Patents

Literature

52results about How to "Easy to hoist and construct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

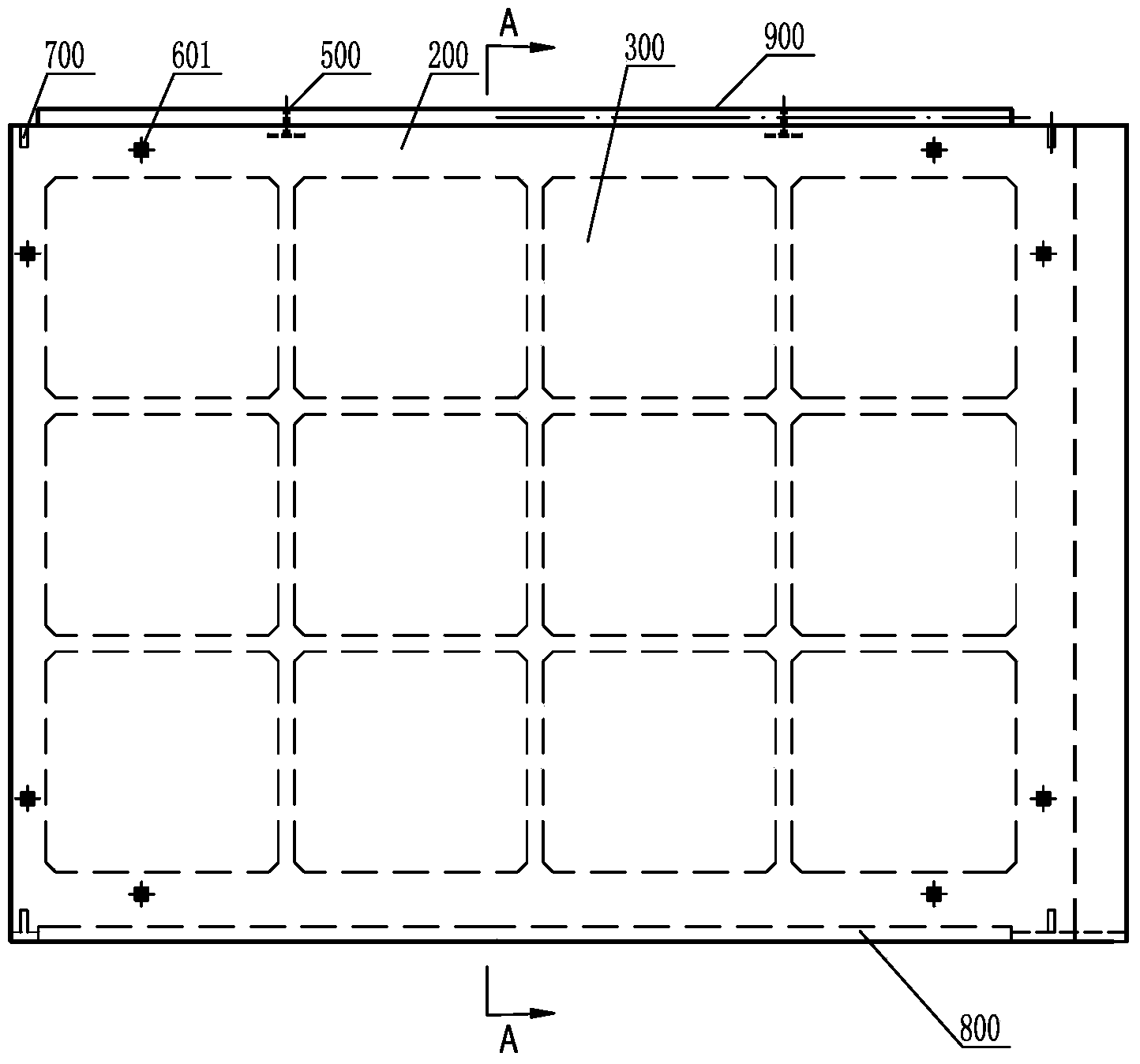

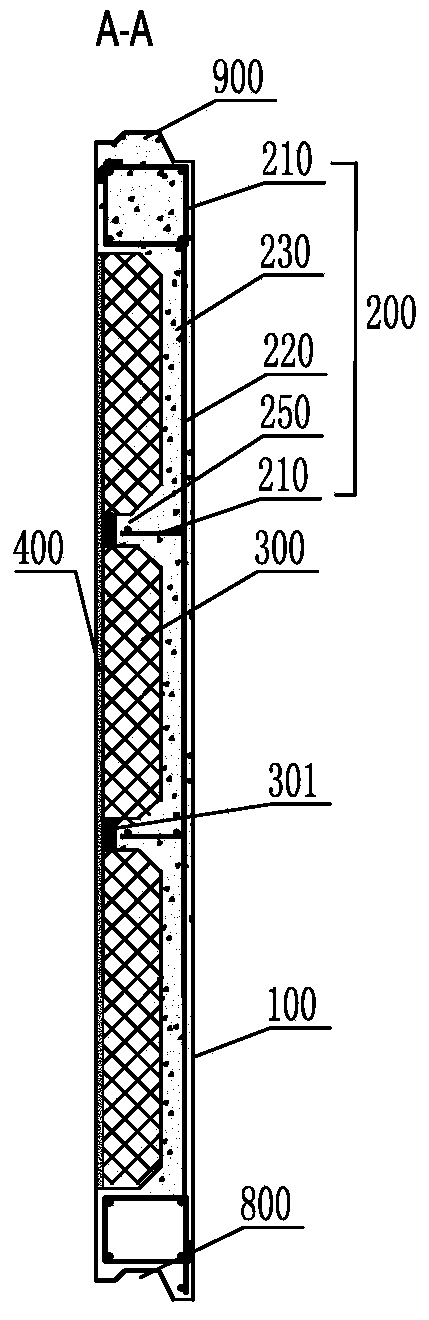

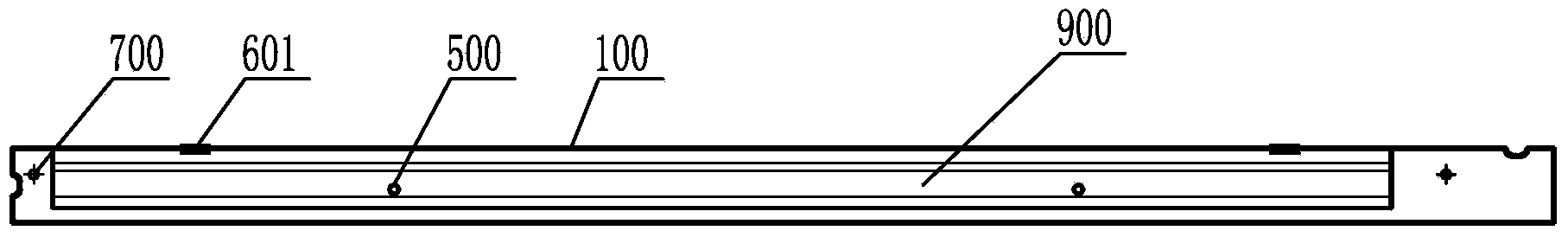

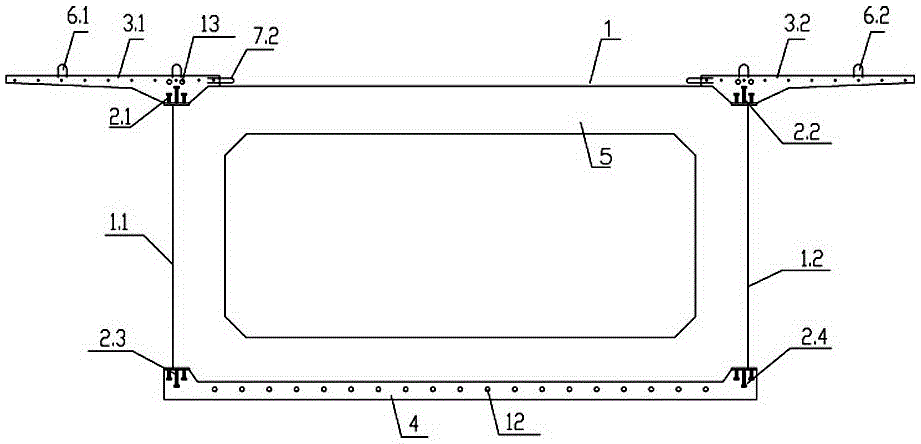

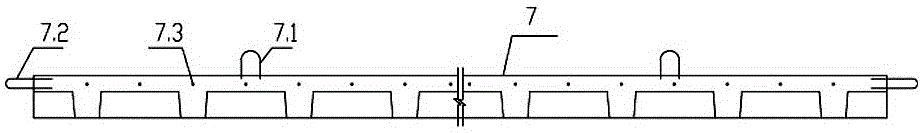

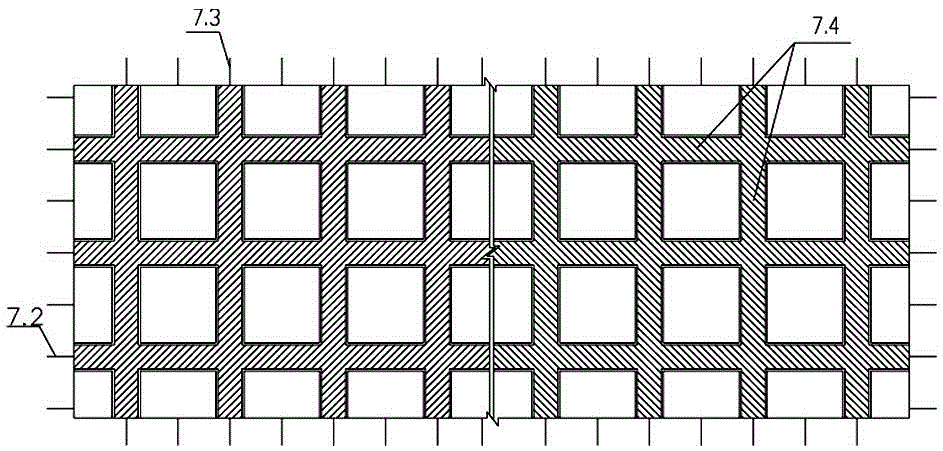

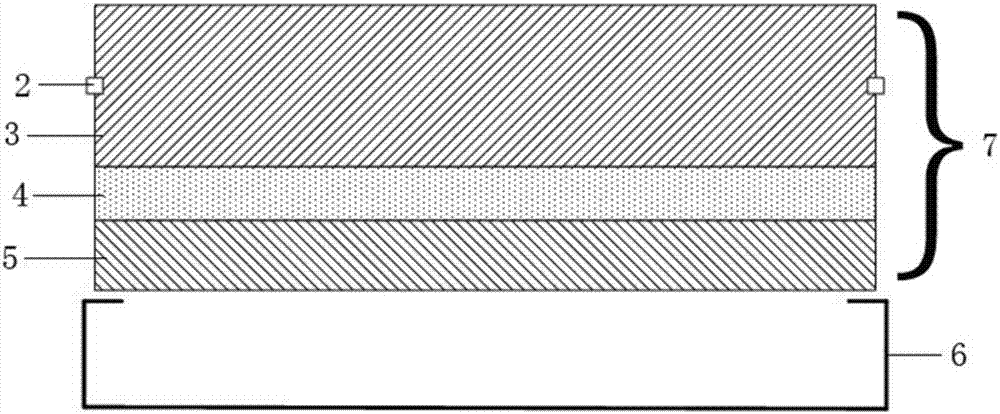

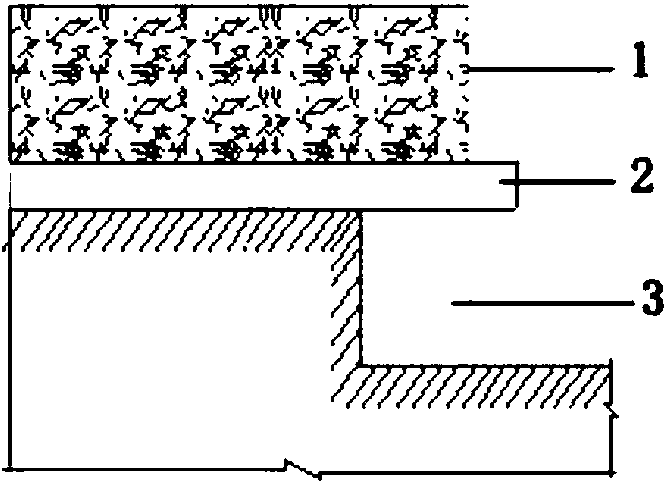

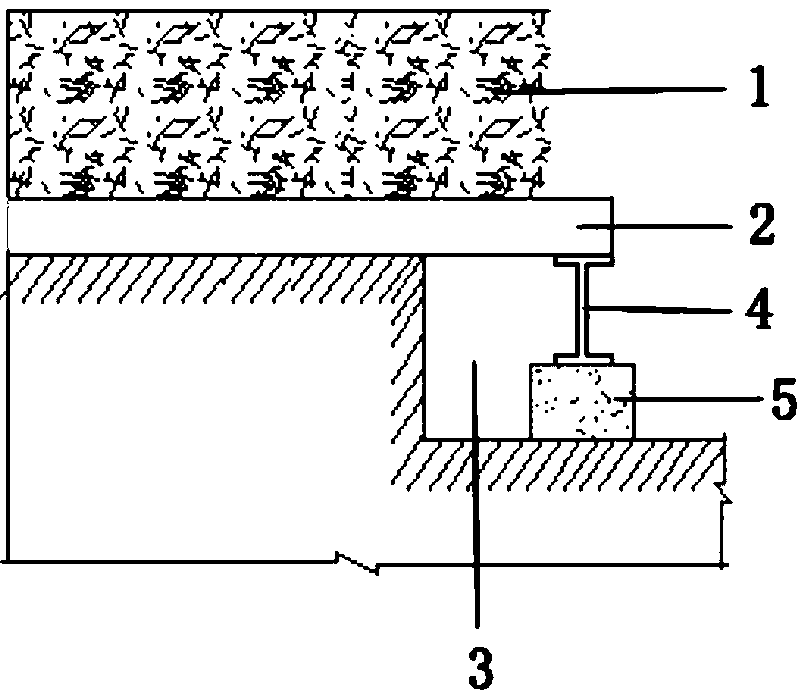

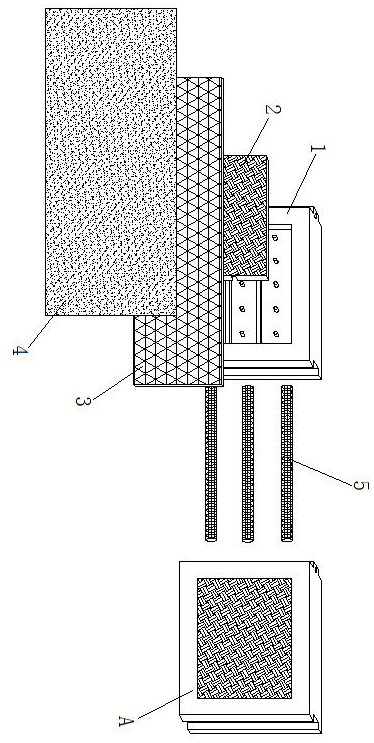

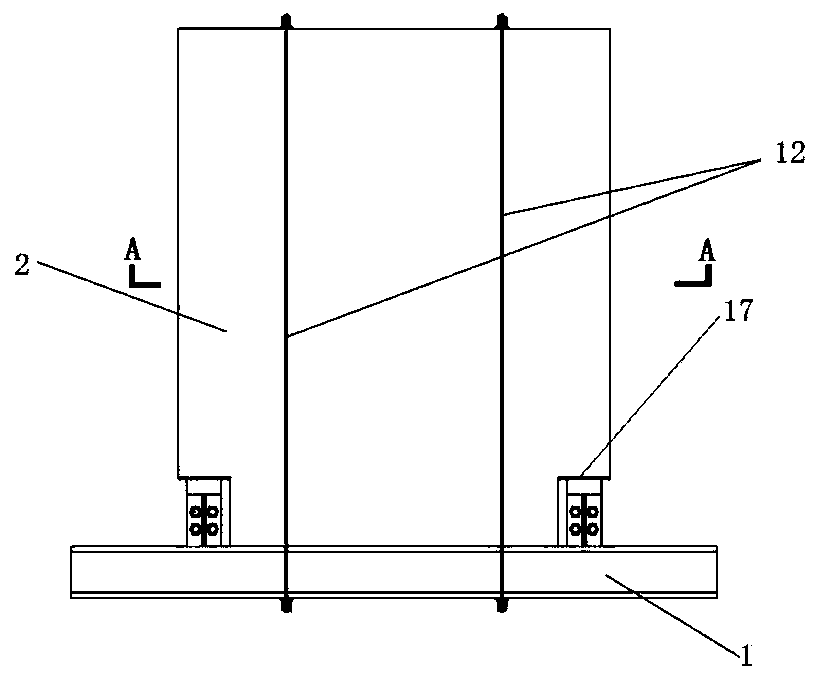

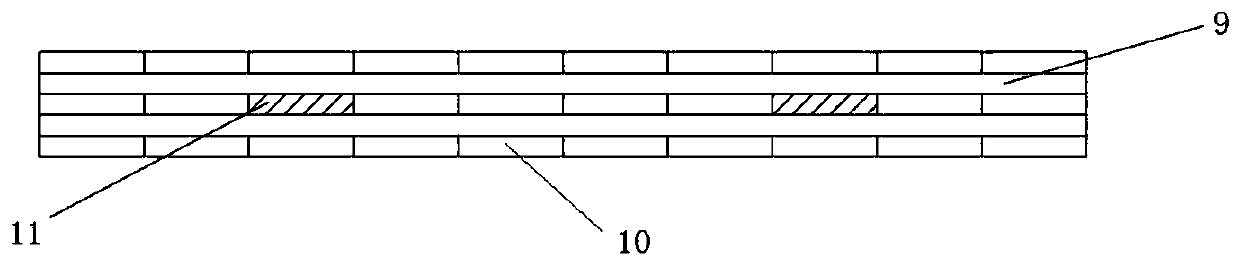

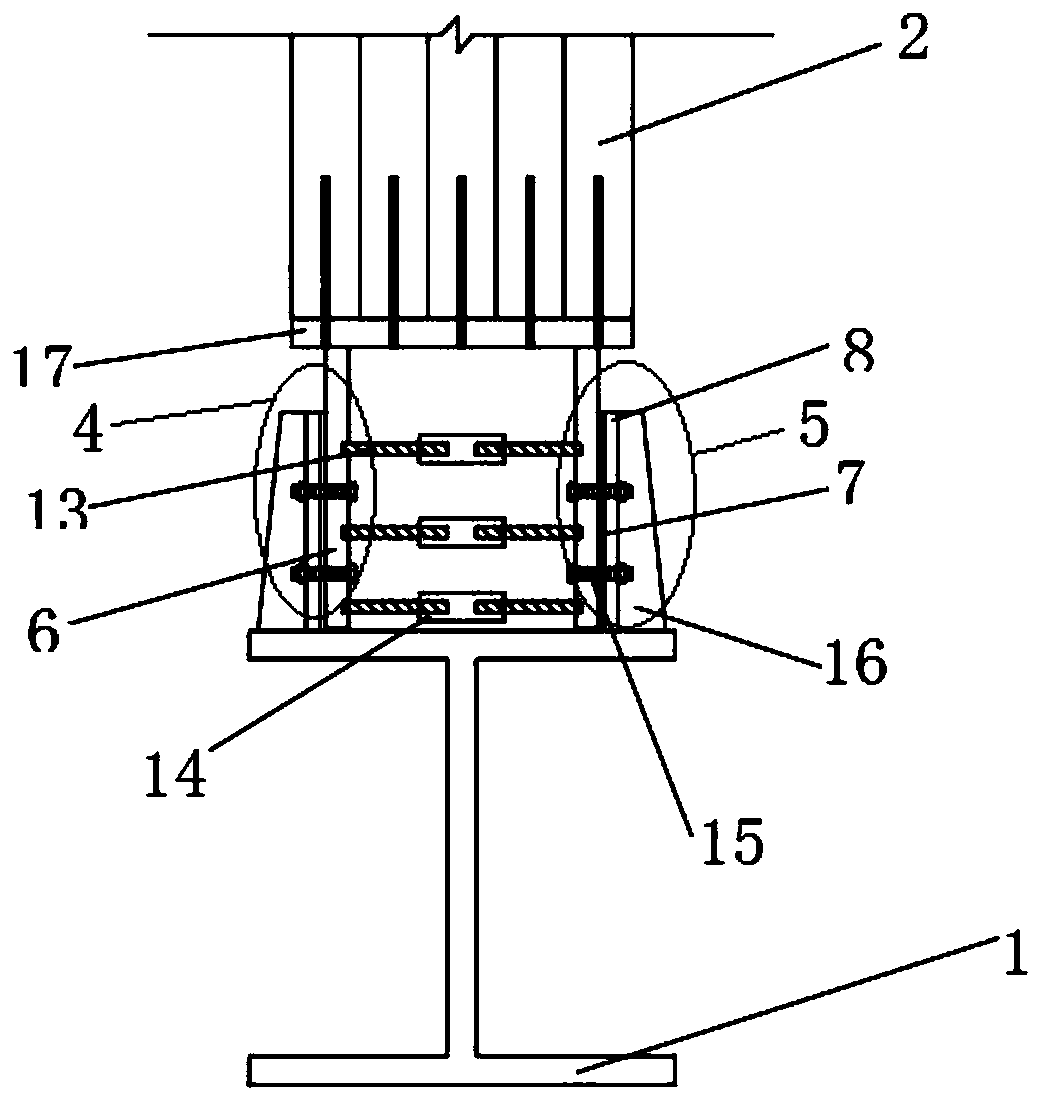

Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

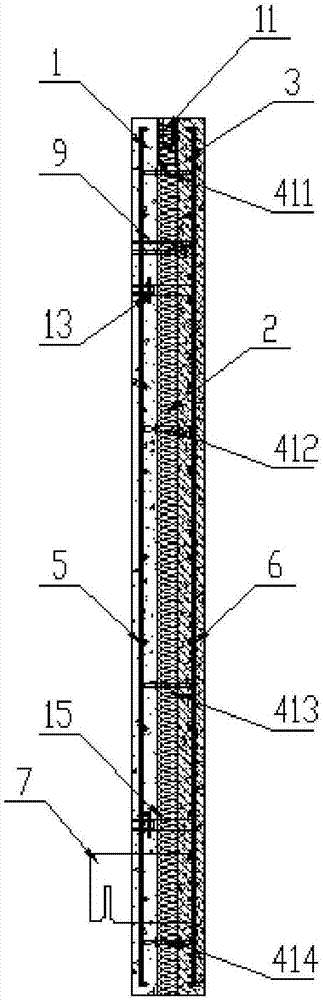

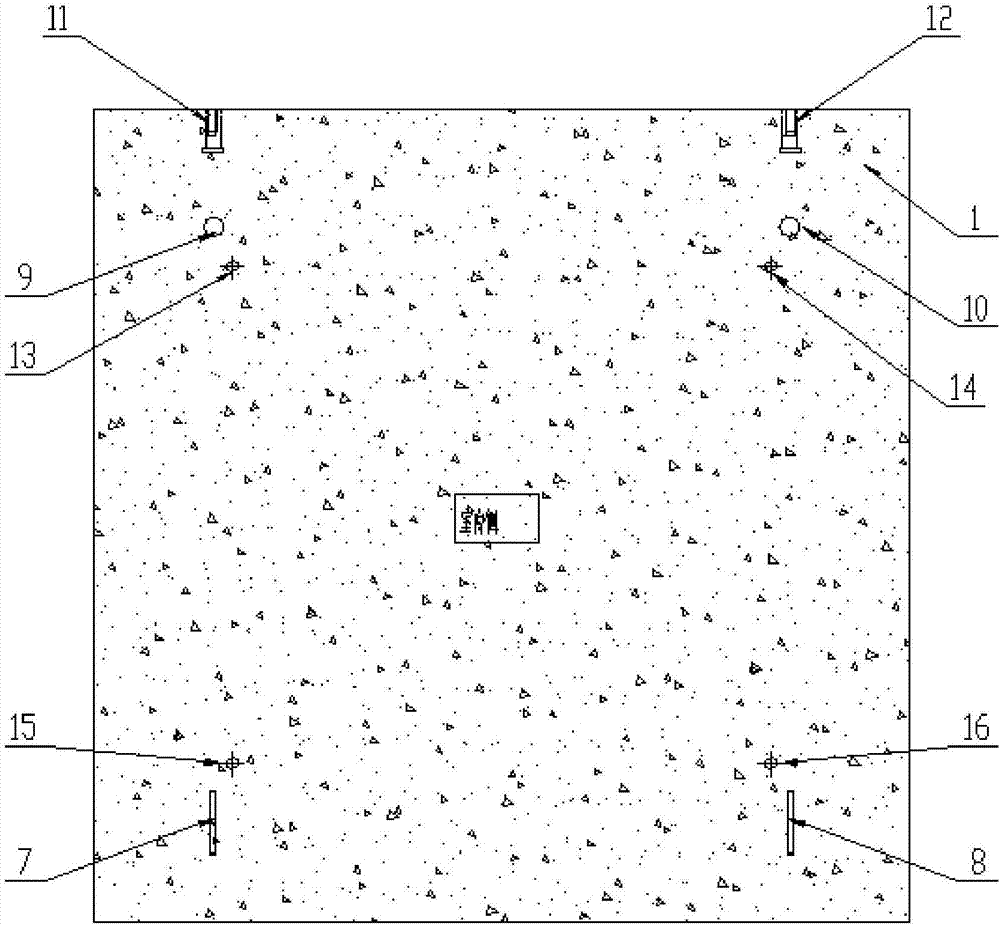

The invention discloses an integrally prefabricated multifunctional composite external wall panel and an industrial building external wall. The external wall panel comprises an outer decoration layer, a reinforcing bar fine aggregate concrete structural layer, a light-weight heat insulation layer and an indoor decoration layer which are fixedly connected from the outside to the inside, wherein the reinforcing bar fine aggregate concrete structural layer is filled into the light-weight heat insulation layer for forming plate ribs; heat insulation pads are arranged on the end surfaces of the plate ribs; first connecting elements are arranged on the periphery of the external wall panel; the top and the bottom of the external wall panel are respectively provided with positioning mechanisms; the top of the external wall panel is provided with hanging rings; and pre-buried accessories are arranged in the external wall panel. The external wall is formed by the external wall panels through vertical and horizontal distribution, surrounding and shielding, the periphery of each external wall panel is provided with a connecting mechanism connected with a main body stress component; the back part of the connecting mechanism is pre-buried in the reinforcing bar fine aggregate concrete structural layer of the external wall panel; and the adjacent external wall panels are sealed and connected through telescopic sealing elements. The integrally prefabricated multifunctional composite external wall panel and the industrial building external wall have the advantages that the industrial production can be realized; the weight is light; the transportation and the construction are convenient; the heat insulation performance and the sound isolation performance are good; the intensity and the weatherability are good; the internal and external decoration construction is not needed; and the installation is convenient.

