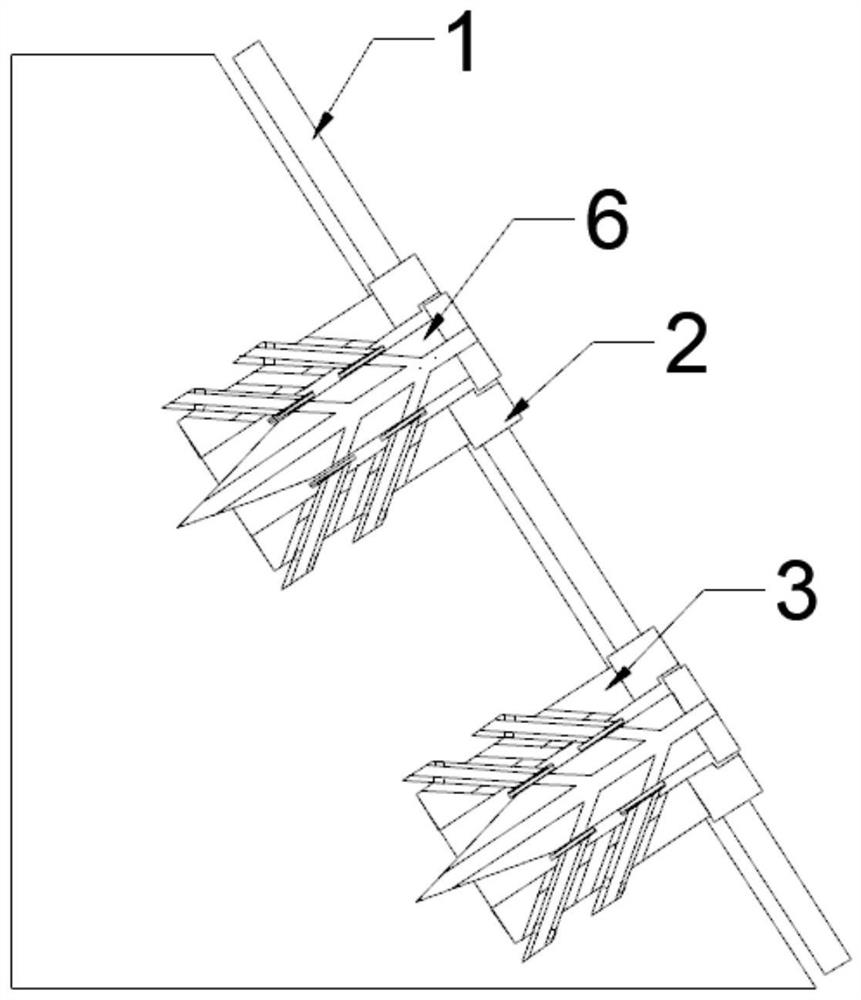

Geotechnical engineering slope reinforcing device and reinforcing method

PendingCN110725326AReliable reinforcementReinforcement and stabilityExcavationsBulkheads/pilesLandslideScrew thread

The invention discloses a geotechnical engineering slope reinforcing device and reinforcing method. The device comprises a plurality of reinforcing columns arranged in a slope, a first connecting headis arranged at the upper end of each reinforcing column, a second connecting head is arranged at the lower end of each reinforcing column, one or more threaded connecting holes are formed in the sidewalls of the second connecting heads, a plurality of reinforcing rods are arranged in the slope, external threads matched with the threaded connecting holes are formed in one ends of the reinforcingrods, and the second connecting head of each reinforcing column is in threaded connection with at least one reinforcing rod; a third connecting head is arranged at one end, located outside the slope,of each reinforcing rod, and each third connecting head is connected with an adjacent first connecting head through a soil fixing inhaul cable; and each soil fixing inhaul cable is further connected with a plurality of transverse soil fixing strips arranged in the direction of the slope. According to the device and method, the landslide force generated locally by the slope is no longer mainly applied to a local position, below the landslide, of the reinforcing device, but the landslide force is dispersed on the whole reinforcing device, and the stress of the structure of the local reinforcingdevice is reduced.

