Vertical and horizontal integrally superposed concrete frame structural body and superposed forming body

A concrete and structure technology, applied in building construction, construction, etc., can solve the problems of difficult to control on-site construction safety, high cost of construction measures, low degree of industrialization, etc., and achieves light weight, fast construction speed, and high installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]An embodiment of the present invention provides a vertically and horizontally laminated concrete frame structure, including laminated frame column prefabricated parts, laminated frame beam prefabricated parts and laminated floor prefabricated parts;

[0040] Wherein, the composite frame column prefabricated part includes a vertically arranged composite frame column prefabricated concrete shell, and the hollow part located in the composite frame column precast concrete shell is the composite frame column hollow part; along the composite frame column The edge inner layer of the prefabricated concrete shell is provided with a plurality of vertically arranged main reinforcements of the laminated frame columns; the top of each of the main reinforcements of the laminated frame columns is a straight threaded section of the main reinforcement of the laminated frame columns;

[0041] The laminated frame beam prefabricated part and the laminated frame column prefabricated part are ...

Embodiment 2

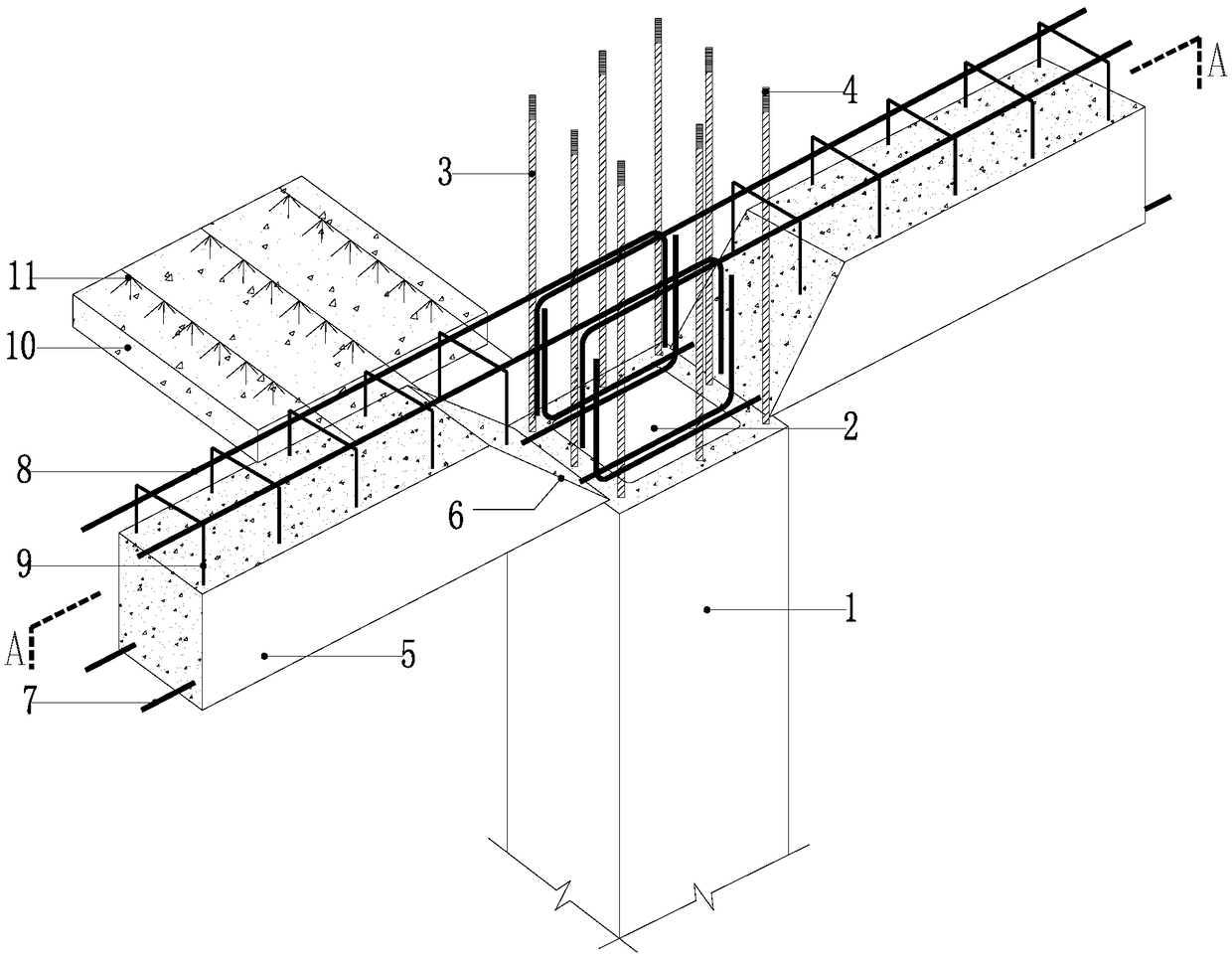

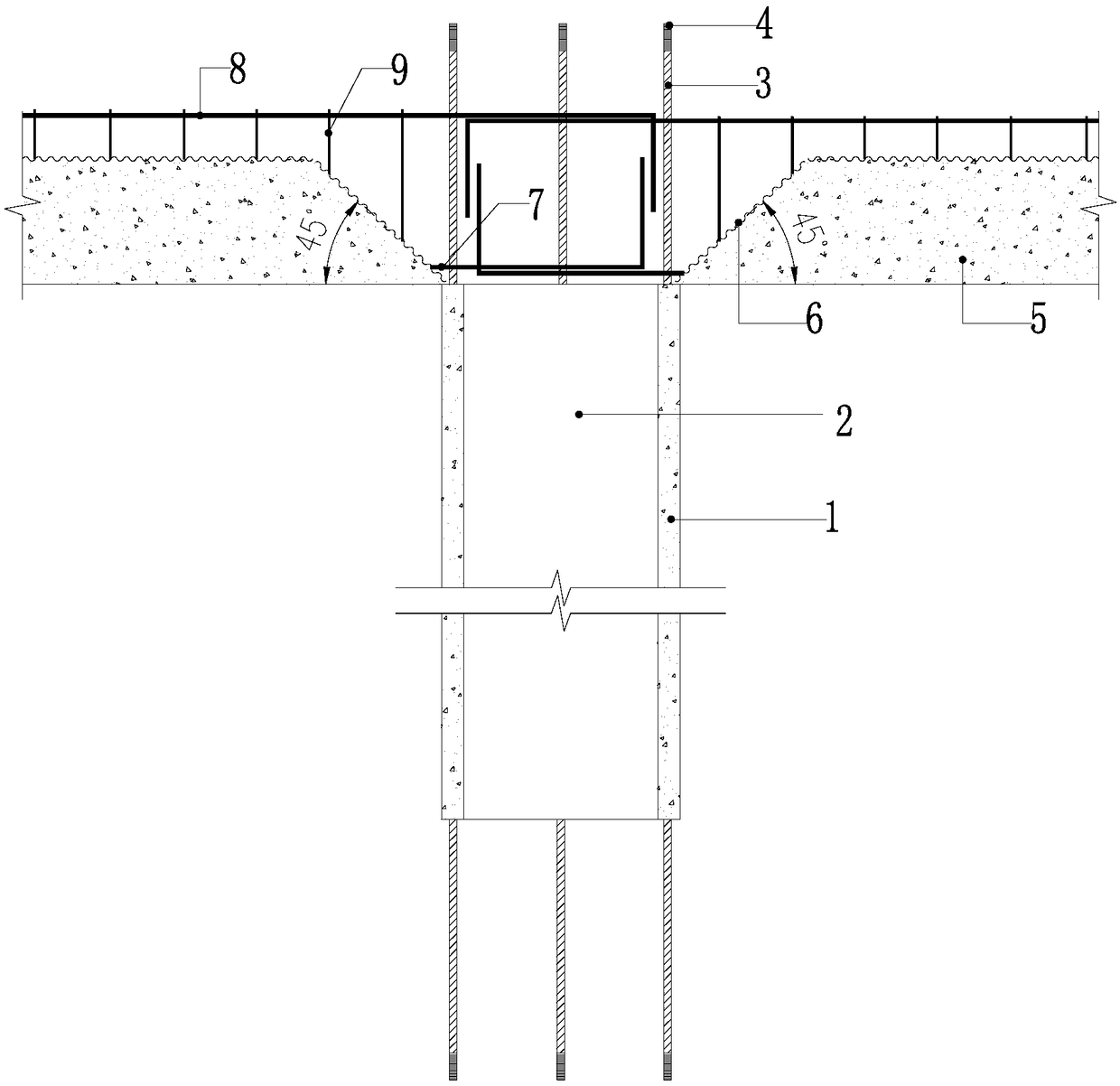

[0045] see figure 1 as well as figure 2 , Embodiment 2 of the present invention provides a vertical and horizontal integral laminated concrete frame structure, including laminated frame column prefabricated parts, laminated frame beam prefabricated parts and laminated floor slab prefabricated parts;

[0046] Wherein, the laminated frame column prefabricated part includes a vertically arranged laminated frame column precast concrete shell 1, and the hollow part located in the laminated frame column precast concrete shell 1 is the laminated frame column hollow part 2; along the laminated frame column The edge inner layer of the composite frame column prefabricated concrete shell 1 is provided with multiple vertically arranged composite frame column main reinforcements 3; the top of each composite frame column main reinforcement 3 is a composite frame column main reinforcement straight thread section 4;

[0047] The laminated frame beam prefabricated part and the laminated fram...