Owner:黄涛 +1

PC light composite sandwich thermal-insulated integrated wallboard

The invention relates to a PC light composite sandwich thermal-insulated integrated wallboard, and belongs to the technical field of building structure construction. The light composite sandwich thermal-insulated integrated wallboard sequentially comprises an inner vane plate, a thermal insulating layer and an outer vane plate, an inner mesh is arranged in the inner vane plate, and an outer mesh is arranged in the outer vane plate; a plurality of connecting pieces are connected between the outer mesh and the inner mesh, a pre-embedded piece is arranged on the outer mesh, the pre-embedded piece penetrates through the thermal insulating layer and the inner vane plate, the outer end of the pre-embedded piece extrudes above the inner surface of the inner vane plate. The PC light composite sandwich thermal-insulated integrated wallboard is applied to steel building construction, and has the advantages of being small in weight, high in thermal insulation, convenient and efficient.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Concrete material prepared by utilizing wastes and preparation method of concrete material

ActiveCN106587783AReduce manufacturing costAvoid polluting the environmentSolid waste managementBreaking strengthCompressive strength

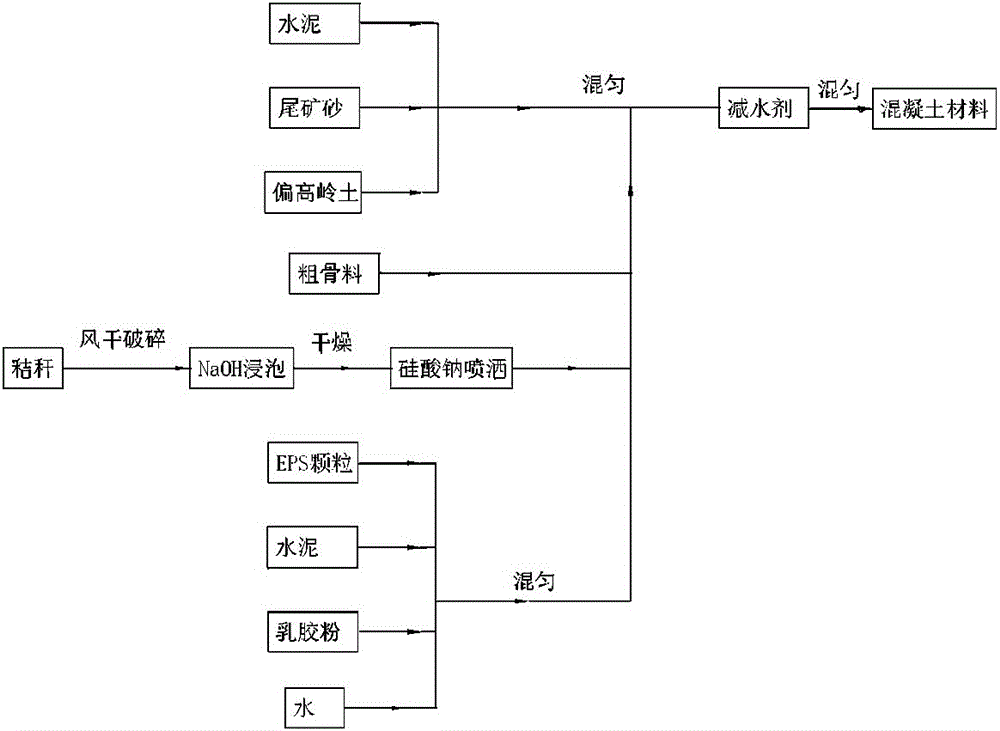

The invention relates to the technical field of concrete materials and discloses a concrete material prepared by utilizing wastes and a preparation method of the concrete material. The concrete material disclosed by the invention comprises the following raw material components in parts by weight: 50-60 parts of coarse aggregate, 5-15 parts of cement, 15-30 parts of tailing sand, 0.1-0.3 part of straw, 0.2-0.4 part of EPS granules, 3.2-10.3 parts of additives, 1.2-2.0 parts of sodium hydroxide solution, 1.0-1.2 parts of sodium silicate solution and 5-15 parts of water. The concrete material disclosed by the invention is economic and readily available in raw materials, high-efficiency and environmental-friendly and has excellent compressive strength and breaking strength.

Owner:上海青城绿浦环境资源发展有限公司

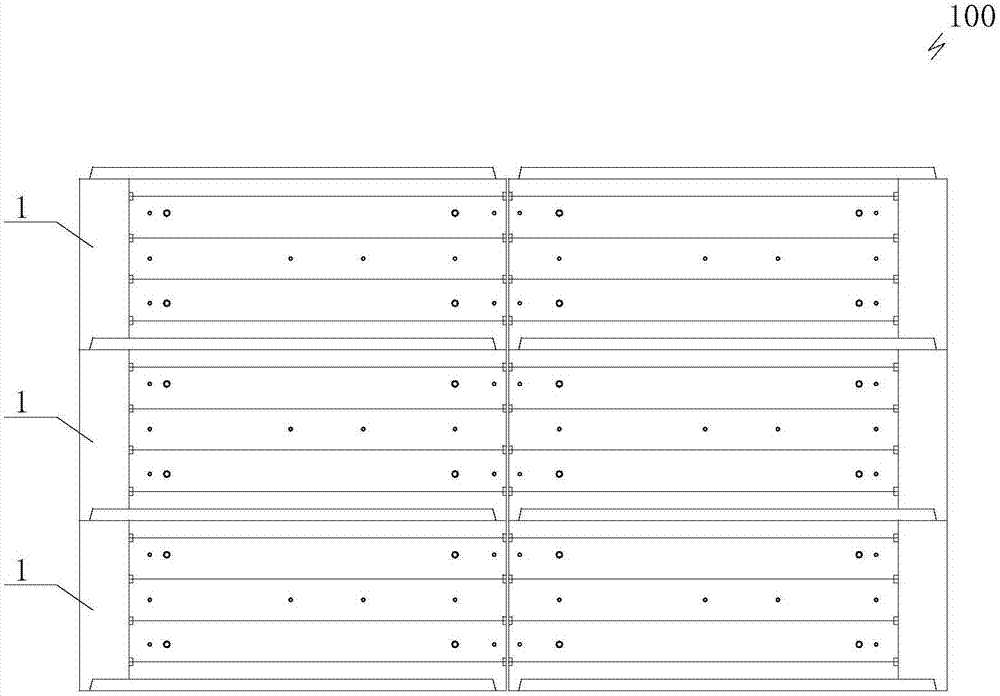

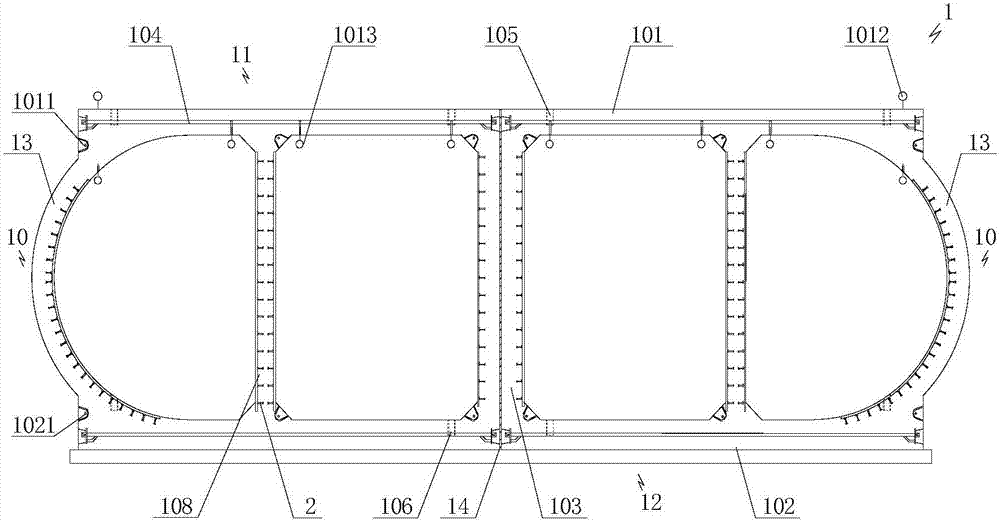

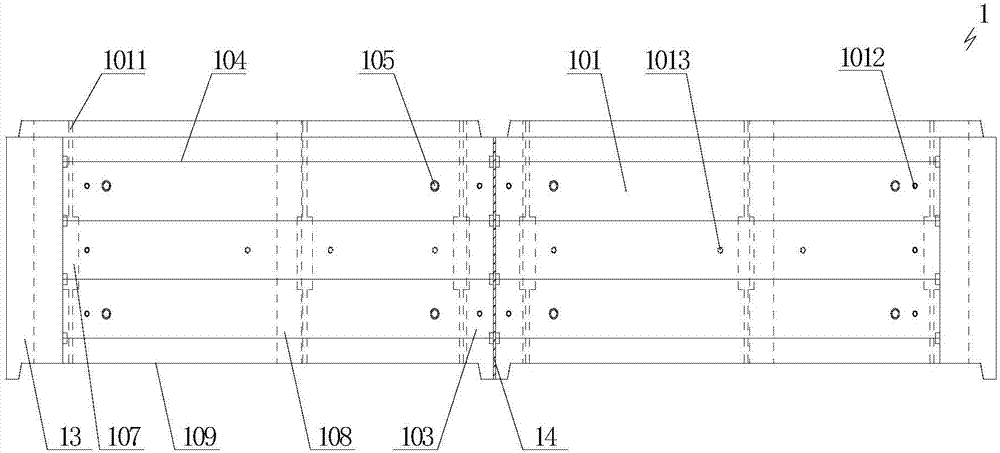

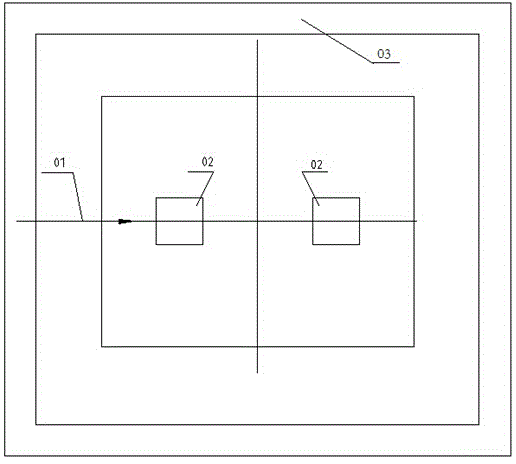

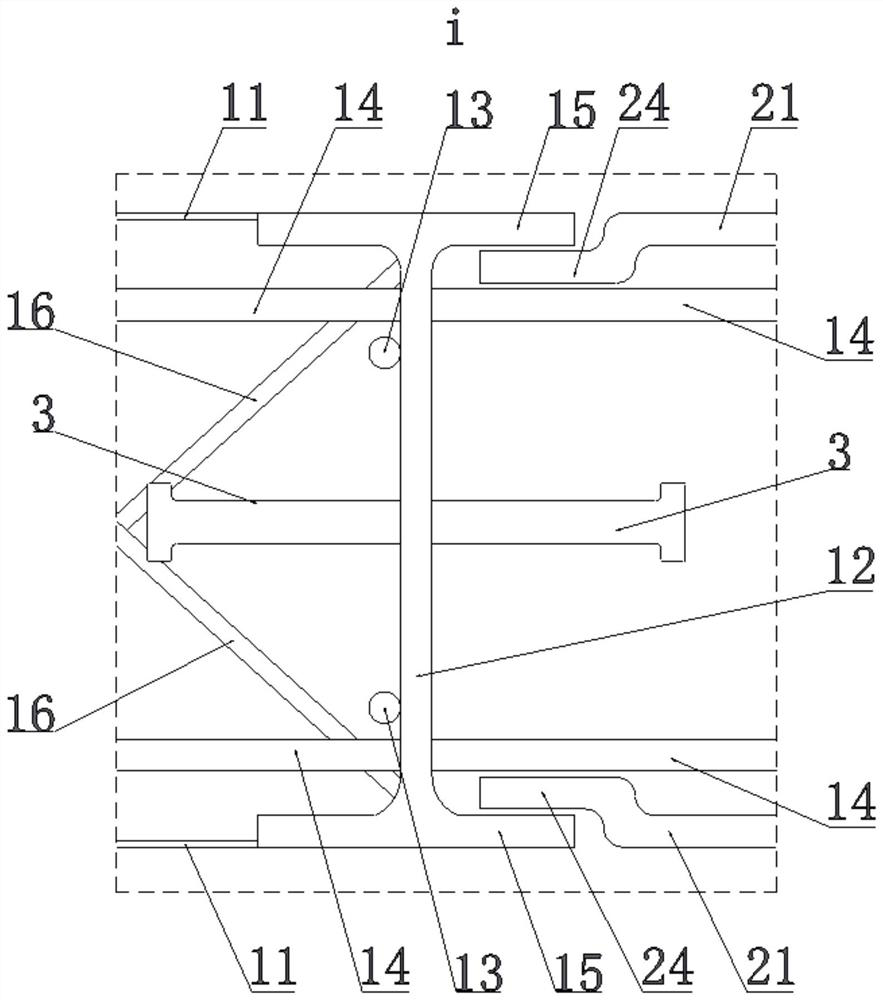

Prefabricated comprehensive pipe gallery

ActiveCN107313452AReasonable forceReduced sidewall thicknessArtificial islandsHydro energy generationUtility tunnelSelf weight

The invention provides a prefabricated comprehensive pipe gallery which is formed in the manner that multiple pipe gallery prefabricated units are longitudinally spliced. Each pipe gallery prefabricated unit comprises a top plate and a bottom plate, wherein the top plate and the base plate are parallel and arranged in a spaced manner. The two sides of each pipe gallery prefabricated unit are provided with arc side walls which are connected with the top plate and the bottom plate in a seal manner. The prefabricated comprehensive pipe gallery solves the problems that in the prior art, construction of the cast-in-place technology is slow, the construction quality is difficult to guarantee, a rectangular cross section is large in dead load in the prefabricating technology, transportation and installation are inconvenient, and cost is high. According to the prefabricated comprehensive pipe gallery, the arc side walls are adopted to optimize the stress of the comprehensive pipe gallery, the dead load and cost of the comprehensive pipe gallery are reduced, the durability of the comprehensive pipe gallery is improved, and the construction quality is easy to guarantee.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

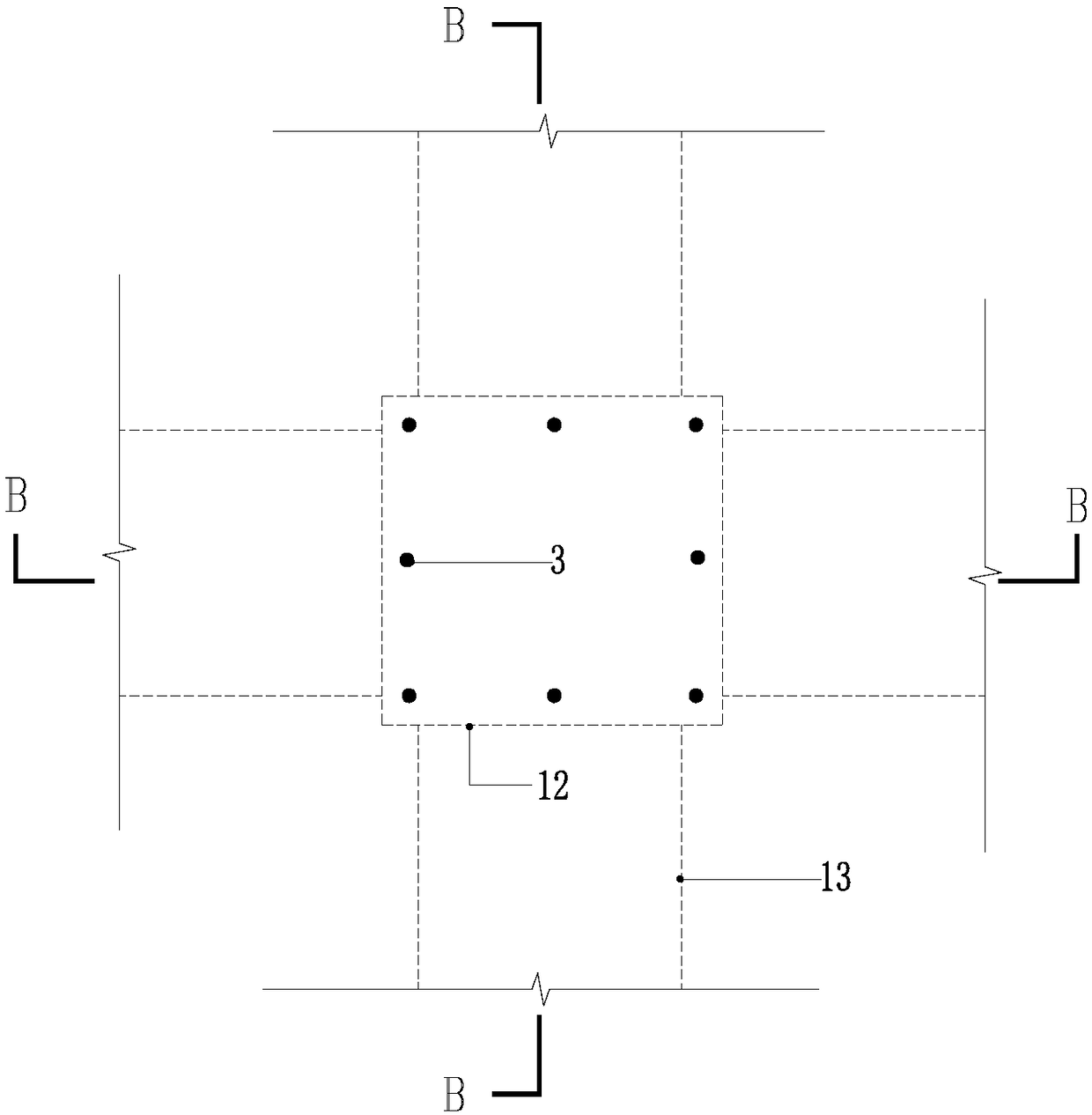

Vertical and horizontal integrally superposed concrete frame structural body and superposed forming body

PendingCN108867855AReduce installation usageReduce weightBuilding constructionsFloor slabPrecast concrete

The invention discloses a vertical and horizontal integrally superposed concrete frame structural body and a superposed forming body. The vertical and horizontal integrally superposed concrete frame structural body comprises a superposed frame column prefabricated member, a superposed frame beam prefabricated member and a superposed floor slab prefabricated member; the superposed frame column prefabricated piece comprises a superposed frame column fabricated concrete shell which is arranged vertically, and a hollow portion which is positioned on the superposed frame column prefabricated concrete shell is a superposed frame column hollow portion; the superposed frame beam prefabricated member and the superposed frame column prefabricated member are arranged in a crossed manner; and end surfaces of the ends, which are close to the superposed frame column prefabricated concrete shell, of two prefabricated concrete superposed frame beams are inclined end surfaces. According to the verticaland horizontal integrally superposed concrete frame structural body, frame beams, plates and columns are superposed integrally, the superposed portions not only are stressed, but also serve as part of templates, the use amount of field templates is reduced, raised dust of a construction site and building garbage are reduced, and the promotion and application value is quite high.

Owner:SANY CONSTR TECH CO LTD

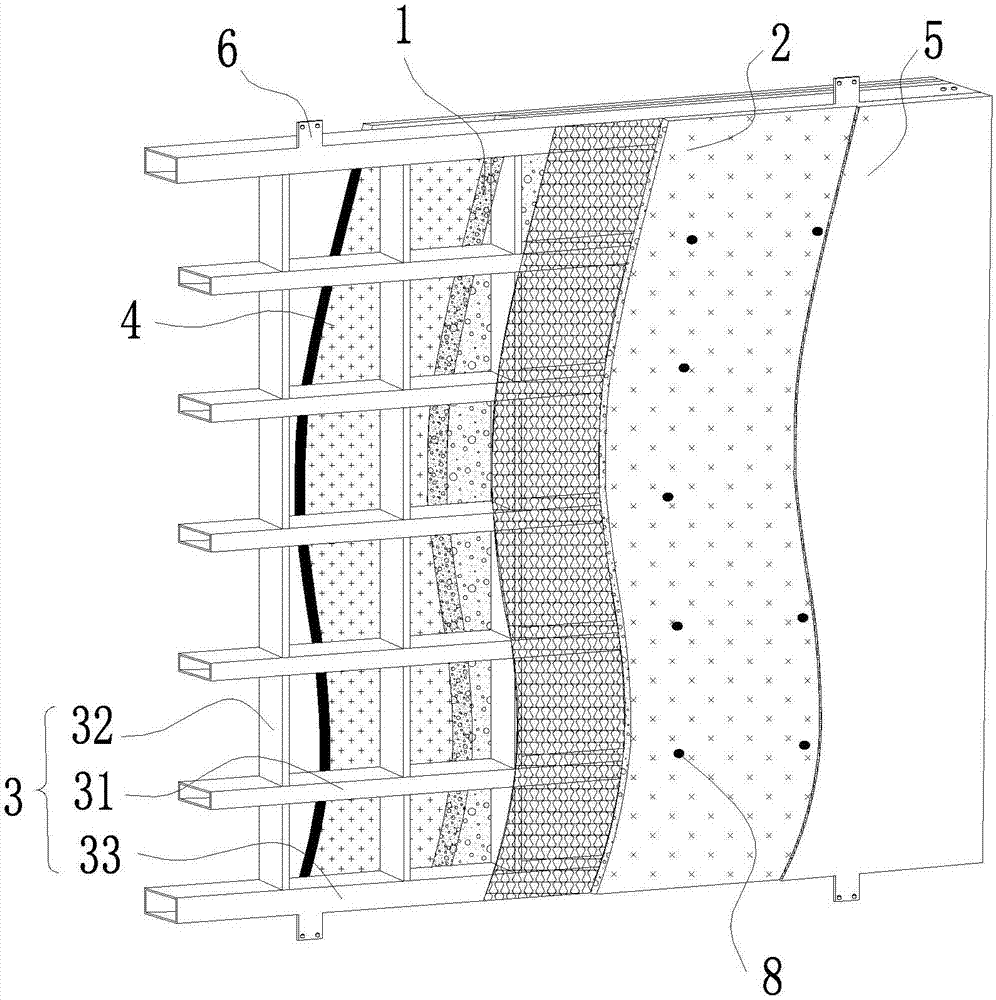

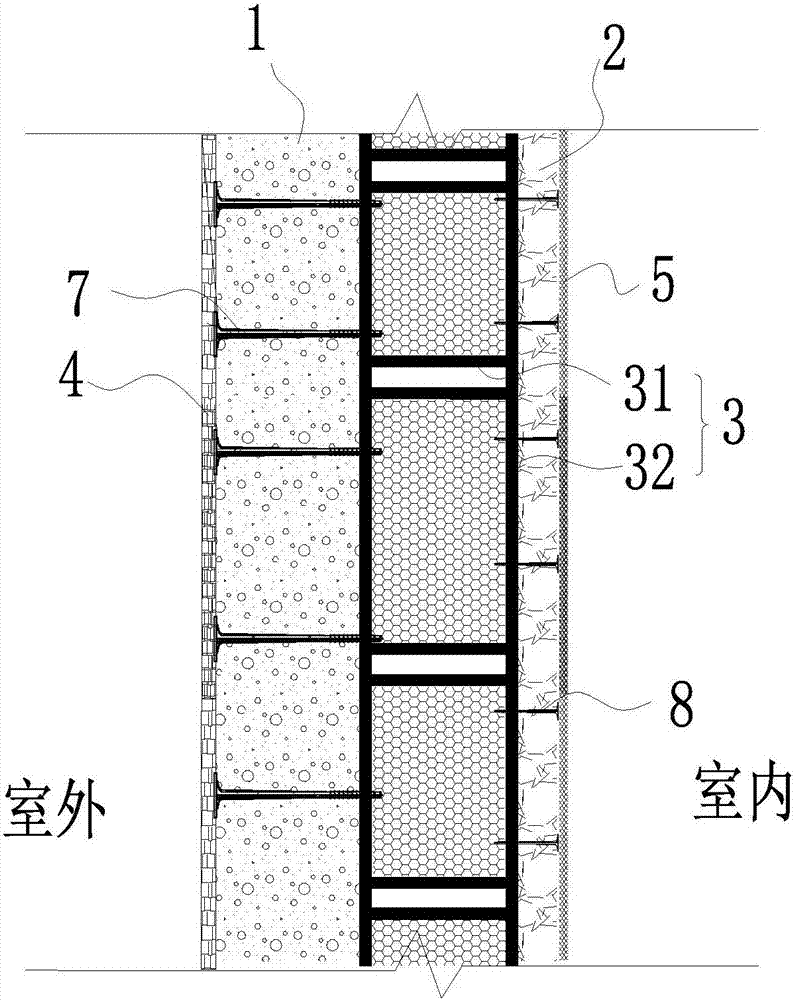

Assembled external wall plate and preparation method thereof

PendingCN107254935ALower requirementAvoid crackingCovering/liningsLayered productsBuilding materialWall plate

The invention relates to the field of a building material, in particular to an assembled external wall plate. The assembled external wall plate comprises an outer side plate, an inner side plate and a multifunctional structure layer, wherein the multifunctional structure layer is arranged between the outer side plate and the inner side plate; one side of the outer side plate is connected with one side of the multifunctional structure layer; an outer decoration layer is compounded at the other side of the outer side plate; one side of the inner side plate is connected with the other side of the multifunctional structure layer; an inner decoration layer is compounded at the other side of the inner side plate; the multifunctional structure layer comprises a force bearing frame; and waterproof heat insulation and heat preservation materials are filled in gaps between the outer side plate and the force bearing frame and gaps between the inner side plate and the force bearing frame. The quality can be ensured; the construction and the hoisting are easy; the construction efficiency is improved; the integral performance is stable; the impact resistant performance is good; the conventional common quality faults of wall plate cracking and deformation, edge missing, corner falling and the like can be avoided; after once installation completion, the veneer construction is not needed; and the engineering manufacturing cost and the construction period are reduced.