Owner:LUOYANG INST OF SCI & TECH

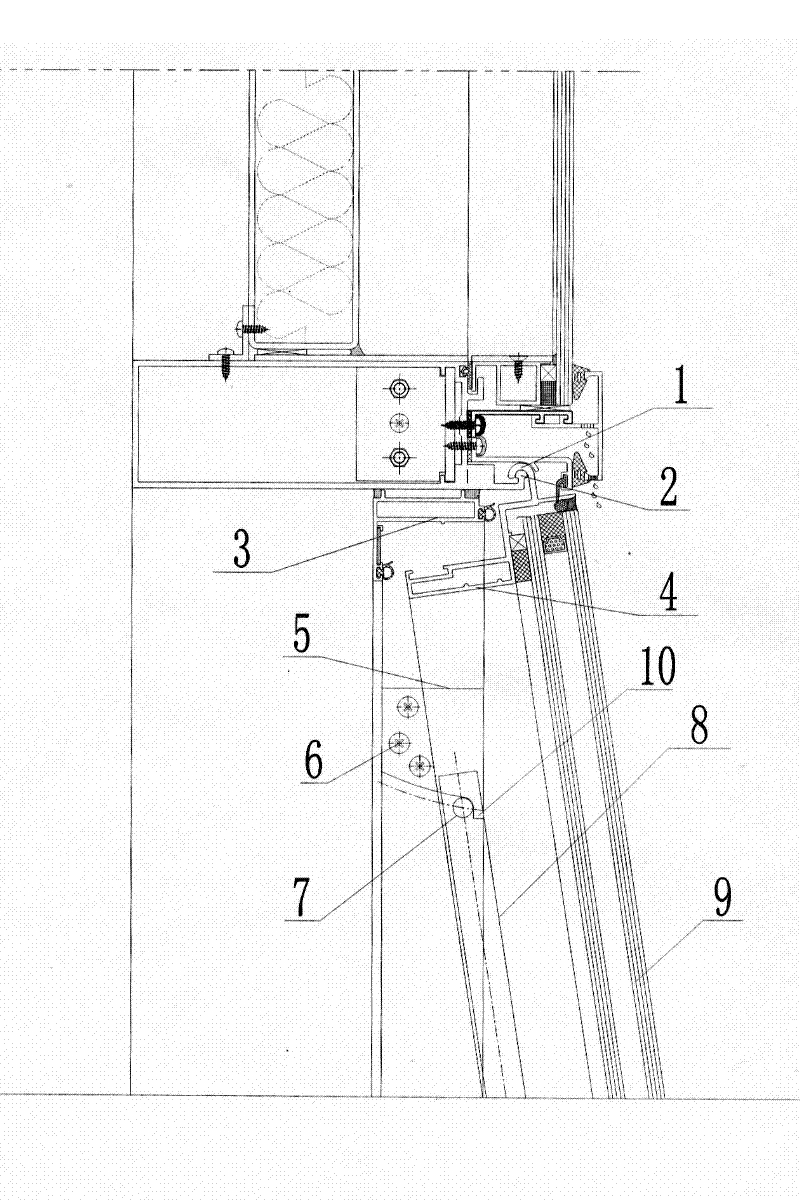

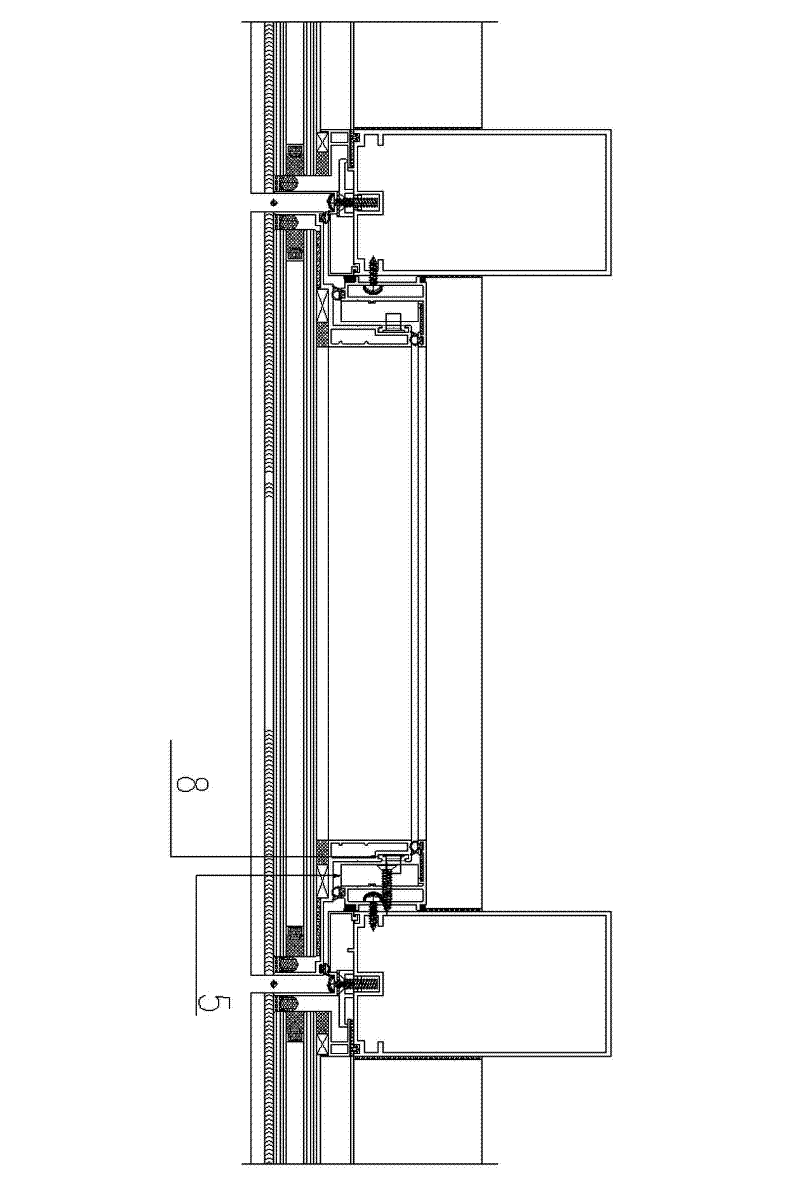

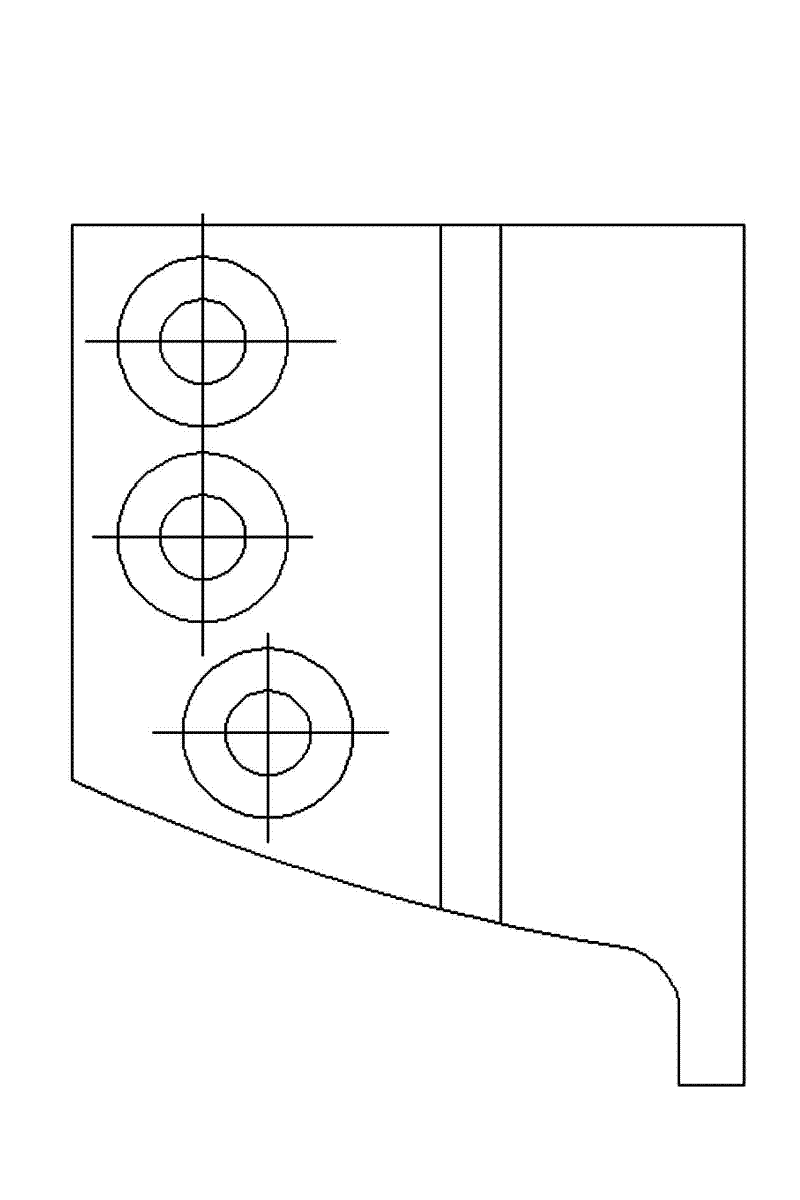

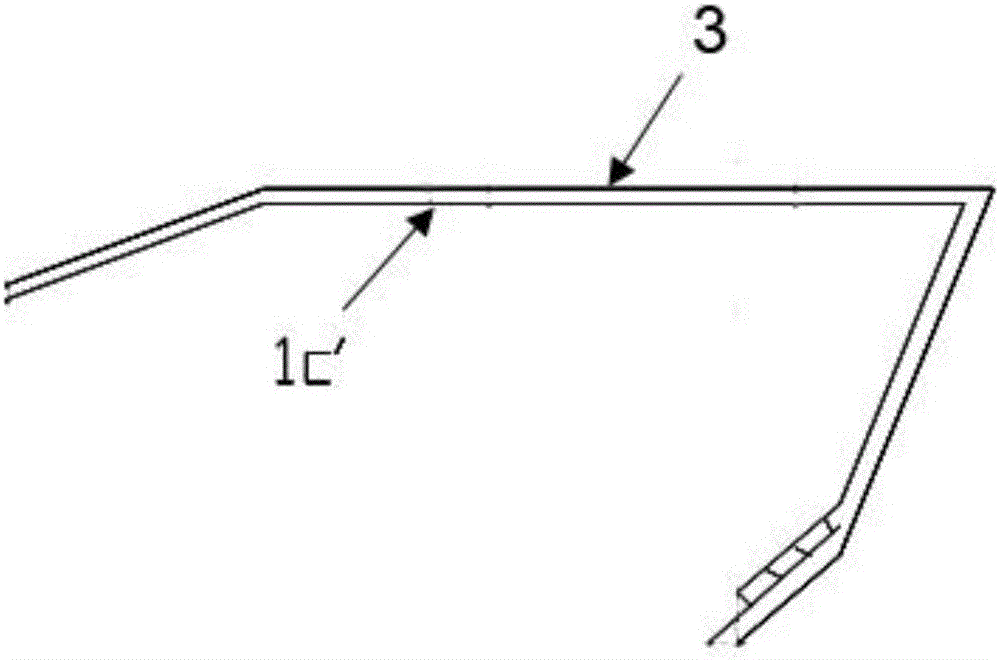

Strengthened pivoted window of curtain wall

InactiveCN102635293APlay the role of double protectionDoes not affect the forceWing fastenersWing arrangementsFixed frameCurtain wall

The invention provides a strengthened pivoted window of a curtain wall, which comprises a fixed frame and a top-hung pivoting sash. The strengthened pivoted window of the curtain wall is characterized by further comprising a strengthening limiting device which comprises a locking point, a sliding rod and a limiting block for limiting running track of the locking point. The limiting block is arranged on a side frame of the fixed frame, the sliding rod is arranged in a C-shaped groove on the lateral side of the sash, and the locking point is arranged on the sliding rod and moves in a limiting track of the limiting block. The strengthened pivoted window of the curtain wall is simple in construction, time-saving and labour-saving, low in cost, long in service life, firm in strengthening and good for popularization and application.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

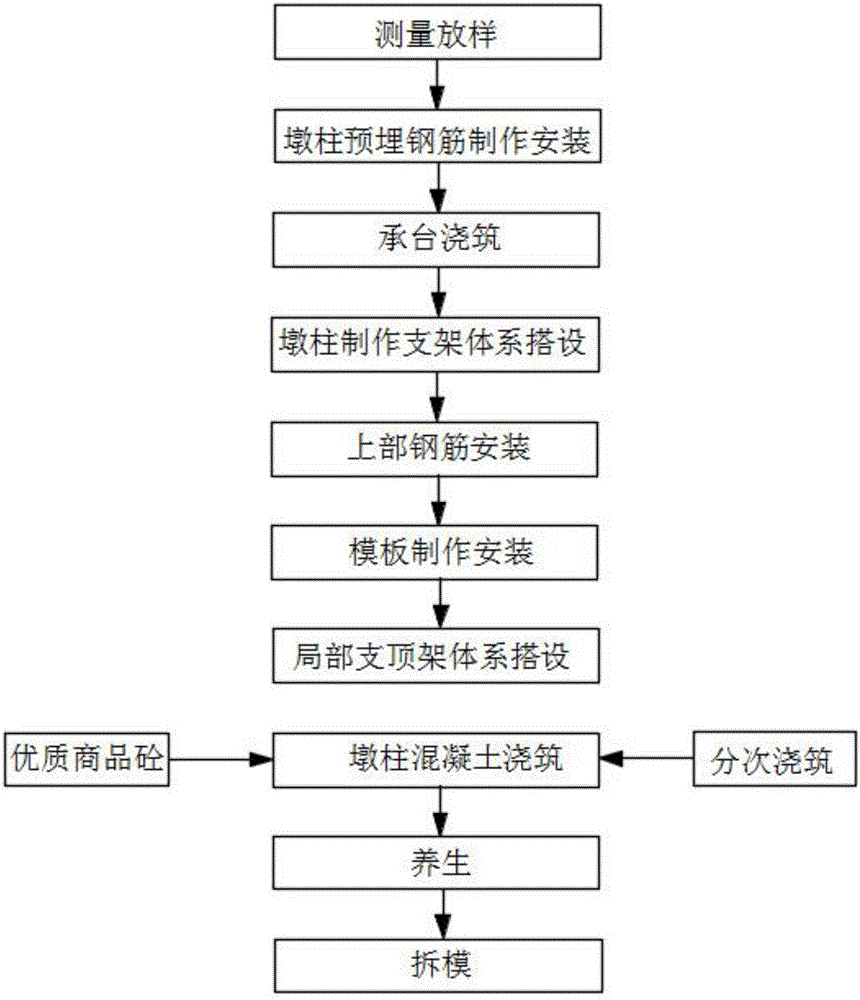

Graded casting construction method for cast-in-place annular cantilever pier stud

ActiveCN106049288AEasy to installEffective bondingBridge structural detailsBridge erection/assemblySupporting systemReinforced concrete

The invention relates to the technical field of construction of special-shaped cast-in-place reinforced concrete structures of urban bridges and expressway bridges, in particular to a graded casting construction method for a cast-in-place annular cantilever pier stud. The method mainly includes the steps of staking out in survey, manufacturing and mounting of pier stud embedded bars, bearing platform casting, erection of a pier stud manufacturing support system, mounting of upper steel bars, manufacturing and mounting of a formwork, erection of a local support system, pier stud concrete pouring, curing and form removal. By means of the method, the overall appearance quality and geometric dimension precision of a finished pier stud are greatly improved, construction safety is guaranteed, and the construction cost is reduced.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

