Ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcing device and constructing method

A formwork reinforcement and concrete technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc. Simple assembly and disassembly, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

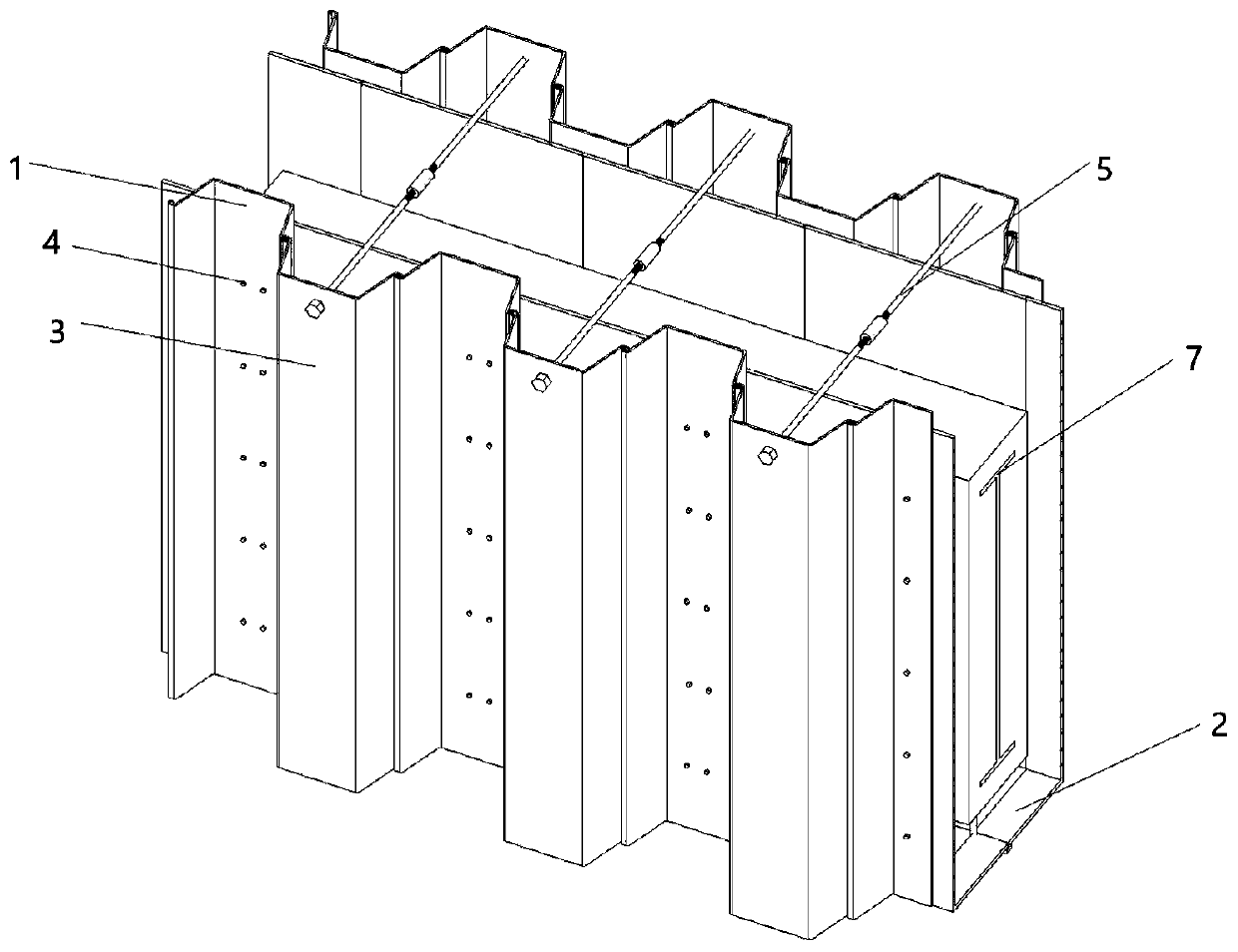

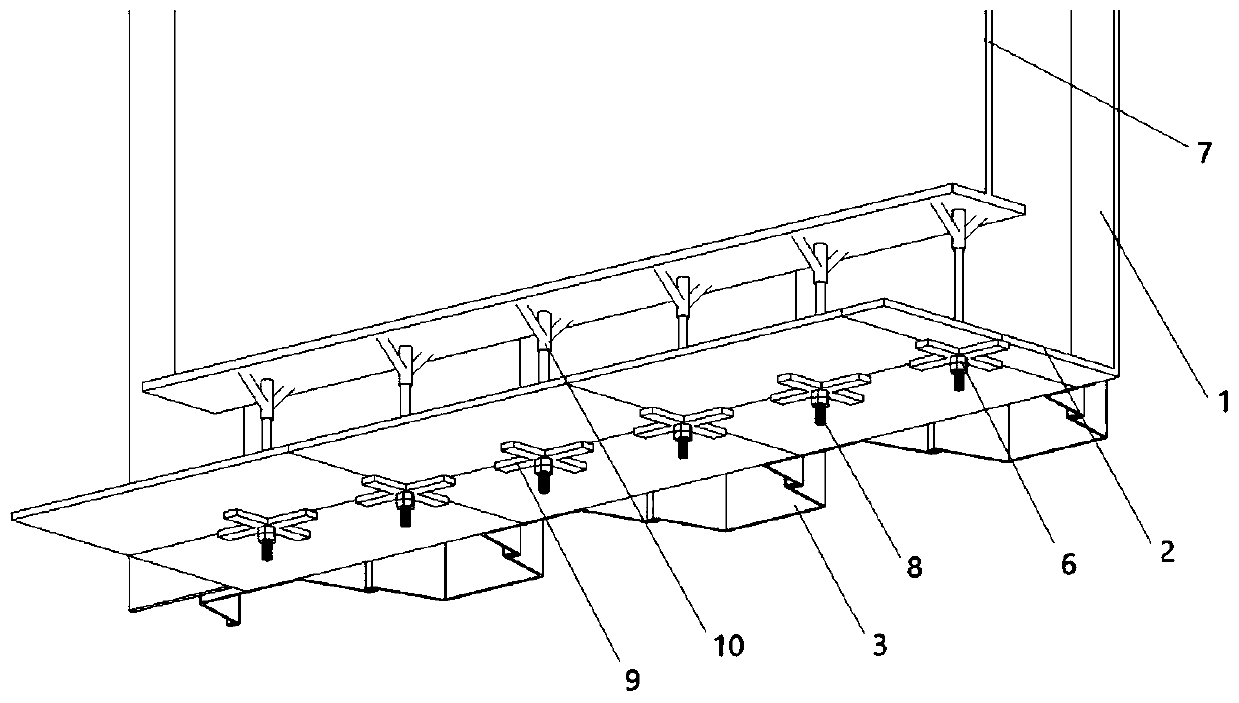

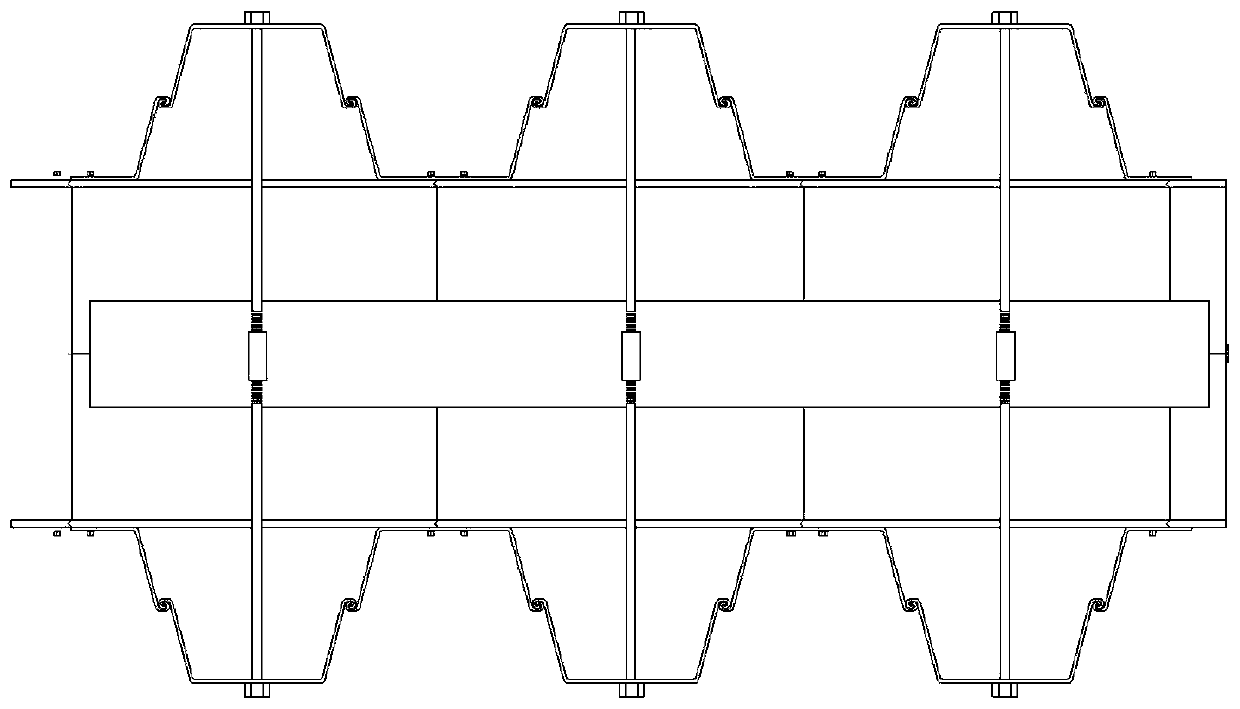

[0031] Such as Figures 1 to 5 As shown, a super-high and large-span steel concrete cast-in-place beam formwork reinforcement device is composed of several reinforcement units. steel beams.

[0032] The beam side formwork and the beam bottom formwork are an integrated L-shaped structure, and the two L-shaped structures are docked to form a U-shaped structure as a whole. The outside of the beam side formwork is fixed by using high-strength bolts and the side back of the Larsen steel plate. The corresponding positions on the beam side formwork and the Larsen steel back flute are preset with through holes, and the tops of the Larsen steel back flute on both sides of the U-shaped structure are connected by round steel tie rods. The round steel tie rod includes a mechanical sleeve and two threaded rods connected with the threaded sleeve. The two threaded rods are located at both ends of the mechanical sleeve, and the two ends are provided with fasteners. The round steel tie rod T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com