Owner:重庆佳良建筑设计咨询有限公司

Construction method for ultra-high-performance concrete corrugated steel web composite box girder bridge

The invention discloses a construction method for an ultra-high-performance concrete corrugated steel web composite box girder bridge. The construction method comprises the steps that a U-shaped groove structural part of each span of box girder is prefabricated according to the design requirements at first; a bridge floor middle plate is prefabricated according to the prefabricated U-shaped groove structural part; a bridge abutment and a bridge pier are constructed, the prefabricated U-shaped groove structural part and the bridge floor middle plate are hoisted in position, transverse connecting steel bars are bound, and after transverse wet joints are poured, the complete box girder is formed; the next bridge pier is constructed, a second box girder is hoisted in position, corrugated steel webs of the adjacent box girders are welded, longitudinal connecting steel bars between the adjacent box girders are bound, longitudinal wet joints between the adjacent box girder segments are poured or a cross girder is casted in place, and a continuous bridge structure is formed; after wet joint concrete reaches the designed strength value, top plate prestressed steel strands are tensioned; and the above steps are repeated, so that the multi-span continuous bridge structure is completed. According to the construction method for the ultra-high-performance concrete corrugated steel web composite box girder bridge, the box girders are light in weight and small in torsional distortion, the bridge floor plate load distribution capacity is good, construction and erection are convenient, and the construction method has wide application prospects in large and middle span bridges.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

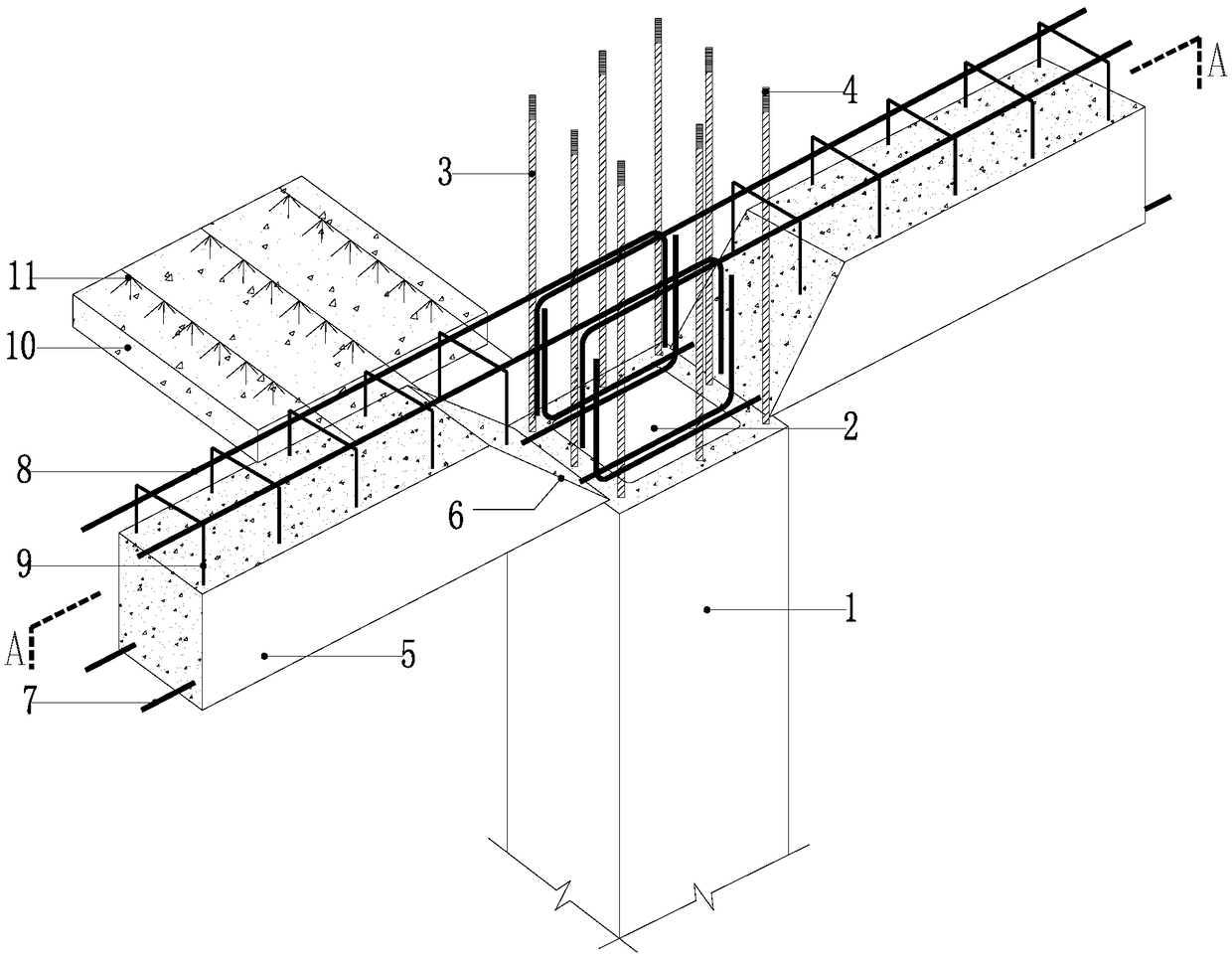

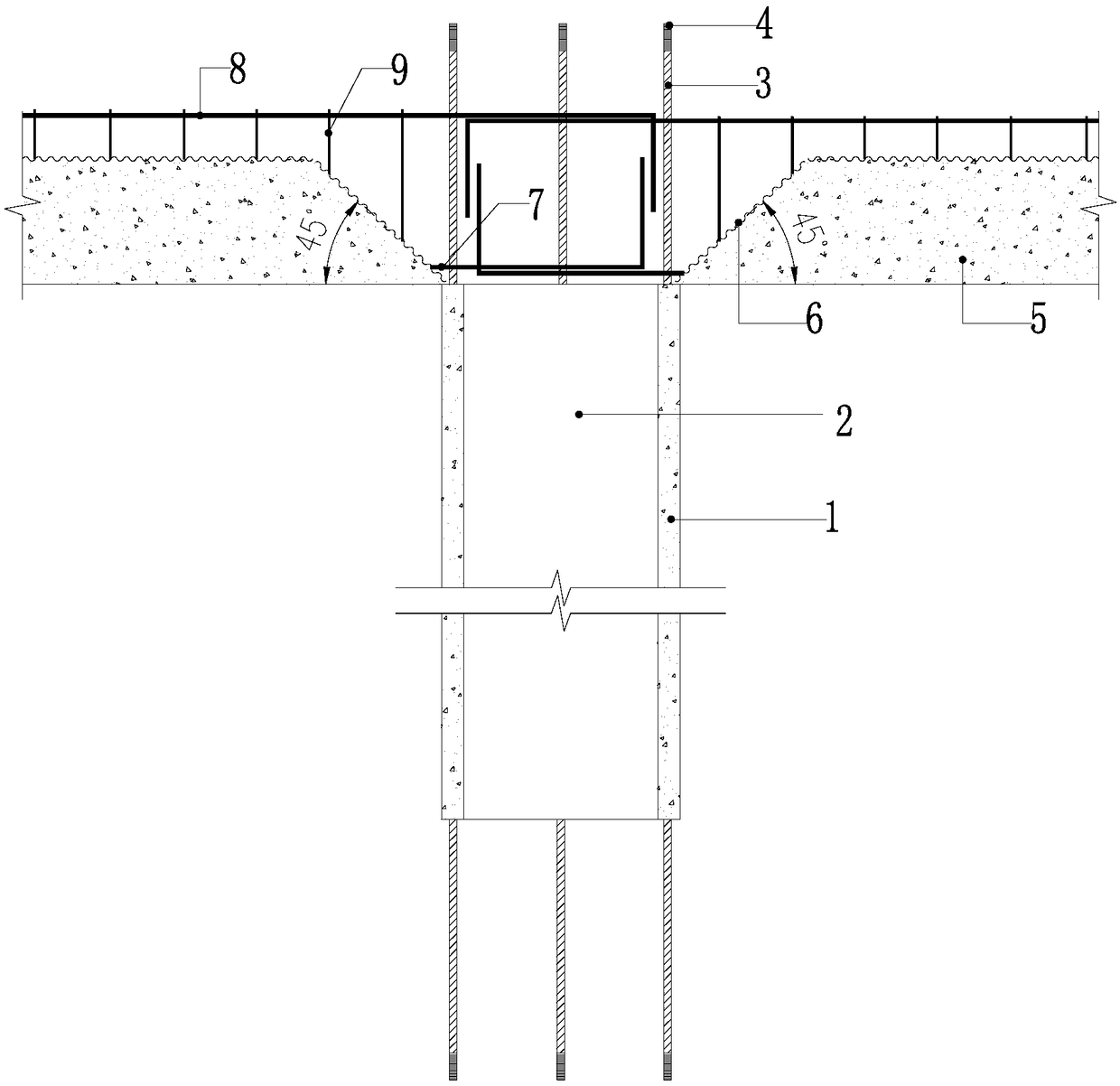

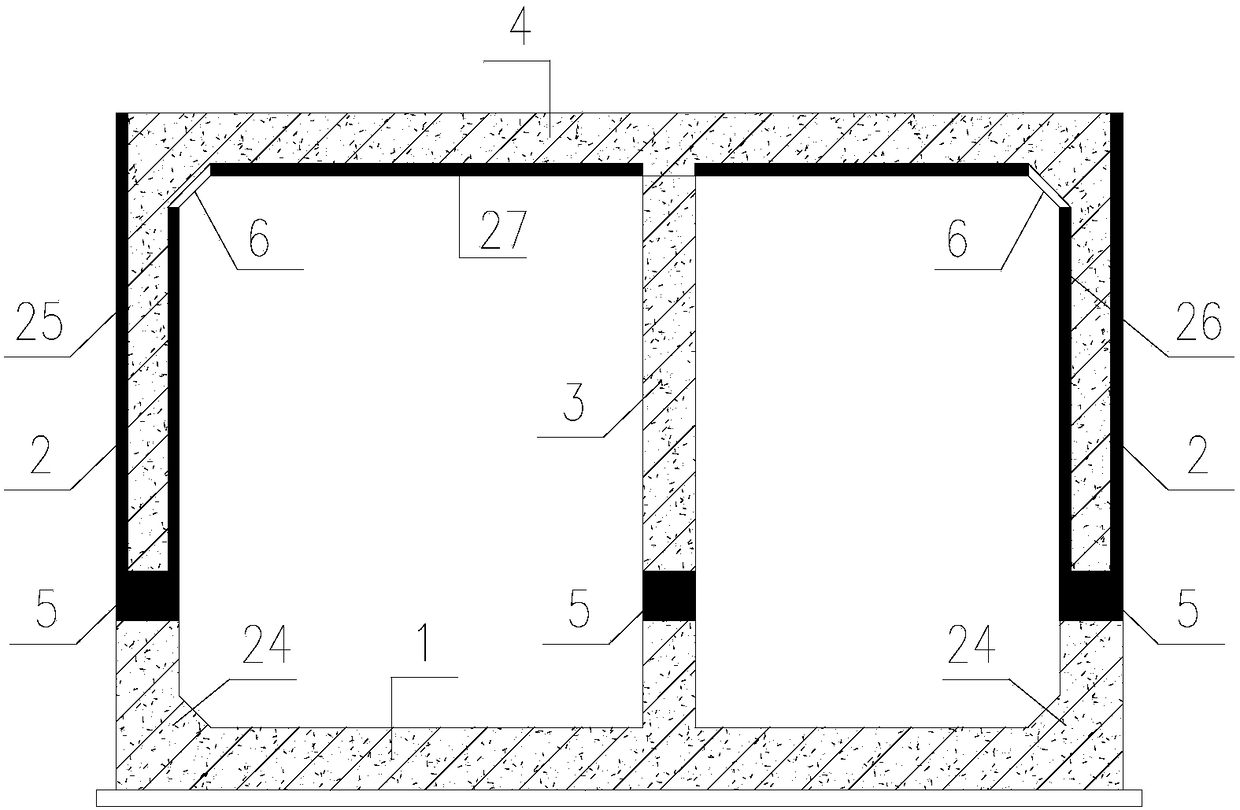

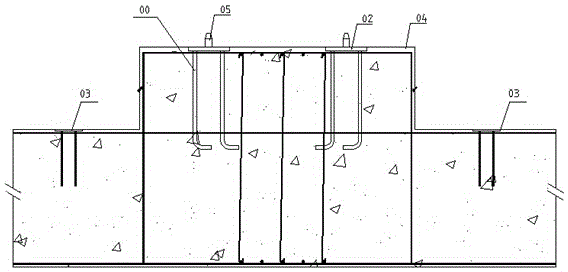

Prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and construction method thereof

ActiveCN108086353ALight weightSolving prefab assembly challengesArtificial islandsUnderwater structuresUtility tunnelHollow core

The invention discloses a prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and a construction method thereof. The two ends of a cast-in-place bottom plate are connected with the lower part of a double-sided prefabricated hollow core-filled side wall through a splicing hidden beam separately; the middle part of the cast-in-place bottom plate is connected with the lower part of a fully-prefabricated middle partition wall through a splicing hidden beam; the two ends of a laminated top plate are connected with the upper part of the double-sided prefabricated hollow core-filled side wall separately; and the middle part of the laminated top plate is connected with the upper part of the fully-prefabricated middle partition wall.The prefabricated utility tunnel integrates the advantages of a prefabrication process and a cast-in-place process; and the dead weights of prefabricated parts can be reduced through reasonable detachment, and the parts can be connected into one piece through cast-in-place core filling and the splicing hidden beams, so that the purpose of prefabrication for a multi-cabin tunnel and a non-standardsection of the tunnel can be achieved.

Owner:中建五局第三建设有限公司

Prefabricated stair

The invention discloses a prefabricated stair which comprises prefabricated stair plates, variable-section stair beams, stair beam top building surface layers, stair beam bottom overhang lugs and stair beam top overhang lugs. The prefabricated stair plates are factory prefabricated parts, one end surfaces of the variable-section stair beams are arranged at one ends of the stair beam top building surface layers and further provided with the stair beam top overhang lugs, the other end surfaces of the variable-section stair beams are provided with the beam bottom overhang lugs, and the variable-section stair beams, the stair beam top building surface layers, the stair beam bottom overhang lugs and the stair beam top overhang lugs are cast on site to form cast-in-situ parts; the cast-in-situ parts are arranged at the upper ends and the lower ends of the prefabricated stair plates, the upper ends of the prefabricated stair plates are fixedly connected to the stair beam bottom overhang lugs,the lower ends of the prefabricated stair plates are slidably supported on the stair beam top overhang lugs, and the last steps of the prefabricated stair are formed by the height difference betweenthe variable-section stair beams, the stair beam top building surface layers and the top surfaces of the upper end parts of the prefabricated stair plates. the span of the prefabricated stair plates is reduced, and overweight of a single prefabricated stair plate is avoided.