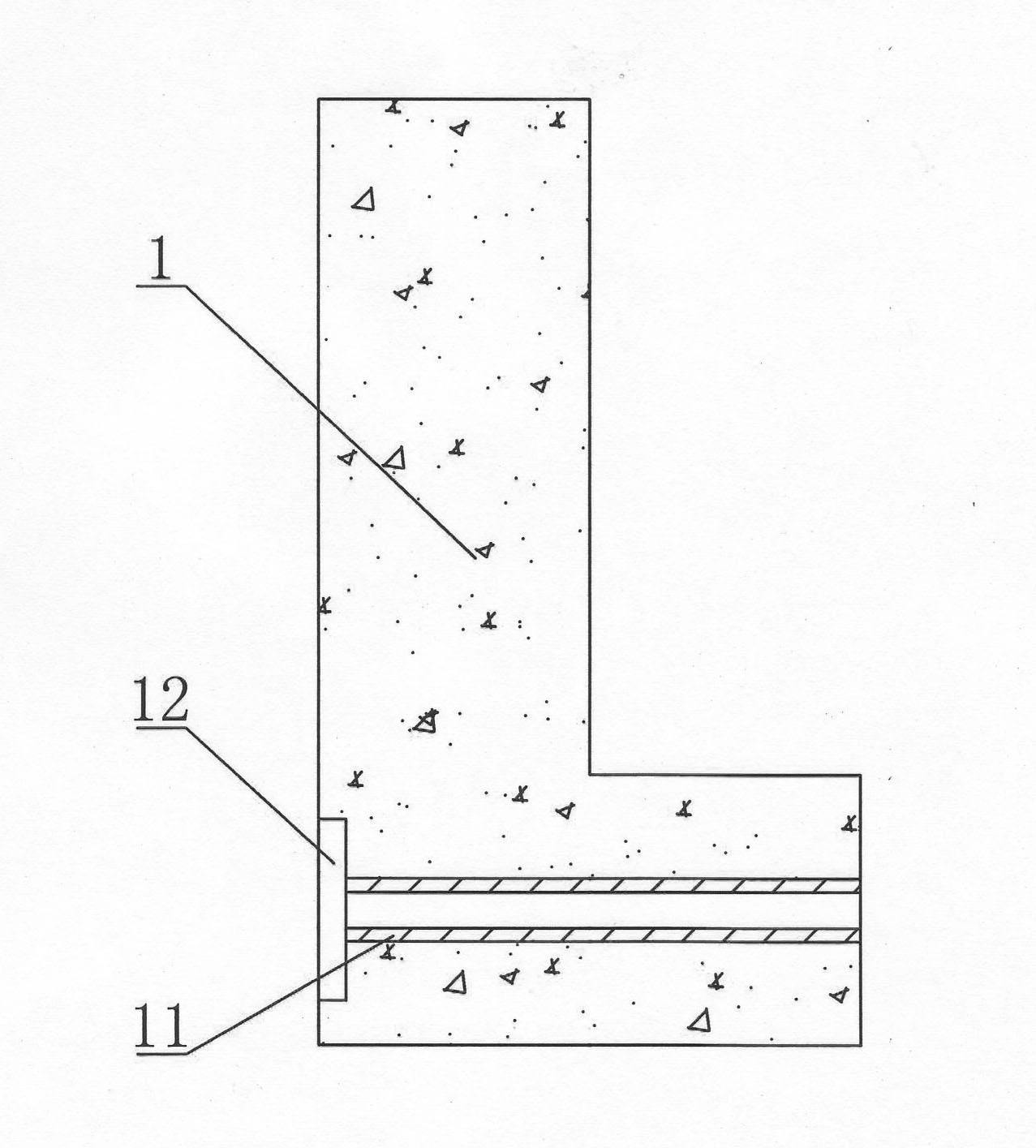

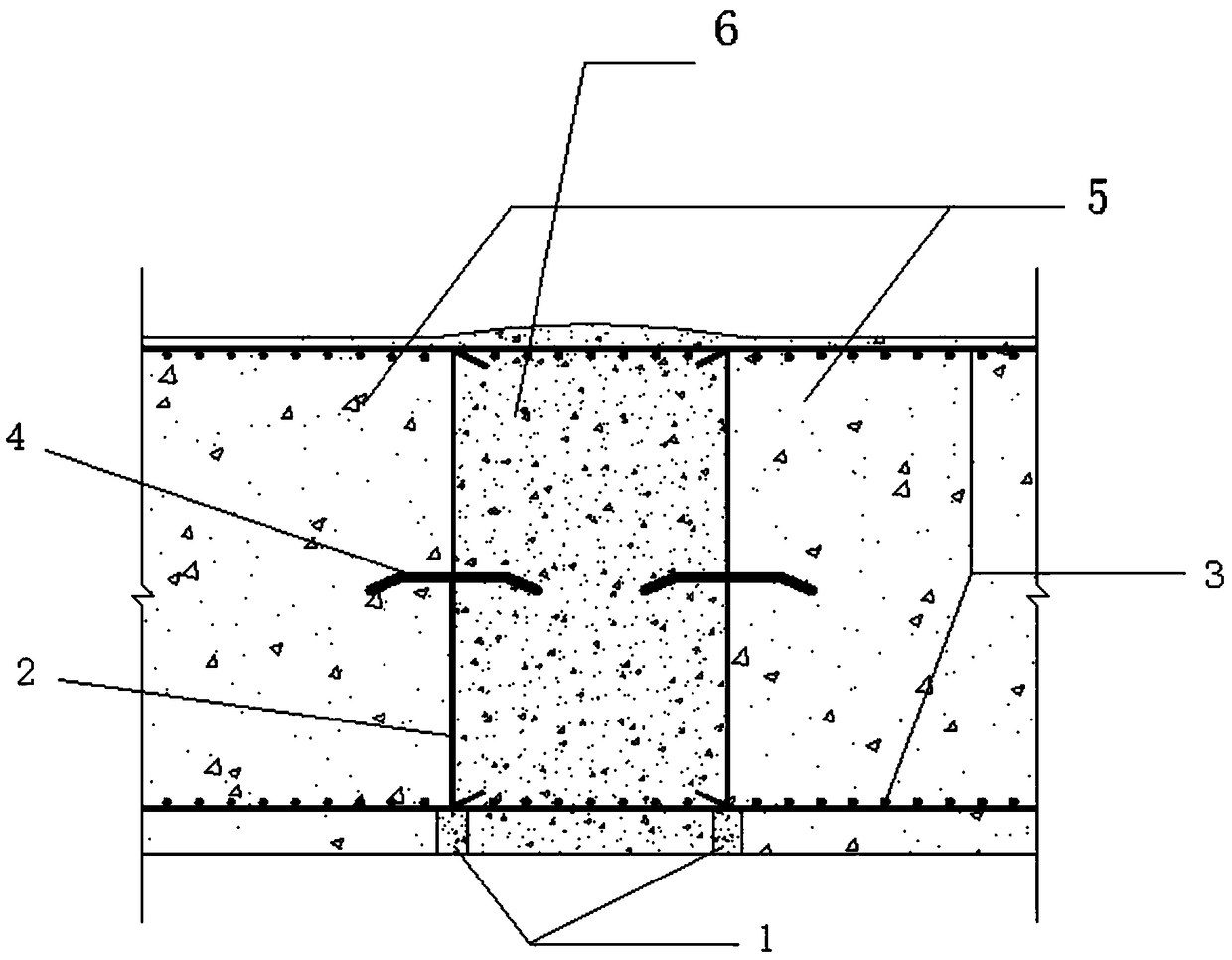

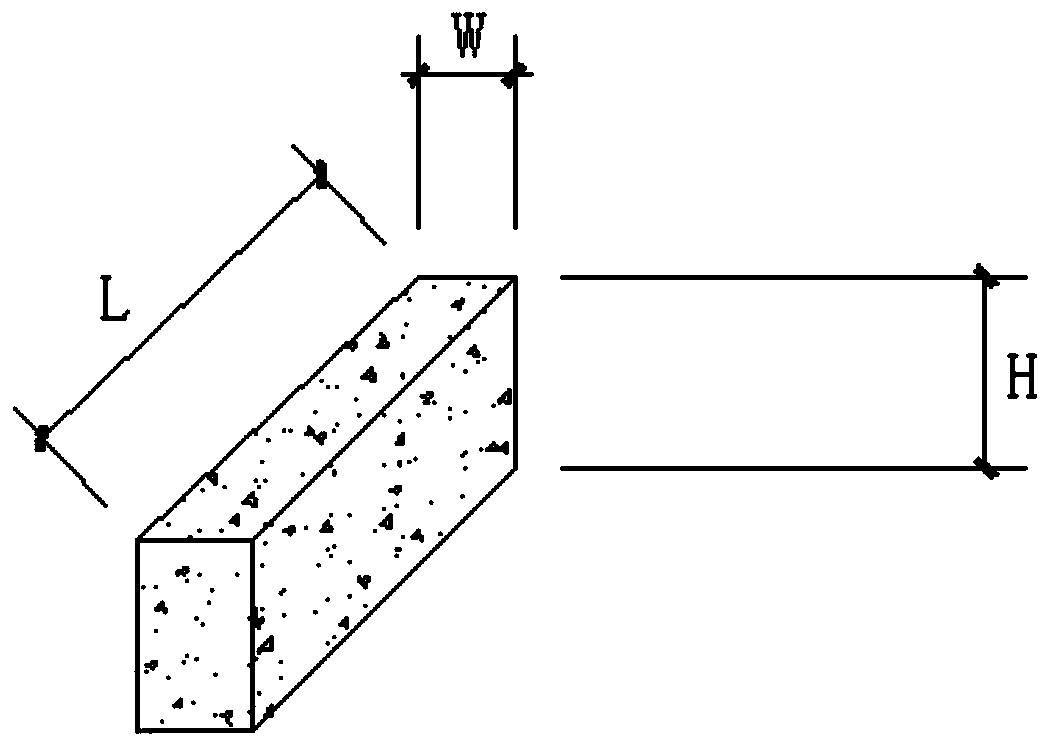

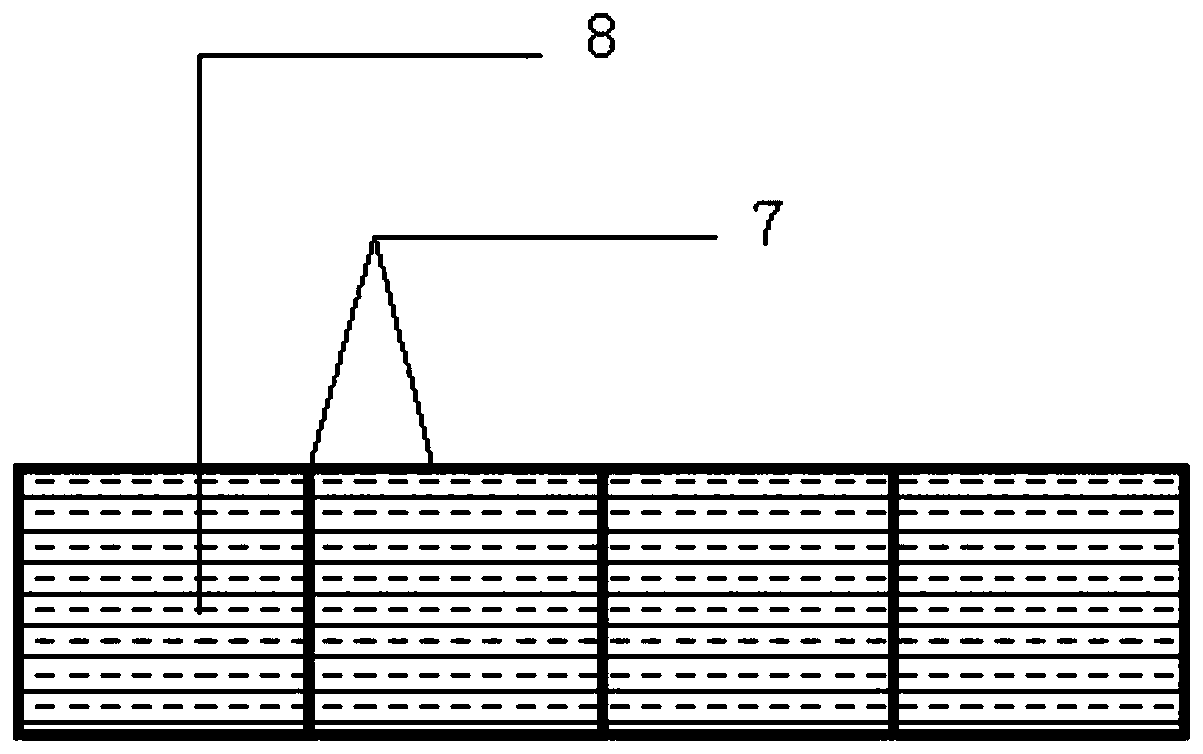

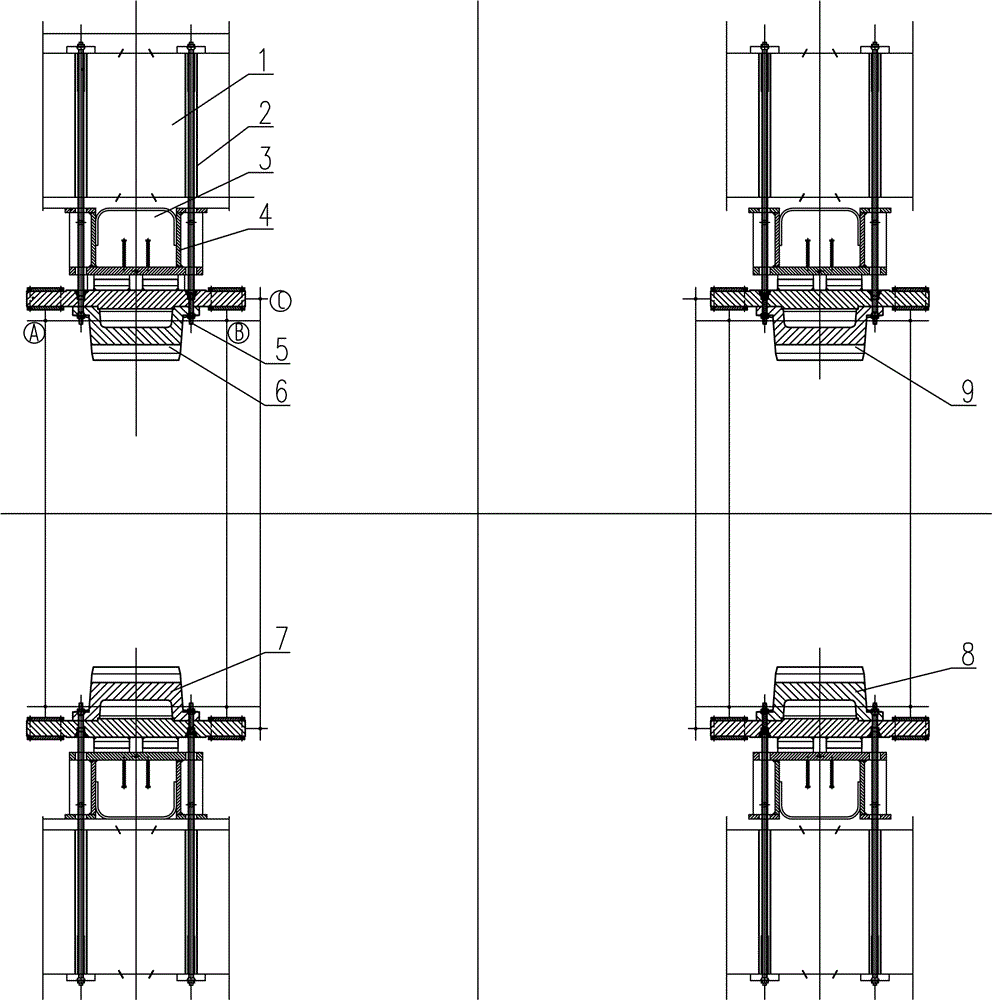

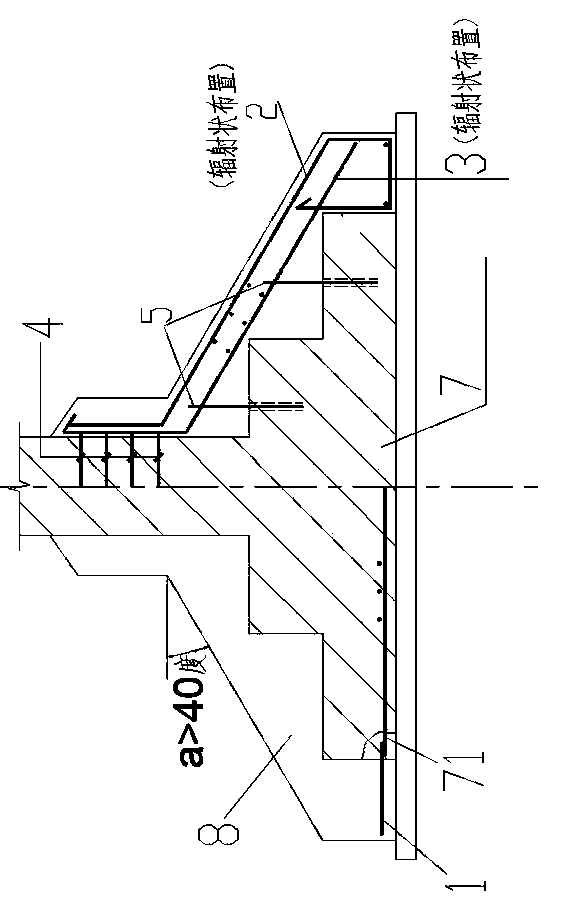

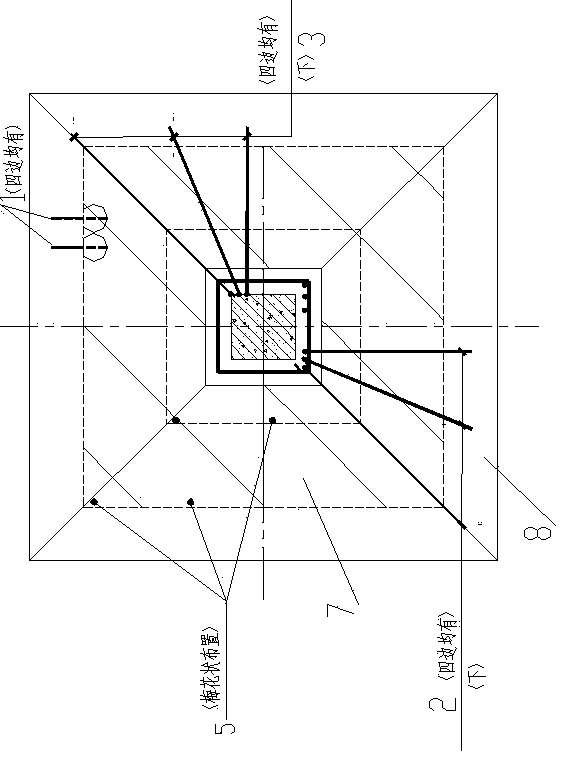

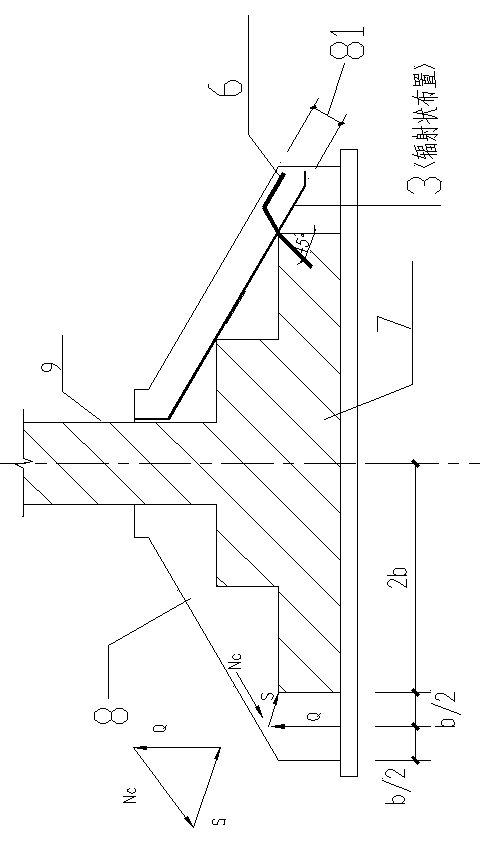

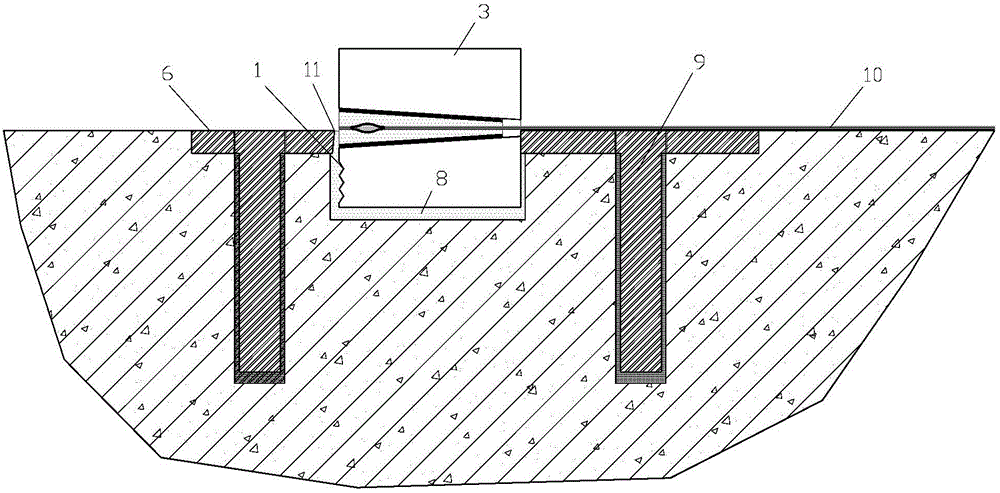

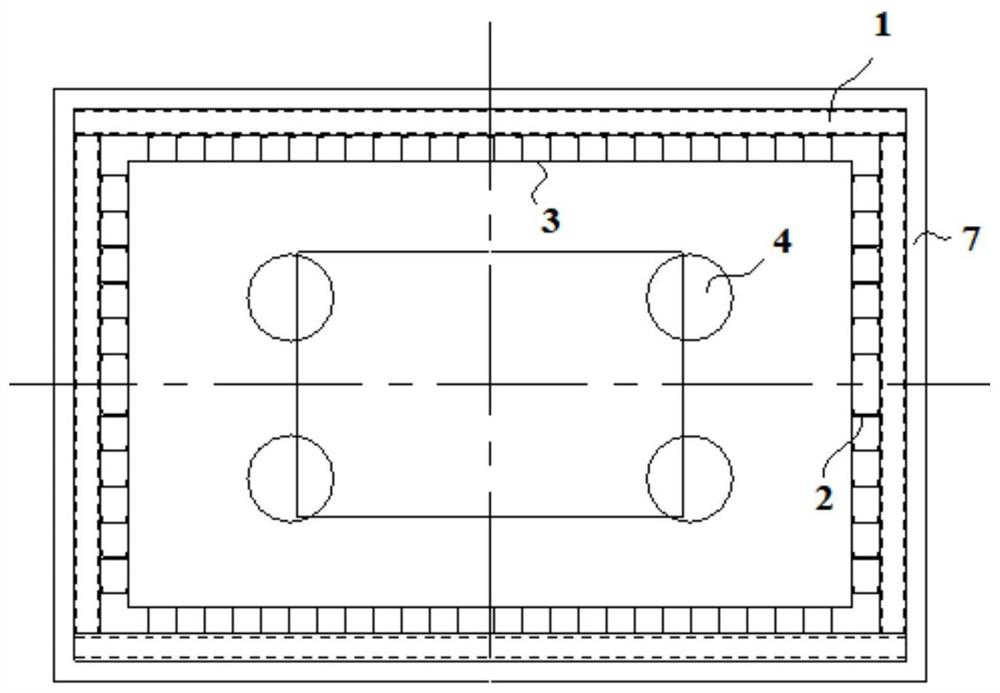

Novel foundation strengthening method and structure

The invention relates to a novel foundation strengthening method and structure, and belongs to the technical field of building strengthening. The foundation strengthening method includes the steps that a surrounding sleeve is formed on the periphery of an original foundation through pouring, outer corners on the periphery of the original foundation are connected with the surrounding sleeve with the embedded steel bar technology, and the original foundation is accordingly strengthened. The foundation strengthening structure comprises the original foundation and the surrounding sleeve, and a plurality of embedded steel bars are distributed at the contact positions of the outer corners of the original foundation and the surrounding sleeve to serve as connecting pieces between the original foundation and the surrounding sleeve; a sixth reinforcing steel bar is additionally arranged to provide balance force S, and the space effect of the surrounding sleeve is sufficiently achieved; meanwhile, the sixth reinforcing steel bar right serves as a supporting point to achieve the anti-bending effect of a third reinforcing steel bar in the surrounding sleeve due to the existence of the sixth reinforcing steel bar. Reliable strengthening between the original foundation and the surrounding sleeve is fundamentally achieved, technical measures are simple and ingenious, the effect is remarkable, the leveraging effect is achieved, electrowelding operation in a traditional strengthening scheme in the field can be eliminated, a first reinforcing steel bar is not used, and therefore the construction working loads are greatly reduced.

