Prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and construction method thereof

A comprehensive pipe gallery and prefabricated assembly technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of unsafe waterproofing at joints, difficult transportation and hoisting, and many assembled components, so as to facilitate construction hoisting and transportation Easy hoisting, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation of a hollow-core wall panel mixed prefabricated comprehensive pipe gallery spliced with cast-in-place concealed beams and its construction method will be described in detail below in conjunction with the accompanying drawings and specific examples.

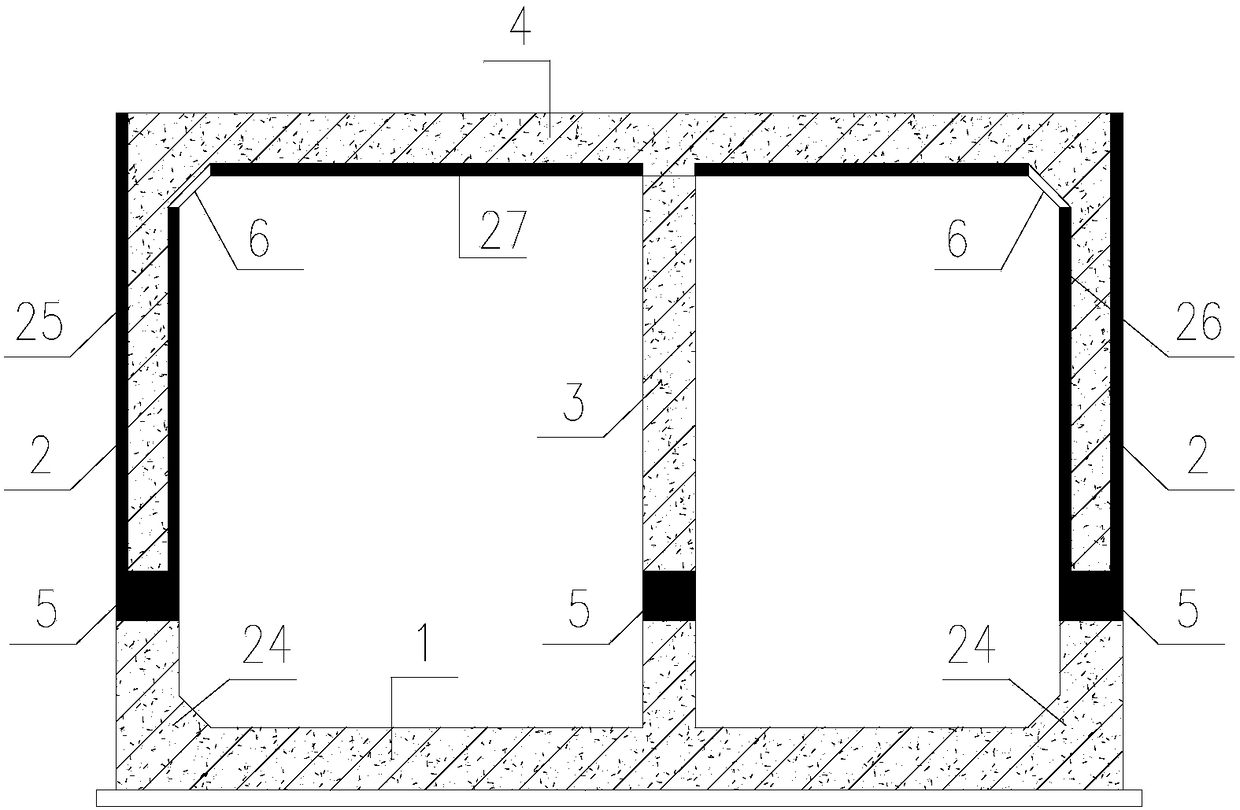

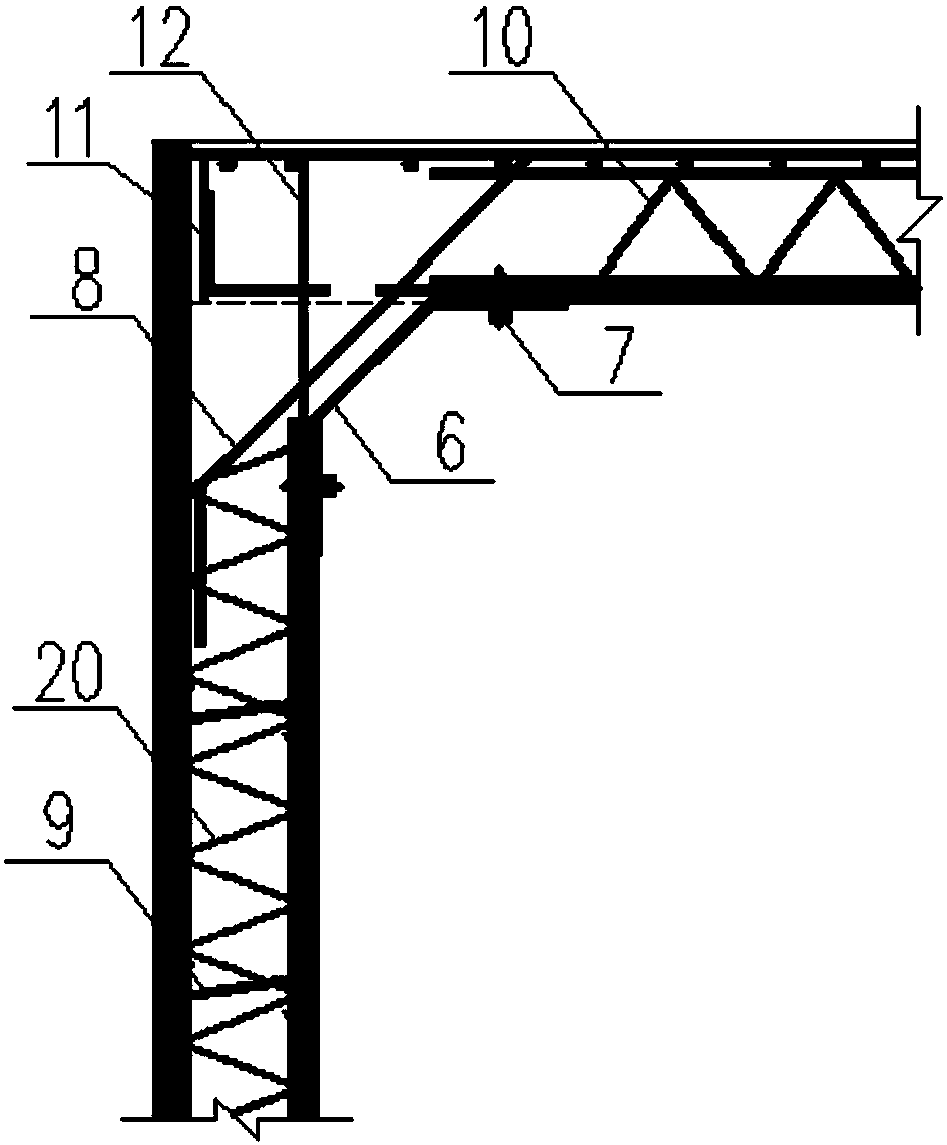

