A Rotary Guide Device Based on Bearing Processing Line

A technology of rotary guidance and bearing processing, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of suitable positioning of bearings with different sizes and specifications, complex equipment as a whole, single application, etc., and achieve good discharge and use effect. , reduce complexity, and apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

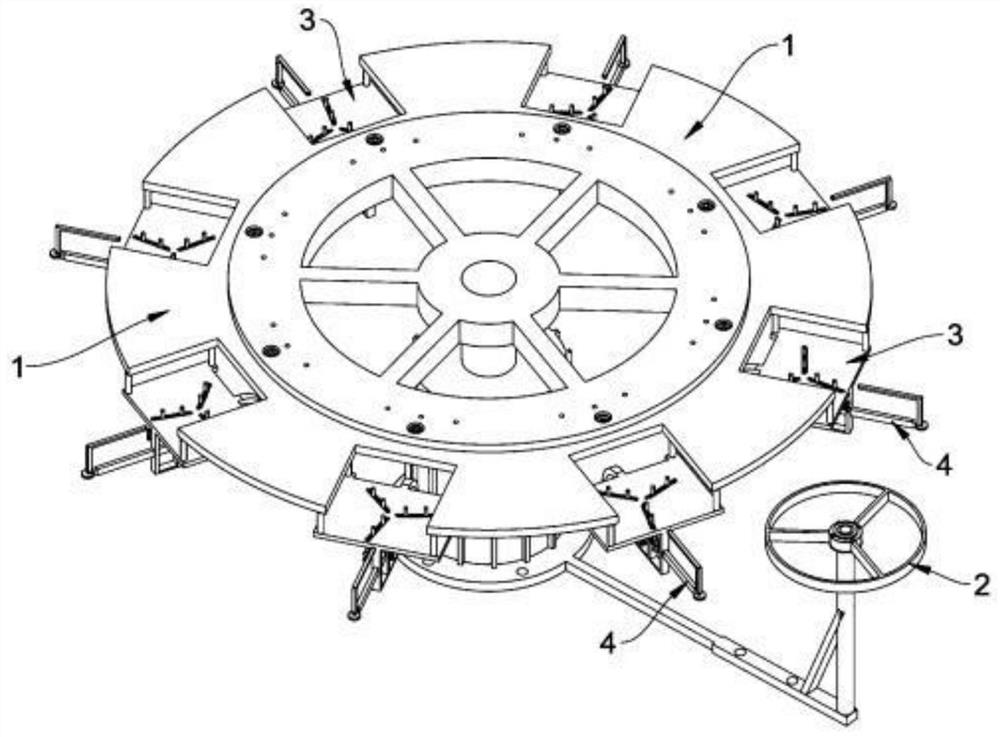

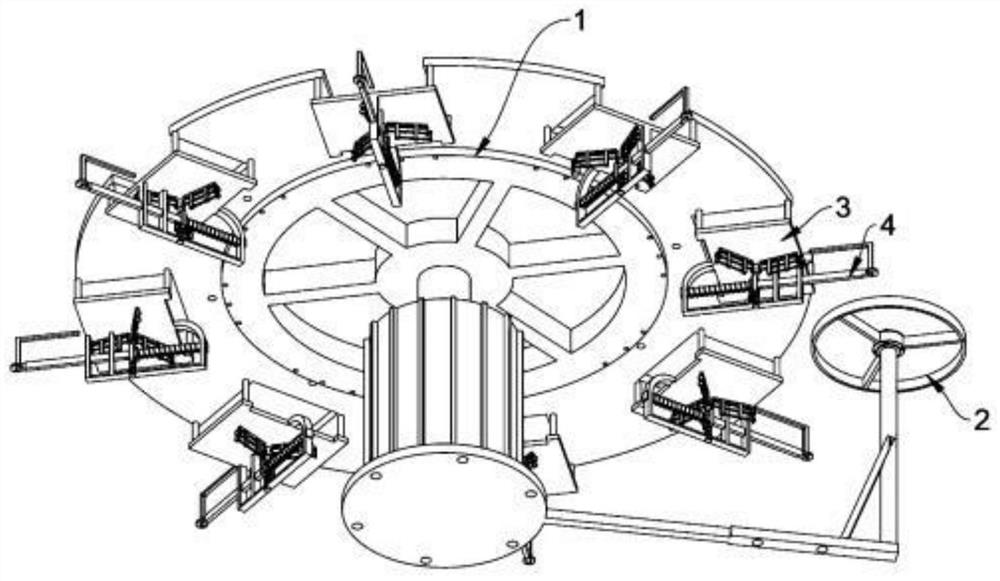

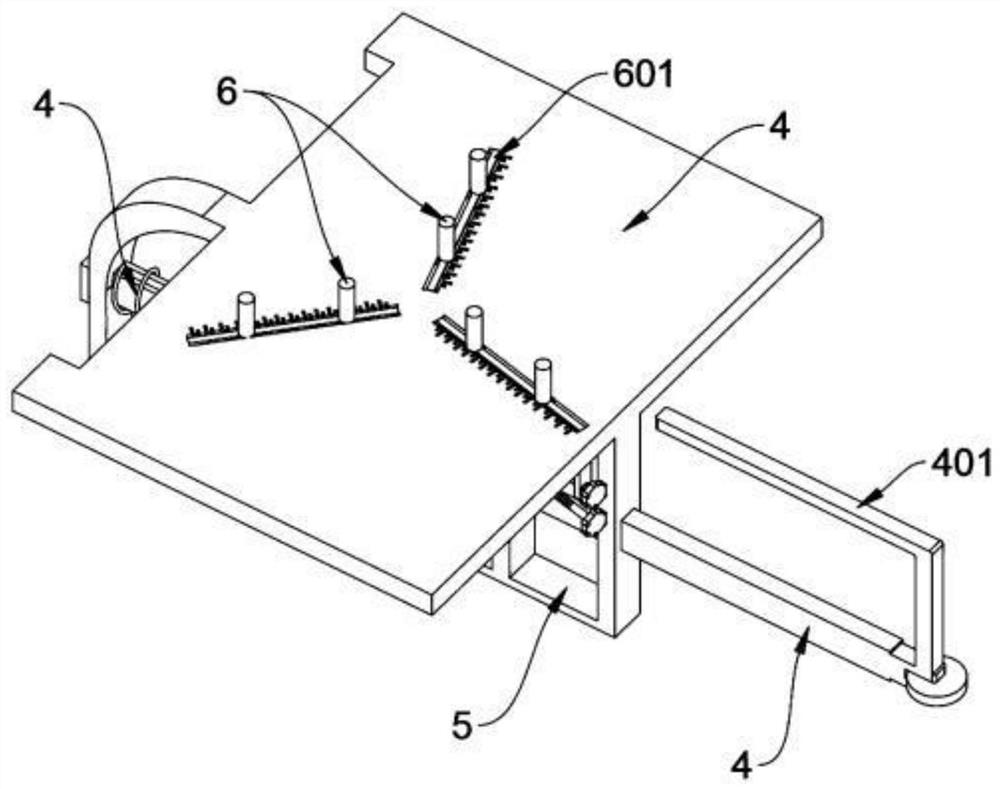

[0031] as attached figure 1 To attach Figure 8 Shown:

[0032] The present invention provides a rotating guiding device based on a bearing processing line, which includes a turntable 1, a top runner 2, and a short positioning shaft 6. The position of the eaves is arranged in a circular array, and eight square gaps are opened through, and a square support plate 3 is supported and suspended under the eight square gaps; a top runner 2 is supported close to the left side of the top runner 2, The top runner 2 is at the same level as the telescopic square rod 4; a mounting frame 5 is supported downward in the middle of the bottom of the supporting plate 3, and the telescopic square rod 4 is inserted through the spring to push through it for installation. The front, middle and rear vertical support connecting rods of the frame 5; the bottom support of the positioning short shaft 6 is welded with a square slide bar, and a total of six positioning short shafts 6 corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com