Owner:上海纺织建筑设计研究院有限公司

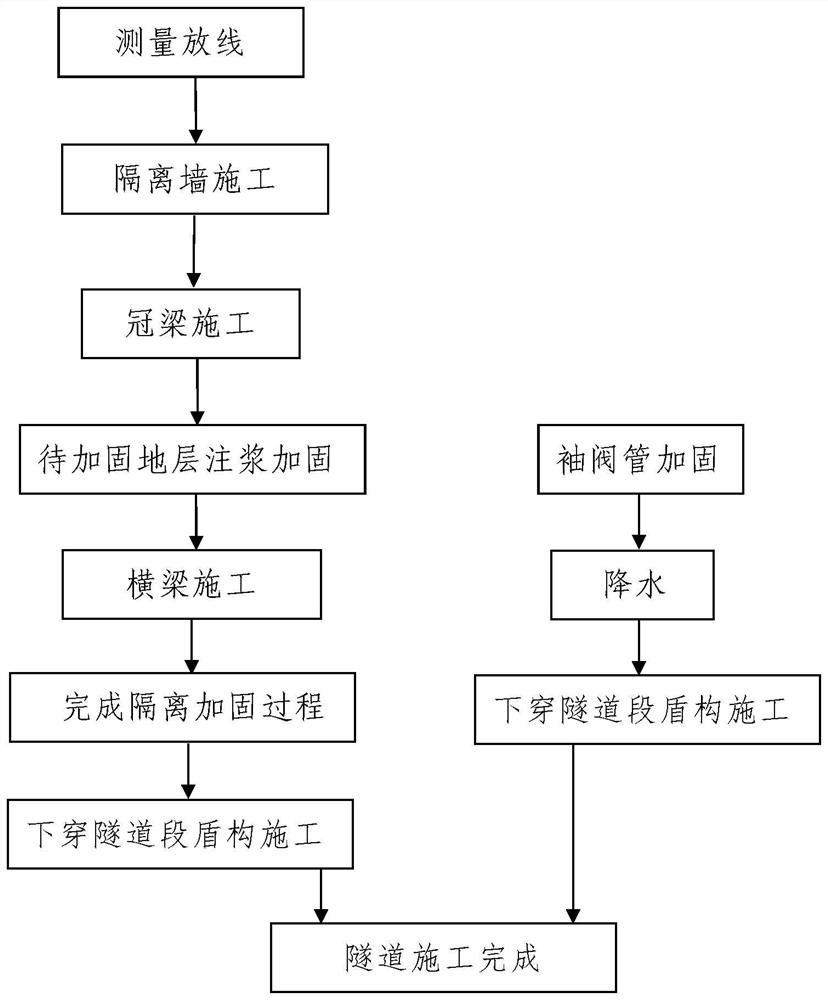

Water-rich sand layer shield tunnel construction method

ActiveCN112502732AThe method steps are simpleEasy constructionUnderground chambersHydro energy generationSlurryShield tunneling

The invention discloses a water-rich sand layer shield tunnel construction method. A constructed tunnel is a double-hole tunnel and is a subsurface tunnel with a hole body located in a water-rich sandlayer, the constructed tunnel comprises an underneath pass tunnel section passing through an existing viaduct and three non-underneath pass tunnel sections, shield construction is performed after theunderneath pass tunnel section is isolated and reinforced, and precipitation is not needed. The shield construction is conducted after precipitation of the non-underneath pass tunnel sections. The method is reasonable in design, easy and convenient to construct and good in using effect, a shield tunnel is divided into the underneath pass tunnel section and the non-underneath pass tunnel sectionsaccording to whether the viaduct is underneath pass or not, and construction is directly conducted after the non-underneath pass tunnel sections are subjected to precipitation. The underneath pass tunnel section is isolated and reinforced to form a slurry consolidated body, so that a shield tunneling machine performs tunneling construction in the slurry consolidated body, and soil disturbance andformation pressure caused by tunneling of the shield tunneling machine during construction are resisted through the slurry consolidated body. Separation walls are arranged on the two sides of the slurry consolidated body respectively, the formation pressure can be completely blocked, and safety and zero settlement of the viaduct on the upper side of the underneath pass tunnel section are guaranteed.