Owner:ELITE ARCHITECTURAL CO LTD

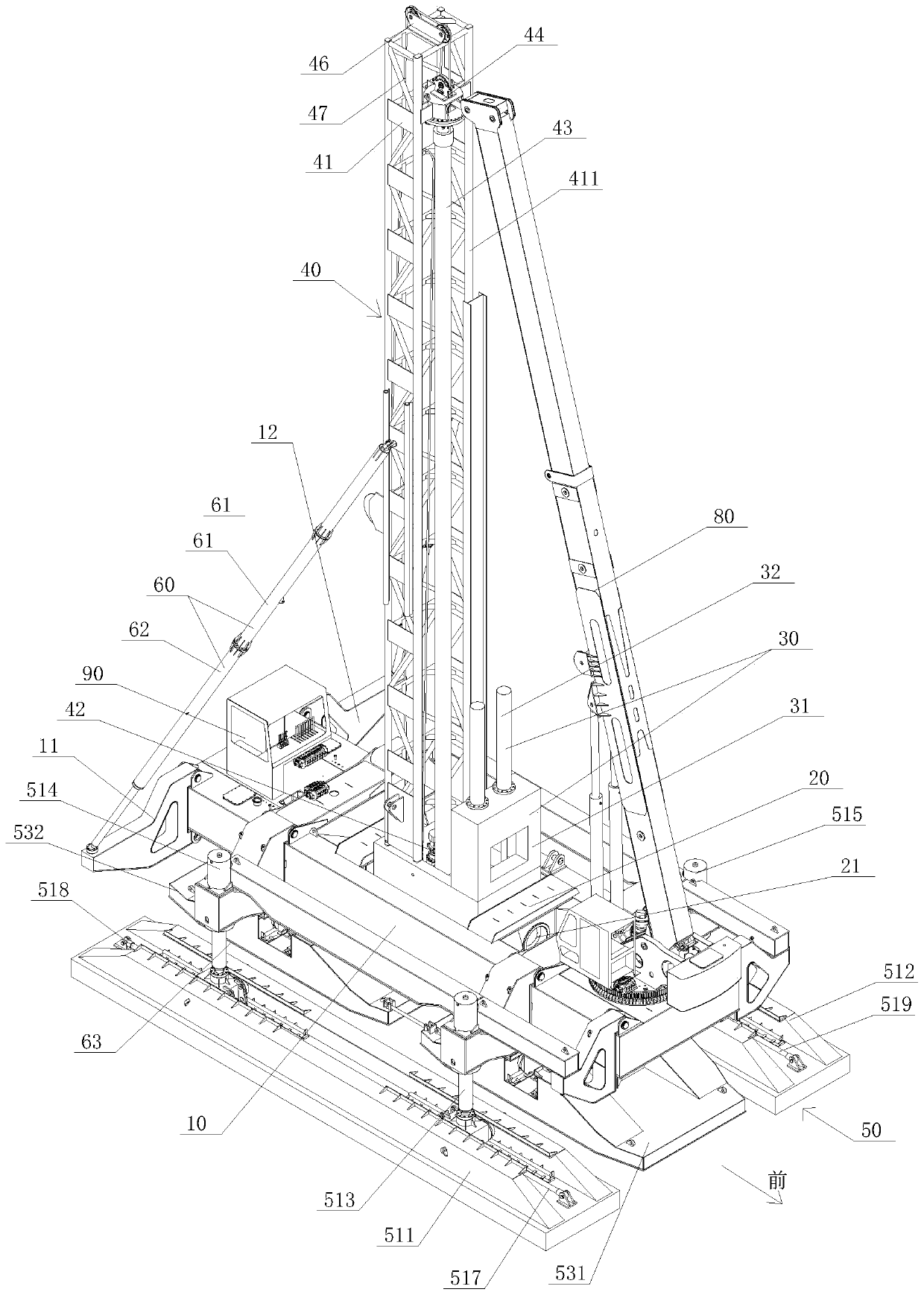

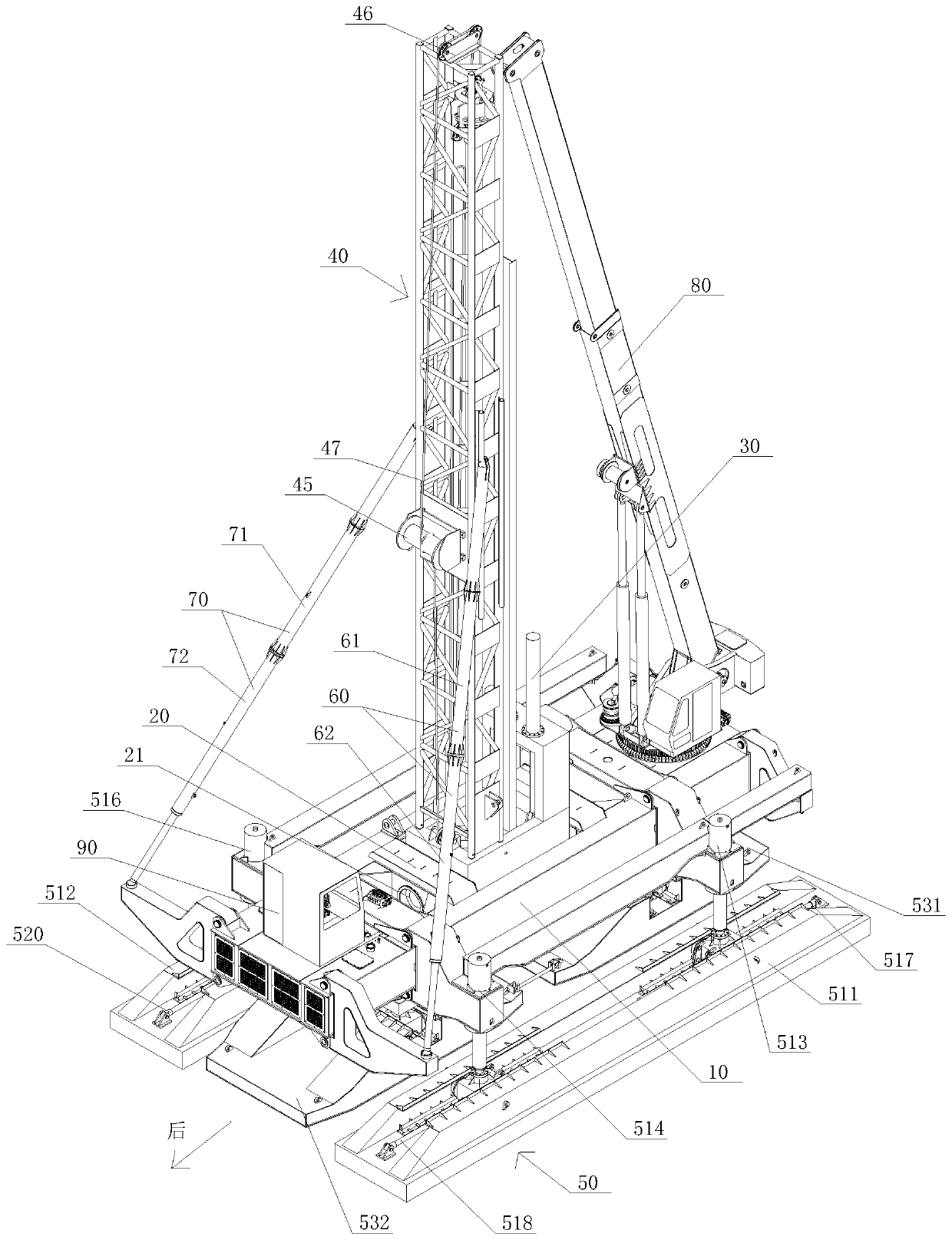

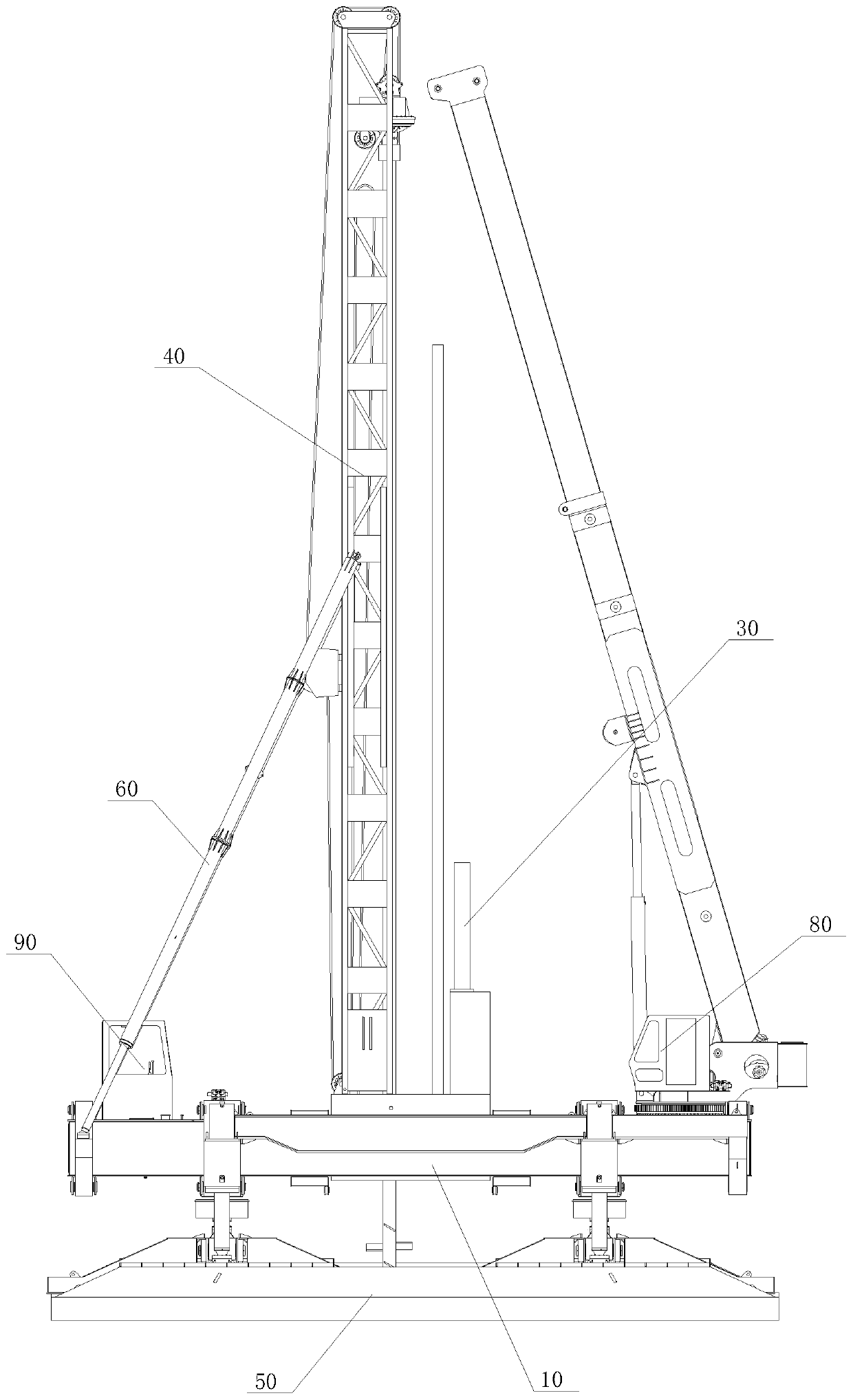

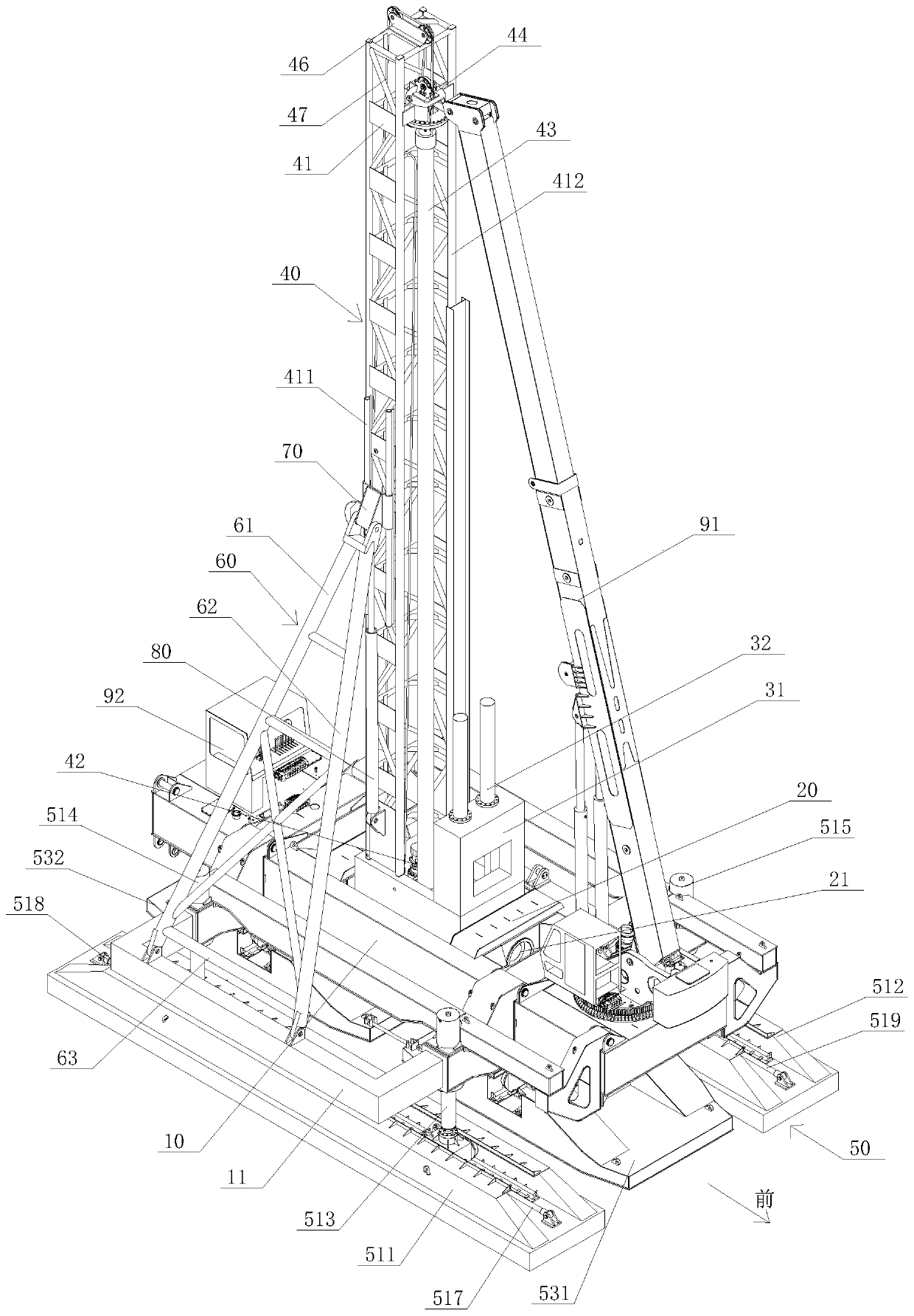

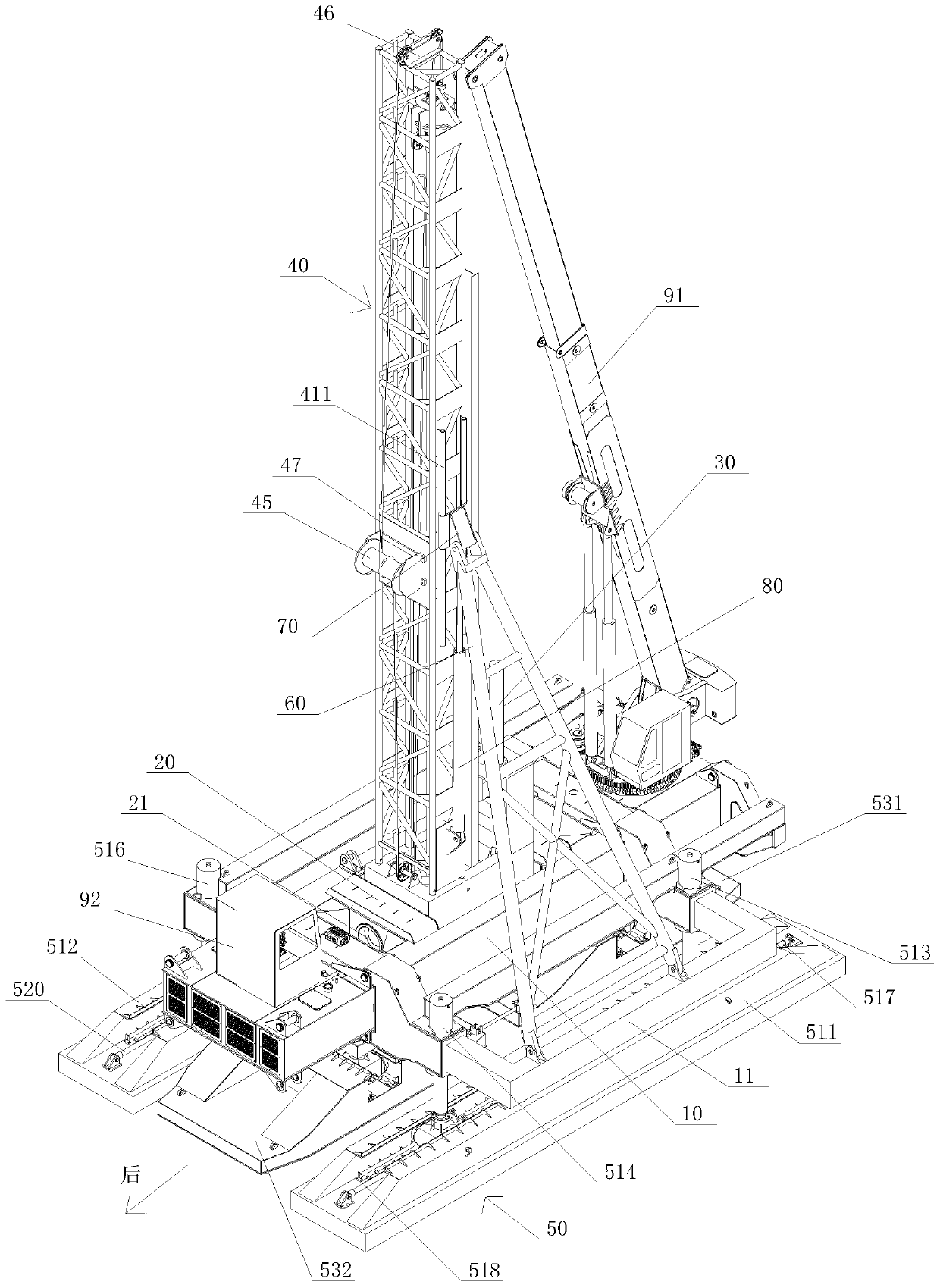

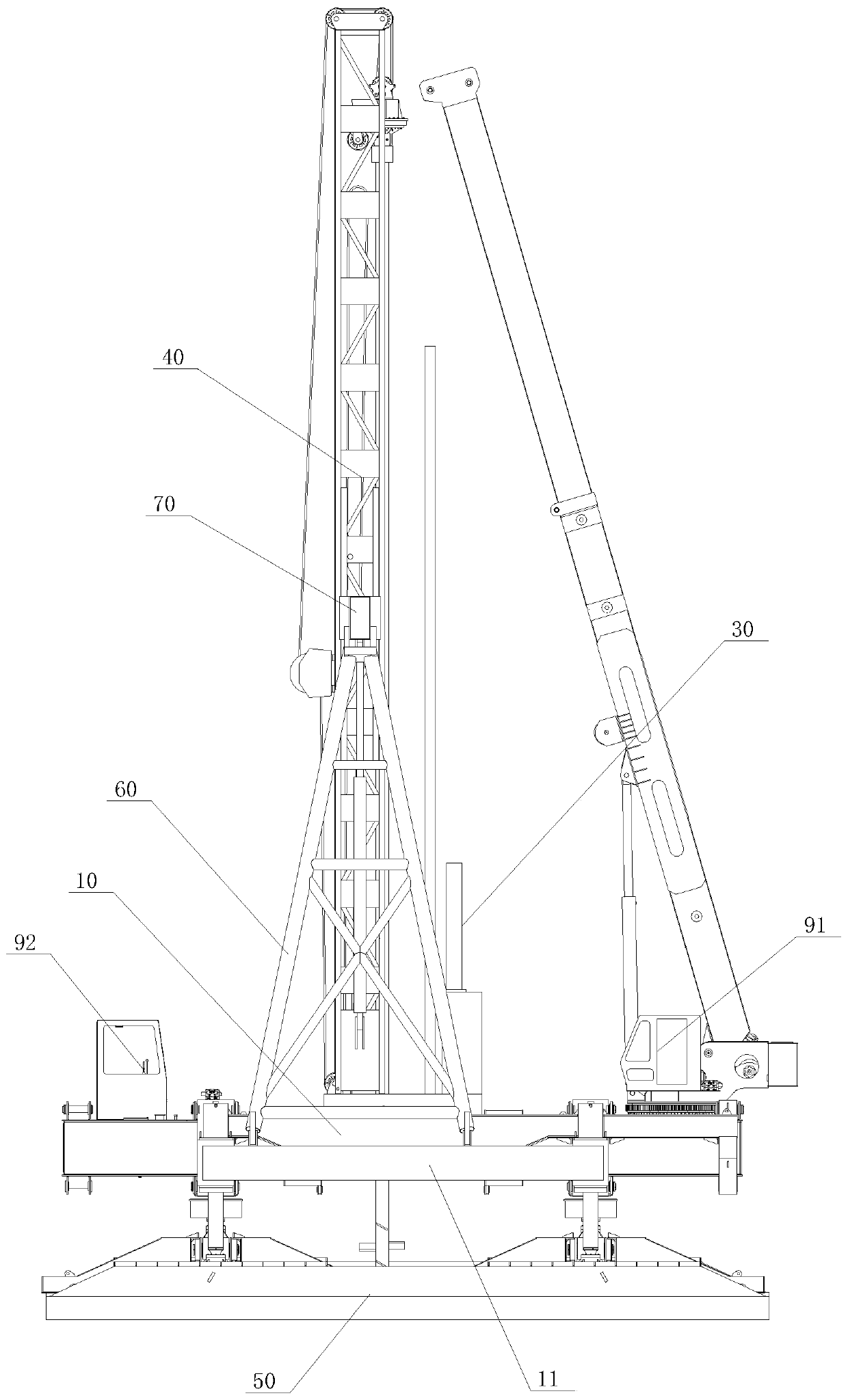

End-supporting variable-amplitude stirring and pile pressing integrated machine as well as construction method thereof

The invention discloses an end-supporting variable-amplitude stirring and pile pressing integrated machine as well as a construction method thereof. The construction method comprises the following steps: step 1, a piling machine is put in place; step 2, the inclination angle is adjusted; step 3, a cement mixing pile is constructed; step 4, a cored pile is mounted; and step 5, the pile pressing operation is performed. The construction method has the beneficial effects that the inclination angle of a cored mixing pile can be accurately controlled by adjusting the inclination angle of a verticalperpendicular axis between a tower frame and a main machine platform, and then the precise construction of the cored mixing pile at the set inclination angle can be achieved. The integrated machine comprises the main machine platform, a rotating support, a rotating shaft, a hydraulic pile pressing mechanism, a mixing and pile drilling mechanism, a moving mechanism, a first telescopic inclined supporting rod and a second telescopic inclined supporting rod. The integrated machine has the beneficial effects that through the telescopic control of the first telescopic inclined supporting rod and the second telescopic inclined supporting rod, both the hole drilling inclination angle of the mixing and pile drilling mechanism and the pile pressing inclination angle of the hydraulic pile pressing mechanism can be adjusted, and then the inclination angle of the cored mixing pile can be controlled; and meanwhile, the relatively high concentricity can be kept.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

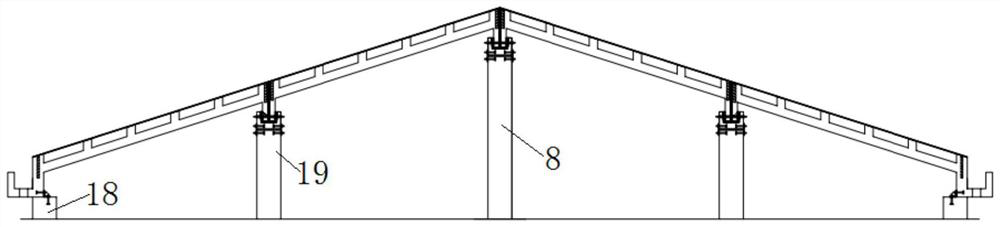

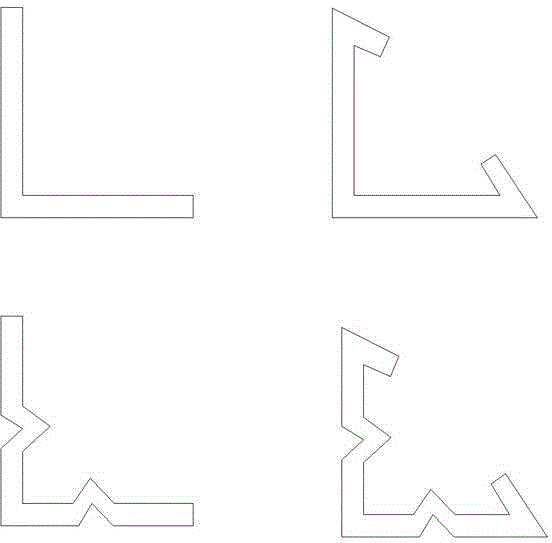

Fabricated pitched roof structure and construction method thereof

PendingCN113293907ASimple structureEasy assembly and constructionBuilding roofsRoof coveringShaped beamButt joint

The invention discloses a fabricated pitched roof structure and a construction method thereof. The fabricated pitched roof structure comprises two pitched roof bodies, and the top ends of the two pitched roof bodies are in butt joint to form a ridge; L-shaped beams are arranged at the upper end and the lower end of the pitched roof bodies correspondingly, the upper ends of the L-shaped beams are fixed to the ends of the pitched roof bodies, and the lower ends of the L-shaped beams vertically extend to be fixedly connected with stand columns, wherein the L-shaped beams at the top ends of the two pitched roof bodies are spliced to form a ridge beam, and the lower end of the ridge beam is fixedly connected with a first stand column through a prefabricated groove beam; the L-shaped beams at the lower ends of the pitched roof bodies are fixedly connected with a second stand column. According to the fabricated pitched roof structure, the L-shaped beams are arranged at the two ends of the pitched roof bodies, the L-shaped beams at the two ends of the two pitched roof bodies with the tops in butt joint are spliced to form the ridge beam, the ridge beam is fixed to the stand columns through the prefabricated groove beam, and the L-shaped beam at the lower end is fixedly connected with the stand column; block prefabricated structural members are adopted, the requirement for factory prefabrication is met, construction efficiency is high, on-site formwork erecting is not needed, energy is saved, environment friendliness is achieved, and structural integrity is good.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and construction method of half-prefabricated assembled comprehensive pipe gallery

InactiveCN108166525ALight weightSolving prefab assembly challengesArtificial islandsCeramic shaping apparatusLap jointEngineering

The invention provides a half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and a construction method of the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery comprises a plurality of comprehensive pipe gallery bodies, wherein each comprehensive pipe gallery body is formed by splicing a cast-in-situ baseplate and an upper prefabricated pipe gallery; U-shaped dowel bars I are reserved on the sides, facing the corresponding upper prefabricated pipe gallery, of the two ends and themiddle of each cast-in-situ baseplate; U-shaped dowel bars II which are matched with the U-shaped dowel bars I in position are arranged on each upper prefabricated pipe gallery; and all the cast-in-situ baseplates and upper prefabricated pipe galleries are connected in a staggered lap-joint manner through the U-shaped dowel bars I and the U-shaped dowel bars II. The construction method comprisesthe following steps: after the manufacturing of prefabricated components as well as the positioning and setting-out operation, binding steel bars of the cast-in-situ baseplates, casting the cast-in-situ baseplate, and carrying out curing and demolding; and then, assembling the prefabricated components, mounting steel bars and mold plates at the splicing positions, and carrying out concrete pouringat the cast-in-situ parts, so as to form the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery provided by the invention integratesthe advantages of both the prefabrication and cast-in-situ processes; not only can the own weights of the prefabricated components be reduced through reasonable splitting and the hoisting constructionbe facilitated, but also all the prefabricated components can be connected as a whole through the cast-in-situ hidden beams; and under the premise that the overall bearing capacity and the deformability of the comprehensive pipe gallery bodies are not reduced, the problem about how to prefabricate and assemble a multi-cabin gallery and a non-standard gallery segment can be solved.

Owner:中建五局第三建设有限公司

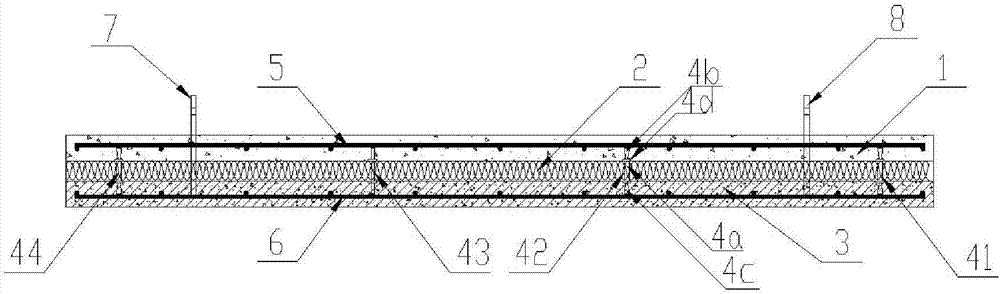

Fabricated self-heat-preservation metal decorative outer wall board

ActiveCN107237471AEfficient self-insulation functionLower requirementCovering/liningsFlooringPorosityMetal sheet

The invention discloses a fabricated self-heat-preservation metal decorative outer wall board which comprises a metal shell and a wall body. The metal shell forms the outer surface of the outer wall board, and the wall body is poured into the metal shell; after being hardened, the metal shell and the wall body are combined into the overall outer wall board; the metal shell is of a groove-shaped half-surrounded structure, and the groove opening edge of the metal shell is inwards folded by 90 degrees; the length of the metal shell is equal to that of the wall body, the width of the side face is 30-80 mm, and the metal shell is made of 0.8-2.0 mm metal sheets with decorative and water-proof effects; and the side where the metal shell is located serves as the outer side of the wall body, and the wall body sequentially comprises 30-100 mm thick light high-specific-strength high-porosity concrete, a 0-50 mm heat-preservation layer and 100-160 mm thick light high-specific-strength low-porosity concrete from outside to inside. According to the outer wall board, the problems that in a current building wall board, the self-weight is large, the water-proof effect is poor, the heat-preservation effect is poor, and assemblage is difficult to achieve are solved, and the functions of decoration, heat preservation, water resistance and the like are integrated, so that adoption of assembly construction of building industrialization is facilitated.

Owner:NANJING CONSTR ENG GRP +1

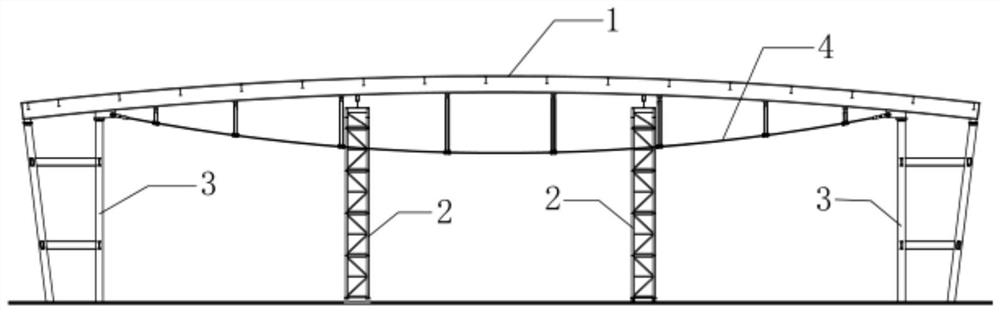

Segmented dismantling construction method of large-span beam string structure

InactiveCN112267709AThe transformation principle is clearReduce investmentBuilding repairsMechanical engineeringBreaking point

The invention discloses a segmental dismantling construction method for a large-span beam string structure. The segmental dismantling construction method comprises the following steps of arranging a plurality of breaking points on a beam string structure, and arranging supporting jig frames for supporting the beam string structure at the breaking points; dismantling secondary components, irrelevant to a transverse supporting frame system for keeping the beam string structure, on the beam string structure; cutting the beam string structure at the breaking points to form multiple sections of beam string units; disconnecting the beam string structure units from building vertical force bearing components, hoisting the beam string structure units to the ground and then disassembling the beam string structure units; and dismantling supporting jig frames. The segmented dismantling construction method is suitable for beam string structures of various space models, the conversion principle of astructure stress system in the dismantling process is clear, no special requirement is needed for a field site, safety is good, implementation performance is high, the influence on the surrounding environment is smaller, construction operation is easy, investment of large hoisting equipment and the number of supporting measures is reduced,, the construction cost is saved, and the construction cost is lower.

Owner:CHINA CONSTR SCI & IND CORP LTD

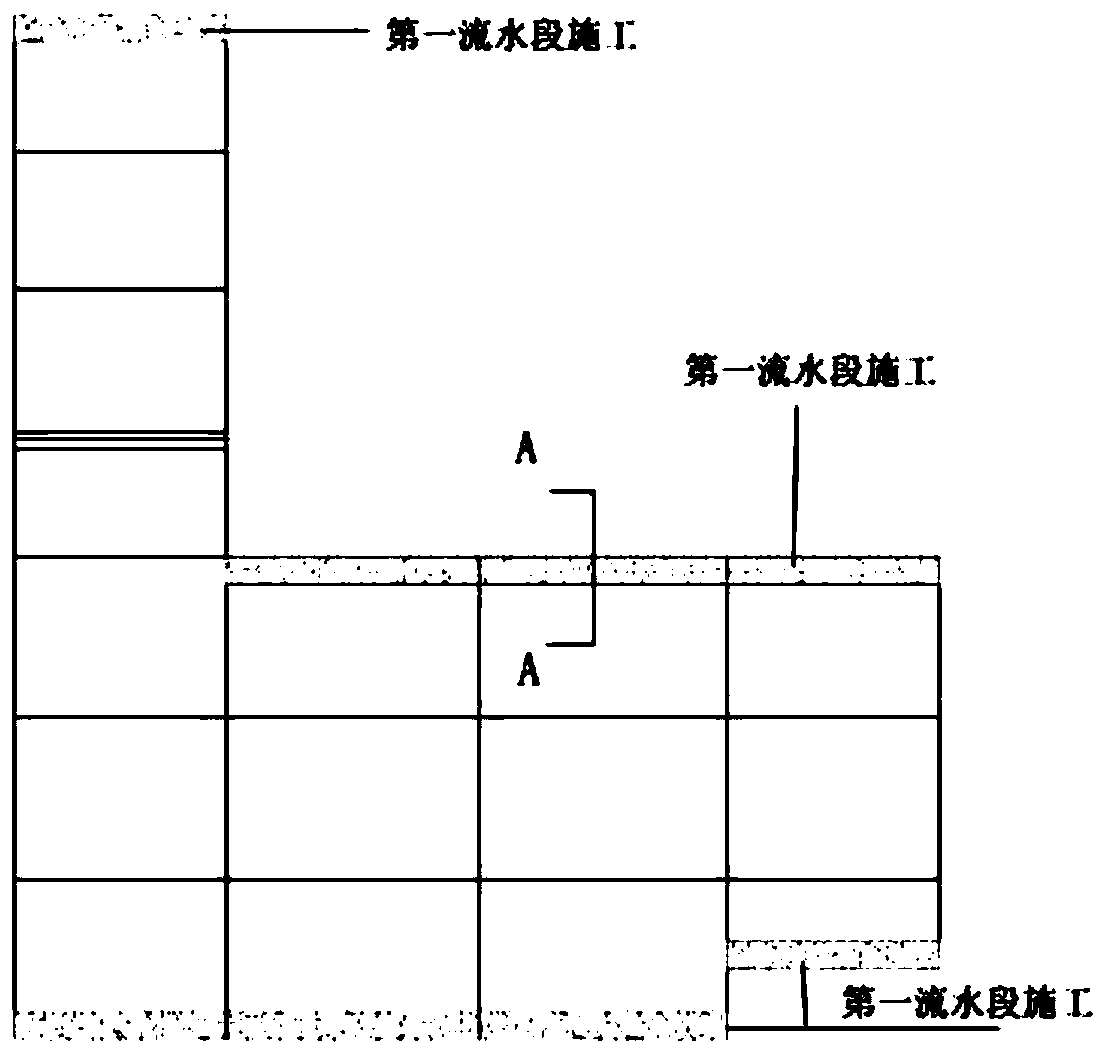

Construction method for architecture site move-out protection

ActiveCN110295765AIntegrity guaranteedStable supportProtective foundationBuilding repairsEngineeringBuilding construction

The invention discloses a construction method for architecture site move-out protection. The construction method comprises the following steps: 1) pipe jacking construction: arranging steel pipes at aposition below soil mass of a site area by a pipe jacking device to separate the soil mass of the site area up and down; 2) rail foundation jacking construction: constructing the site area in flowingsections at intervals in sequence; 3) vertical separating: separating the site area from a non-site area by a static cutting device, and cutting the site area; 4) jacking construction: performing jacking construction on the cut site area by a jack; 5) translation construction: mounting a reaction frame, and performing translation construction on the cut site area by a thrust system; and 6) hoisting construction. The construction method has the beneficial effects that the site area is effectively separated and cut by adopting an advanced technology, the protection effectiveness of the site area is ensured, and the direction is provided for site protection.

Owner:HANGZHOU MUNICIPAL CONSTR GRP CO LTD

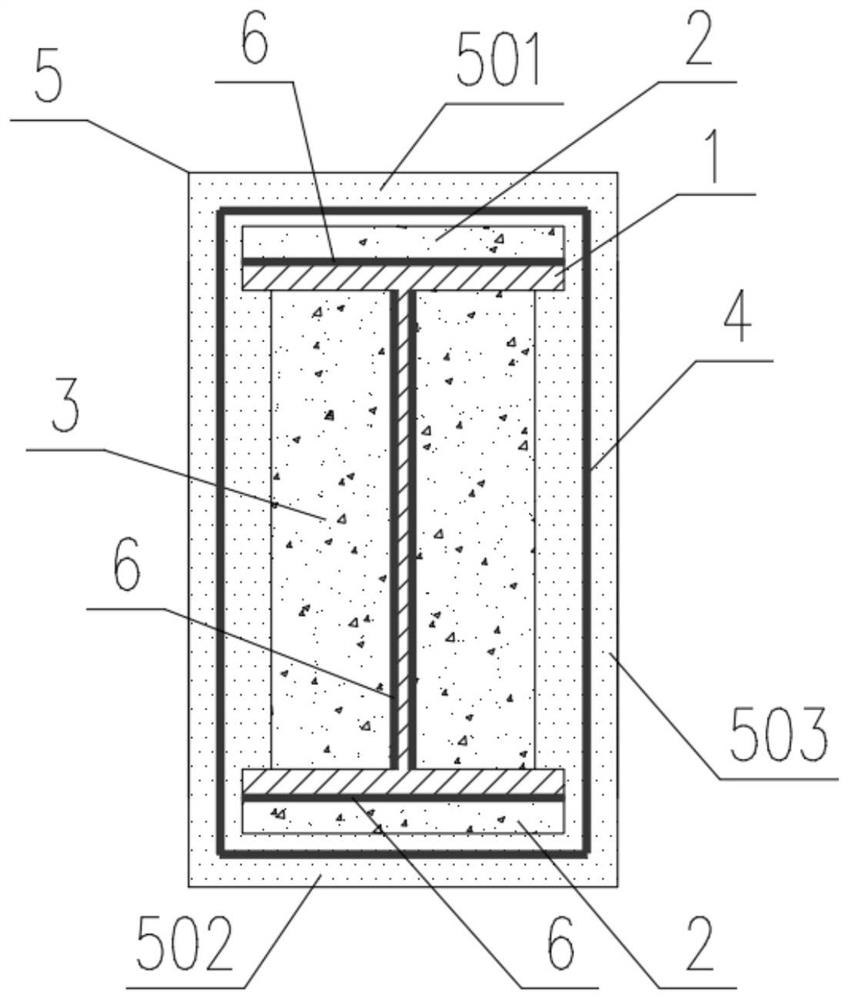

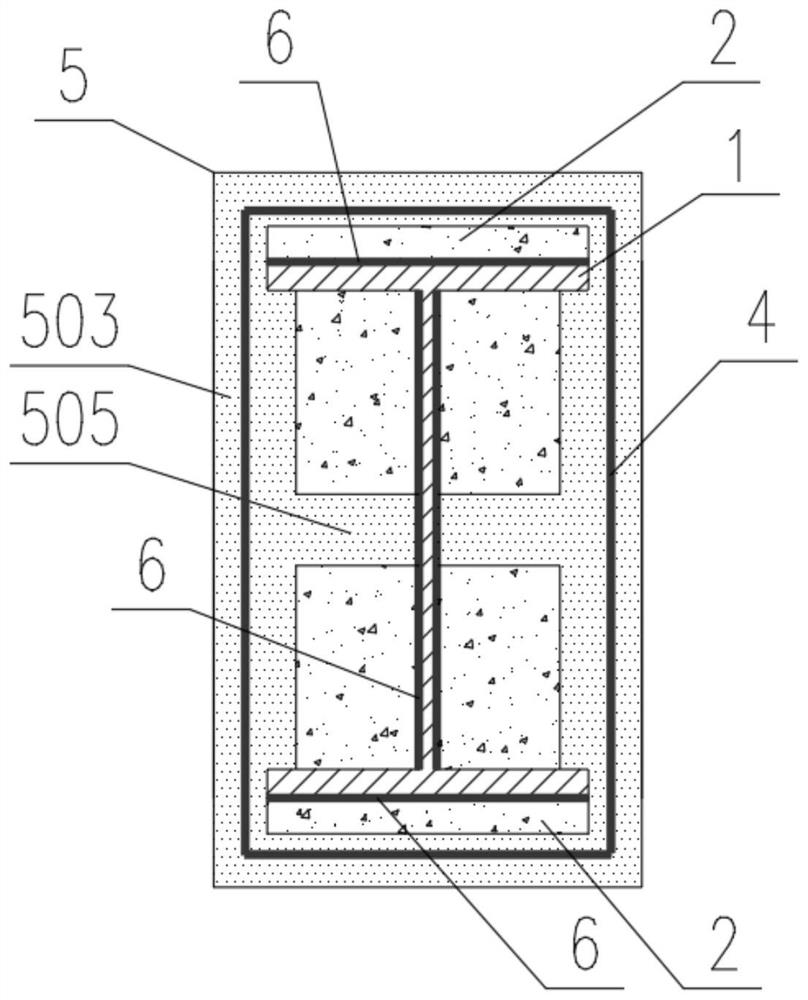

Uhpc-based I-shaped steel beam fireproof and anticorrosion structure

The invention discloses a uhpc-based I-shaped steel beam fireproof and anticorrosion structure. The uhpc-based I-shaped steel beam fireproof and anticorrosion structure comprises a first fireproof layer, second fireproof layers, an outer wrapping anti-cracking layer and a uhpc anti-corrosion layer, wherein the first fireproof layer is arranged on the top surface of an upper flange plate and the bottom surface of a lower flange plate and completely covers the width of the upper flange plate and the width of the lower flange plate; the second fireproof layers are arranged on the two sides of a web plate and completely or at least mostly cover the height of the web plate; the outer wrapping anti-cracking layer completely wraps I-shaped steel beam, the first fireproof layer and the second fireproof layers from the periphery; the uhpc anti-corrosion layer is formed by pouring uhpc on the periphery of the outer wrapping anti-cracking layer and completely wraps the outer wrapping anti-cracking layer, the I-shaped steel beam, the first fireproof layer and the second fireproof layer from the periphery. According to the uhpc-based I-shaped steel beam fireproof and anticorrosion structure, the comprehensive performance of the uhpc is brought into full play, durability is good, corrosion resistance and anti-seepage performance are good, cracking cannot occur generally, small cracks have the self-repairing capacity, and the defect that a traditional steel structure needs to be maintained every ten years in the operation and maintenance period is overcome; complete factory batch production is realized, the process is simple, and the production efficiency is high; on-site wet operation is little, and environmental protection is achieved.

