Aluminum plate glass curtain wall cold and hot bridge conversion structure and construction method

A glass curtain wall and conversion structure technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of high requirements for concrete forming effects, inability to form fireproof coatings at one time, increase labor and construction period costs, and reduce labor and materials. cost, improve aesthetics, and load-bearing and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The invention provides a construction method for a cold-heat bridge conversion structure of an aluminum plate glass curtain wall, comprising steps:

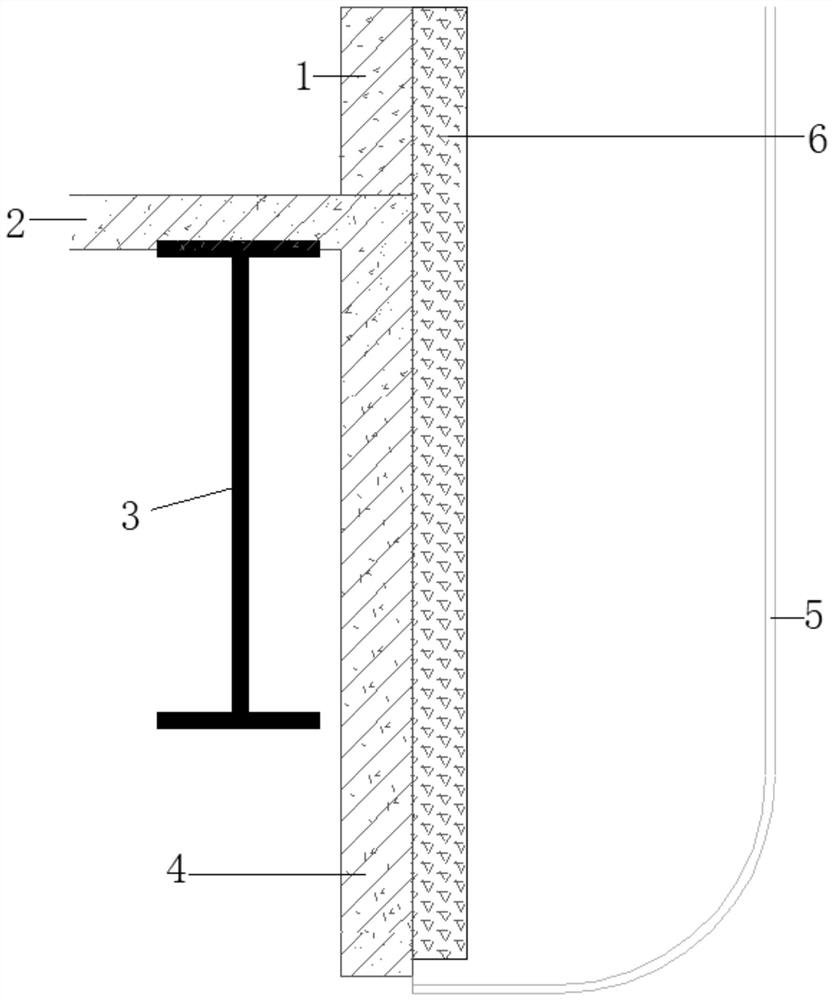

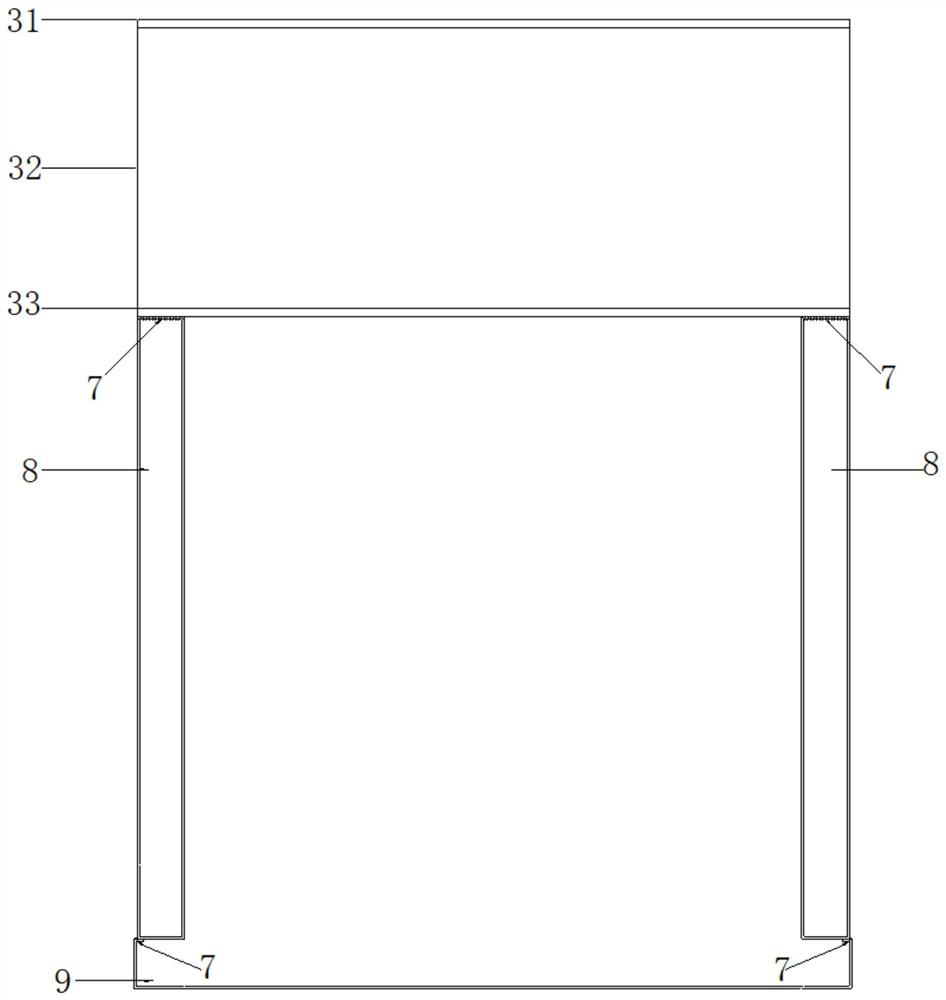

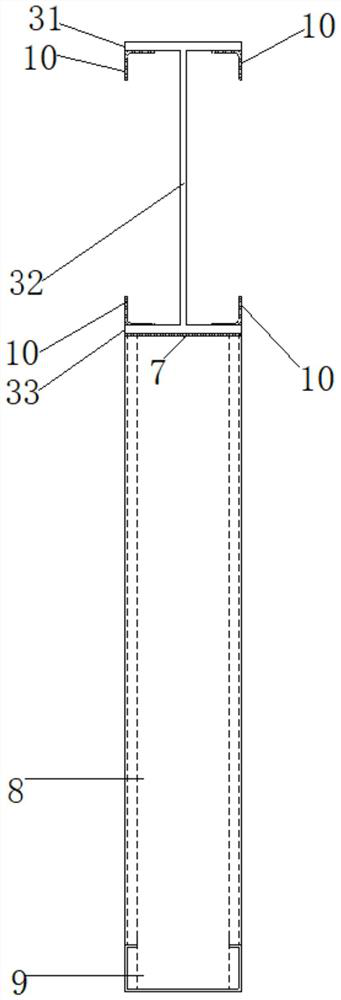

[0028] S1. Before the aluminum glass curtain wall construction, if figure 2 As shown, the vertical C-shaped steel 8 is welded along the bottom side of the lower flange 33 of the main structural steel beam 3, and the two sides of the vertical C-shaped steel 8 are aligned with the main structural steel beam 3, and are welded along the line at the bottom of the vertical C-shaped steel 8 Horizontal C-shaped steel 9, the opening of the horizontal C-shaped steel 9 faces upwards and the two sides are aligned with the vertical C-shaped steel 8, the main structural steel beam 3, the vertical C-shaped steel 8, and the horizontal C-shaped steel 9 constitute a load-bearing system for the conversion of cold and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com