Owner:CHINA RAILWAY 20 BUREAU GRP

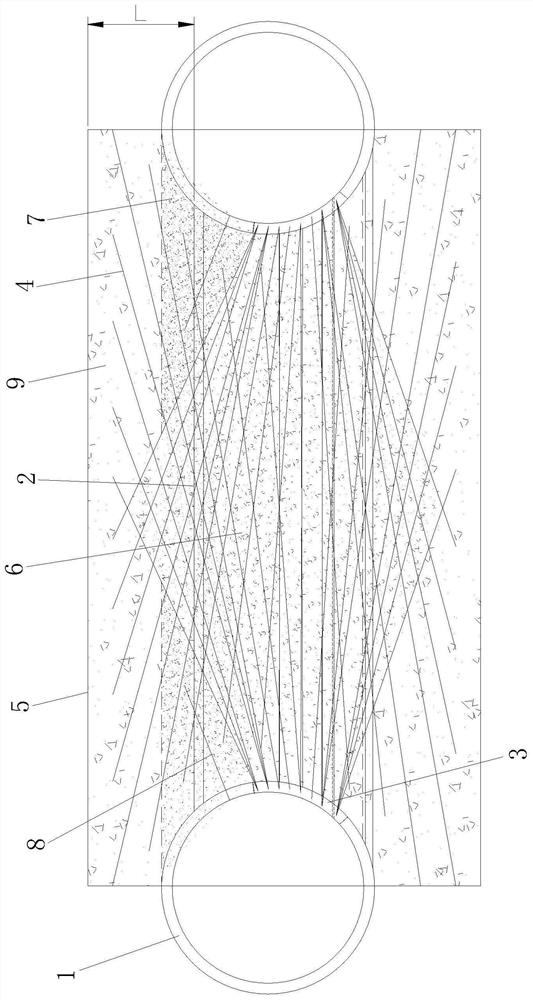

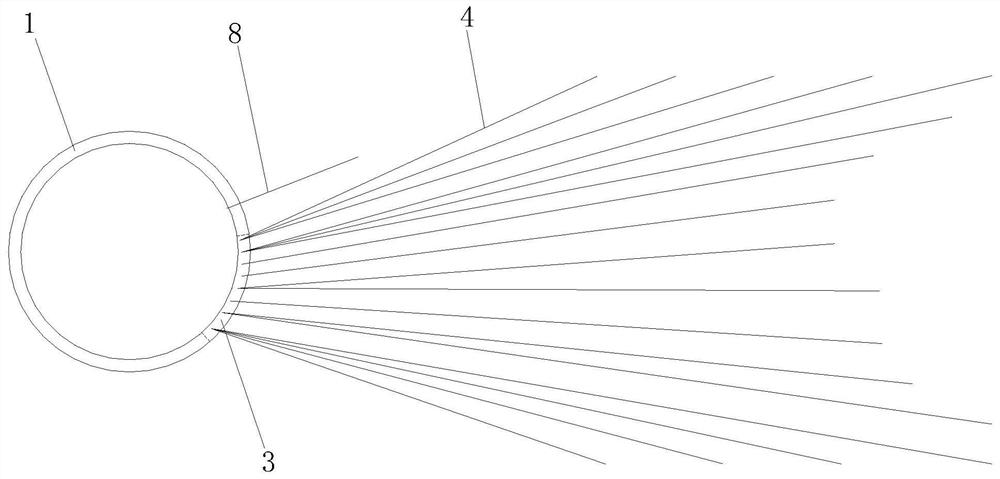

Water-rich sand layer shield interval contact channel stratum pre-reinforcement structure and method

ActiveCN112502731ASimple structureReasonable designUnderground chambersHydro energy generationStructural engineeringShield tunneling

The invention discloses a water-rich sand layer shield interval contact channel stratum pre-reinforcement structure and method. The pre-reinforcing structure comprises a channel stratum overall reinforcing structure for reinforcing the stratum of the area where a constructed connection channel is located and two channel end portion stratum reinforcing structures for reinforcing the stratum of thefront end and the stratum of the rear end of the constructed connection channel. The method comprises the following steps of 1, arranging advanced small conduits; 2, grouting and reinforcing the stratum at the end parts of the channel; and 3, integrally grouting and reinforcing the channel stratum. The pre-reinforcing structure is reasonable in design, easy and convenient to construct and good inreinforcing effect, the advanced to-be-reinforced area of the water-rich sand layer contact channel stratum is divided, the grouting reinforcing structure of the corresponding type is adopted for effective reinforcing, the reinforced stratum and a shield segment of the constructed shield tunnel are fixedly connected into a whole, and the structural stability of the shield tunnel can be effectivelyimproved while the stratum reinforcing effect of the constructed connection channel is further improved.