Owner:重庆涛扬绿建科技有限公司

Side part support variable amplitude mixing pile pressing integrated machine and construction method thereof

The invention discloses a side part support variable amplitude mixing pile pressing integrated machine and a construction method thereof. The construction method comprises the following steps that a pile machine is in place, the tilting angle is adjusted, and a cement stirring pile is constructed; a core-added pile is installed; and pile pressing is conducted. According to the construction method,by adjusting the tilting angle of a vertical axis between a tower frame and a main machine platform, the tilt angle of a core-added stirring pile is accurately controlled, and the precise construction of the core-added stirring pile with the set tilt angle is achieved; and the side part support variable amplitude mixing pile pressing integrated machine includes the main machine platform, a rotating support, a rotating shaft, a hydraulic pile pressing mechanism, a stirring and pile drilling mechanism, a moving mechanism, a support frame, a sliding seat and a variable amplitude oil cylinder. According to the side part support variable amplitude mixing pile pressing integrated machine, through the expansion control of the variable amplitude oil cylinder, the support angle of the support frame is changed, so as to adjust the drilling inclination angle of the stirring pile drilling mechanism and the pile pressing inclination angle of the hydraulic pile pressing mechanism simultaneously, the precise control of the inclination angle of the core-added stirring pile is realized, at the same time, high concentricity of the stirring pile and the core-added stirring pile is maintained, and construction quality and safety are improved.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

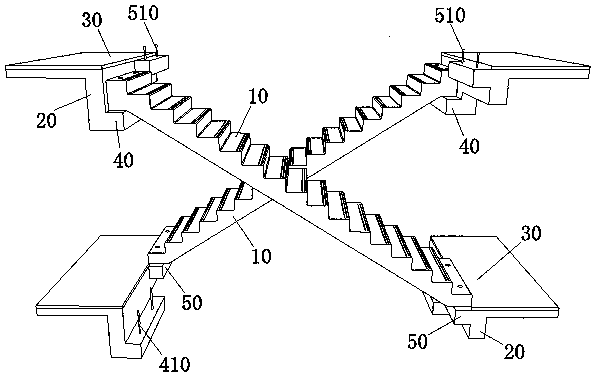

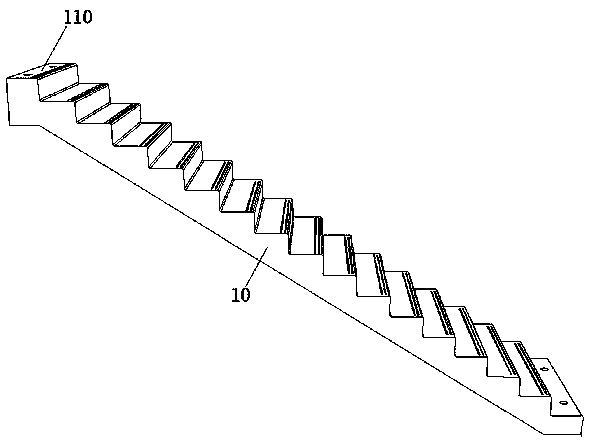

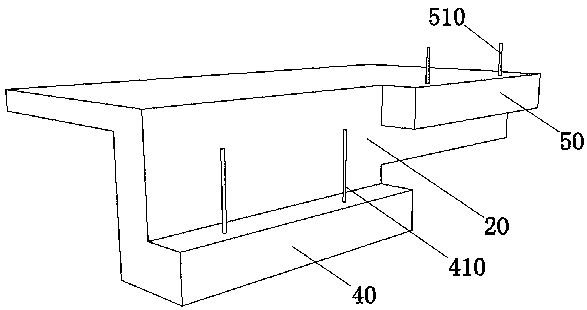

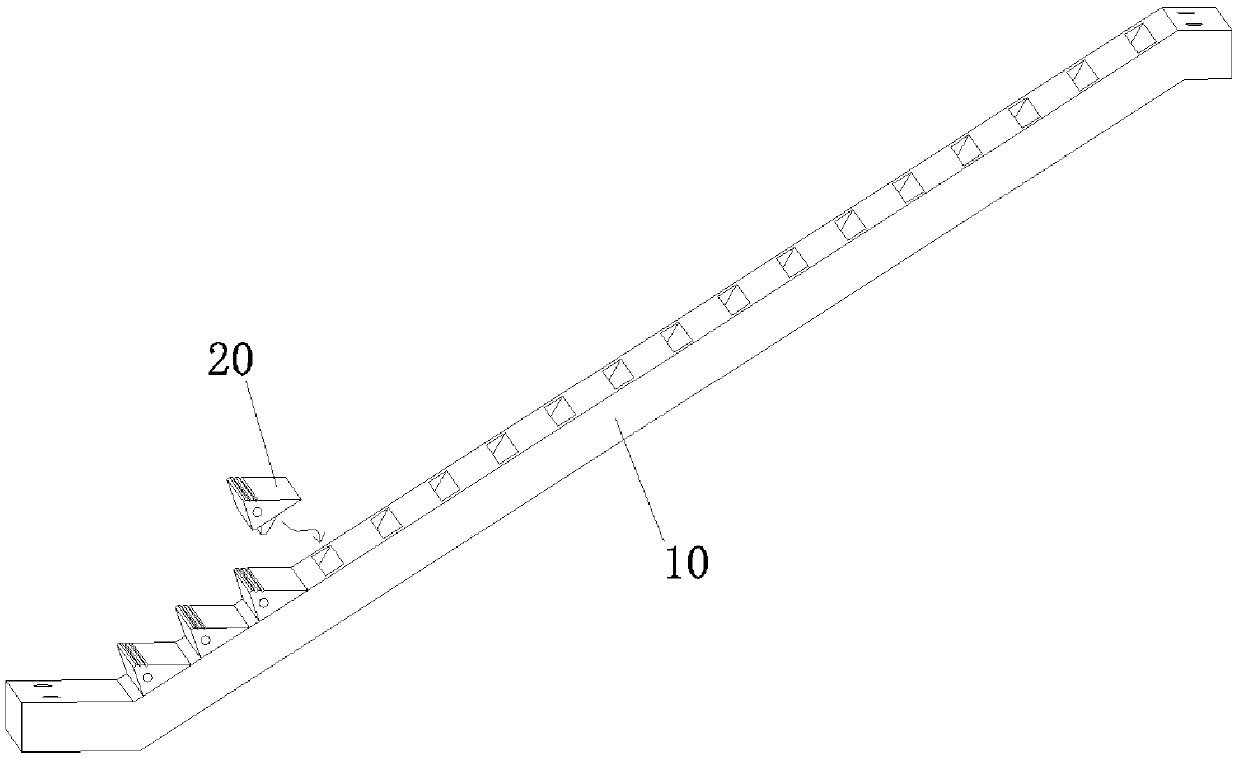

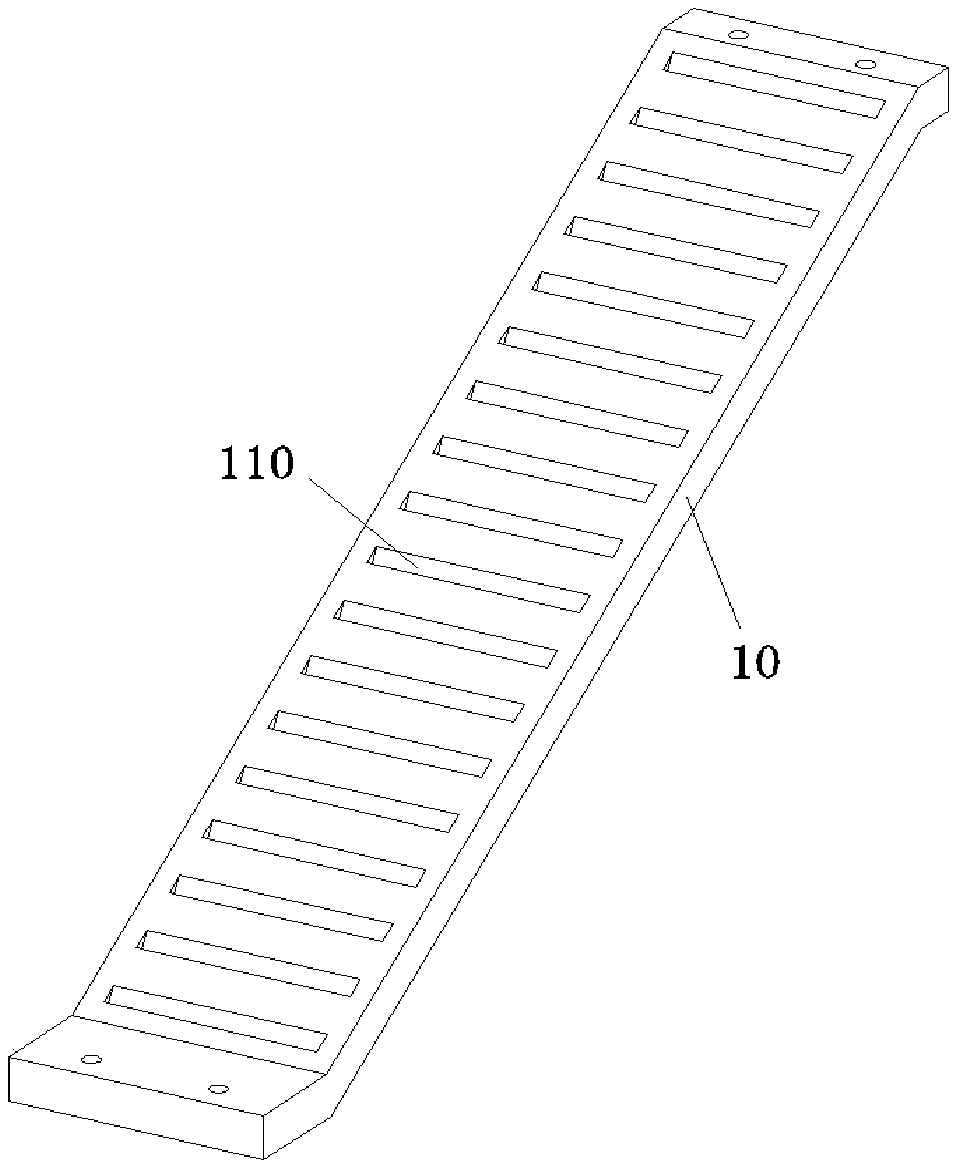

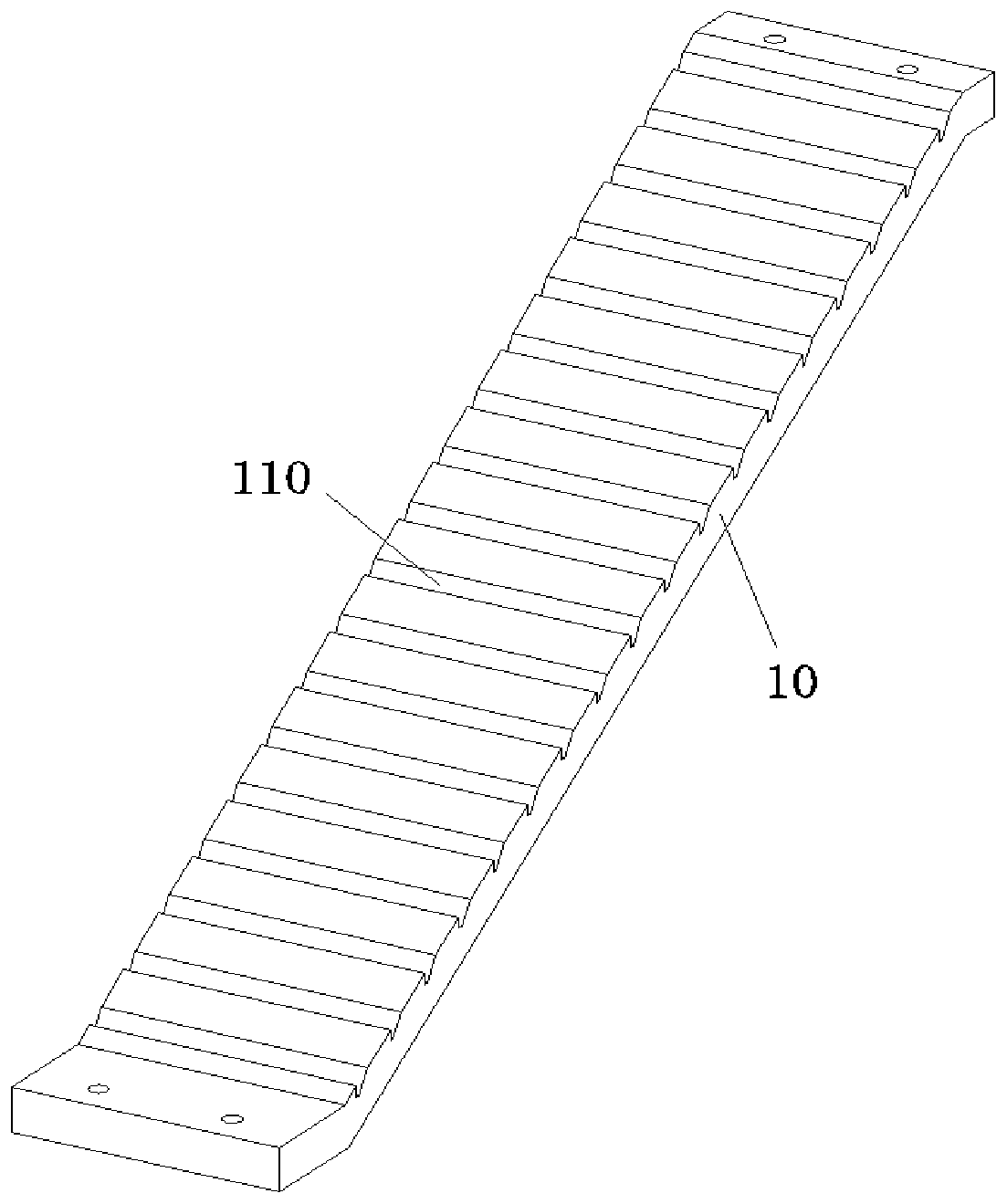

Combined prefabricated stairway

The invention relates to the technical field of building stairs, in particular to a combined prefabricated stairway. The combined prefabricated stairway includes a prefabricated bottom board and a plurality of stepping blocks arranged on the prefabricated bottom board; and the prefabricated bottom board includes a plurality of clamping grooves formed in the prefabricated bottom board at intervals,the stepping blocks include stepping block bodies and clamping keys fixedly arranged on the lower parts of the stepping block bodies, lightening holes are formed in the stepping block bodies, and theclamping keys and the clamping grooves are installed in a matched mode. According to the combined prefabricated stairway, the problem that stairway board production and transportation costs are increased due to an overweight whole prefabricated stairway can be avoided, the connection structure is simple, transportation and hoisting construction are convenient, and the project cost is saved.

Owner:ELITE ARCHITECTURAL CO LTD

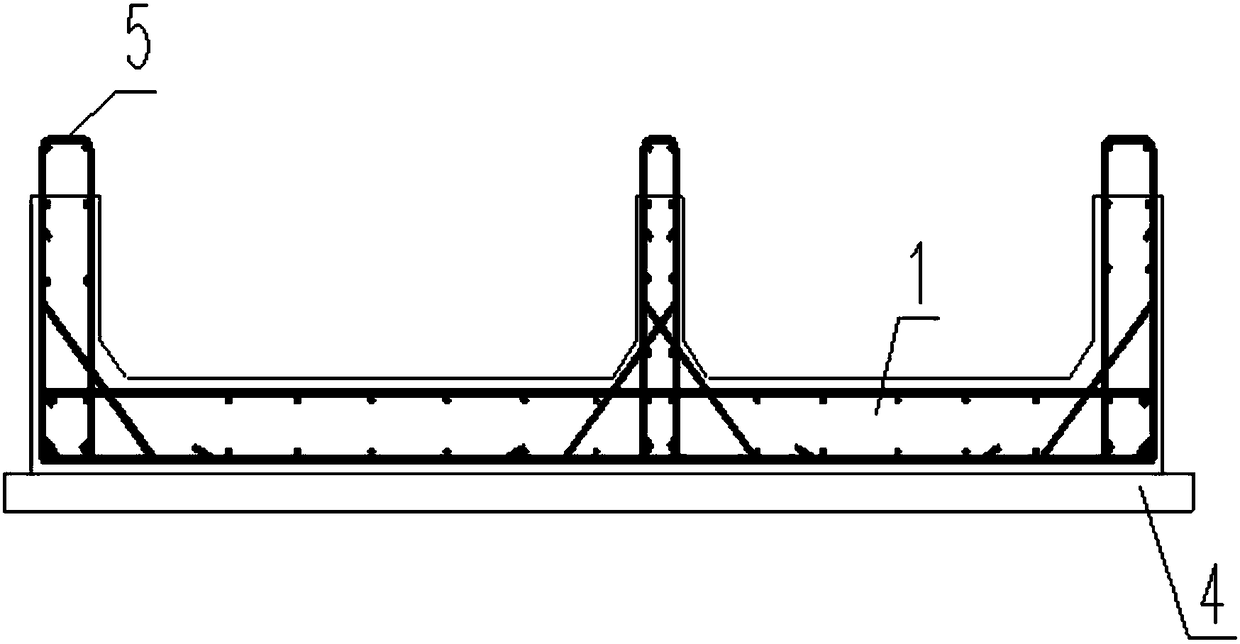

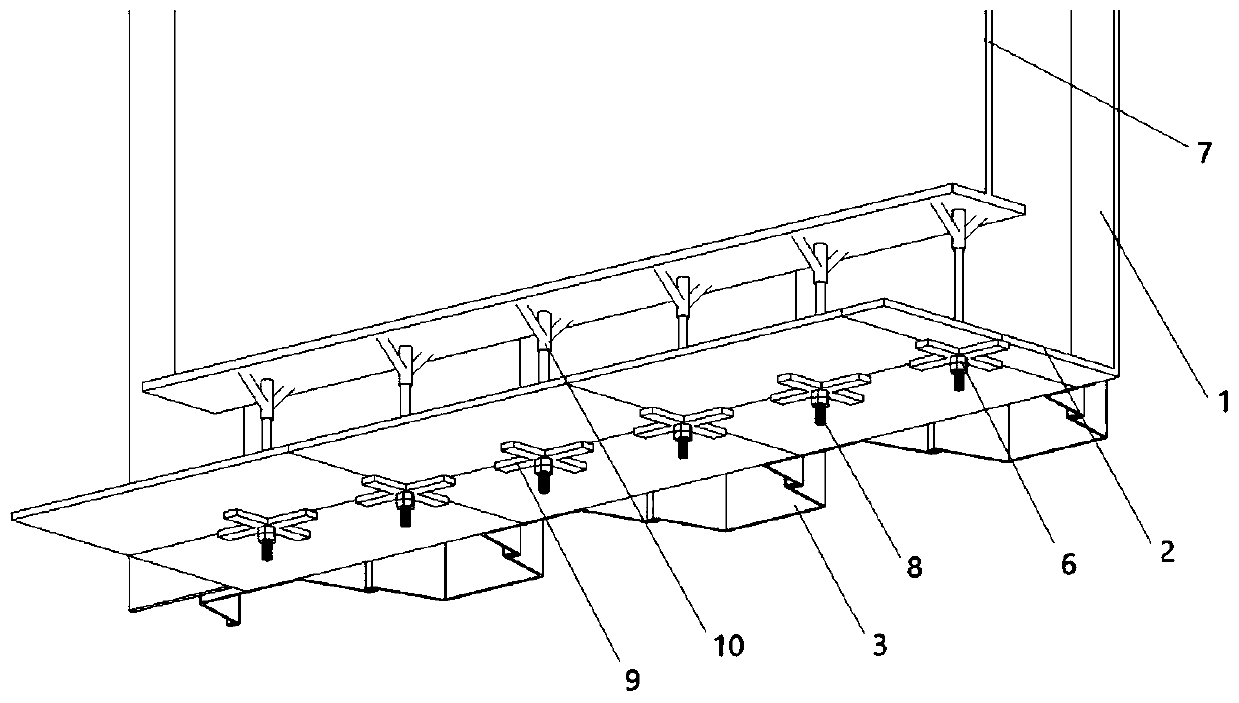

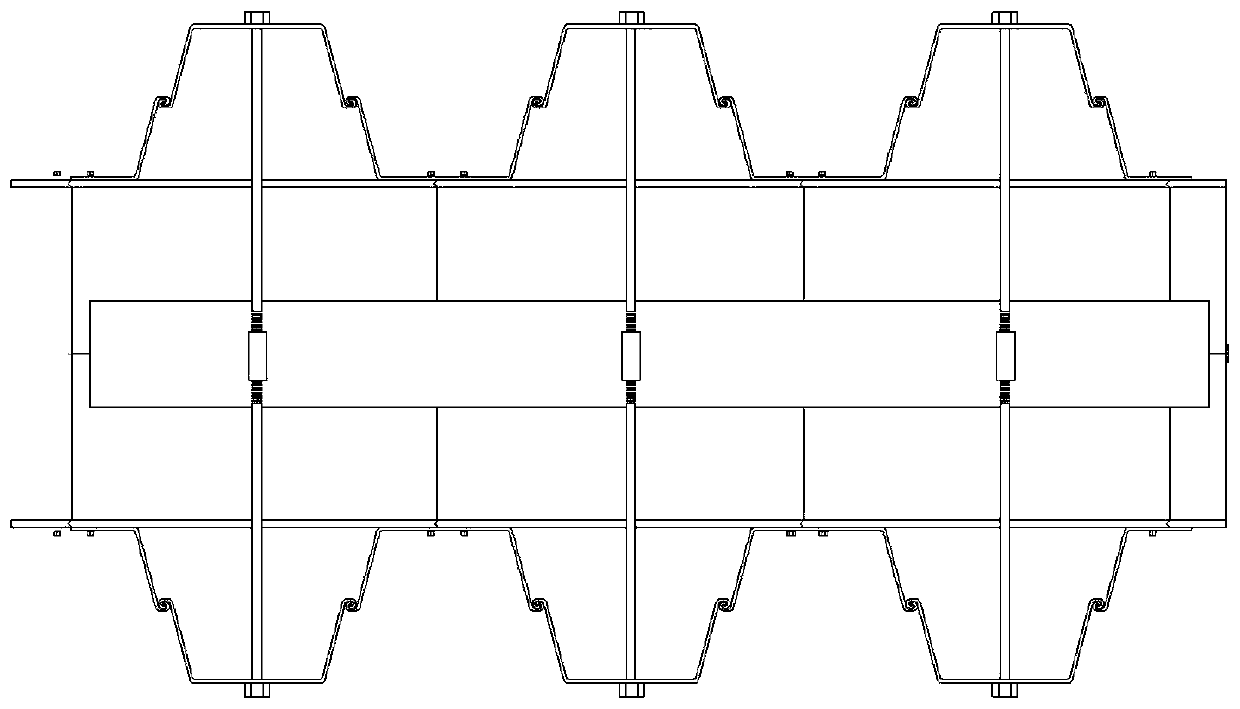

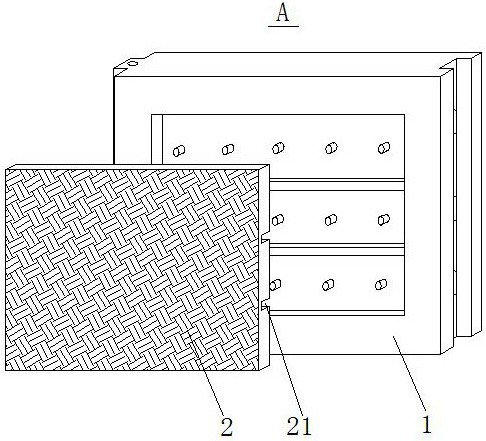

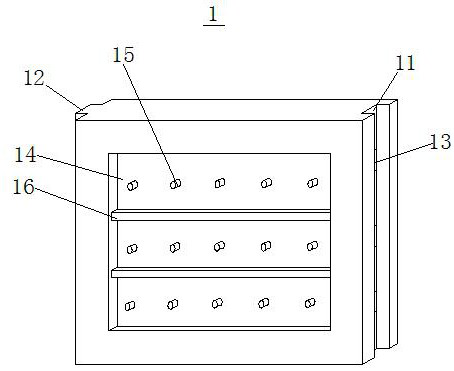

Ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcing device and constructing method

ActiveCN110714613AGuaranteed accuracyEasy to assemble and disassembleForms/shuttering/falseworksReinforced concreteButt joint

An ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcing device is composed of a plurality of reinforcing units. Each reinforcing unit comprises beam side formworks,beam bottom formworks, Larson steel plate side back edges, a round steel tying rod and a steel reinforced beam, wherein each beam side formwork and the corresponding beam bottom formwork are welded toform an integrated L-shaped structure, the two L-shaped structure are in butt joint to form a U-shaped structure, the outer portions of the beam side formworks are fixed to the Larson steel plate side back edges through high-strength bolts, the tops of the Larson steel plate side back edges on the two sides of the U-shaped structure are connected through the round steel tying rod, the steel reinforced beam is placed in the U-shaped structure, a reserved hole is formed in the joint of the two beam bottom formworks at the bottom of the U-shaped structure, a Y-shaped mechanical sleeve is weldedto the bottom of the steel reinforced beam, a cross-shaped fastener is arranged on the lower side of the reserved hole of the beam bottom formworks, and the mechanical sleeve is connected with the cross-shaped fastener through reverse hoisting bolts. The invention further discloses a constructing method of the ultra-high large-span steel reinforced concrete cast-in-place beam formwork reinforcingdevice.