Embodiment 3

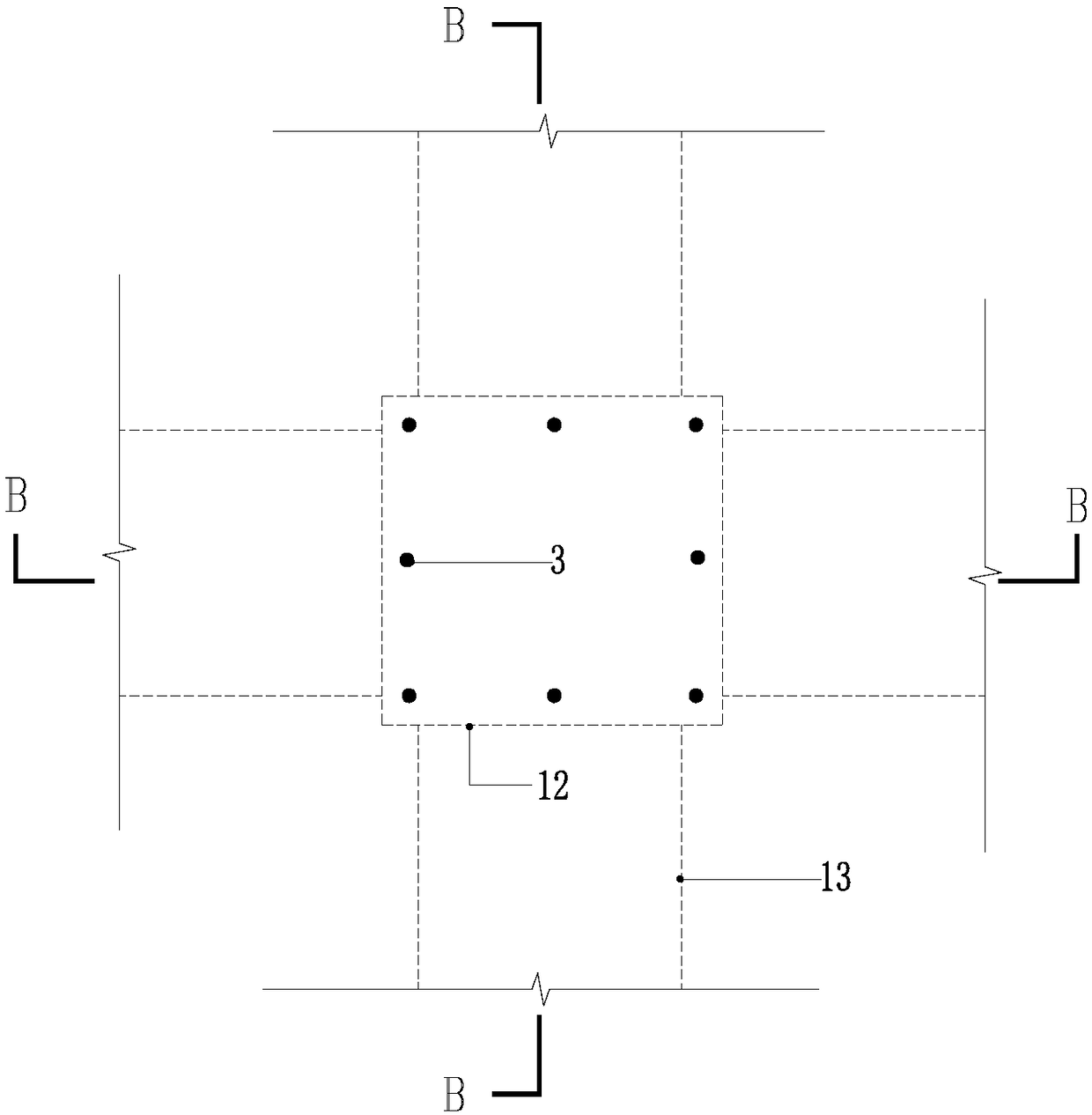

[0059] Correspondingly, Embodiment 3 of the present invention also provides a laminated molded body, including the above-mentioned vertical and horizontal integrally laminated concrete frame structure, and also includes a concrete pouring layer;

[0060] The concrete pouring layer (that is, cast-in-place forming) is filled and arranged in the hollow part 2 of the laminated frame column in the inner layer of the laminated frame column prefab; the concrete pouring layer (that is, cast-in-place forming) is also filled and arranged in The space between the top of the precast concrete shell 1 of the composite frame column and the inclined end faces of the two sections of the precast concrete composite frame beam 5 . Such as Figure 4 As shown, the prefabricated concrete shell 1 of the composite frame column and the two sections of the precast concrete composite frame beam 5 are all prefabricated, but the cast-in-place concrete layer part 14 of the composite column and the cast-in-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com