Owner:中铁二十局集团第五工程有限公司

Fixture for injecting glue into and preheating ceramic core

InactiveCN107807423ASimple structureEasy to operateCoupling light guidesEngineeringMechanical engineering

The present invention provides a fixture for ceramic ferrule injection and preheating. The fixture includes a base, two rotating shafts and two pressing plates, wherein the rotating shafts are installed at both ends of the base, and the pressing plates are connected to the pressing plates. The rotating shaft is connected, and the opening and closing between the pressing plate and the base is realized through the rotation of the rotating shaft. The fixture described in the present invention is simple in structure, easy to operate, more reliable for the reinforcement of the ceramic ferrule, does not affect each other between the two processes of glue injection and preheating, realizes two functions through the fixture, and improves Improve work efficiency, but also increase the diversity and universality of fixtures.

Owner:戎旭阳

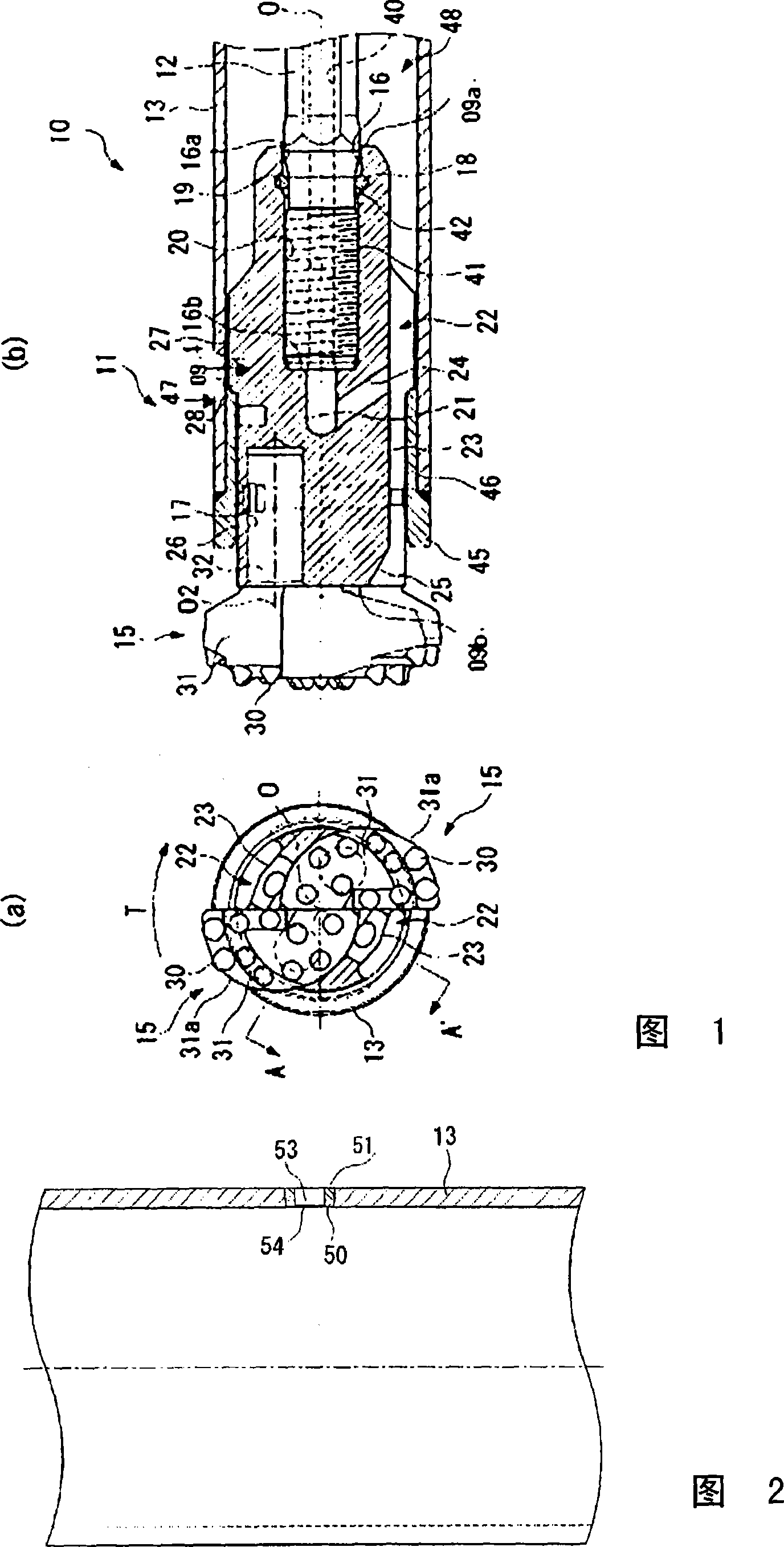

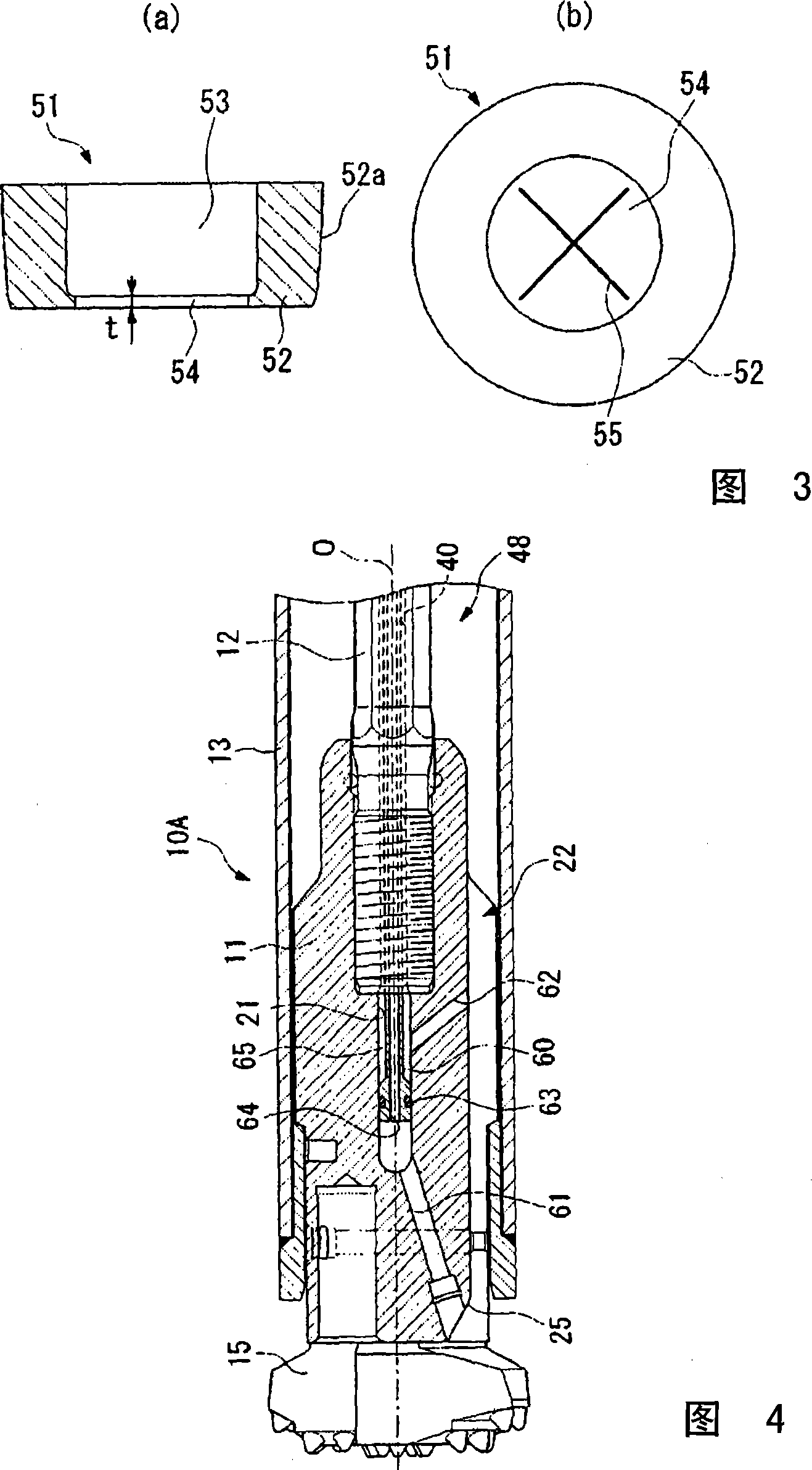

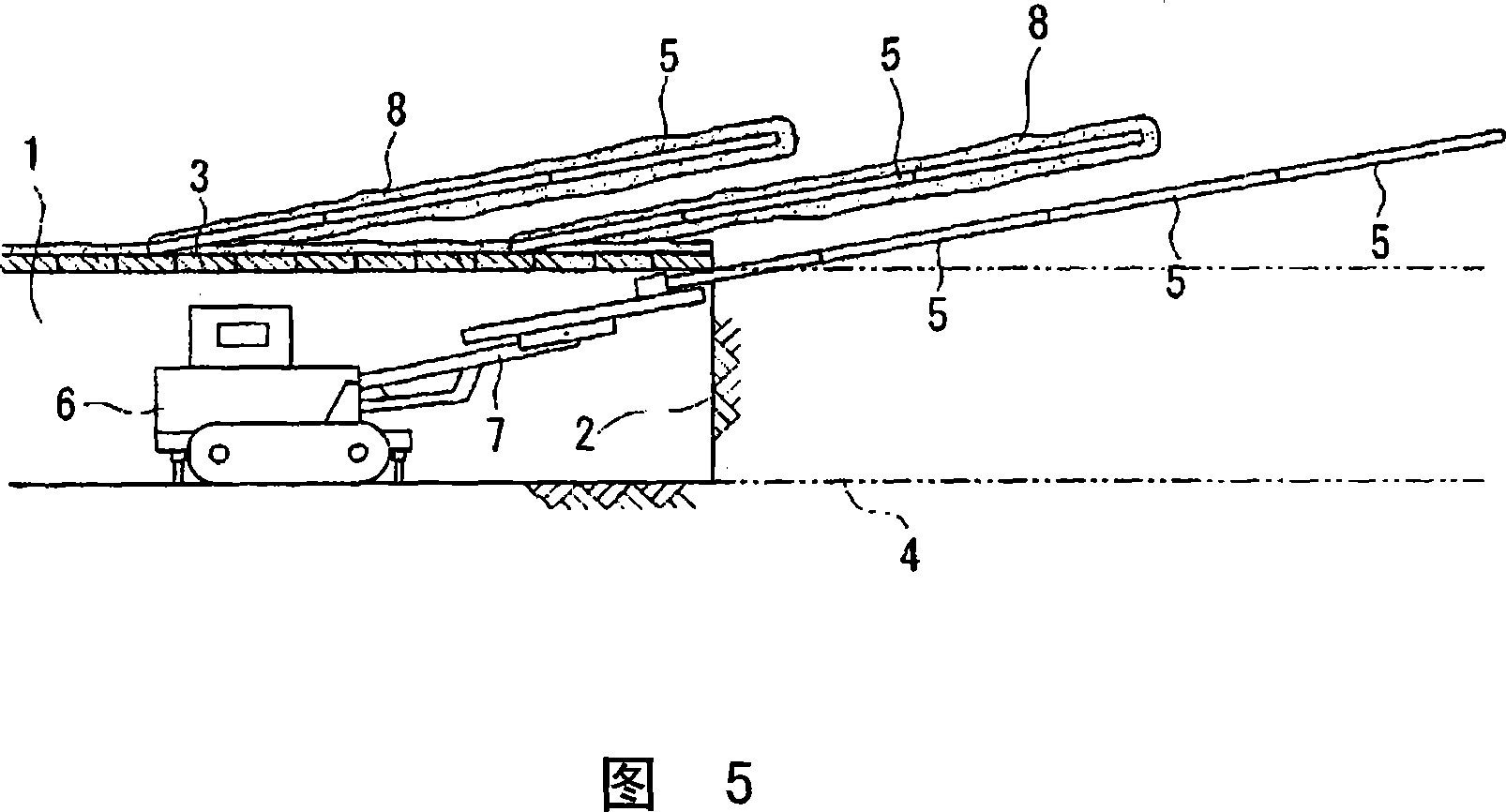

Excavating tool and steel pipe forepoling method

An excavating tool capable preventing the natural ground from being loosened by excavated water and smoothly discharging excavated chips and a steel pipe forepoling method capable of securely providing earth reinforcing effects by using the excavating tool. The excavating tool (10) comprises a boring rod (12) rotatingly drivable around an axis (0), a tool body (11) fitted to the front of the boring rod (12) in the forward excavating direction, and a cylindrical steel pipe (13) having a specified clearance relative to the boring rod (12) with the boring rod (12) inserted therein. The excavating tool is characterized in that a flow passage (21) for supplying drilling water to the axial forward direction is formed