Owner:CHINA FIRST METALLURGICAL GROUP

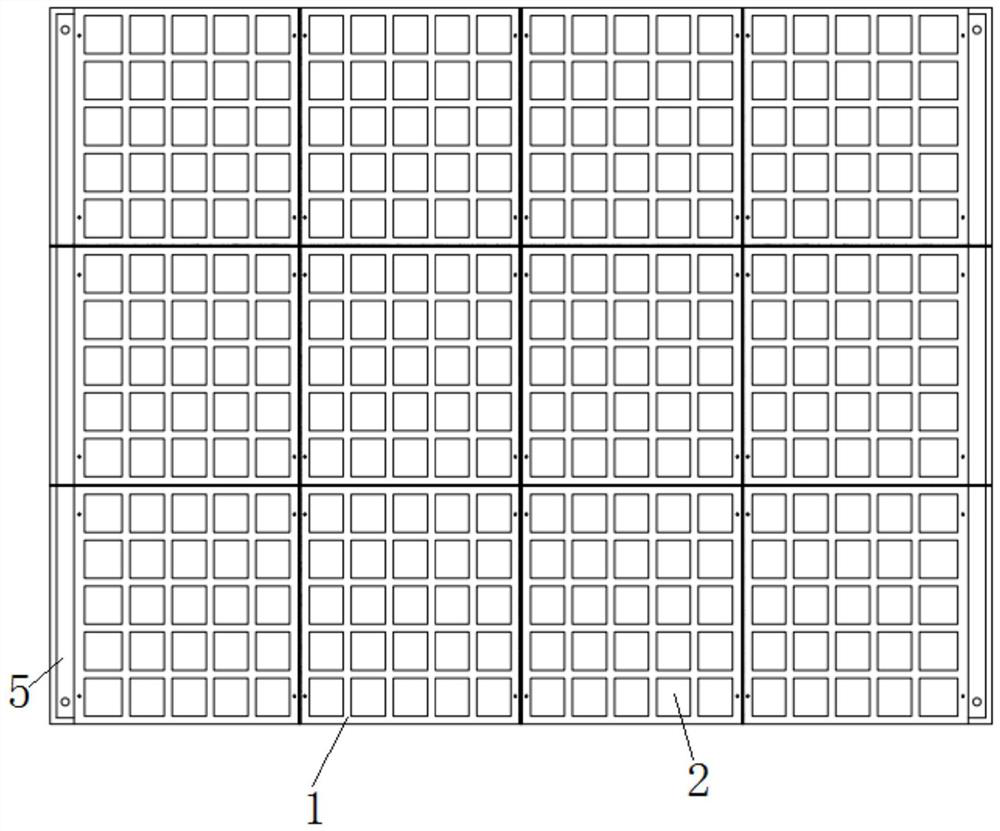

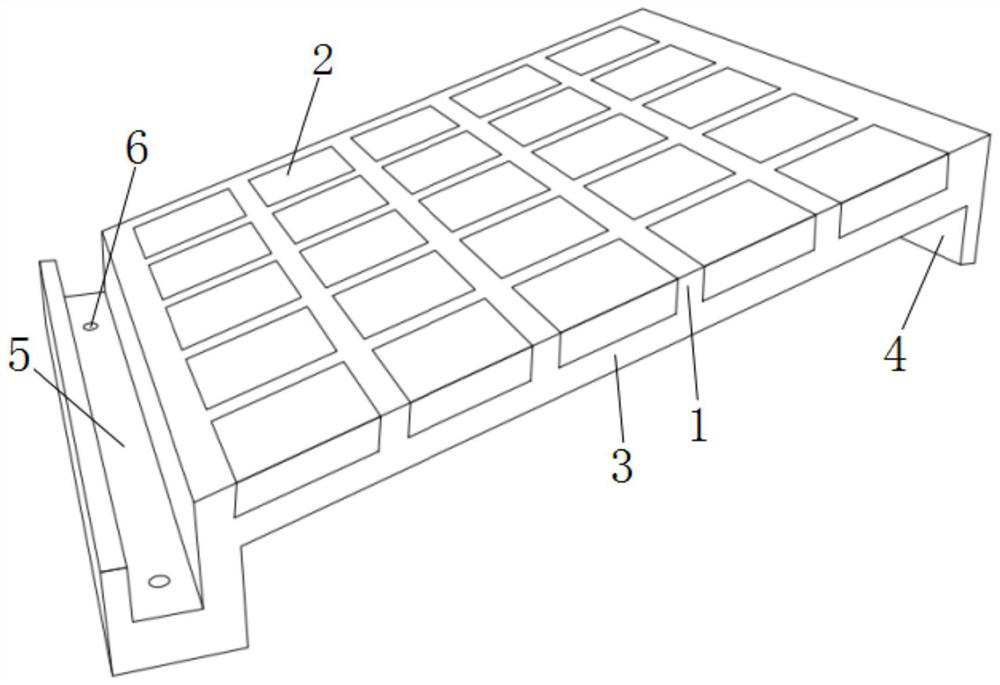

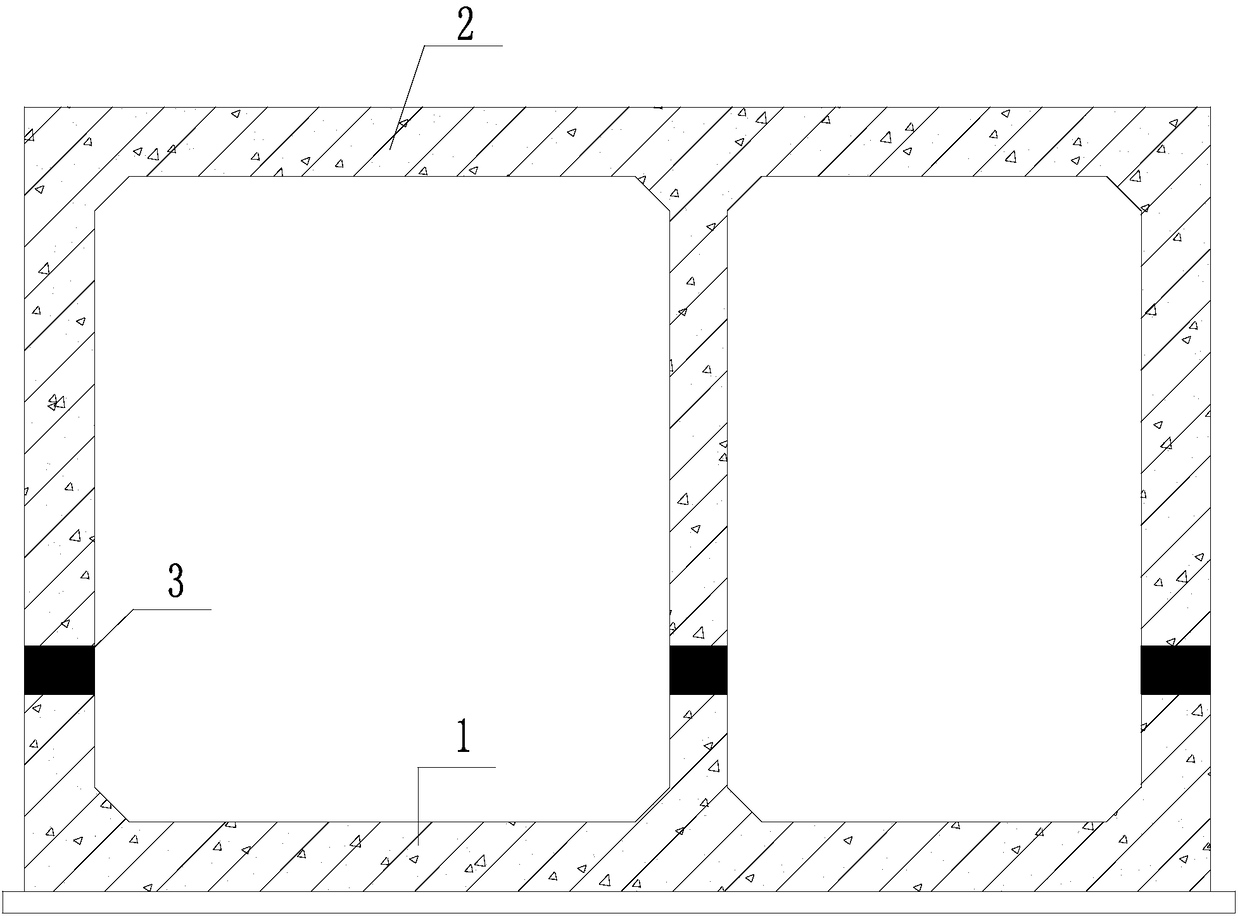

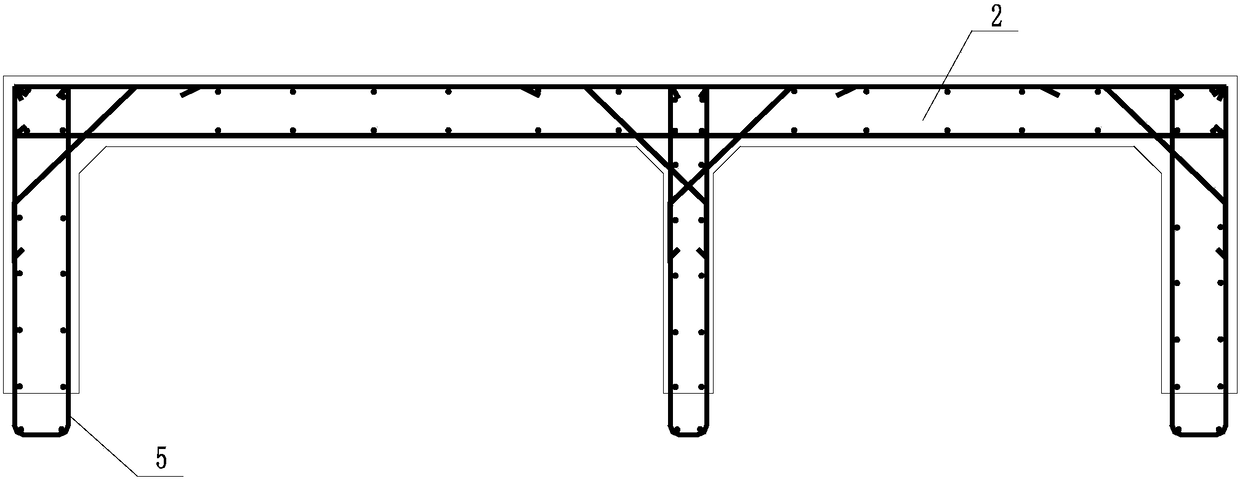

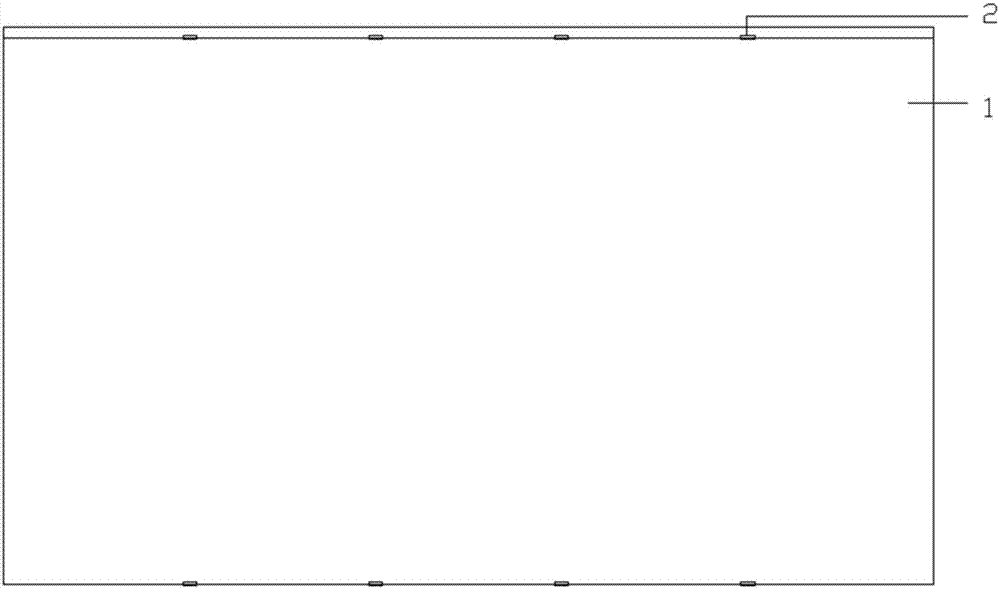

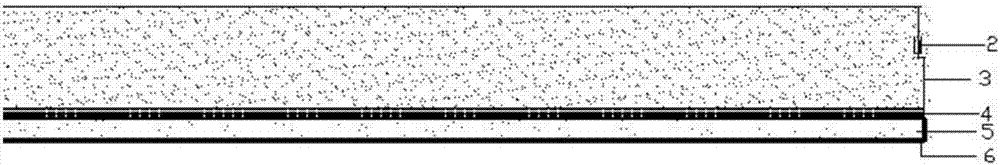

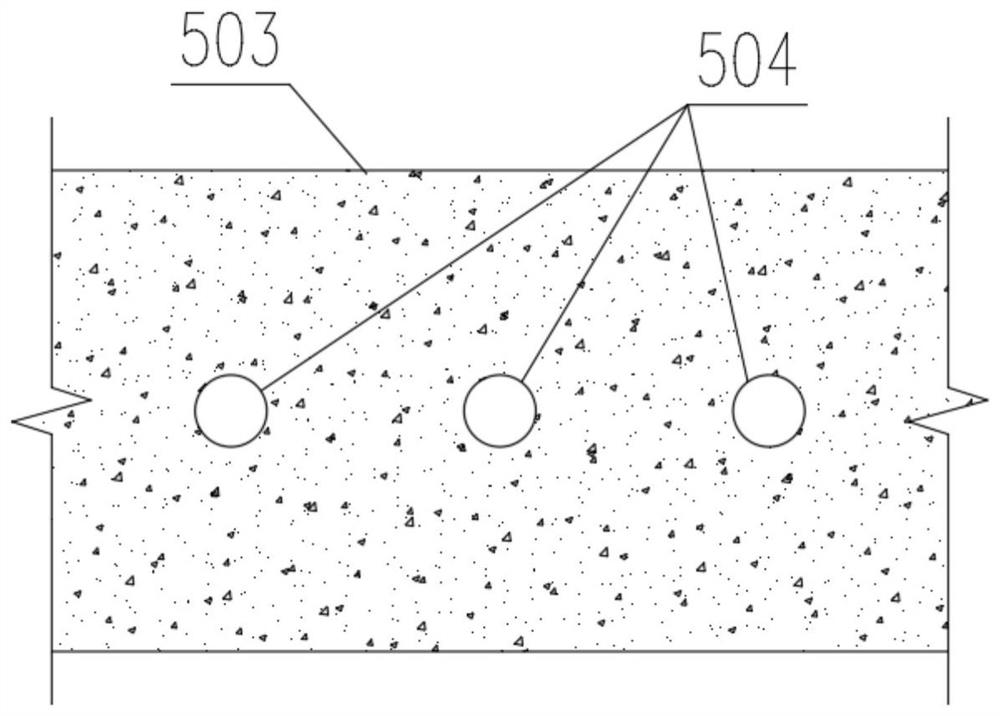

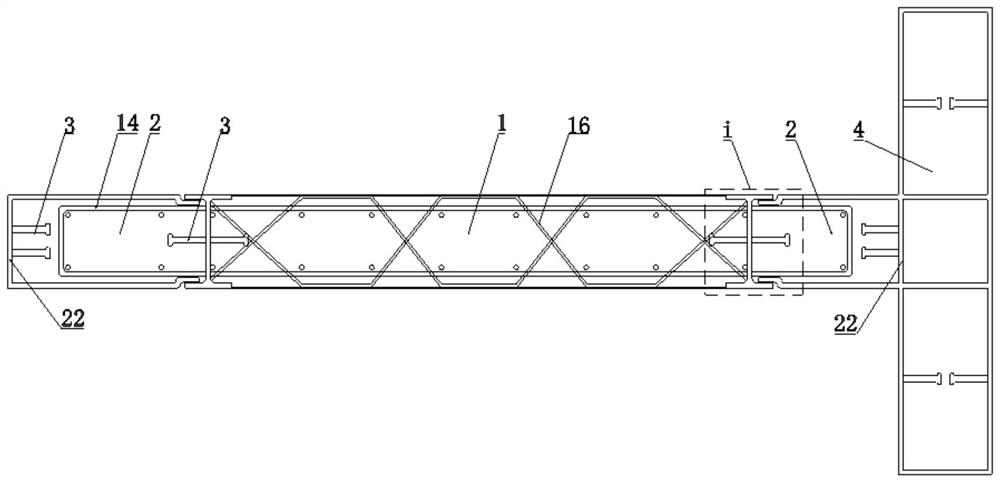

Prefabricated internally-filled concrete wallboard and manufacturing method thereof

InactiveCN112196177ALose weightImprove the firmness of the connectionMouldsHeat proofingReinforced concreteArchitectural engineering

The invention discloses a prefabricated internally-filled concrete wallboard and a manufacturing method thereof. The prefabricated internally-filled concrete wallboard comprises a wallboard body formed by pouring reinforced concrete, wherein the wallboard body is composed of a prefabricated concrete base plate and a heat preservation filling plate; the heat preservation filling plate is installedon the inner side of the prefabricated concrete base plate, and an alkaline mesh layer is glued to the outer surface of the heat preservation filling plate; and the inner surface of the prefabricatedconcrete base plate is coated with a mortar plastering layer. The manufacturing method comprises the following steps of 1, steel bar bundling; 2, anchor rod welding; 3, steel pipe placing; 4, pouring;5, steel pipe taking out; 6, curing; 7, hoisting; and 8, heat preservation filling plate installing. According to the prefabricated internally-filled concrete wallboard and the manufacturing method thereof, hoisting construction is convenient, and the overall connectivity of the wallboard is good.

Owner:山东汇富建设集团建筑工业有限公司

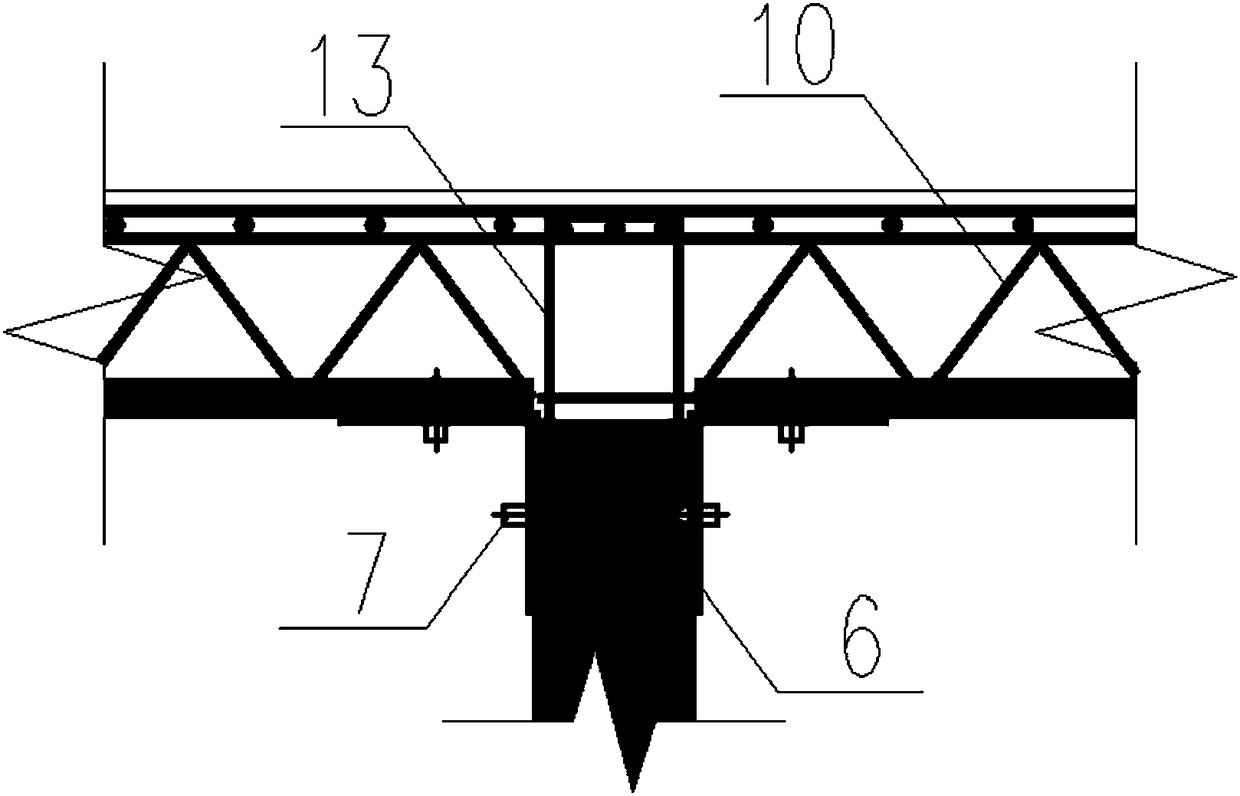

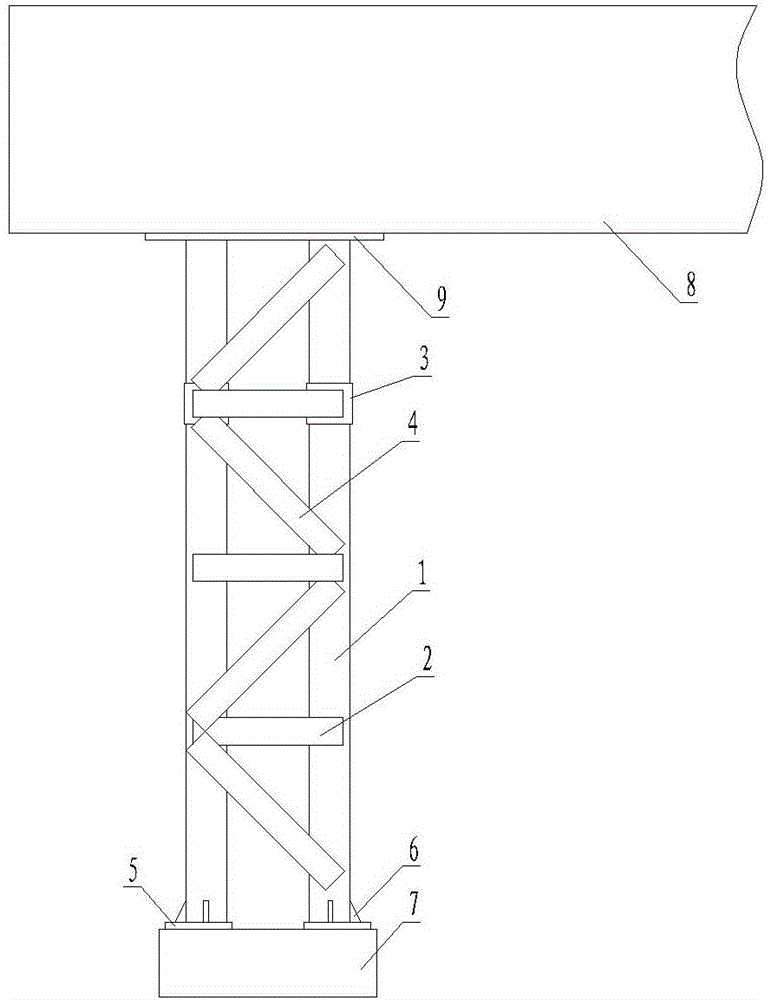

Assembled steel integrated bridge

ActiveCN104612039ALose weightReduce the amount of constructionBridge structural detailsBridge materialsFull bridgeRoad surface

The invention discloses an assembled steel integrated bridge which comprises a steel pier stud fixed to a bearing platform or a pile foundation, a cover beam arranged at the top end of the steel pier stud, and a girder arranged on the cover beam. The assembled steel integrated bridge is characterized in that the structure of the steel pier stud comprises four or five steel stand columns and energy consumption components connecting the steel stand columns, and each steel stand column is formed by connecting a plurality of sections of steel stand column bodies through connecting pieces. The assembled steel integrated bridge has the advantages that all parts of the bridge are prefabricated and finished in a factory and assembled on the field, the construction speed is increased, the engineering quality is effectively ensured, and traffic interference on an existing route is relieved; a connecting assembly is used for connecting the pier stud and the cover beam, flexibility of the steel pier stud is utilized, a support and part of expansion joints can be removed, and the comfort of running of vehicles on the road surface is greatly improved; the whole bridge is of a steel structure, the dead weight of the bridge is greatly reduced, field lifting construction is convenient, the construction amount of a bridge pier is reduced, and the vertically-integral light weight of the structure of the bridge is achieved.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

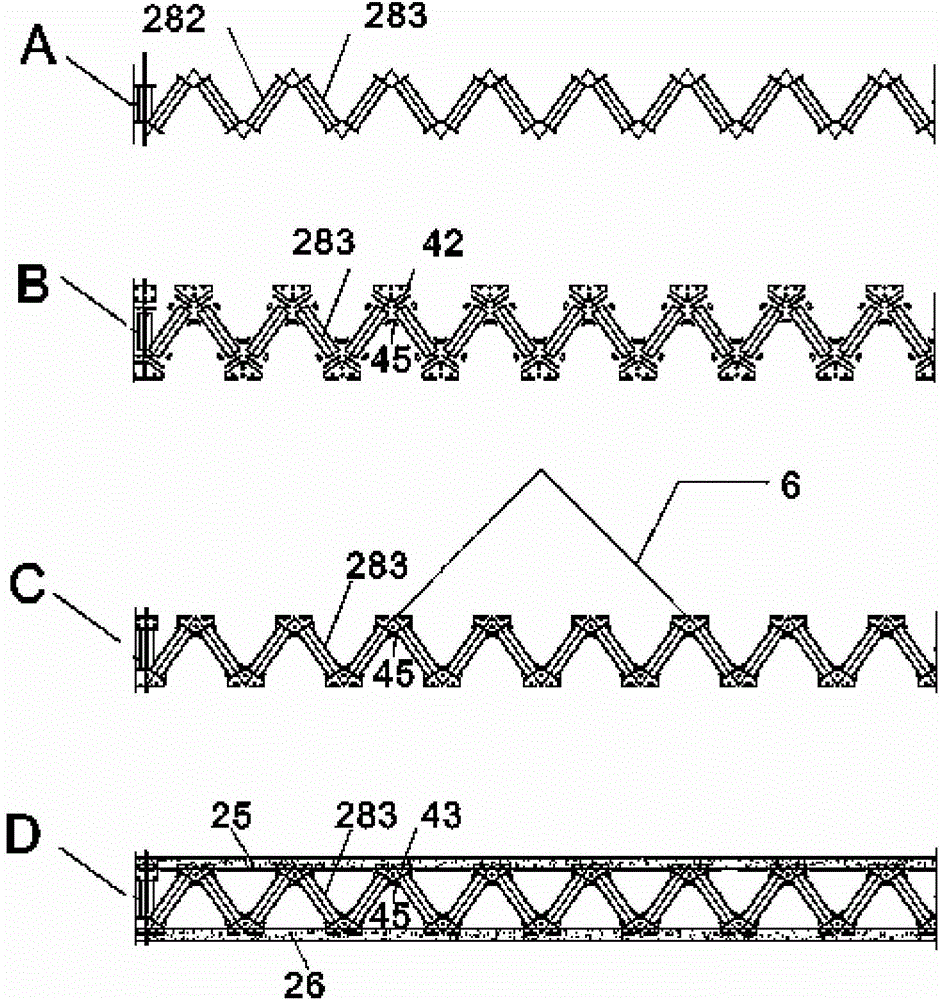

Self-reset cross-laminated bamboo wallboard (CLB) swing wall and preparation method thereof

InactiveCN110042981AExcellent flexibilityExcellent toughnessProtective buildings/sheltersShock proofingPre stressPositive pressure

The invention discloses a self-reset cross-laminated bamboo wallboard (CLB) swing wall and a preparation method thereof. The self-reset CLB swing wall comprises a foundation steel beam, a CLB arrangedon the foundation steel beam and friction energy-dissipation devices arranged at the corners of the bottom end of the CLB; each friction energy-dissipation device comprises a first friction energy dissipater and a second friction energy dissipater which are symmetrically arranged and connected. During preparation, the CLB is arranged on the foundation steel beam, the corners of the bottom end ofthe CLB are removed, and the friction energy-dissipation devices are mounted. According to the swing wall, firstly, the CLB is arranged on the foundation steel beam, unbonded pre-stressed tendons andthe friction energy-dissipation devices are arranged, thus in the swing process, the bottom is not prone to being collided and damaged, injury and deformation of the structure can be controlled, the continuous and stable positive pressure can be provided in the swing process, friction force is not lowered in the swing process, and the energy dissipation ability is improved; and in addition, the preparation method of the swing wall is easy and convenient, and operability is high.

