Prefabricated internally-filled concrete wallboard and manufacturing method thereof

A technology of precast concrete and a manufacturing method, which is applied to manufacturing tools, building structures, building components, etc., can solve the problems of easy cracking of joints, troublesome hoisting construction, weak resistance to external forces, etc. The effect of easy hoisting and construction, reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

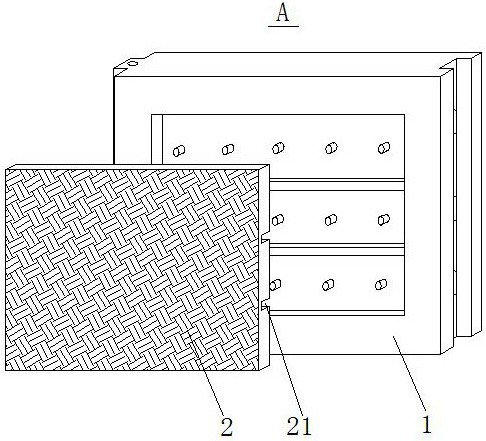

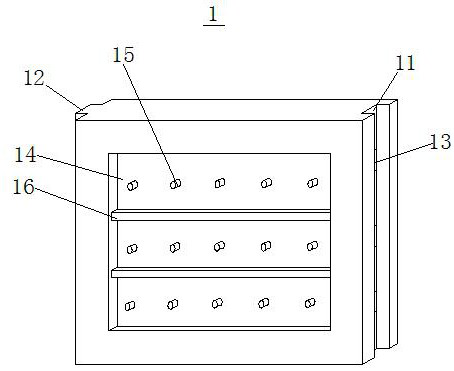

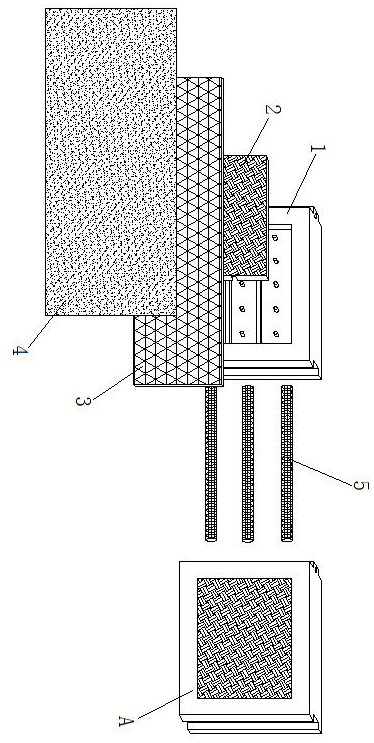

[0031] Such as Figure 1 to Figure 3 The prefabricated inner filled concrete wall panel includes a wall panel body A poured from reinforced concrete; the wall panel body A is composed of a prefabricated concrete base plate 1 and a thermal insulation filling plate 2, and the prefabricated concrete base plate is filled with a fixed thermal insulation filling board to improve the thermal insulation effect of the wallboard body; the thermal insulation filling board 2 is installed on the inner side of the precast concrete substrate 1, and the outer surface of the thermal insulation filling board 2 is glued with an alkaline mesh layer 3; the precast concrete substrate 1 Its inner surface is coated with a mortar plastering layer 4; during on-site construction, a large-area alkaline mesh layer can be used to glue and fix the insulation filling board of the adjacent wallboard body, so that the surface of the adjacent wallboard body can pass through the alkali The permanent mesh layer a...

Embodiment 2

[0046] Such as Figure 4 The structure of the prefabricated inner filled concrete wall panel shown is basically the same as that of Example 1, wherein the thermal insulation filling panel 2 is composed of a first thermal insulation board 2A and a second thermal insulation board 2B; the first thermal insulation board 2A is clamped and fixed In the card slot 14, and the upper and lower adjacent first insulation boards 2A are separated by positioning clips 16; the second insulation board 2B is glued and fixed on the outside of the first insulation board 2A. The first insulation board 2A is evenly distributed with a plurality of through holes 6 for inserting anchor rods; the second insulation board 2B is evenly distributed with a plurality of holes coaxial with the through holes of the first insulation board 2A. Positioning slots (not shown in the figure), when installing the insulation filling board, the first insulation board of the insulation filling board will be inserted into...

Embodiment 3

[0048] Such as Figure 5 and Figure 6 The manufacturing method of the prefabricated interior filled concrete wallboard shown is basically the same as that of Example 1, wherein, after the insulation filling board is installed, it also includes bonding an alkaline mesh cloth layer on the outer surface of the insulation filling board; Smear cement mortar on the surface of the mesh layer and the precast concrete substrate to form a mortar plastering layer, bond the alkaline mesh layer on the outer surface of the insulation filling board, and apply mortar on the surface of the precast concrete substrate with the alkaline mesh layer The surface layer is plastered so that the insulation filling board can be fixed firmly with the precast concrete base.

[0049] The prefabricated internally filled concrete wallboard and its manufacturing method of the present invention can use a large-area alkaline mesh cloth layer to glue and fix the thermal insulation filling boards of the adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com