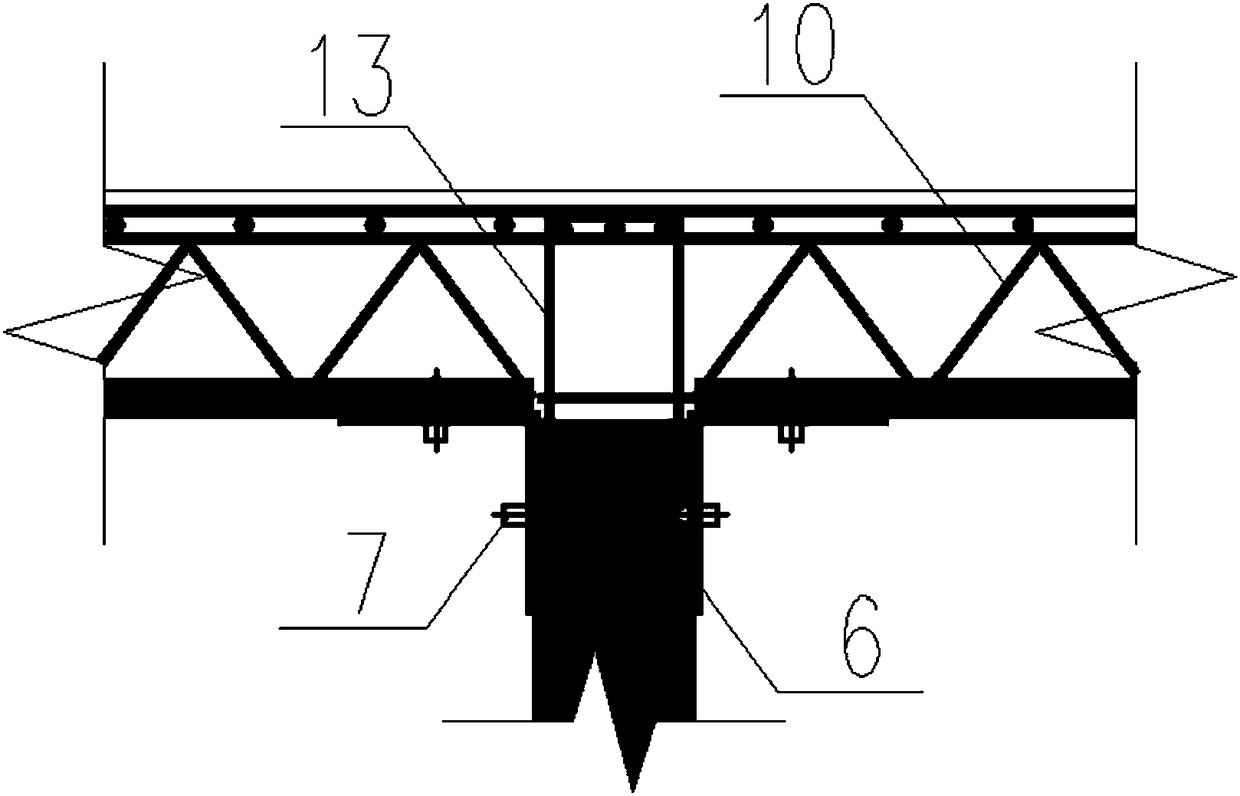

[0041] Such as Figure 1 to Figure 5As shown, a hollow-core wall panel mixed prefabricated comprehensive pipe gallery spliced with cast-in-place hidden beams, including a multi-section comprehensive pipe gallery body, each section of which is composed of a cast-in-place bottom plate 1, double-sided prefabricated hollow The core-filled side wall 2, the fully prefabricated middle partition wall 3 and the laminated roof 4 are assembled. The middle part of the poured bottom slab 1 is connected with the lower part of the fully prefabricated middle partition wall 3 through splicing hidden beams 5, the two sides of the laminated roof 4 are respectively connected with the upper part of the double-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com