Owner:SOUTHEAST UNIV

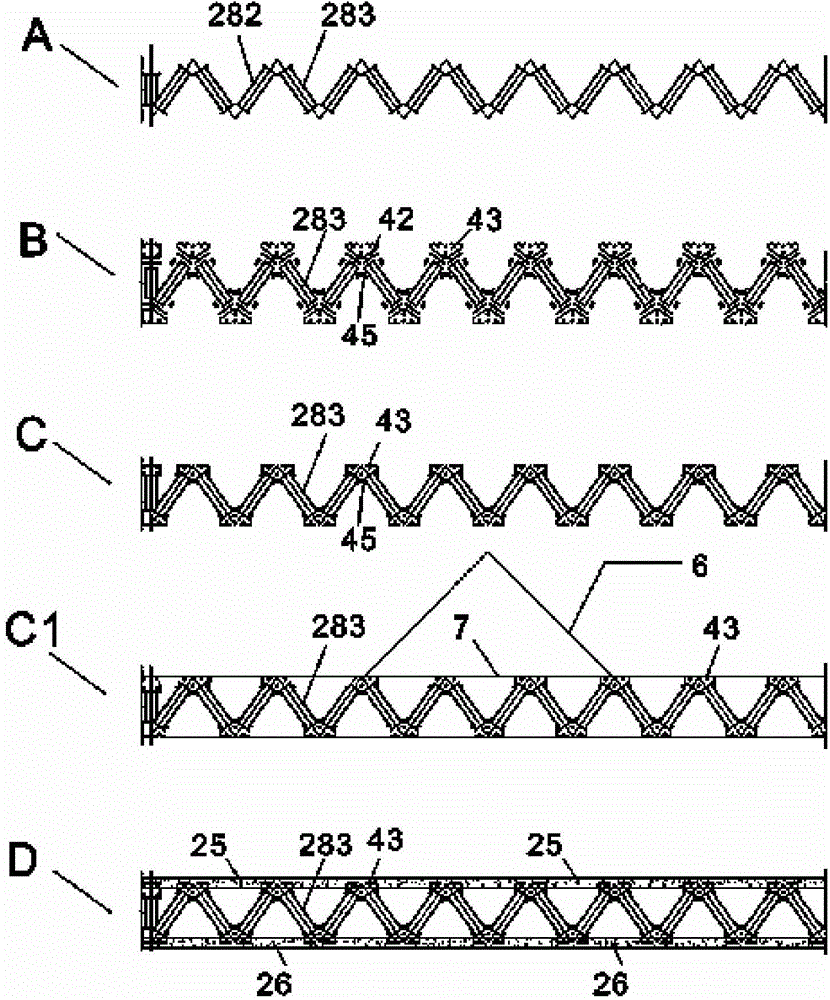

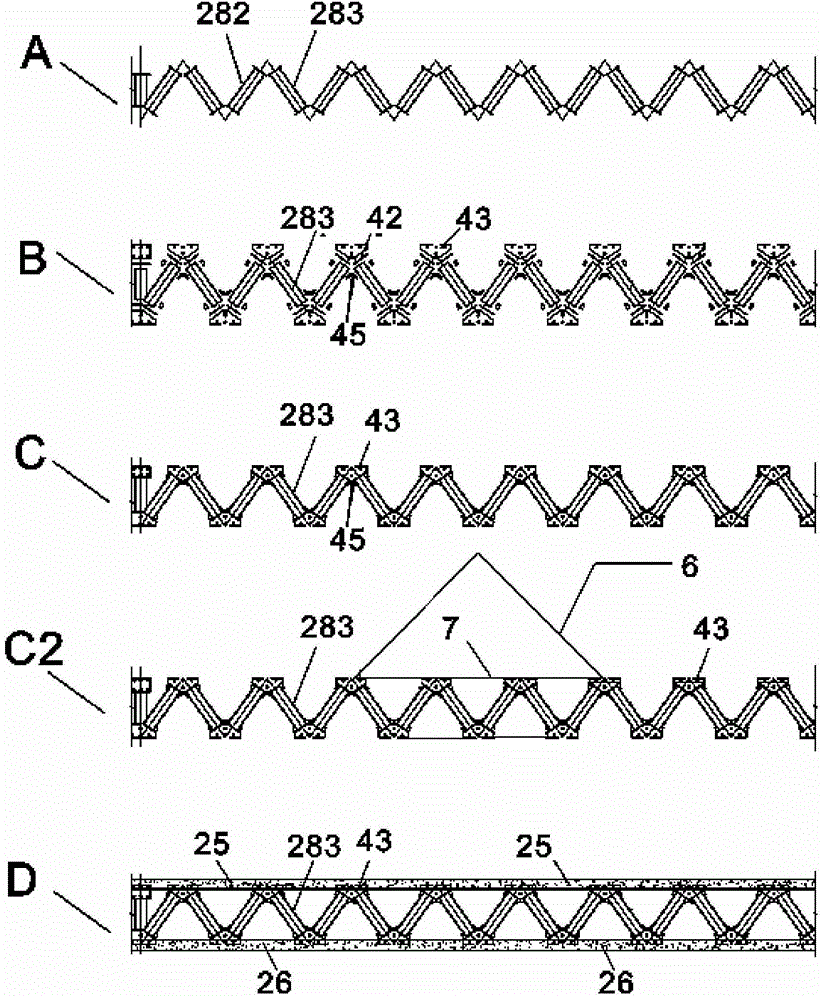

Truss element method without chord members and combined node bridge

ActiveCN104583496AEnsure integrityEnsure safetyTruss-type bridgeLoad-supporting elementsEngineeringShear force

Owner:SHENZHEN UNIV +1

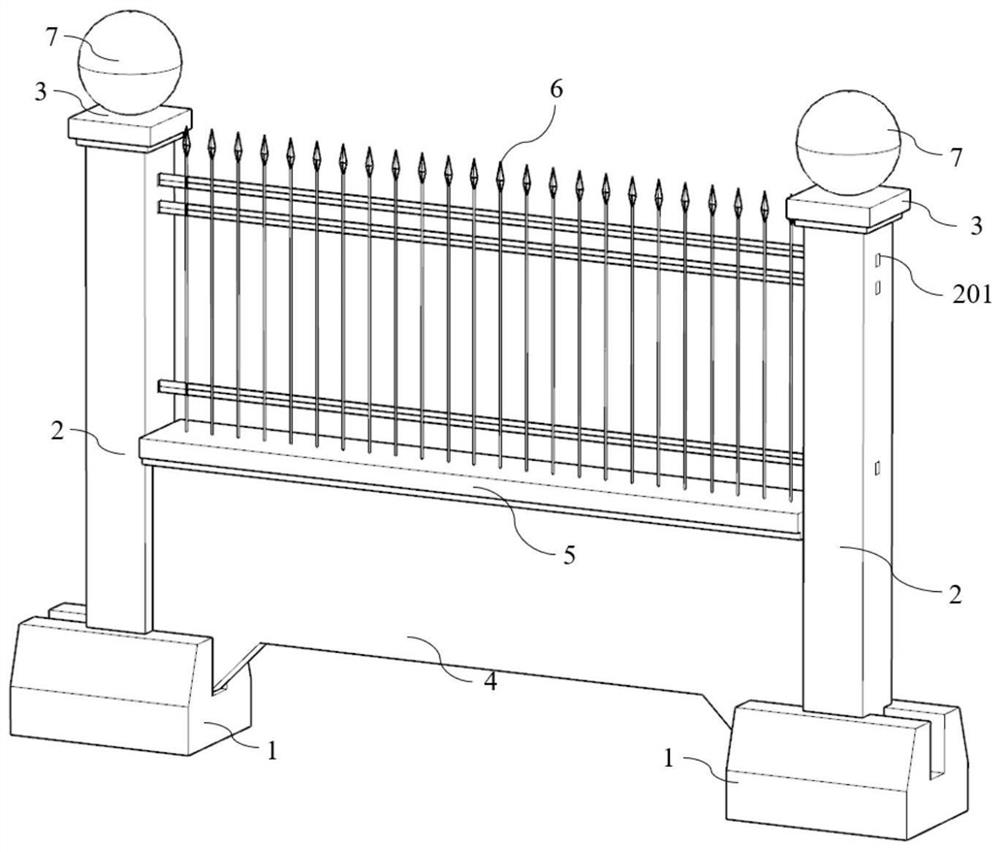

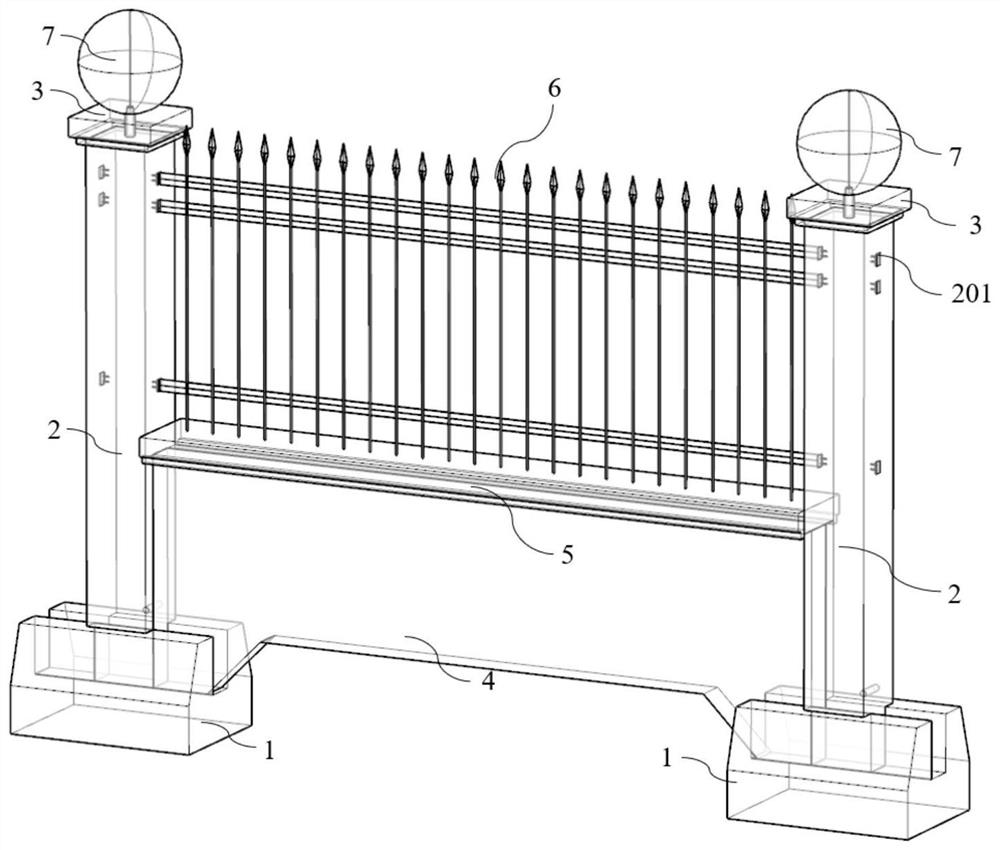

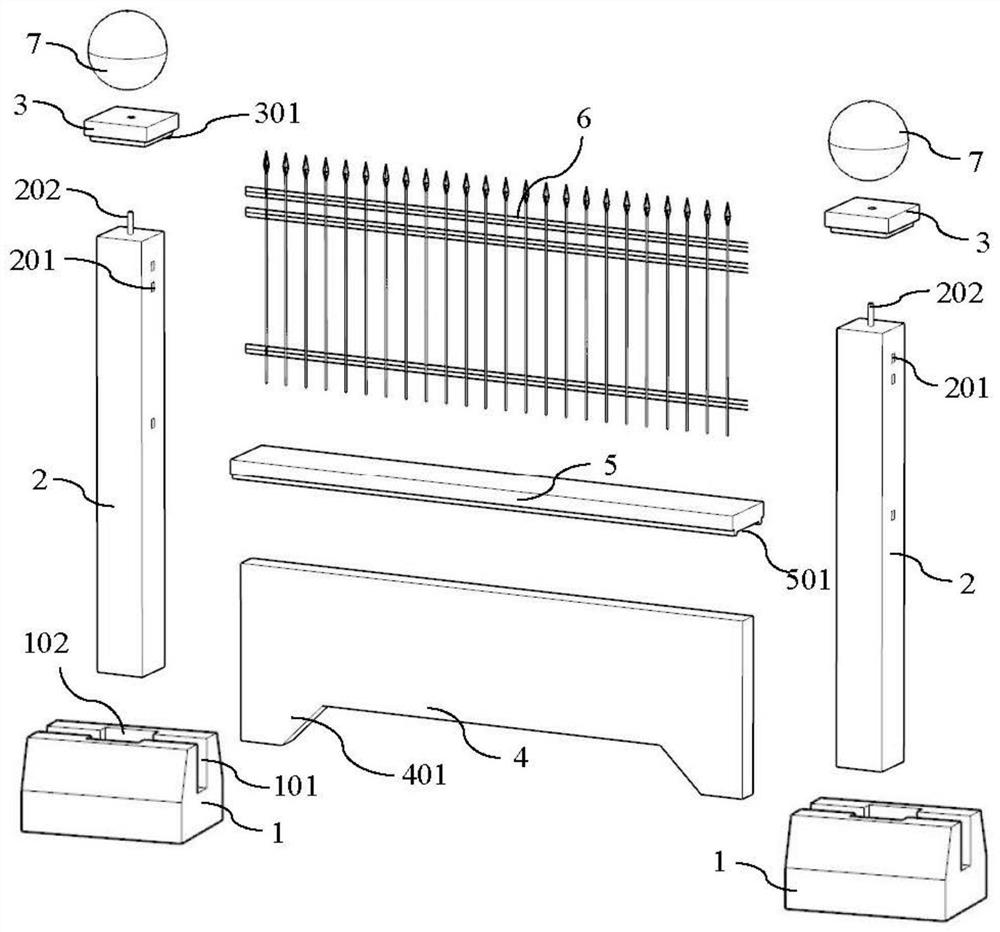

Fully assembled recyclable enclosure wall and construction method

PendingCN111734213AImprove construction efficiencyEasy constructionMechanical apparatusLighting elementsStructural engineeringMechanical engineering

The invention discloses a fully assembled recyclable enclosure wall and a construction method. The enclosure wall comprises PC component bases, a PC component column, a PC component column cover, a PCcomponent enclosure wall page, a PC component enclosure wall page cover, an enclosure wall fence piece and enclosure wall lighting, wherein the PC component column and PC component base are plugged and fixed; the PC component enclosure wall page is located between two PC component bases and both ends of the PC component enclosure wall page are plugged into the two PC component bases, respectively; the PC component enclosure wall page cover is inserted on the PC component enclosure wall page; the PC component column cover is inserted on the PC component column; the enclosure wall fence piece is welded and fixed with a metal embedded part embedded on the side of the PC component column, and the enclosure wall lighting is installed on the top of the PC component column, and at the upper endof the PC component column cover. The fully assembled recyclable enclosure wall, by adopting combined assembly construction, greatly shortens the construction period, saves construction period and labor, improves the overall construction quality at the same time, and has the advantages of saving working procedures, high installation efficiency, detachable assembly and recycling, beautiful appearance and the like.

Owner:WUHAN CONSTR ENG

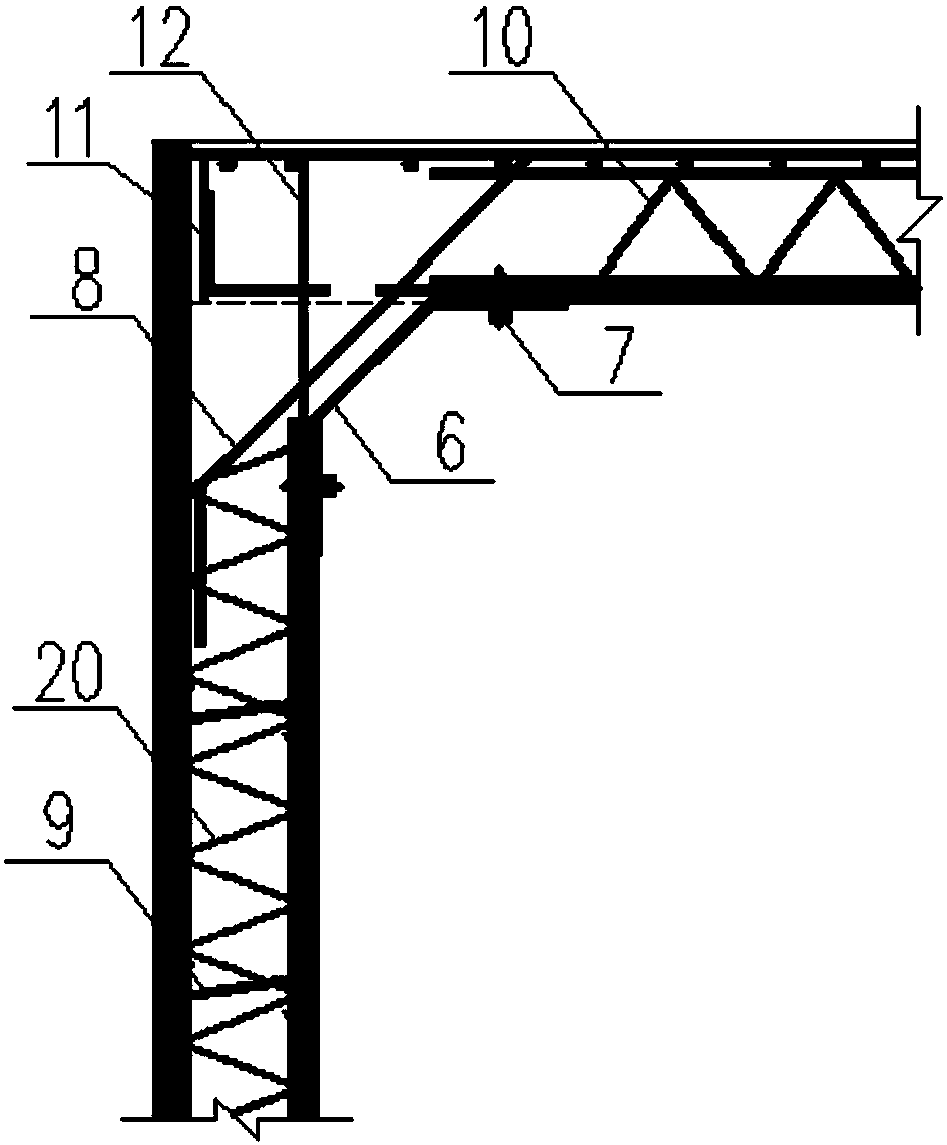

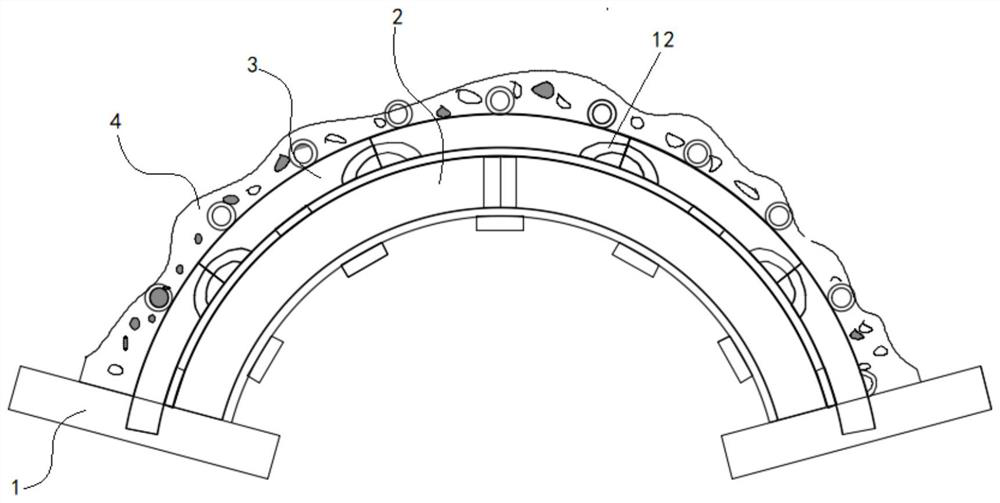

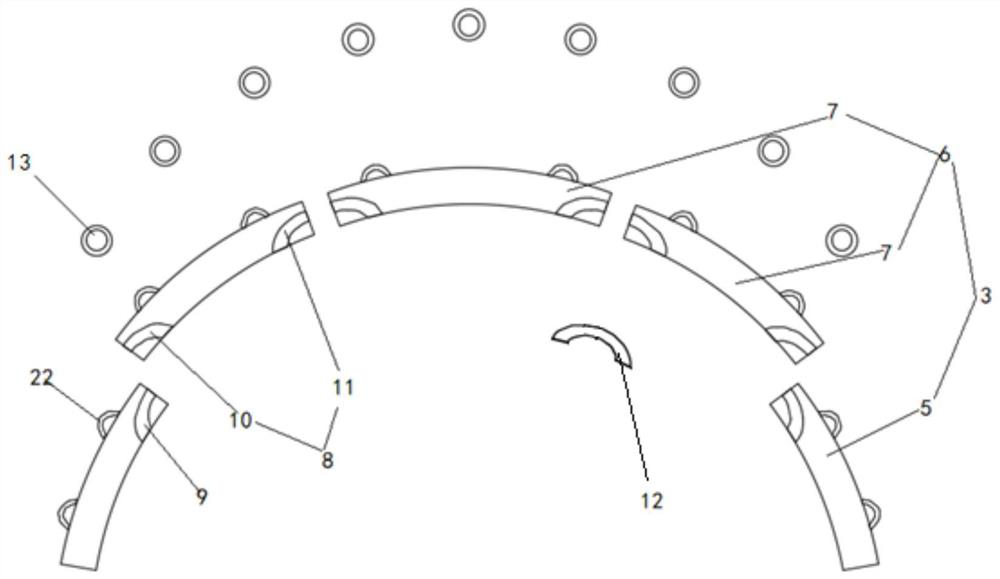

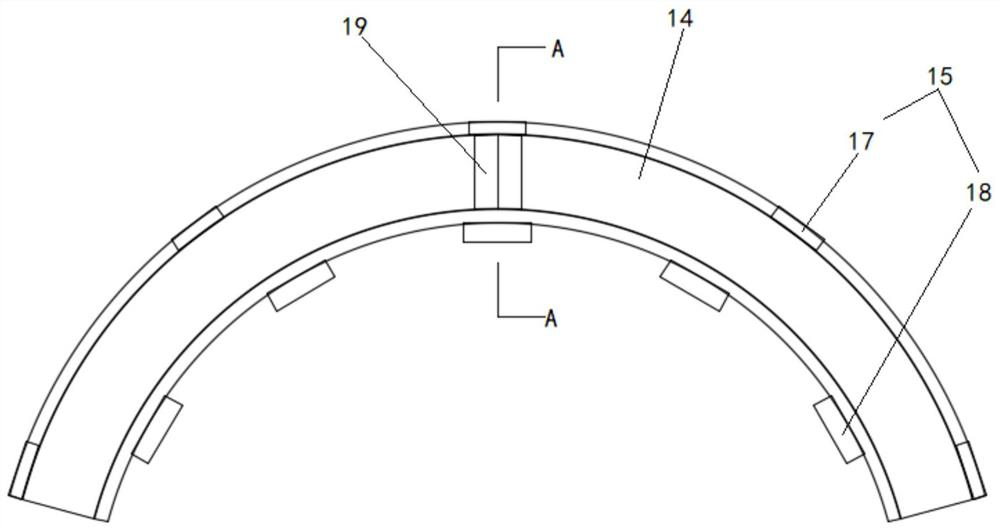

Semi-fabricated independent cover arch structure for tunnel zero excavation and tunnel entering and construction method thereof

ActiveCN113062756AImprove integrityImprove stabilityUnderground chambersTunnel liningShotcreteArchitectural engineering

The invention discloses a semi-fabricated independent cover arch structure for tunnel zero excavation and tunnel entering and a construction method thereof. The semi-fabricated independent cover arch structure comprises a hole foundation, a channel steel frame, a cover arch inner ring and a cover arch outer ring, the channel steel frame is fixedly connected to the hole foundation, the cover arch inner ring is fixedly installed on the channel steel frame, the cover arch outer ring is arranged on the outer side of the cover arch inner ring in a pouring mode, the cover arch inner ring comprises a foundation sleeve ring and a splicing sleeve ring, the foundation sleeve ring is fixedly installed on the hole foundation, the channel steel frame is positioned and installed through the foundation sleeve ring, and the splicing sleeve ring is fixedly installed on the foundation sleeve ring with the channel steel frame as a support. Before construction, all components of the independent cover arch structure are prefabricated, and the prefabricated inner ring is small in segmented weight and convenient to hoist and construct; the arrangement of pipe shed guide pipes is more flexible and convenient, and the influence of the annular length of inner ring sections on the positions of the pipe shed guide pipes does not need to be considered in the prefabricating process of the inner ring sections; an on-site concrete spraying construction technology is adopted for the cover arch outer ring, and the integrity, stability and waterproof performance of a independent cover arch formed through the construction method are good.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

Novel recycled block concrete prefabricated assembly type constructional column and construction method thereof

ActiveCN113374174ASpeed up installation timeReduce labor costsStrutsSolid waste managementArchitectural engineeringRebar

The invention discloses a novel recycled block concrete prefabricated assembly type constructional column and a construction method thereof. The novel recycled block concrete prefabricated assembly type constructional column comprises a top grouting formwork, an upper section, a middle section and a lower section, each of the upper section, the middle section and the lower section comprises inner longitudinal bars, inner stirrups, lateral in-wall steel bars, waste concrete block bodies and common concrete, the inner longitudinal bars and the inner stirrups are bound to form steel reinforcement cages, the lateral in-wall steel bars penetrate through the steel reinforcement cages, the waste concrete block bodies are located in the steel reinforcement cages, the common concrete is wrapped round the steel reinforcement cages and the waste concrete block bodies, the inner longitudinal bars of the lower section are inserted into glue pouring holes in a bottom beam plate, the longitudinal bars at the lower end of the middle section are inserted into glue pouring holes in the lower section, the longitudinal bars at the lower end of the upper section are inserted into glue pouring holes in the middle section, the top grouting formwork is located between the upper section and a top beam plate, the top grouting formwork seals the space between the upper section and the top beam plate, and grouting materials are injected into the top grouting formwork through a PVC one-way check valve.