in the tool body (11), and a fluid supply port (24) communicating with the flow passage (21) and jetting the drilling water is formed only at a position on the tool body opening to the inside of the steel pipe (13) toward the rear of the tool body (11) in the forward excavating direction.

Owner:MITSUBISHI MATERIALS CORP

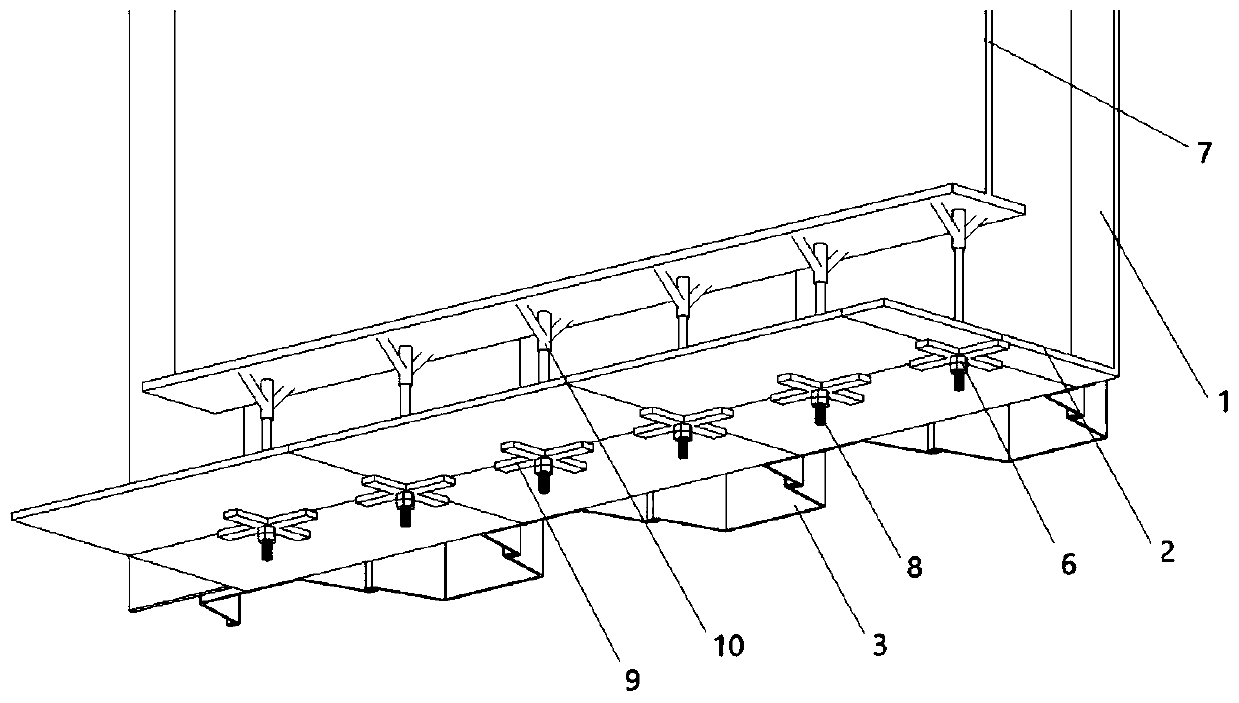

Ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcing device and constructing method

ActiveCN110714613AGuaranteed accuracyEasy to assemble and disassembleForms/shuttering/falseworksReinforced concreteButt joint

An ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcing device is composed of a plurality of reinforcing units. Each reinforcing unit comprises beam side formworks,beam bottom formworks, Larson steel plate side back edges, a round steel tying rod and a steel reinforced beam, wherein each beam side formwork and the corresponding beam bottom formwork are welded toform an integrated L-shaped structure, the two L-shaped structure are in butt joint to form a U-shaped structure, the outer portions of the beam side formworks are fixed to the Larson steel plate side back edges through high-strength bolts, the tops of the Larson steel plate side back edges on the two sides of the U-shaped structure are connected through the round steel tying rod, the steel reinforced beam is placed in the U-shaped structure, a reserved hole is formed in the joint of the two beam bottom formworks at the bottom of the U-shaped structure, a Y-shaped mechanical sleeve is weldedto the bottom of the steel reinforced beam, a cross-shaped fastener is arranged on the lower side of the reserved hole of the beam bottom formworks, and the mechanical sleeve is connected with the cross-shaped fastener through reverse hoisting bolts. The invention further discloses a constructing method of the ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcingdevice.

