Graded casting construction method for cast-in-place annular cantilever pier stud

A construction method and technology for piers and columns, which are used in construction, bridge parts, and erection/assembly of bridges, etc., can solve problems such as insufficient formwork installation, insufficient concrete pouring and vibrating, and defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

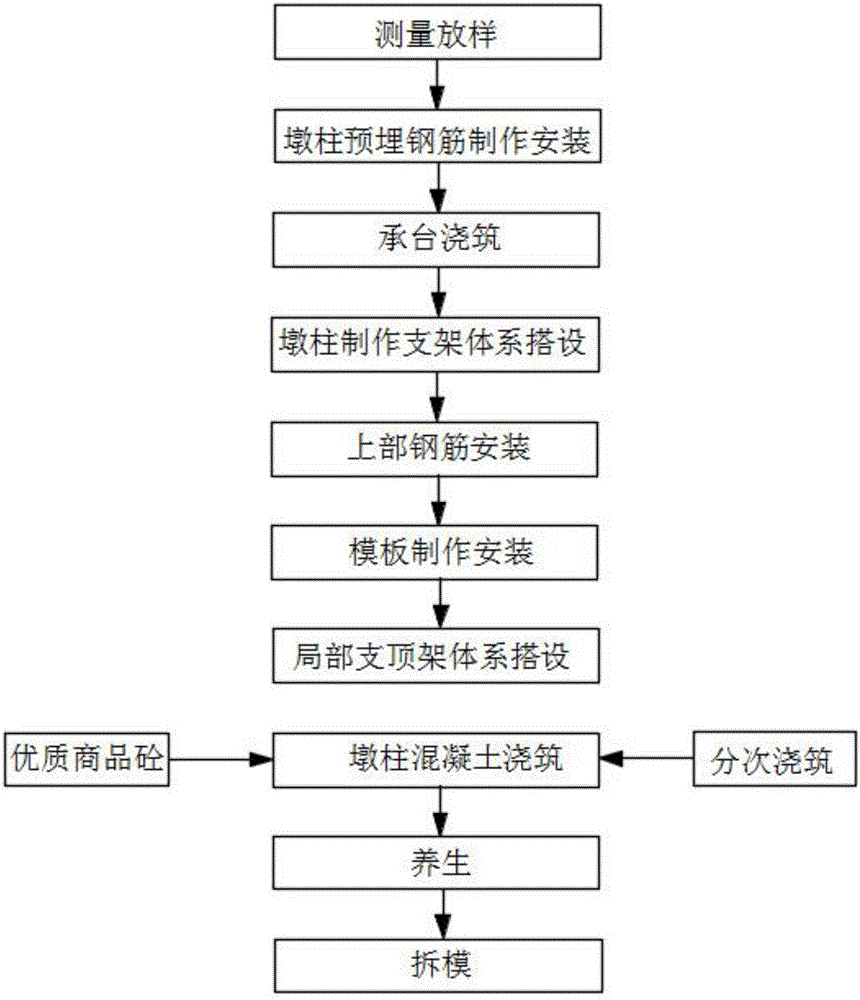

[0030] Such as figure 1 , the cast-in-place annular cantilevered pier construction method in stages according to the present invention comprises the following steps:

[0031] (1) Measurement stakeout

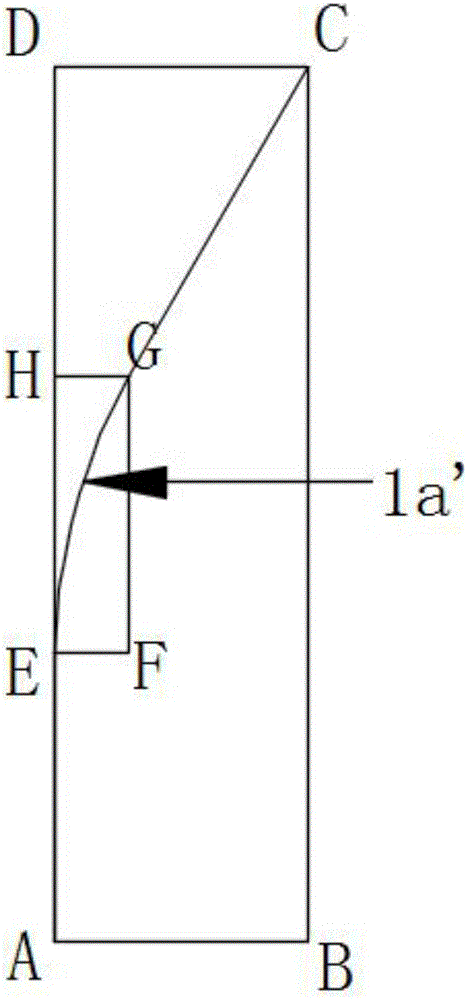

[0032] After the steel bars on the roof cap are installed and before the concrete construction, the measuring team will measure and set out the outer contour of the pier column. Referring to the design dimensions of the cap platform: length 1750cm, width 750cm, and height 200cm, use measuring instruments to release the vertical and horizontal axes of the pier column, so as to determine The outer edge of the bottom of the pier column, the pre-embedded position of the pier column reinforcement and the assembly position of the formwork are ready for the later reinforcement installation and formwork installation.

[0033] (2) Manufacture and installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com