Owner:SOUTH CHINA UNIV OF TECH +1

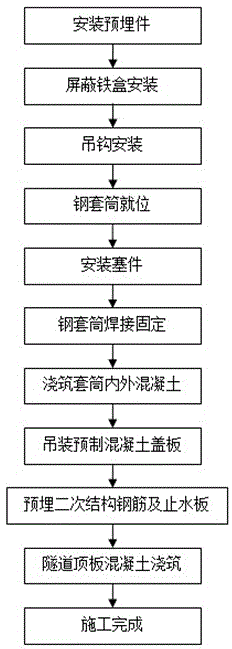

Construction technology of movable shielding iron box crossing tunnel top plate

The invention relates to the field of building, and more particularly relates to a construction technology of a movable shielding iron box crossing tunnel top plate. The construction technology comprises the following steps: a, installing embedded parts and unhooking; b, installing a shielding iron box; c, installing lifting hooks; d, taking an external sleeve in place; e, installing plug members; f, welding and fixing the sleeve; g, pouring concrete inside and outside the sleeve; h, lifting a prefabricated concrete cover plate; I, embedding secondary structural steel reinforces and water-stop plates; j, pouring concrete on the tunnel top plate; k, completing the construction. The construction technology of the movable shielding iron box crossing tunnel top plate provided by the invention can realize the movement of a sub-box so as to facilitate the maintenance and reutilization of the sub-box; the sub-box adopts the installation technology, so that quick installation can be realized, the installation accuracy can be guaranteed, and the integral lifting of the sub-box can be realized; the secondary structural steel reinforces and the water-stop plates are reserved, so that the secondary structural construction needed in later can be facilitated, and the construction quality is guaranteed; due to the adoption of the concrete cover plate, the shielding iron box can be effectively protected during the construction process.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR +1

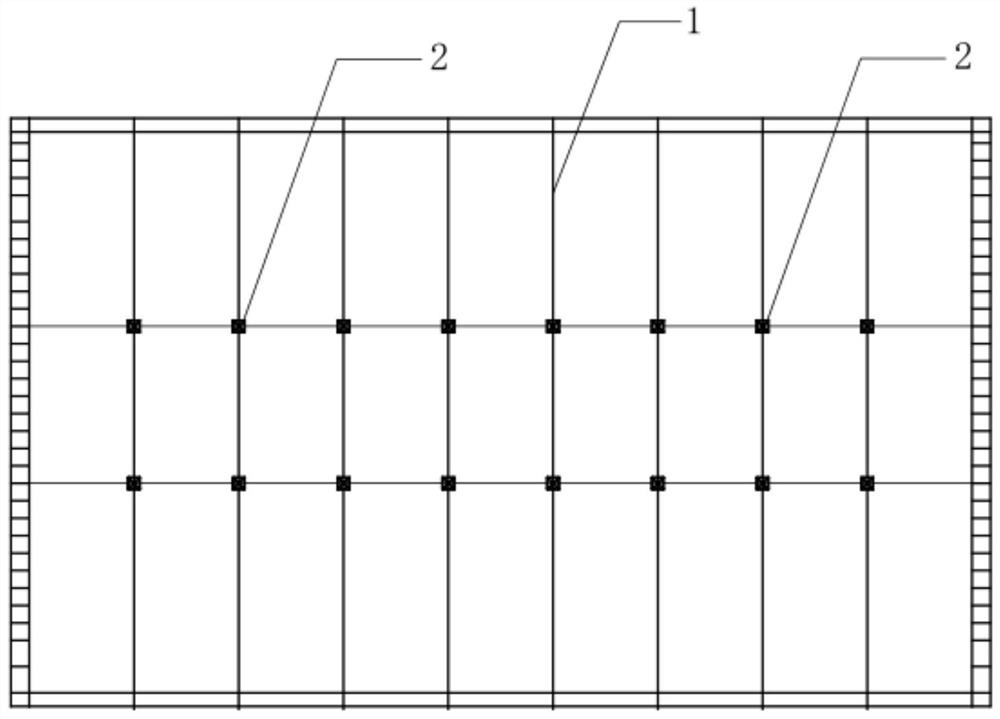

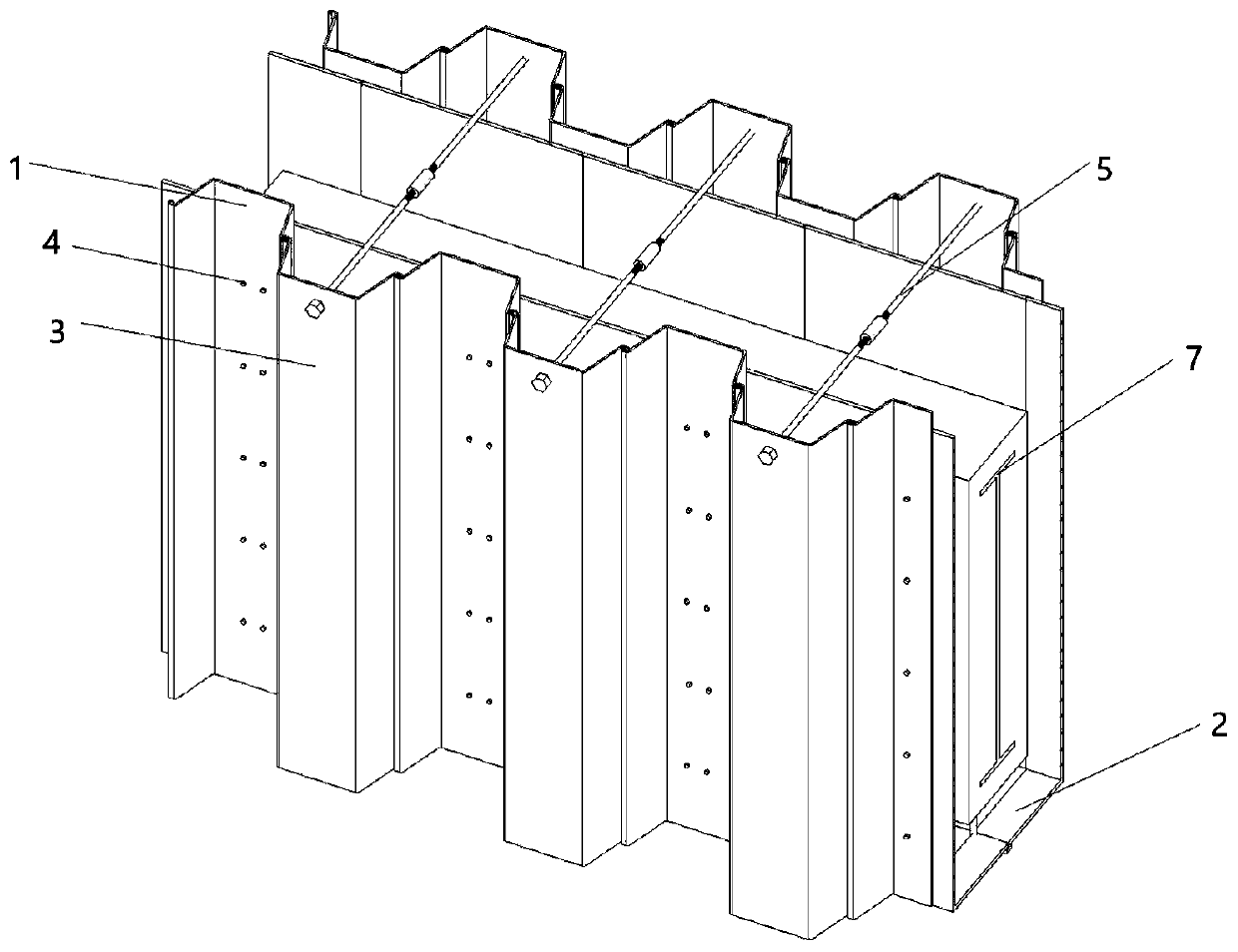

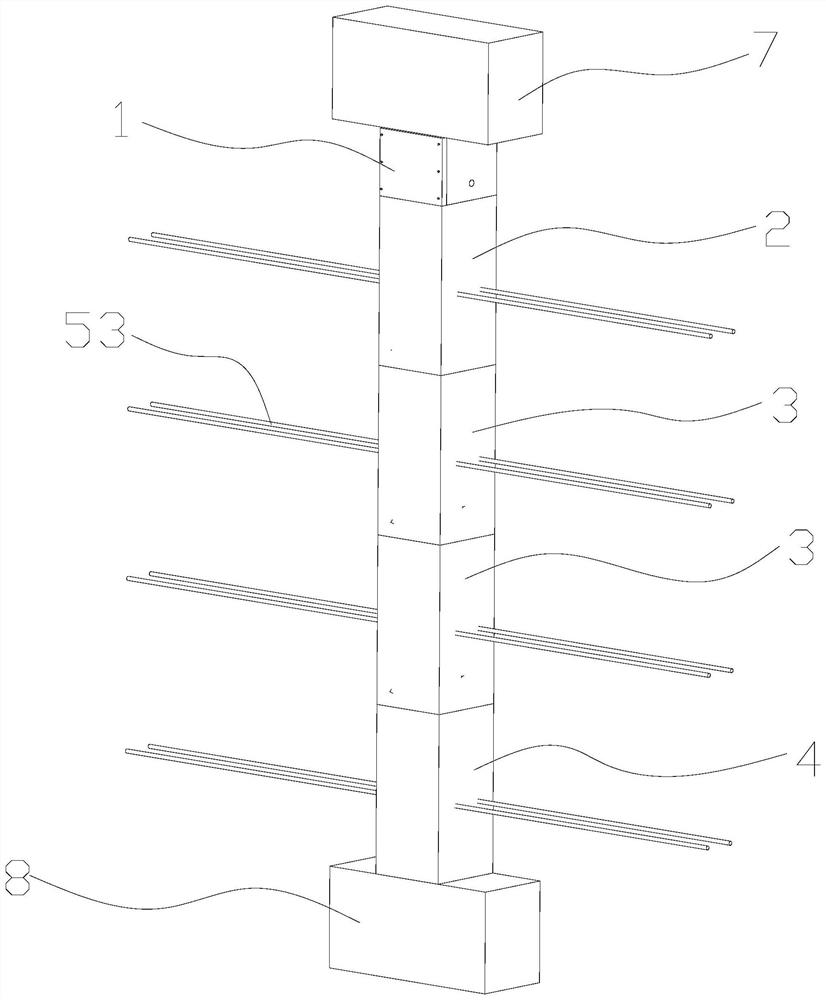

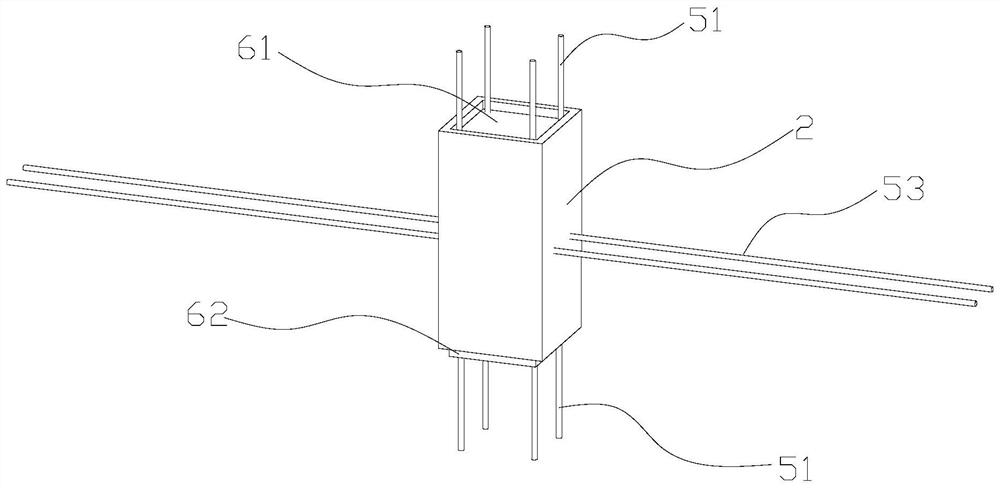

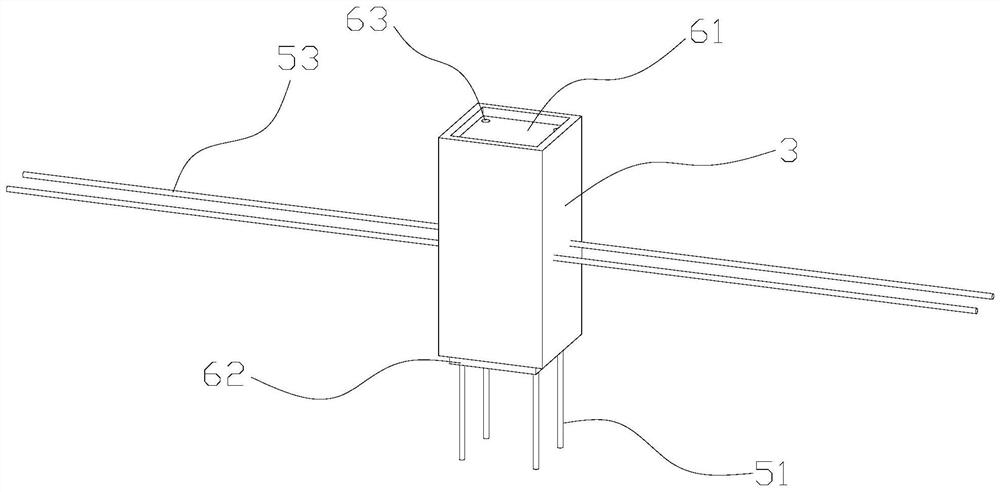

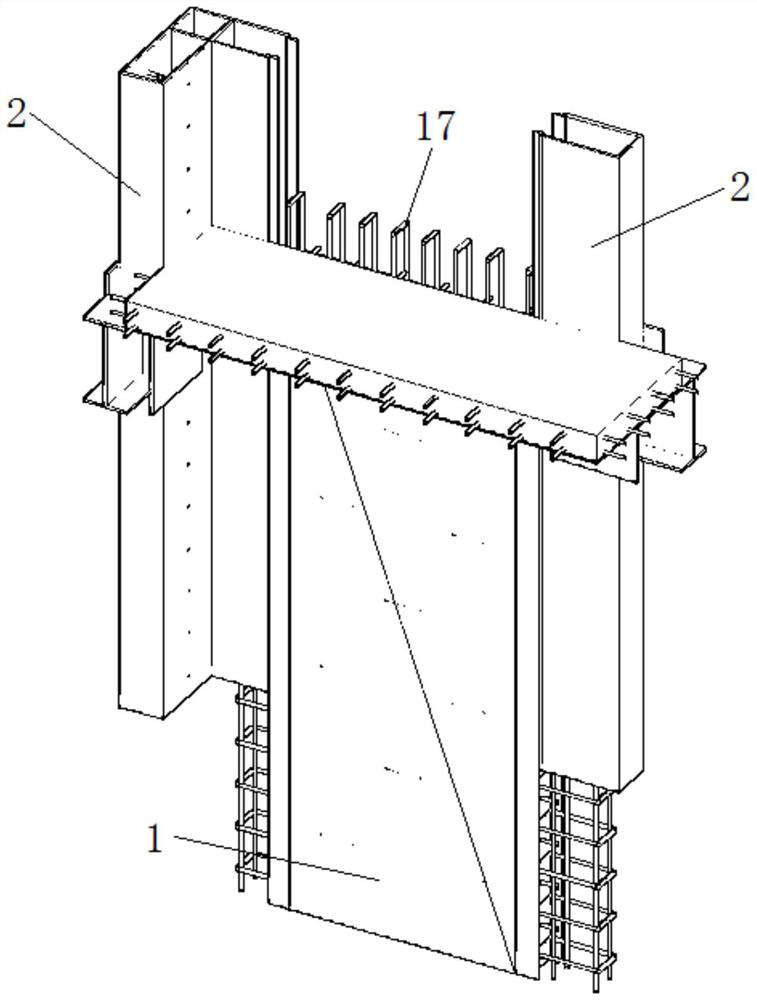

Fabricated steel-concrete composite shear wall and construction method

ActiveCN114059687AReduce weightEasy to hoist and constructWallsBuilding reinforcementsRebarTransverse reinforcement

The invention discloses a fabricated steel-concrete composite shear wall which comprises a middle wall body and two end wall bodies, the middle wall body is located between the two end wall bodies, transverse steel bars in the middle wall body extend into the end wall bodies, and the middle wall body and the end wall bodies are integrally formed through concrete pouring. The construction method comprises the steps that firstly, the middle pouring system is prefabricated, then the end pouring systems are prefabricated, the middle pouring system and the end pouring systems are assembled into a whole to form the shear wall pouring system, and finally concrete is poured to be solidified and formed. The invention has the advantages that the stress defect of the open type steel edge component is overcome, the integrity of the wall is good, and the material performance advantages of a steel structure and a concrete structure are fully exerted. And the technical requirements of on-site assembly construction, template-free and support-free can be met.

Owner:CHONGQING UNIV

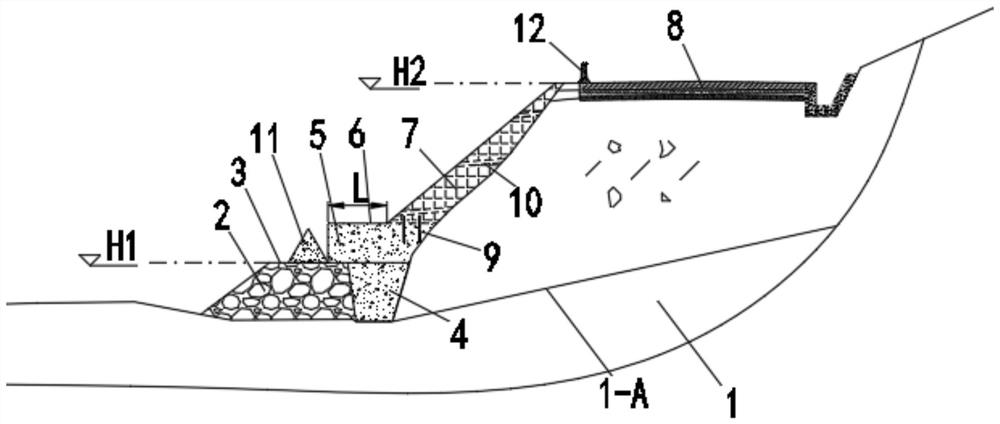

Anti-scouring and anti-sliding structure and its construction method for the road slope opposite the outlet of the diversion tunnel

ActiveCN112900364BGood foot reinforcementAvoid scourCoastlines protectionFoundation engineeringReinforced concreteArchitectural engineering

The invention discloses an anti-scouring and anti-sliding structure and a construction method for the road slope opposite the outlet of a diversion tunnel, belonging to the field of water conservancy and hydropower engineering, and provides a short construction period, convenient construction and low investment suitable for diversion tunnels The anti-scouring and anti-sliding structure and construction method of the road slope on the opposite bank of the exit, the anti-scouring and anti-sliding structure of the road slope on the opposite bank at the exit of the diversion tunnel, specifically includes the slope body, and a traffic road is arranged on the upper part of the slope body. Including concrete cogged foundation, concrete cogged superstructure, lump cinder fill structure and reinforced concrete slope protection. The present invention can form the first construction access road as a construction platform by means of the rapidly built lump slag filling structure itself, which can greatly speed up the construction progress and shorten the construction period; The upper structure of the alveolar can reinforce the better foot protection, greatly improving the stability and anti-shock effect of the overall structure.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

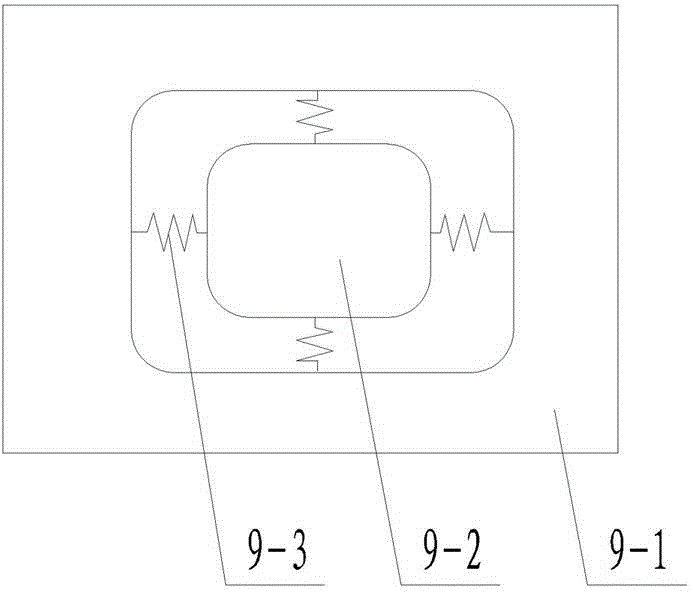

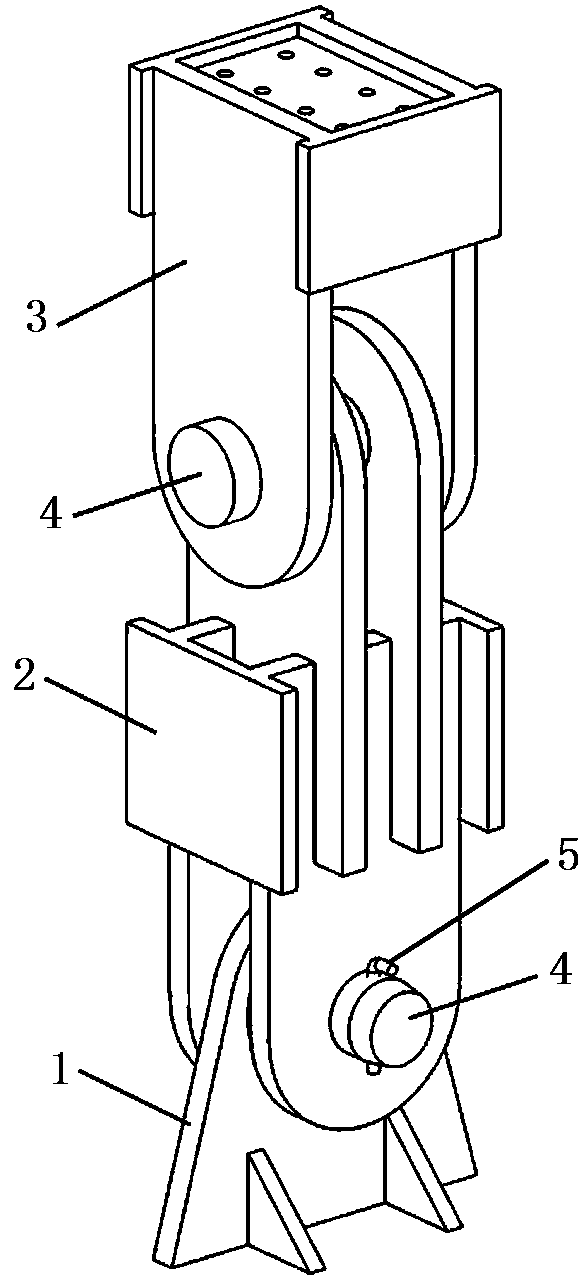

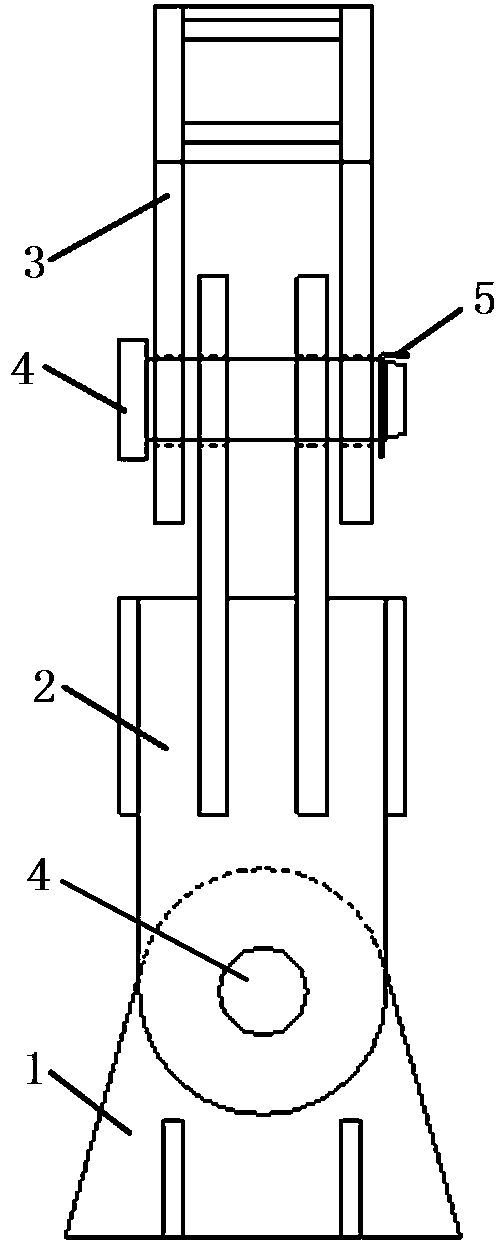

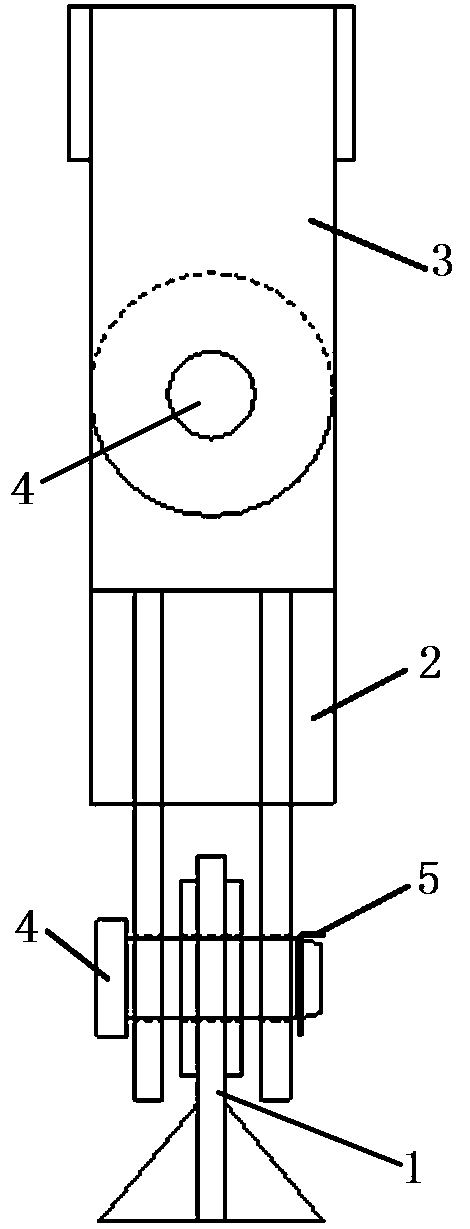

Dual-way rotating lifting lug structure

PendingCN109484964ASimple structureEasy to hoist and constructLoad-engaging elementsCross connectionEngineering

The invention discloses a dual-way rotating lifting lug structure. The structure comprises a lifting lug, a connection turning device and a lifting box which are arranged in sequence from bottom to top, the lifting lug is hinged to the lower portion of the connection turning device through a pin shaft, the upper portion of the connection turning device and the lifting box are hinged through a pinshaft, the tail of the pin shaft is provided with a hole in the radial direction, and a safety pin is inserted in the hole; the lifting lug comprises a lifting lug plate, the connection turning devicecomprises two turning device lower lug plates and two turning device upper lug plates which are vertically in crossed connection, the lifting box comprises a lifting box lower end plate, a lifting box upper end plate and two lifting box lug plates, the lifting box lower end plate and the lifting box upper end plate are provided with corresponding anchor holes, and the upper portions of the two lifting box lug plates are connected to two sides of the lifting box lower end plate and the lifting box upper end plate. The structure is simple, dual-way rotating can be easily achieved, lifting construction is facilitated, and the structure is particularly suitable for component lifting work of complex construction conditions or particular space shapes and undefined gravity positions.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com