Owner:CHINA FIRST METALLURGICAL GROUP

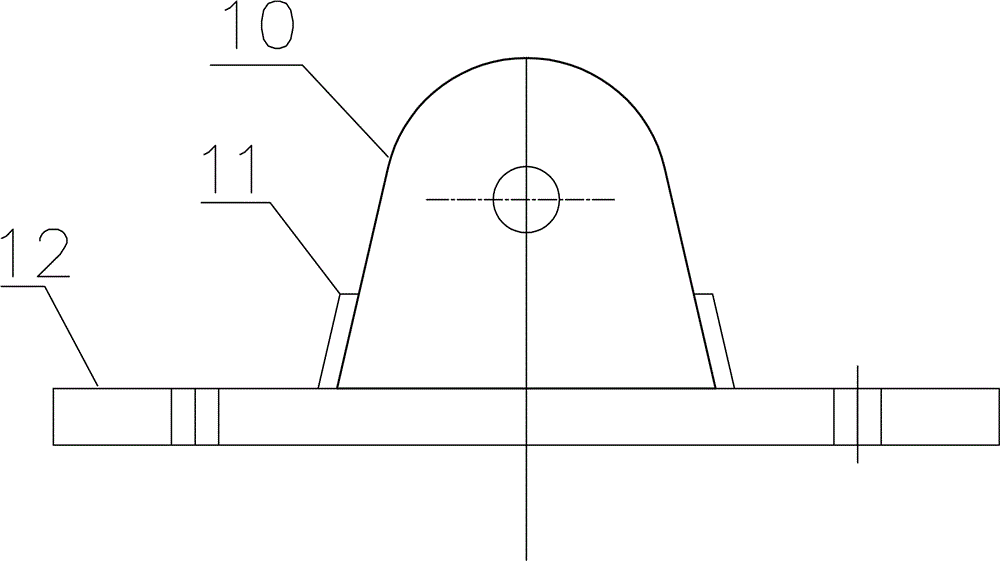

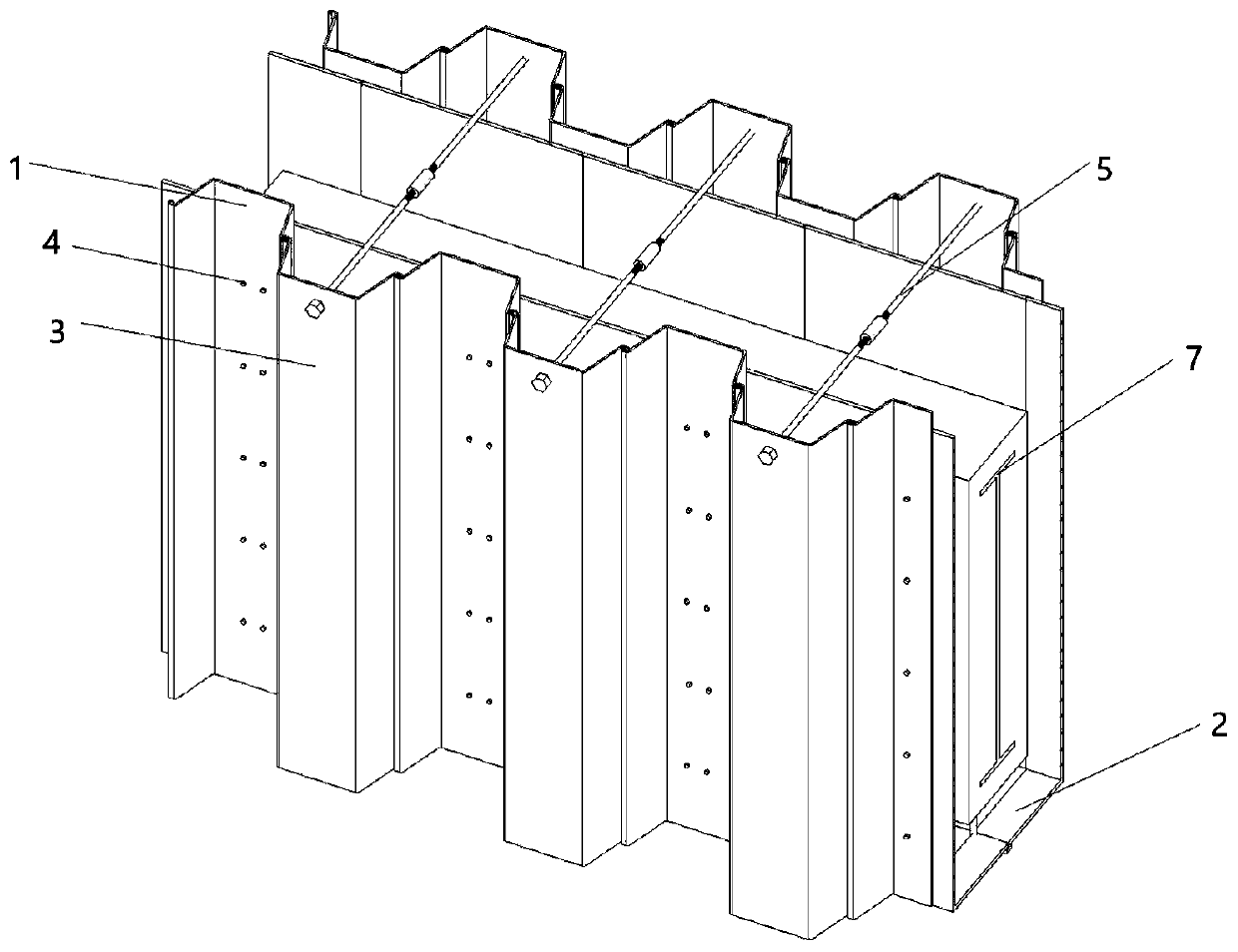

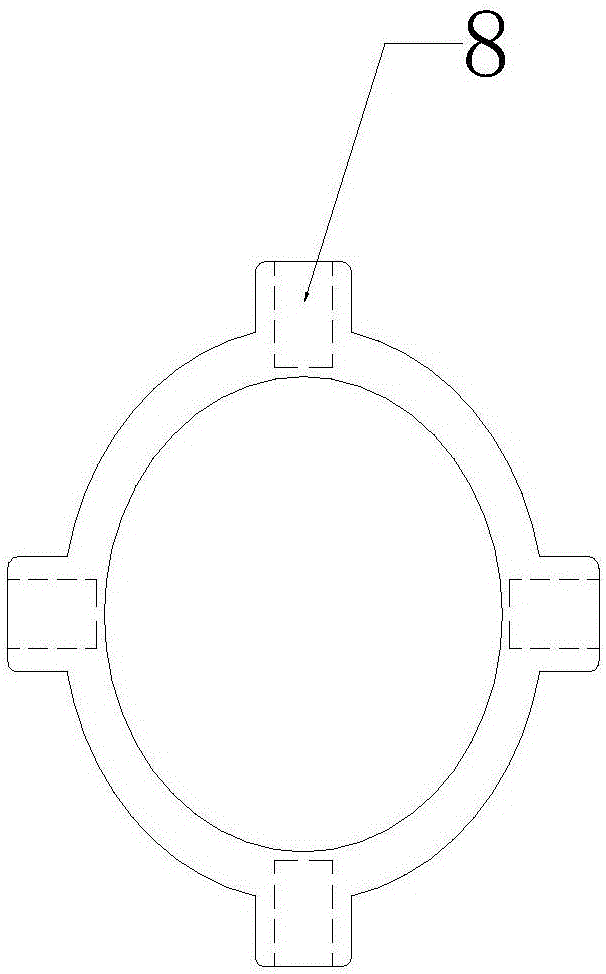

Template reinforcing tool and method for reinforcing wall pier template by using template reinforcing tool

ActiveCN106121227AReliable reinforcementEliminate easy running moldAuxillary members of forms/shuttering/falseworksBuilding material handlingSpecial designEngineering

The invention discloses a template reinforcing tool and a method for reinforcing a wall pier template by using the template reinforcing tool, and belongs to the technical field of building construction. The technical scheme is that the temperature reinforcing tool comprises jackings and an O-shaped clamp, wherein each jacking comprises a screw rod A with external threads and a special nut which is in threaded connection with the screw rod A; a plurality of rocker holes for inserting rockers are formed in the outer side walls of the special nuts; a U-shaped supporting plate is fixedly arranged at one end of each screw rod A; the O-shaped clamp comprises an O-shaped sleeve; the outer side wall of the O-shaped sleeve is fixedly connected with a rectangularly flat clamping arm; the O-shaped sleeve is arranged in a manner of being parallel to the width direction of the clamping arm, and the clamping arm 9 is provided with extending ends towards two radial sides of the O-shaped sleeve 10; a screw hole is formed in one extending end of the clamping arm; and the length of the other extending end of the clamping arm is greater than the diameter of the O-shaped sleeve. According to the template reinforcing tool with special design, by the combination of a general reinforcing technology, a conventional external corner supporting method is changed into a tying mode, so that an external corner template can be reinforced firmly.

Owner:SHANDONG SANJIAN CONSTR ENG MANAGEMENT +1

Anchor assembly, an anchoring structure and construction process thereof

The invention discloses an anchor assembly. The anchor assembly comprises an anchor sleeve used for fixing a reinforced part, and a colloid injection cavity is formed in the anchor sleeve and used for injecting anchoring colloid for anchoring an anchored part; when the anchored part is anchored, one end of the anchored part stretches into the colloid injection cavity, the gap between the inner wall of the colloid injection cavity and the surface of the anchored part is filled with the anchoring colloid, the anchoring colloid is cured through heating, and the anchor sleeve is fixed to the reinforced part to anchor the anchored part. By means of the anchor assembly, the anchored part can be anchored reliably in time on a structural part to reinforce the structural part.

Owner:全学友

Geotechnical engineering slope reinforcing device and method

InactiveCN112663634AImprove stabilityReduce local structural stressExcavationsBulkheads/pilesLandslideStructural engineering

The invention discloses a geotechnical engineering slope reinforcing device. The reinforcing device comprises a reinforcing mounting layer and a nailing mechanism, wherein the reinforcing mounting layer comprises a protective net and a mounting base; the protective net is formed by connecting a plurality of fixing strips, and an assembling hole is formed in the joint of the fixing strips; the mounting base comprises a fixing seat and a mounting pipe; the fixing seat is fixedly connected to the assembling hole; the mounting pipe is connected to one side of the fixing seat; the diameter of the mounting pipe is consistent with that of the mounting hole; the nailing mechanism comprises a reinforcing nail and side nails; a feeding pipe is arranged in the reinforcing nail; inclined holes are formed in the side wall of the mounting pipe; the inclined holes are symmetrically formed in two sides of the mounting pipe; the side nails are fixedly mounted in the inclined holes; and a stop block is fixedly mounted at the end, which is close to the inside of the mounting pipe, of each side nail. By the geotechnical engineering slope reinforcing device, the integrity of the inside of a slope is improved, meanwhile, when landslide occurs, generated landslide force is dispersed through the device, and the stability and firmness of the whole slope are enhanced.

Owner:HENAN UNIV OF URBAN CONSTR

Construction method for shallow foundation reinforcement

ActiveCN112627249AImprove reinforcement effectEasy constructionFoundation repairArchitectural engineeringEnvironmental geology

The invention discloses a construction method for shallow foundation reinforcement, and belongs to the technical field of building construction. The construction method specifically includes the following steps that (1) construction preparation is conducted, and construction related parameters are determined; (2) earth around a shallow foundation is excavated to a designed elevation; (3) layered construction of section steel hoops is conducted; (4) deep foundation earthwork layered excavation is constructed; (5) concrete support layered is conducted; and (6) deep foundation structure construction is conducted and deep and shallow foundation earthwork backfill construction is conducted. By the adoption of the technical scheme, the problems that when construction is conducted according to the sequence from shallow to deep in the prior art, the operation of reinforcing and supporting a built shallow foundation building is complex, the construction period is delayed, and the cost is wasted can be effectively solved. Meanwhile, the construction method for shallow foundation reinforcement is simple, high in safety and relatively low in construction cost.

Owner:马鞍山钢铁建设集团有限公司

Formwork reinforcing tool and method for reinforcing external corner formwork through the same

ActiveCN106013789AReliable reinforcementIt is not easy to run out of molds, etc.Auxillary members of forms/shuttering/falseworksBuilding material handlingSpecial designEngineering

The invention discloses a formwork reinforcing tool and a method for reinforcing an external corner formwork through the same, and belongs to the technical field of building construction. According to the technical scheme, the formwork reinforcing tool comprises a jack and a special buckling piece. The jack comprises a lead screw A with an external thread and a special nut which is in threaded connection with the lead screw A, a plurality of rocker holes into which rockers can be inserted are formed in the outer side wall of the special nut, and a U-shaped supporting plate is fixed to one end of the lead screw A; the special buckling piece comprises a first semicircular buckling piece body and a second semicircular buckling piece body, wherein one end of the first semicircular buckling piece body is rotationally connected with one end of the second semicircular buckling piece body through a rotating shaft, the other end of the first buckle piece body is connected with the other end of the second buckling piece body through a bolt, a buckling piece arm is fixedly connected outside the first buckling piece body and arranged in the radial direction of the first buckling piece body, and a screw hole is formed in the buckling piece arm. According to the formwork reinforcing tool and the method, the special-design formwork reinforcing tool is adopted in cooperation with the universal reinforcing technology, the traditional external-corner-formwork supporting method is changed into a pulling-tying mode, pulling-tying prestress is generated accordingly, and the external corner formwork is firmly reinforced.

Owner:SHANDONG SANJIAN CONSTR ENG MANAGEMENT +1

Capsule and system for beverage preparation

ActiveUS10752431B2Avoid deformationReliable reinforcementBeverage vesselsPackagingEngineeringStructural engineering

A capsule for the preparation of a beverage comprises a lateral wall, an inlet wall and a lower wall forming a hollow body having a substantially central axis, the inlet wall extends from a peripheral end of the lateral wall towards said central axis and a plurality of sunken portions are extending on both lateral and inlet walls across the edge between said walls each portion connecting together the lateral wall and the inlet wall.

Owner:TUTTOESPRESSO SRL

Light guide plate for onboard liquid crystal display and light guide plate assembly thereof

ActiveCN102879856AAchieve fixationReliable reinforcementOptical light guidesLiquid-crystal displayLight guide

The invention discloses a light guide plate for an onboard liquid crystal display and a light guide plate assembly thereof. The light guide plate assembly comprises the light guide plate for the onboard liquid crystal display and a metal structure piece which is used for fixing the light guide plate, wherein two opposite surfaces on each lug of the light guide plate are inclined surfaces; each inclined surface faces the light guide plate and is positioned on four rays by taking the light guide plate as the center; the metal structure piece is provided with two accommodating grooves of which are identical to two lugs in shape; the light guide plate is clamped in the metal structure piece; each lug is accommodated in a corresponding accommodating groove; and gaps exist between between the light guide plate and the metal structure piece except that each inclined surface is in tight contact with a groove. The light guide plate has the advantages that 1, the light guide plate can be reliably reinforced in a high / low-temperature circulation environment; 2, the internal stress of the light guide plate can be avoided and the reinforcing reliability is improved; and 3, the structure is simple, and no auxiliary part is in need.

Owner:中航华东光电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com